Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Expand the scope of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

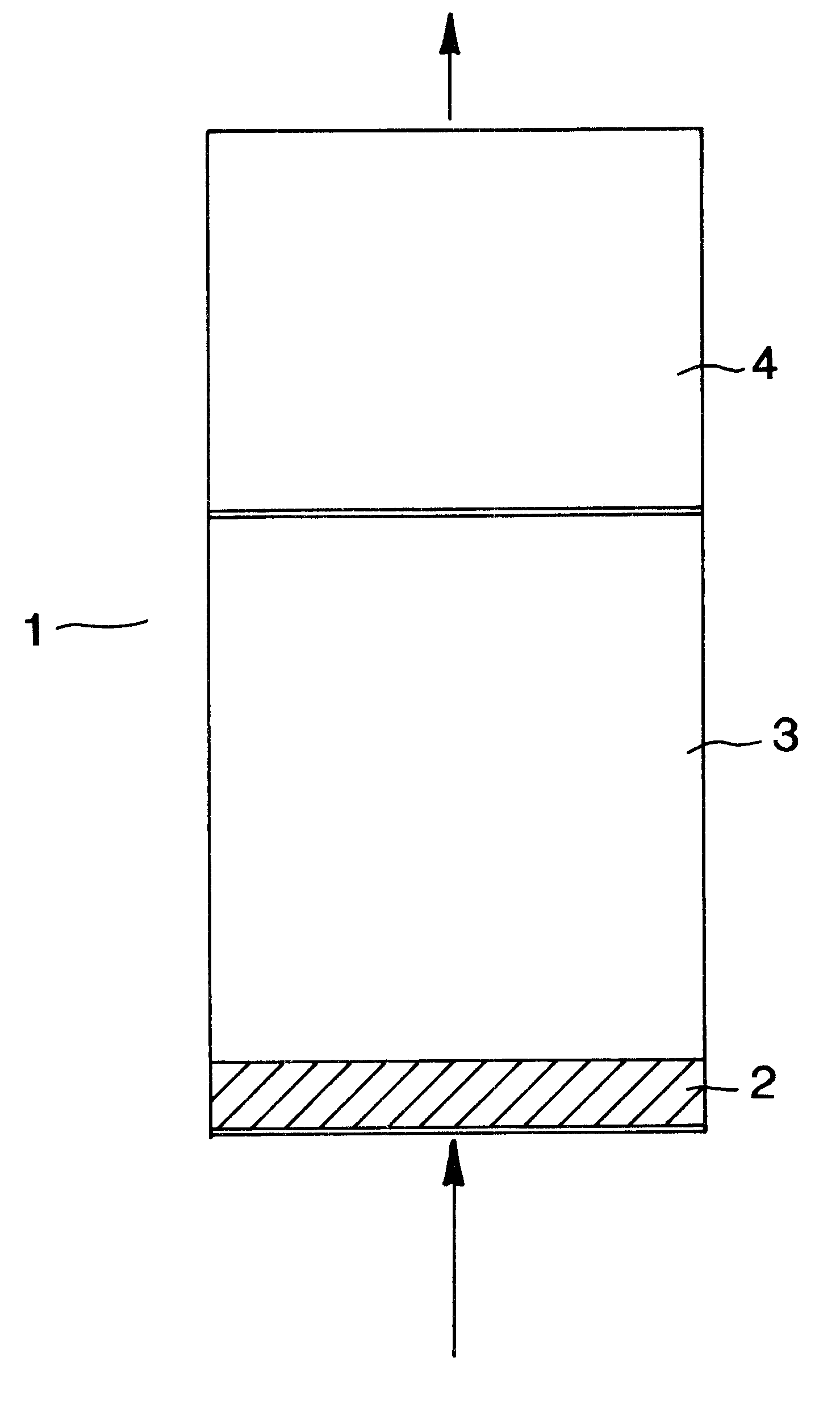

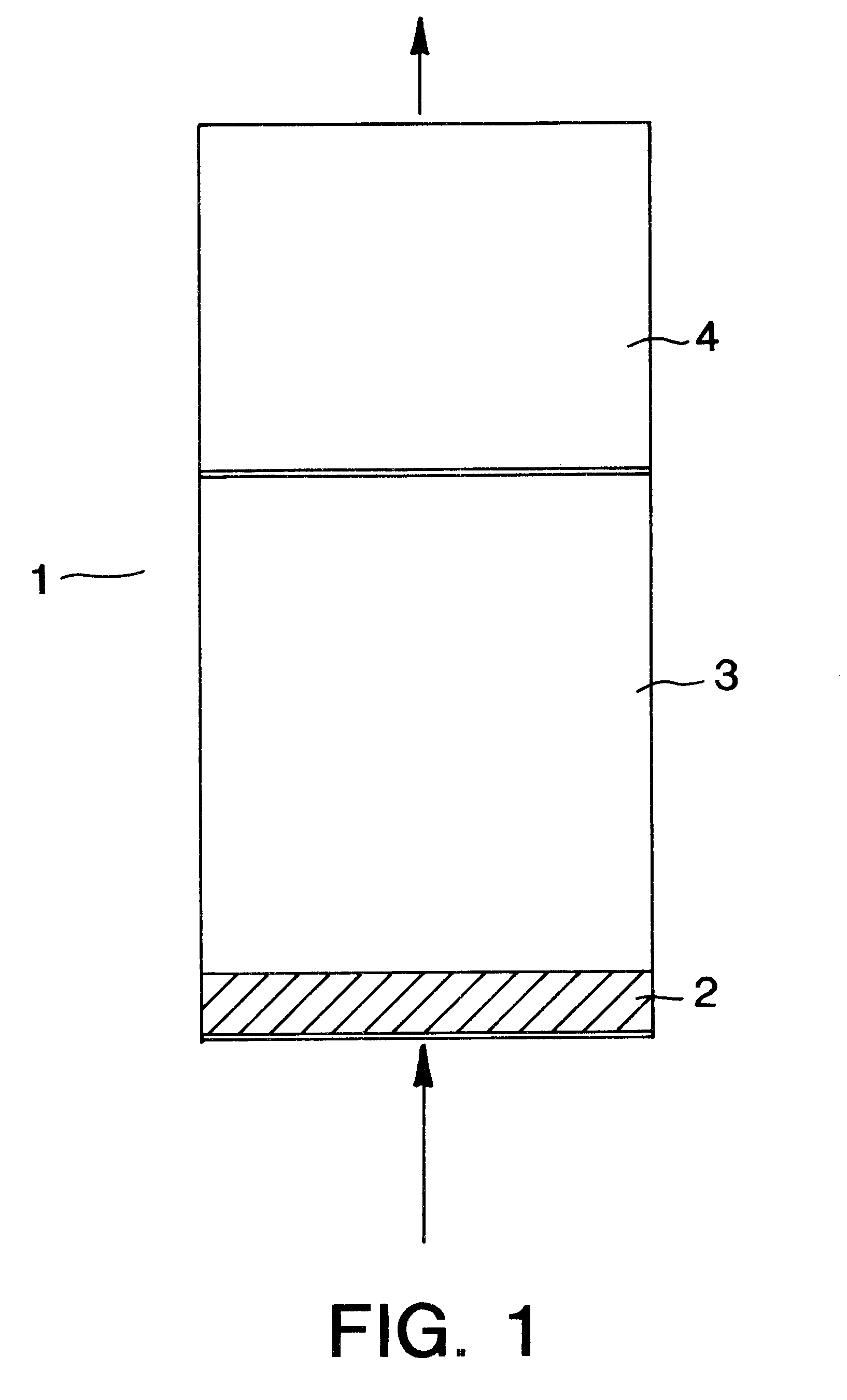

Multilayer adsorbent beds for PSA gas separation

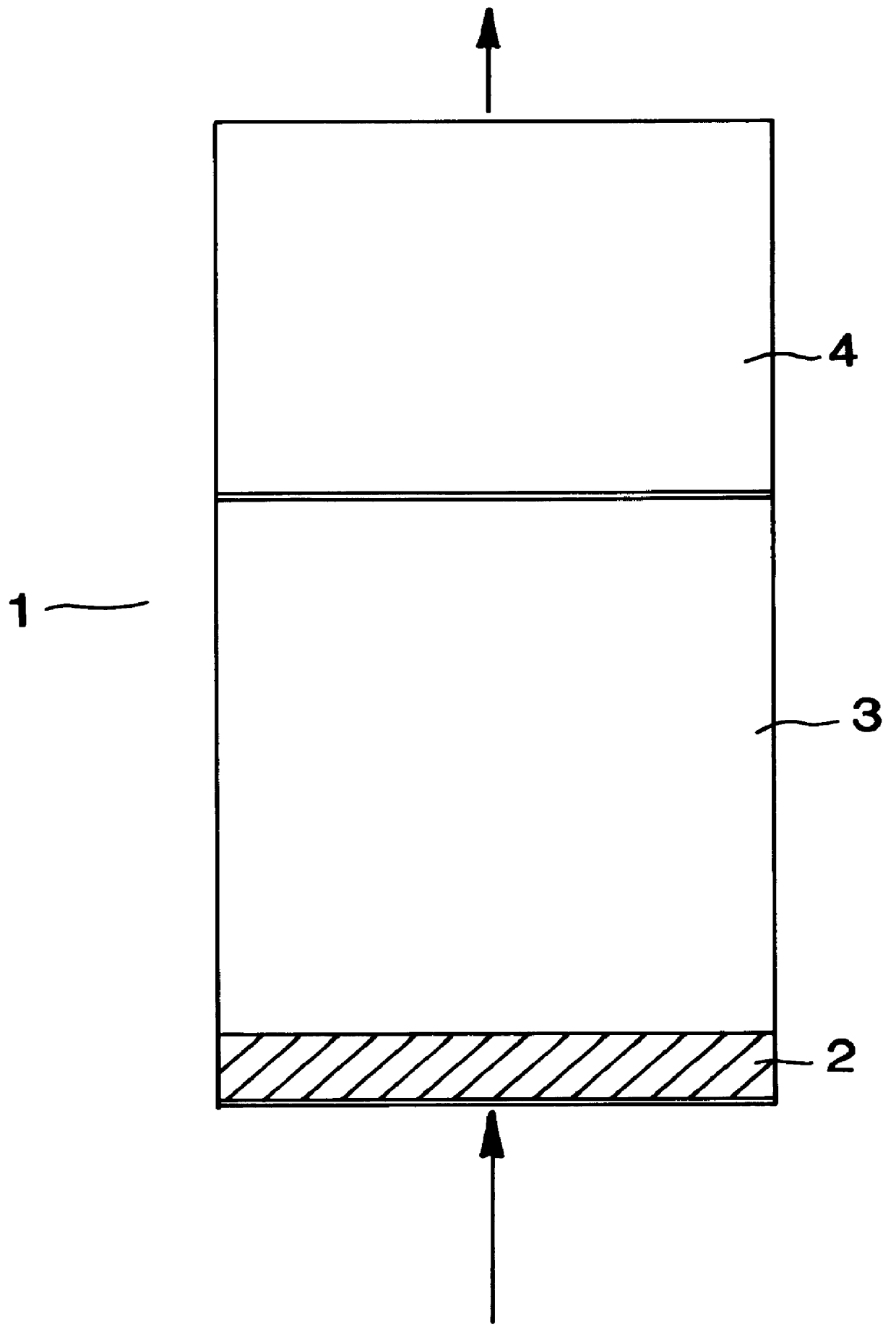

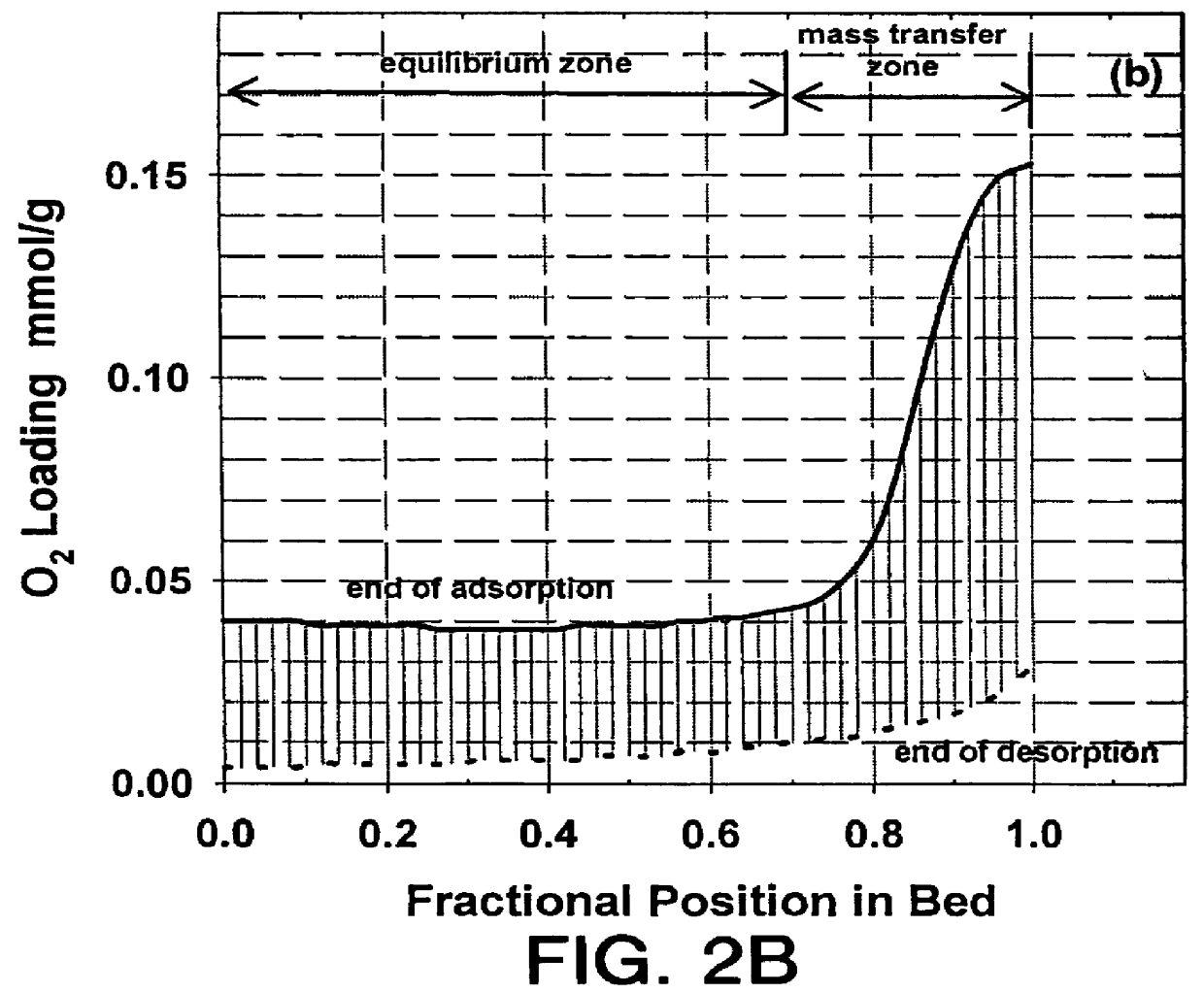

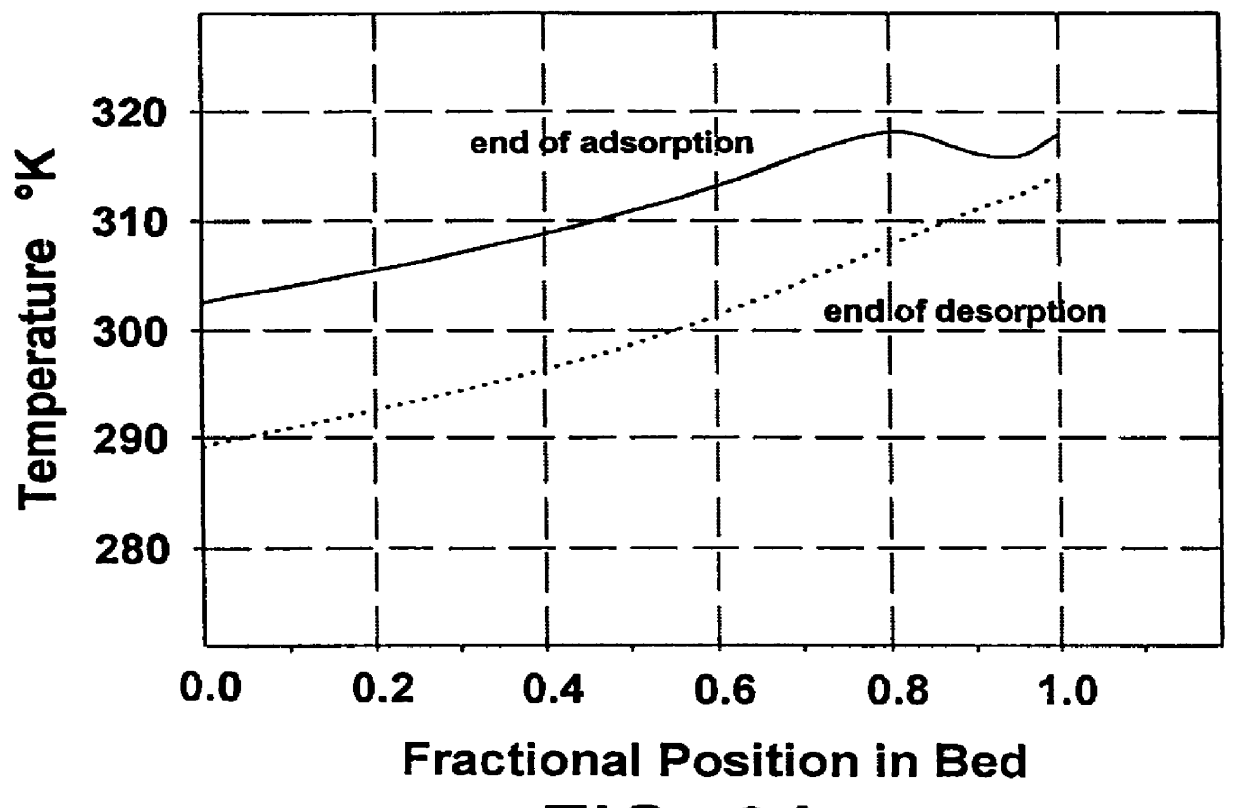

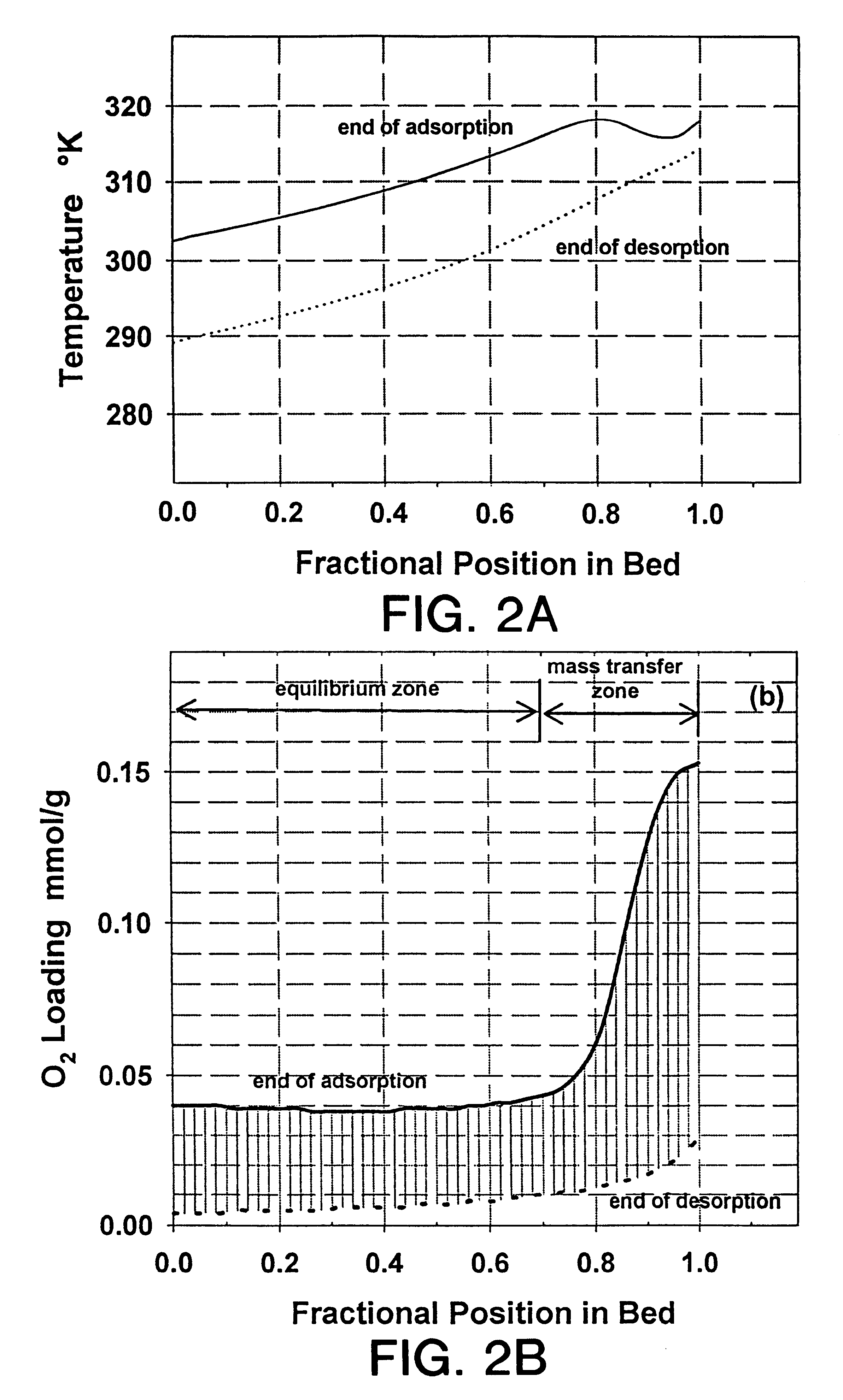

The invention comprises a PSA process and apparatus wherein the fixed adsorbent bed comprises an equilibrium zone and a mass transfer zone. Further, the equilibrium and mass transfer zones each comprise at least one adsorbent material, selective for the adsorption of a more selectively adsorbable component, that is selected on the basis of the performance of that adsorbent material under the process conditions applicable to either the equilibrium or mass transfer zones.

Owner:PRAXAIR TECH INC

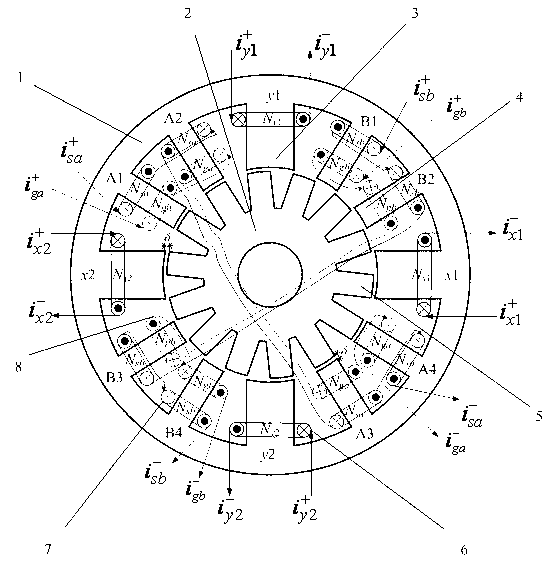

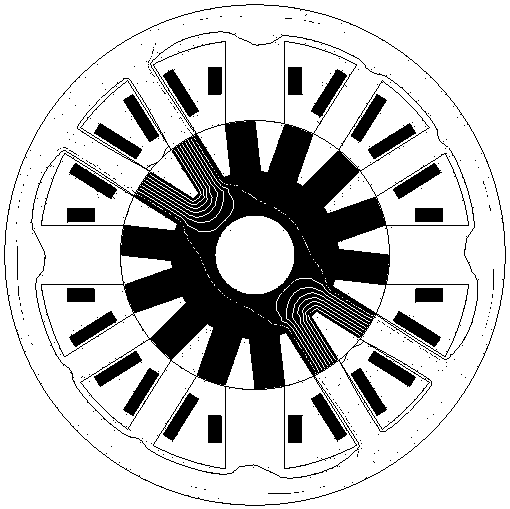

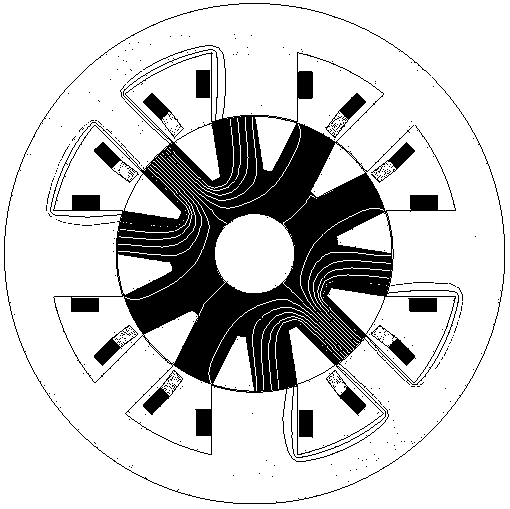

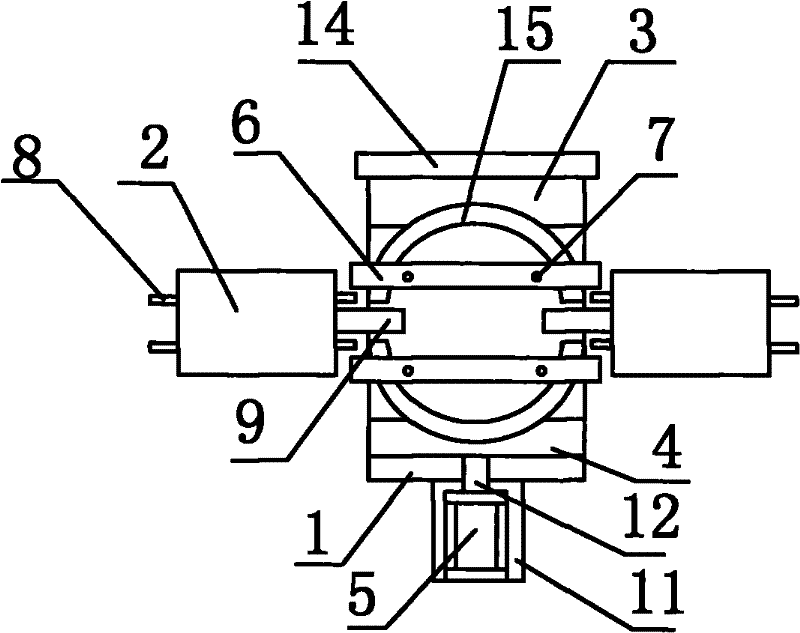

Stator hybrid short magnetic circuit magnetic suspension switched reluctance generator

The invention discloses a stator hybrid short magnetic circuit magnetic suspension switched reluctance generator which is composed of a stator iron core, a rotor iron core, four suspension poles, eight power generation poles, fourteen rotor poles, four sets of suspension windings, two groups of excitation windings and two phase power generation windings. The four suspension poles are arranged on the stator iron core at equal interval, each two of the eight power generation poles are arranged between the four suspension poles at equal interval, the fourteen rotor poles are arranged on the rotor iron core at equal interval, the four sets of suspension windings are respectively wound on the four suspension poles independently, the two phase excitation windings and the two phase power generation windings are wound on the power generation poles opposite in the radial direction in lap mode, pole arcs of the suspension poles are two times of pole arcs of the power generation poles, and pole arcs of the power generation poles are equal to an arc pole of a rotor. The stator hybrid short magnetic circuit magnetic suspension switched reluctance generator adopts a hybrid stator and a short magnetic circuit structure, solves the problem of coupling of excitation, power generation and suspension, overcomes a magnetic flux reversal phenomenon, reduces magnetic motive force and stator iron core loss, and improves working efficiency and output power density.

Owner:JIANGSU UNIV

Multilayer adsorbent beds for PSA gas separation

InactiveUS6471748B1Expand the scope of productionImprove efficiencyGas treatmentOther chemical processesSorbentProcess conditions

The invention comprises a PSA process and apparatus wherein the fixed adsorbent bed comprises an equilibrium zone and a mass transfer zone. Further, the equilibrium and mass transfer zones each comprise at least one adsorbent material, selective for the adsorption of a more selectively adsorbable component, that is selected on the basis of the performance of that adsorbent material under the process conditions applicable to the zone.

Owner:PRAXAIR TECH INC

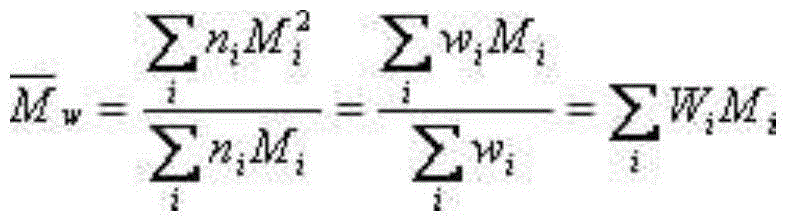

Production method for microfiber leather

InactiveCN106192441AGood flexibilityStrong sense of leatherFilament/thread formingLiquid/gas/vapor textile treatmentWater vapor permeabilityNonwoven fabric

The invention relates to a production method for microfiber leather. The production method comprises the following steps that firstly, composite fibers are spun; secondly, non-woven fabric is made; thirdly, the non-woven fabric is shaped; fourthly, a polyurethane resin working solution with high solid content and high viscosity is prepared; fifthly, a polyurethane resin working solution is smeared; sixthly, a polyurethane resin working solution with low solid content and low viscosity is prepared; seventhly, soaking and continuous rolling are carried out with the polyurethane resin working solution; eighthly, polyurethane is solidified; ninthly, methylbenzene decrement treatment is carried out. Compared with the prior art, the microfiber leather has the advantages of being good in hand touch and drape effect and high in air and water vapor permeability.

Owner:SHANDONG FRIENDSHIP MACHINERY

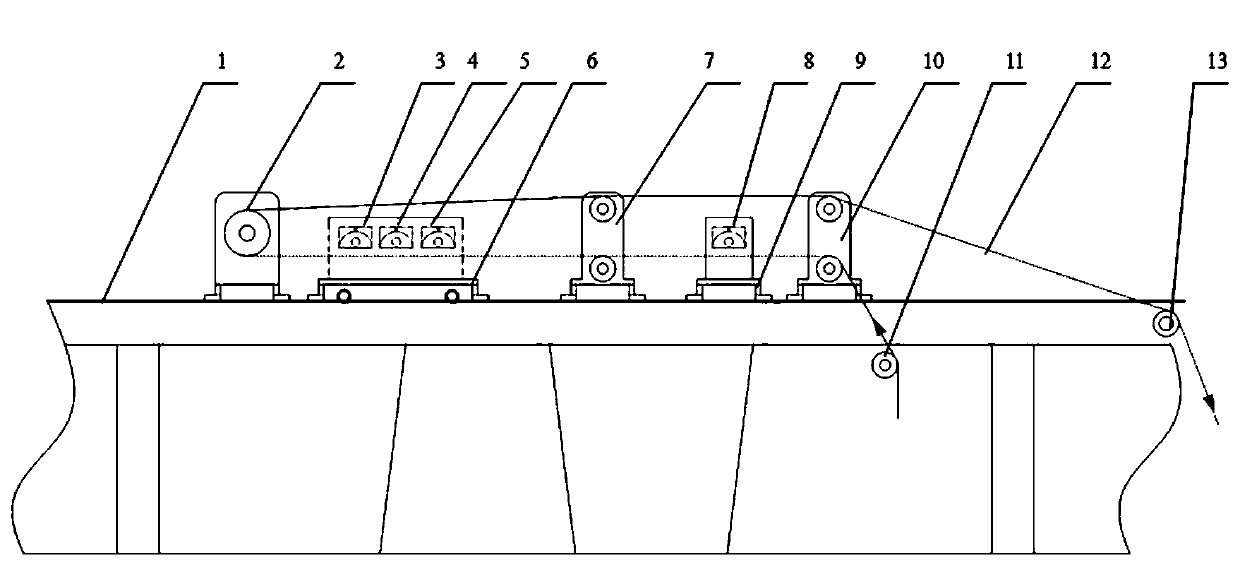

UV drying curing system added on rotogravure printing machine

InactiveCN105269949AAvoid fire and other safety accidentsStrong production adaptabilityPrinting press partsUltravioletPulp and paper industry

The invention provides an UV drying curing system added on a rotogravure printing machine. The system comprises a rotogravure printing machine. The technical scheme is that the top of a longitudinal beam of the rotogravure printing machine is provided with a water-cooling shutter type ultraviolet cold light source drying curing system. The water-cooling shutter type ultraviolet cold light source drying curing system is formed by four sets of ultraviolet cold light sources, wherein three sets are parallel together and are installed on a mobile support, and the other independent set is installed on a fixed support. The front edge and the rear edge of the fixed support are provided with dancing rolls. A paper cooling roller is arranged on the rear of the mobile support. The system enhances production adaptive capacity of an original rotogravure printing machine, realizes a connecting line gravure multiple combination process, overcomes restrictions that a rotogravure printing machine cannot print cortex oil, ice points and snowflake, widens production range of the device, and satisfies more diverse technological requirements.

Owner:桂林澳群彩印有限公司

Device for preventing galvanized plate from sticking roller and method thereof

ActiveCN102061435AExpand the scope of productionReduce the number of abnormal downtimeHot-dipping/immersion processesEngineeringInjection air

The invention relate to a device for preventing a galvanized plate from sticking a roller and a method thereof. The device comprises a front guide plate, an air injection assembly, an upper guide plate and a lower guide plate, wherein the front guide plate is installed in the front of a working roller and supported by a bracket; the air injection assembly is installed at the lower part of the front guide plate; and the upper guide plate and the lower guide plate are installed at the back of the working roller. The device can ensure that the galvanized plate stably passes through the front guide plate to reach the working roller; the galvanized plate is blown by utilizing the air injection assembly so that an air cushion is formed between the galvanized plate and the working roller, therefore, the condition that the galvanized plate is stuck to the working roller, in particular a thin galvanized plate with the thickness of less than 0.7mm is stuck to the roller, can be effectively avoided.

Owner:BENGANG STEEL PLATES +1

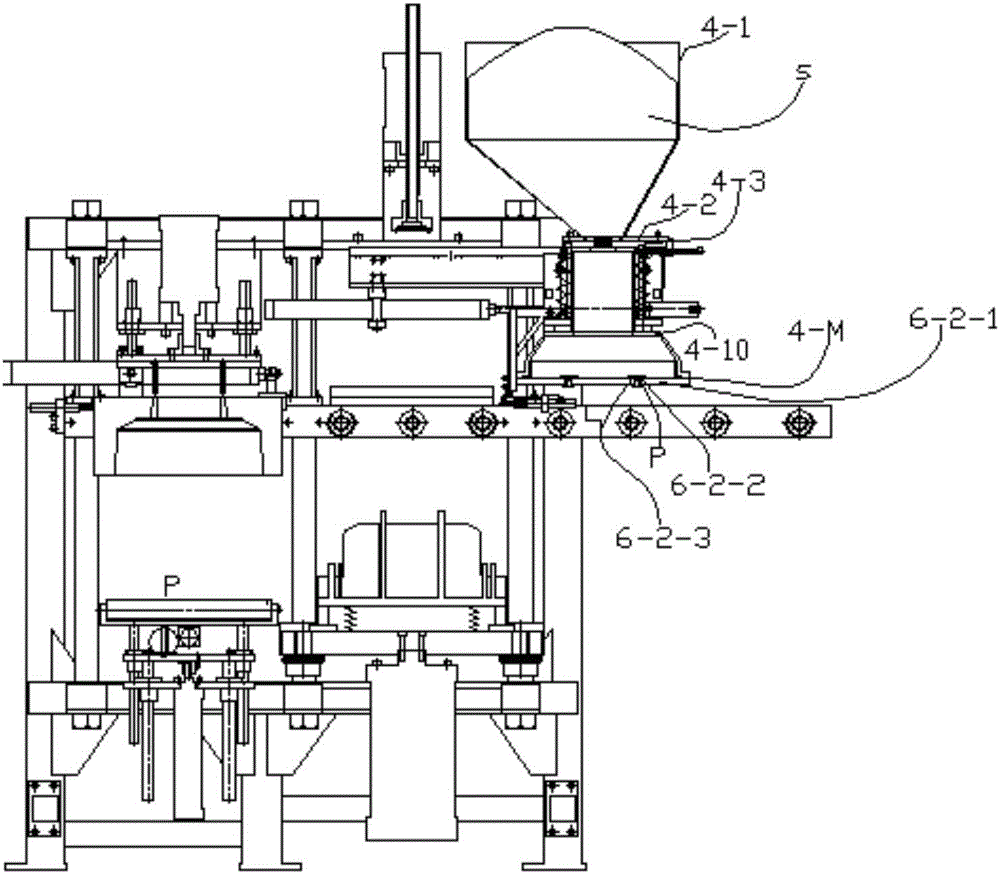

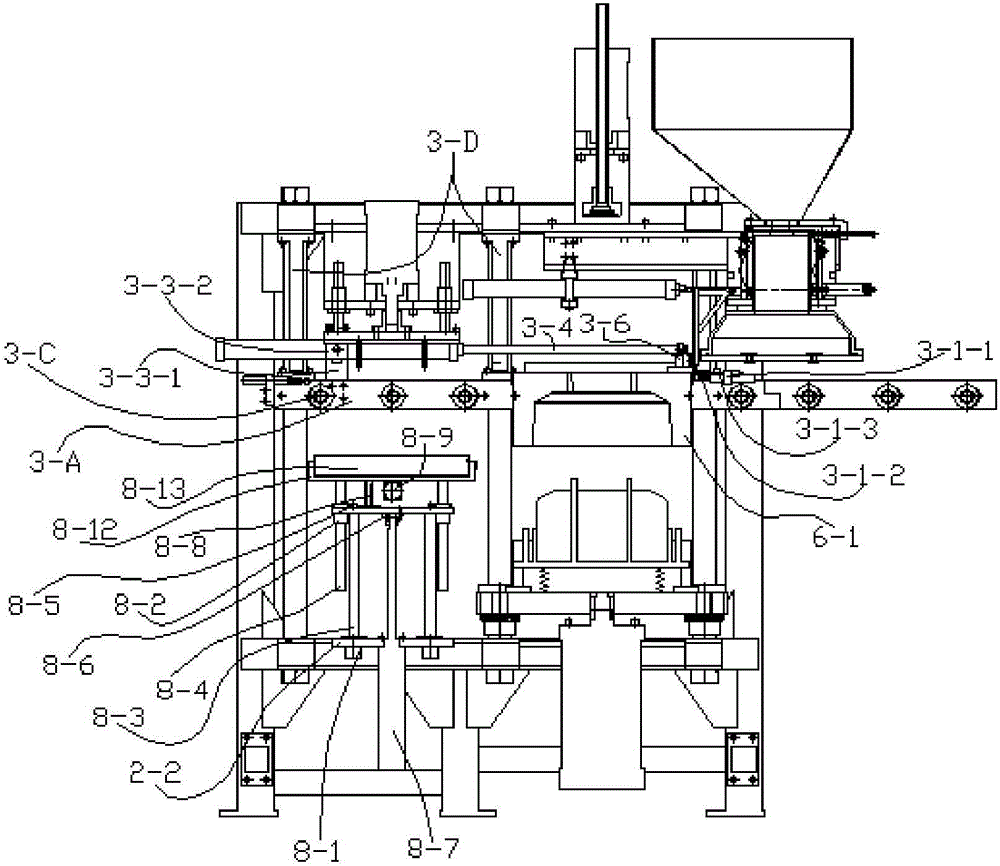

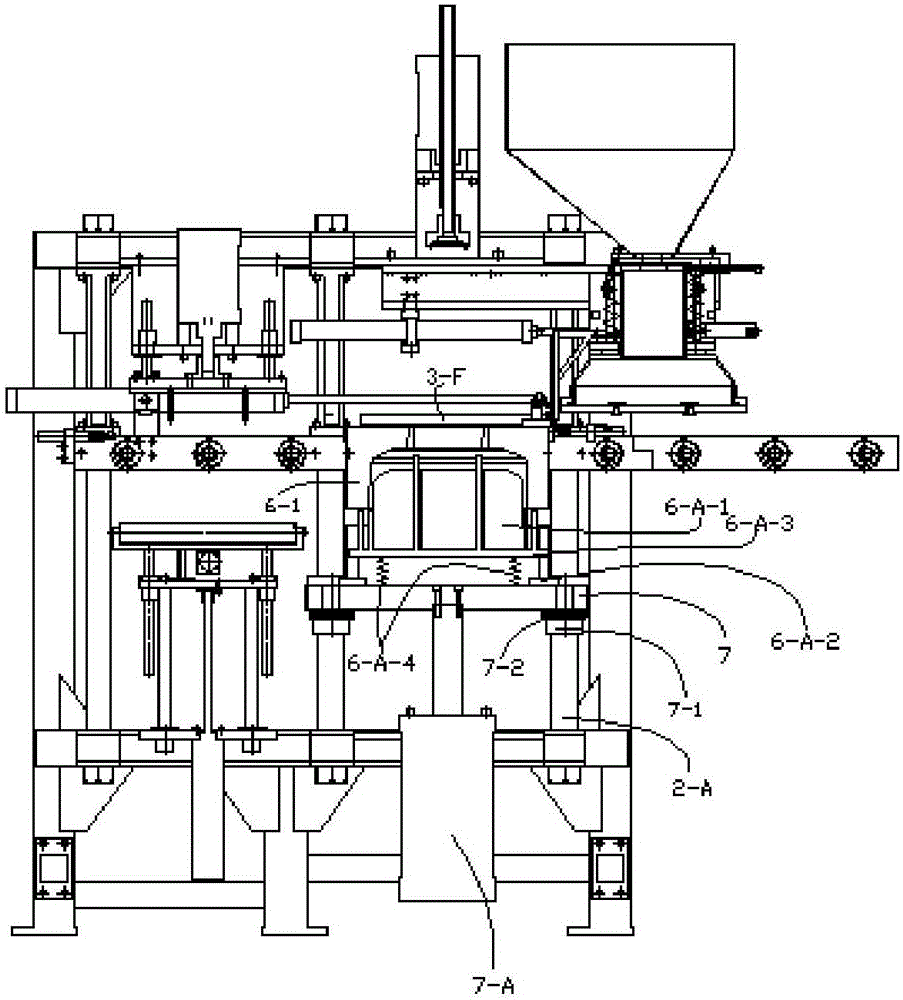

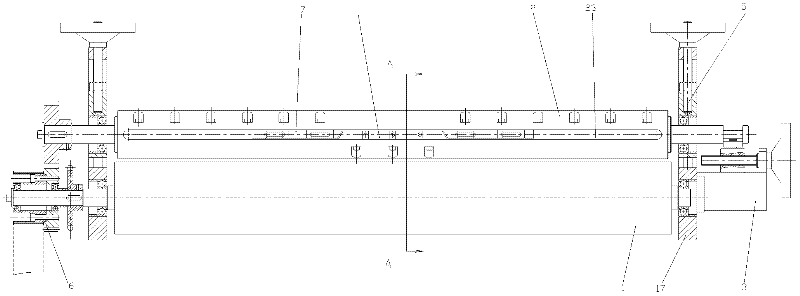

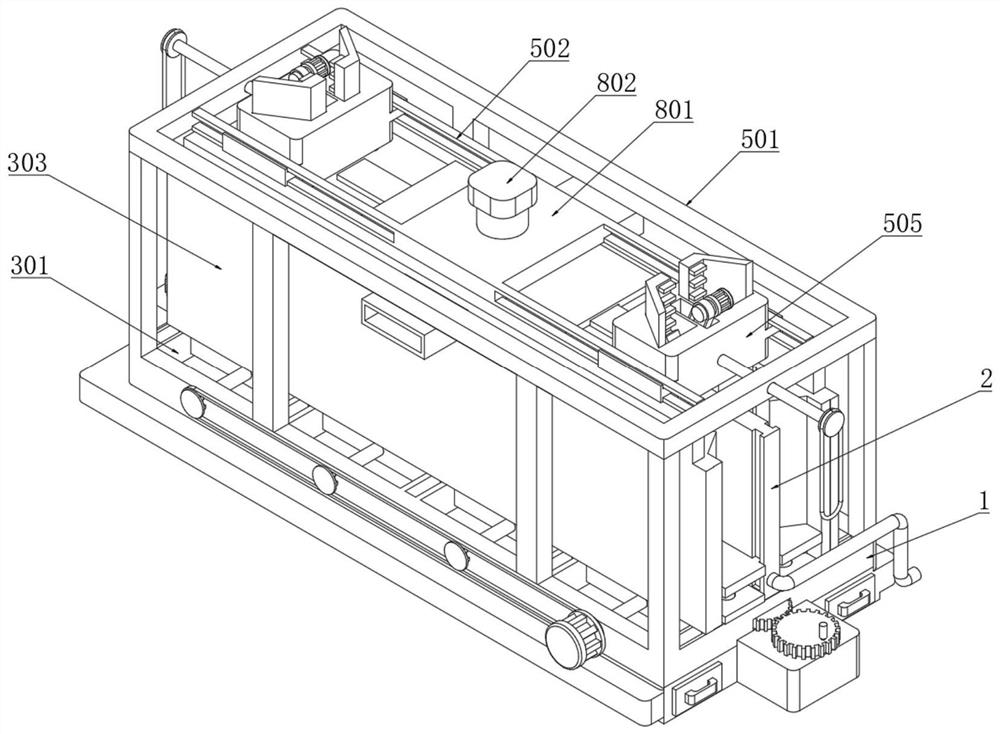

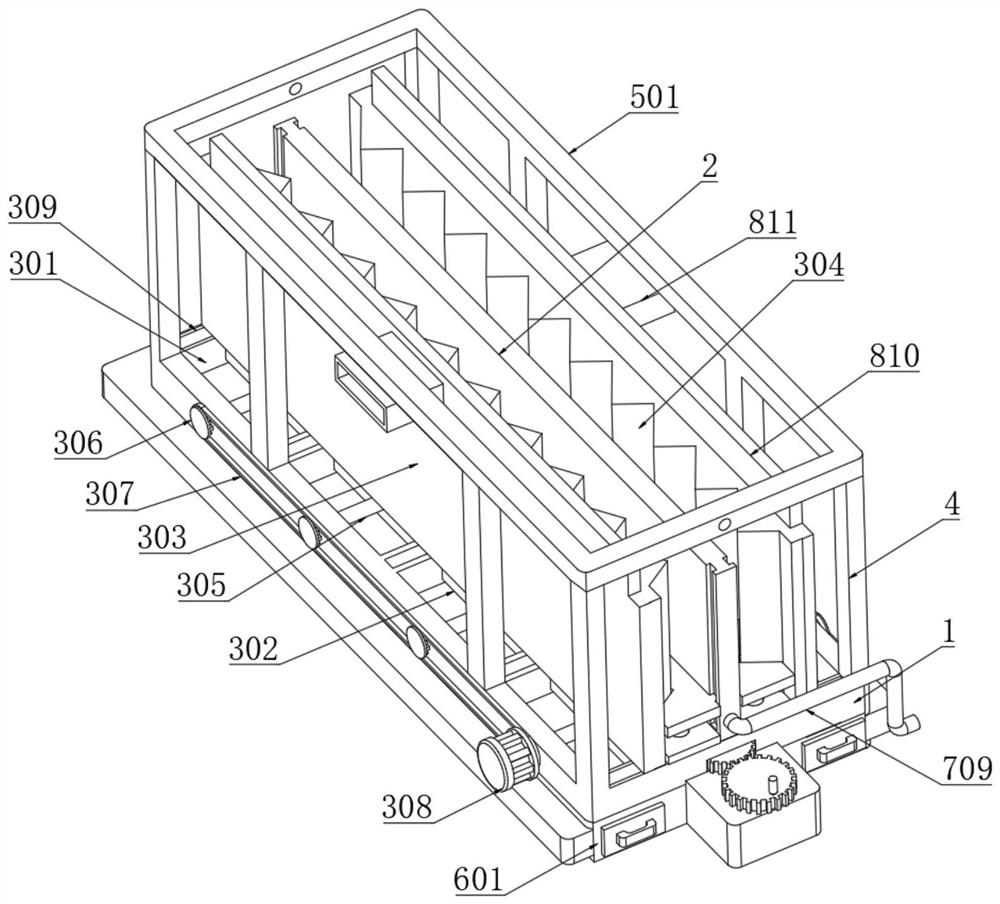

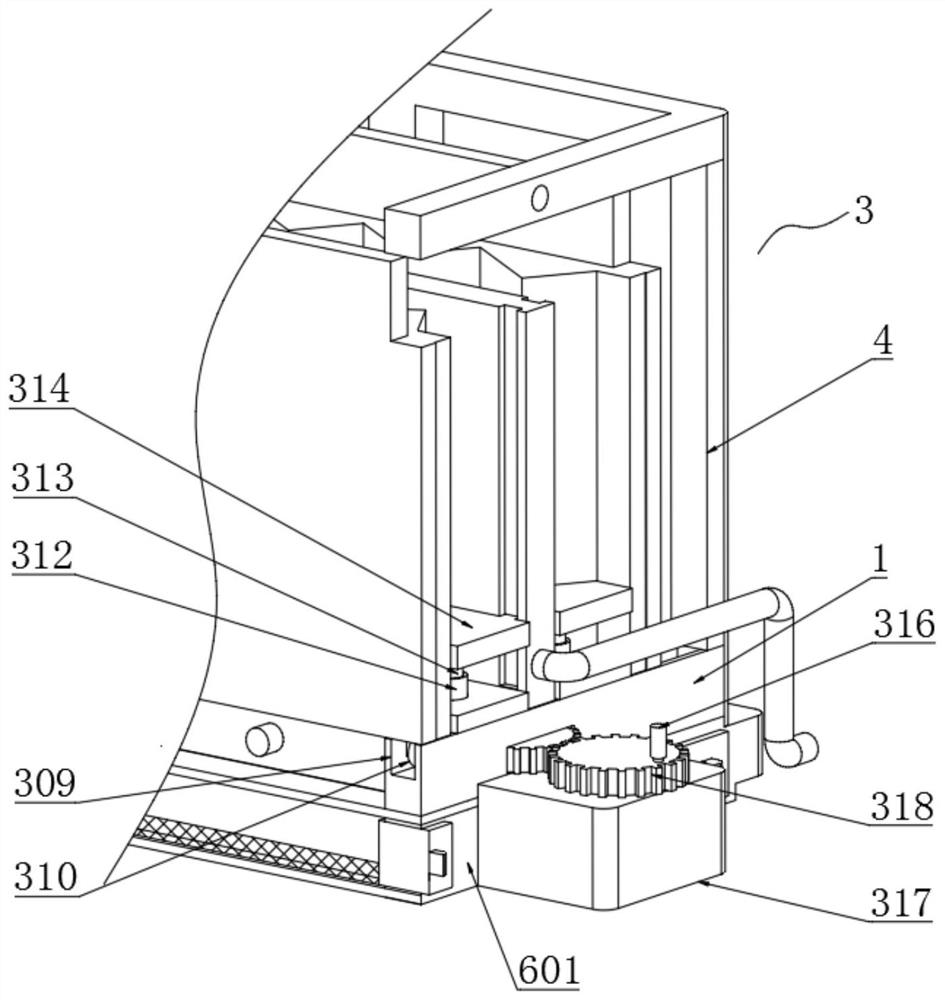

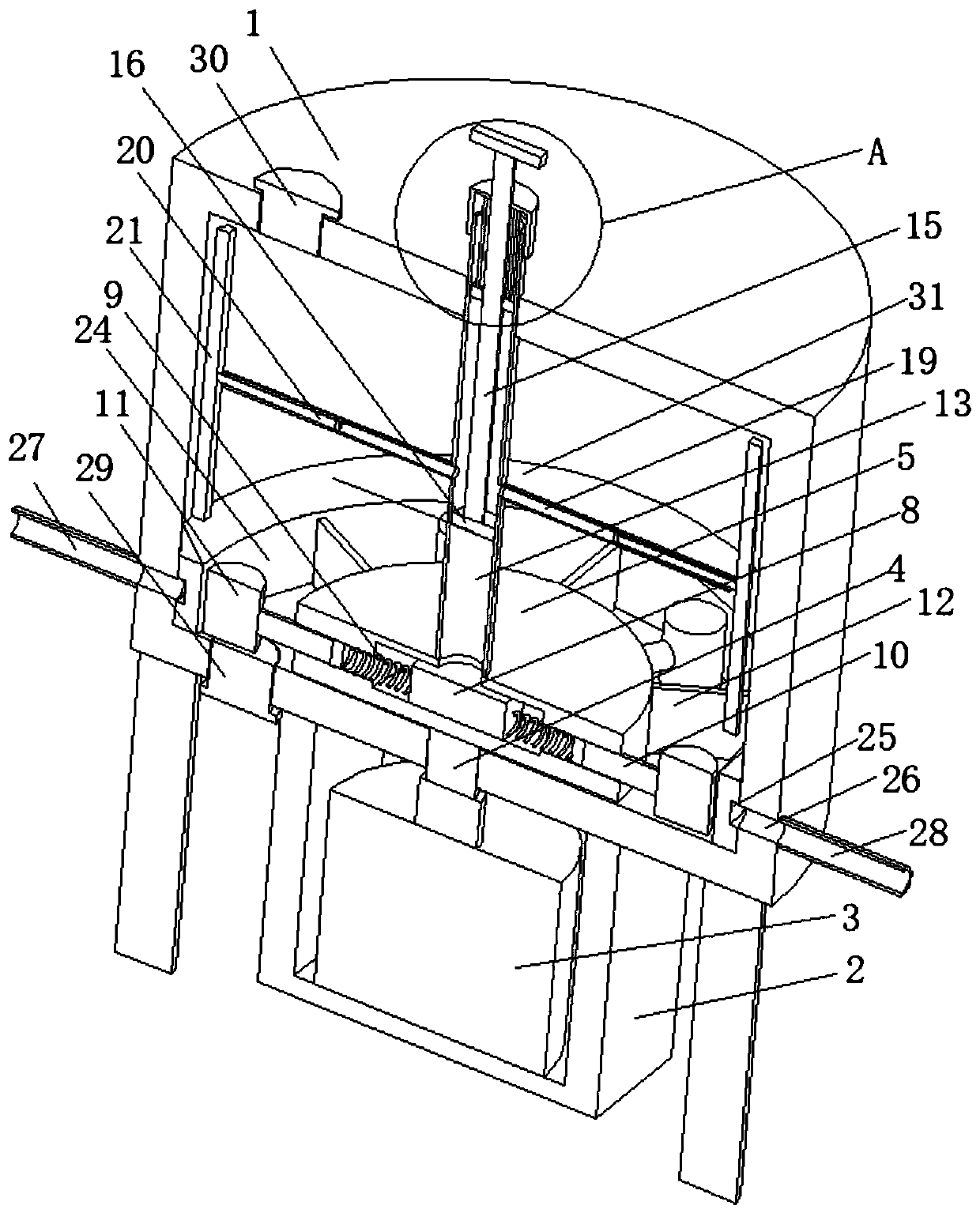

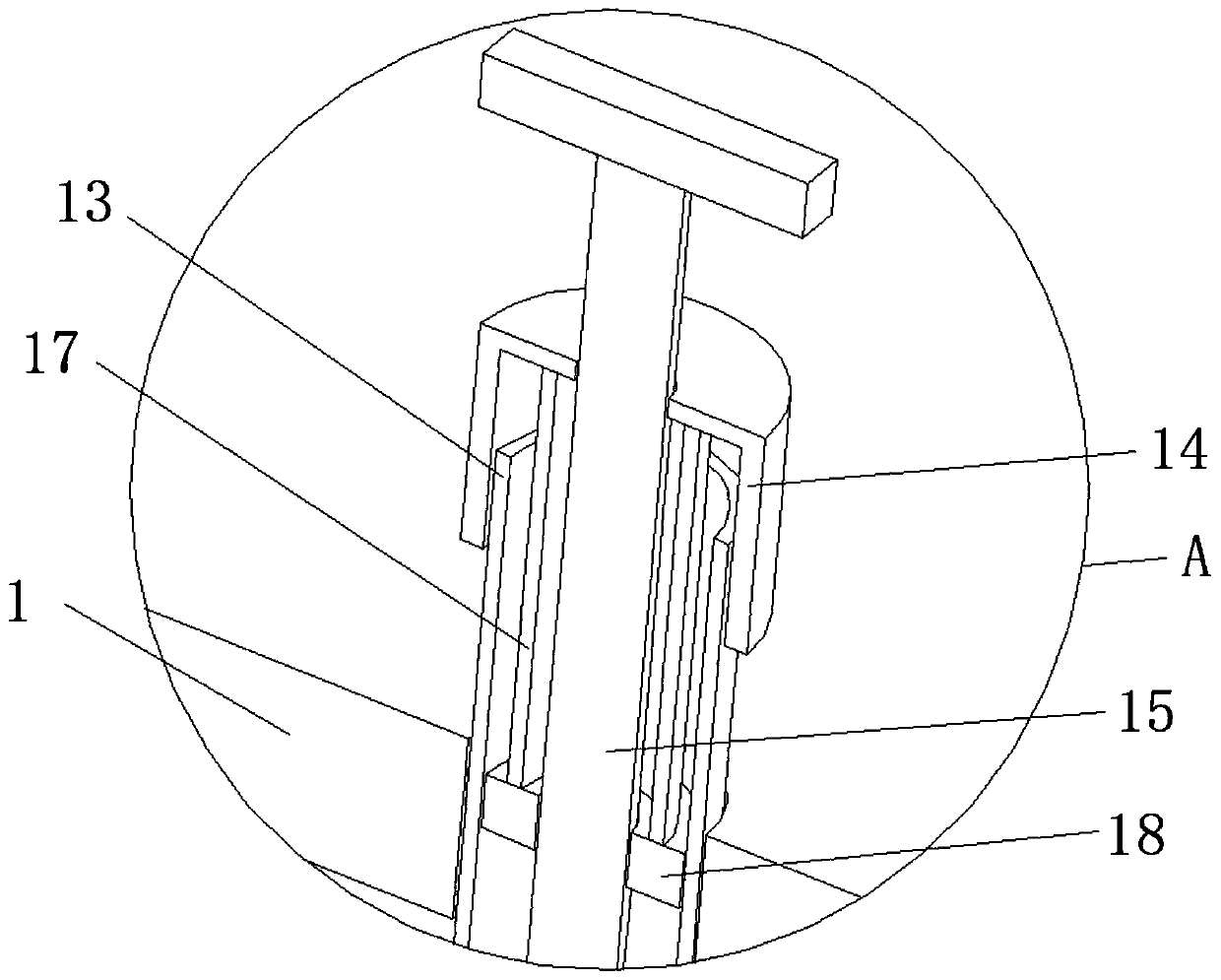

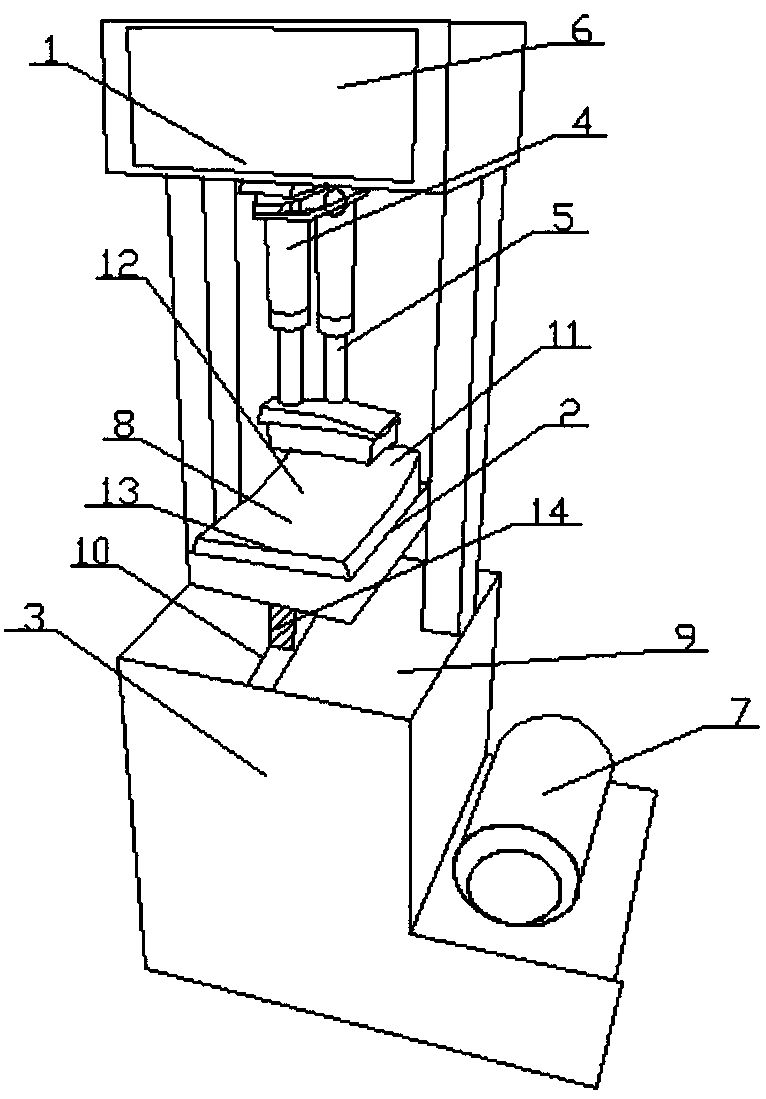

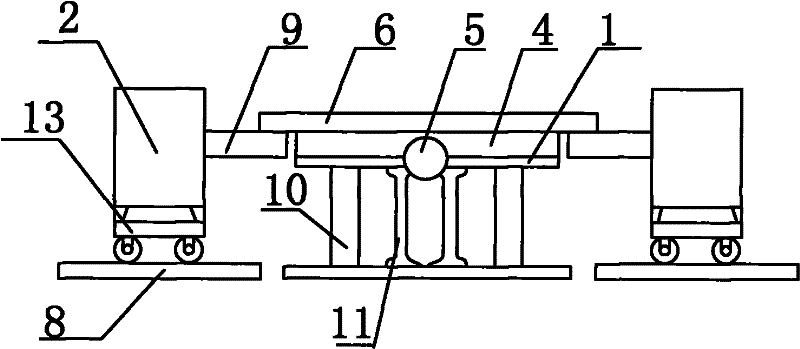

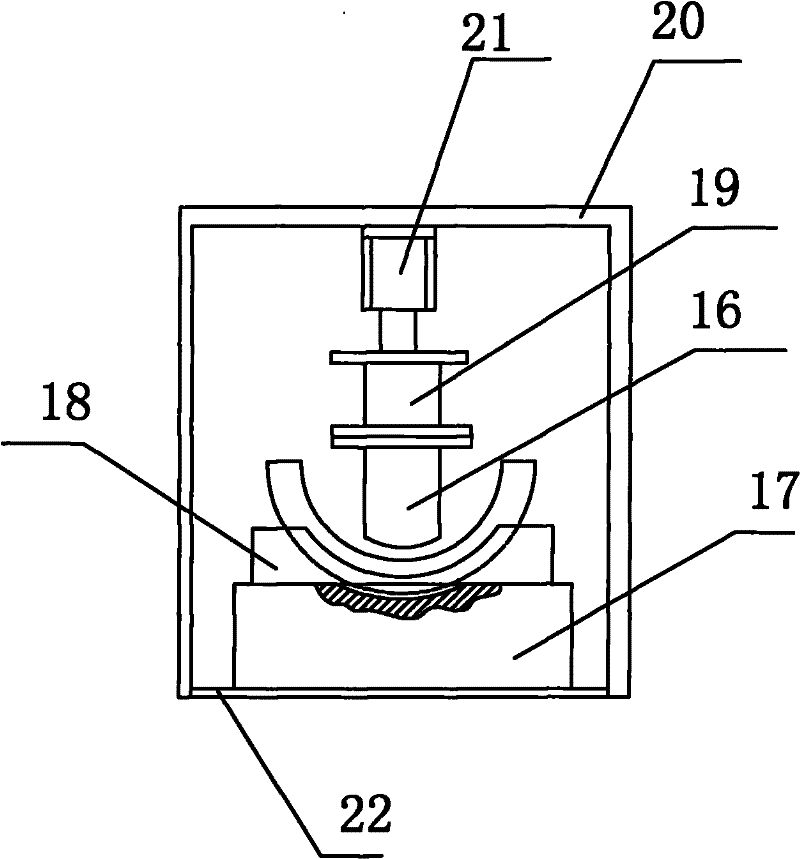

Casting mold manufacturing device

The invention discloses a casting mold manufacturing device which comprises a frame. An upper mold, a lower mold, a mold connecting wheel frame, a driving mechanism, a sand-shooting mechanism, a stripping mechanism and a pushing mechanism are arranged on the frame, molds are smoothly assembled through the mold connecting wheel frame, the molds move and are positioned along the horizontal and perpendicular direction through the driving mechanism, the casting molds are formed through the sand-shooting mechanism, the casting molds automatically move out through the stripping mechanism and the pushing mechanism, the upper mold is mounted on an upper mold moving support, an upper mold driving cylinder drives the upper mold moving support to slide along a mold guide wheel group, a front limiting component and a rear limiting component are arranged at two ends of the mold guide wheel group, and the stripping mechanism matched with the upper mold is mounted on one side of the upper mold and positioned above a receiving mechanism. According to the casting mold manufacturing device, the sand-shooting mechanism, a mold feeding mechanism, a mold discharging mechanism, the receiving mechanism and the pushing mechanism are comprehensively matched, production ranges of the casting molds are widened, the finished product ratio of the casting molds is ensured, the molds are conveniently and rapidly mounted and adjusted, labor intensity is reduced, and working efficiency is improved.

Owner:马鞍山市黎明天工自动化设备有限公司

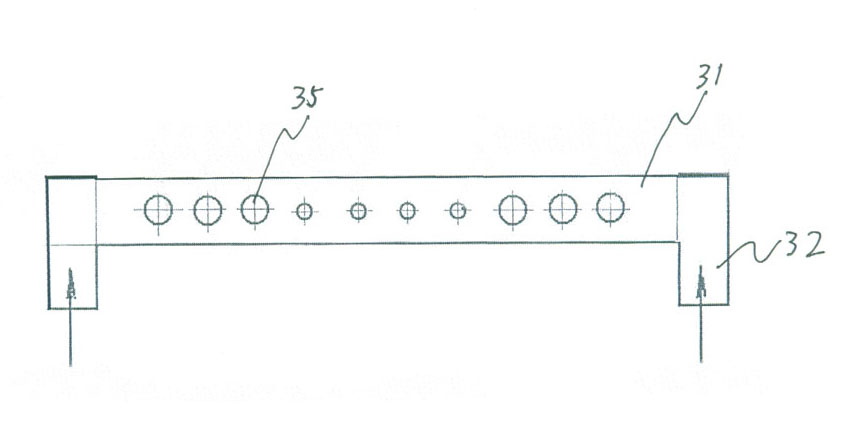

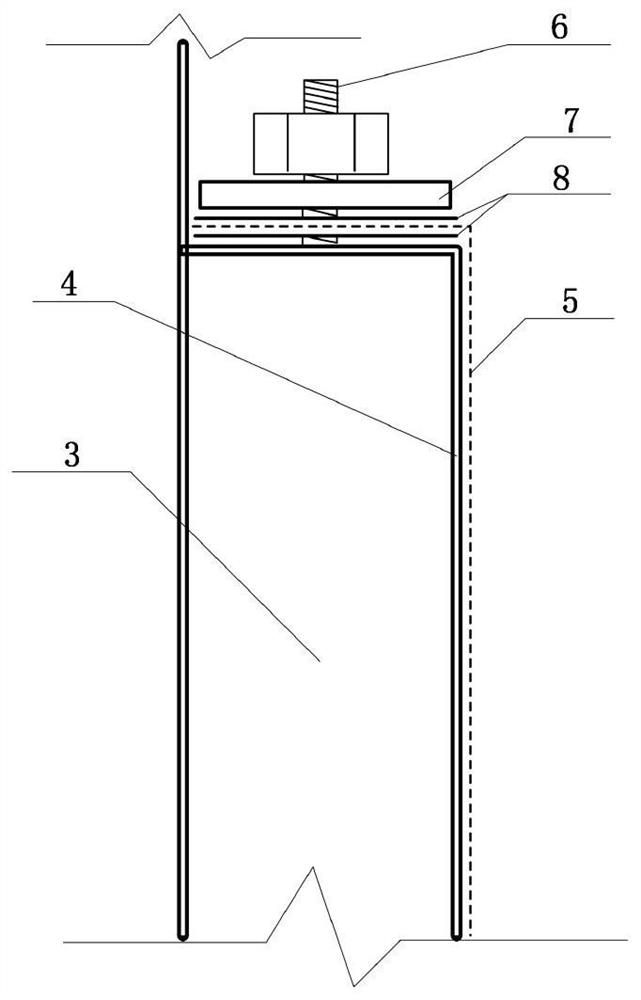

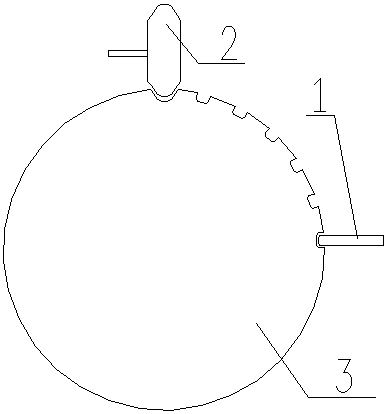

Hole punching cutter type hole punching device

InactiveCN102514232AGuaranteed stabilityExpand the scope of productionContainer making machineryBristlePulp and paper industry

The invention provides a hole punching cutter type hole punching device, which is used for a paper bag machine and comprises a rubber roll, a hole punching arbor, hole punching cutters and hole punching wallboards. The rubber roll is positioned below the hole punching arbor, both the rubber roll and the hole punching arbor are mounted on the hole punching wallboards positioned at the left end and the right end of the hole punching device, the hole punching cutters are bow-shaped and are mounted in mounting grooves of the hole punching arbor, and blades of the hole punching cutters are serrated bristles. The hole punching cutter type hole punching device has the advantages that stability of paper bag production can be ensured, applicable types of paper bag products are increased, paper bags with the lengths ranging from 155 millimeters to 650 millimeters and the widths ranging from 50 millimeters to 250 millimeters can be produced, production efficiency is improved, accordingly, stability of the quality of the paper bag products and stability of equipment are enhanced, and loss is reduced.

Owner:NANJING ZONO MACHINE EQUIP

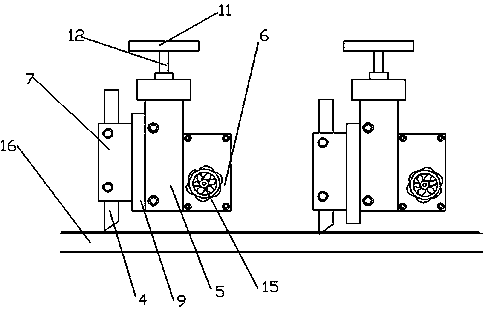

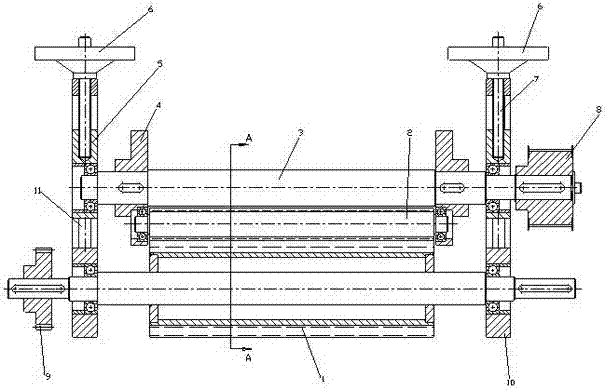

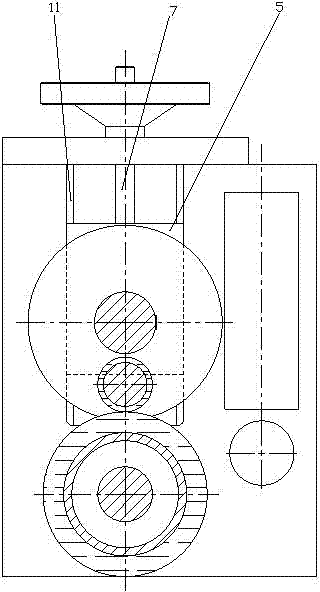

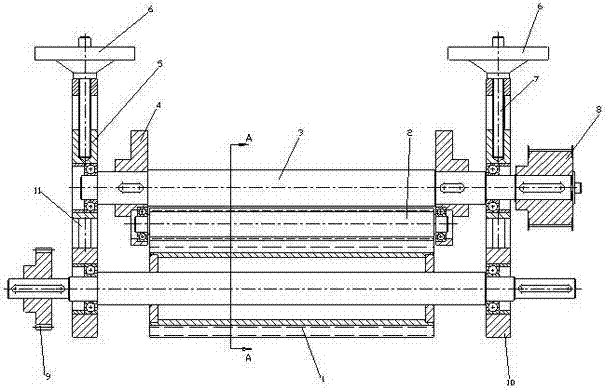

Device for removing burrs of steel pipe welding seam

The invention provides a device for removing burrs of a steel pipe welding seam. The device comprises a first vertical plate, an air extracting hole is formed in the middle of the upper end of the first vertical plate and connected with a fan, the other end of the fan is connected with a waste box, a second vertical plate is arranged on the front portion of the middle lower end of the first vertical plate and positioned at the lower end of the air extracting hole, the first vertical plate and the second vertical plate are fixed on the workbench, and a first-stage burr removing device and a second-stage burr removing device are arranged on the second vertical plate and positioned on a same horizontal plane. The device has the advantages that by the first-stage burr removing device and the second-stage burr removing device, first handwheels and second handwheels are used to adjust longitudinal positions of two cutting knives and horizontal positions of the two burr removing devices to realize a function of removing the burrs of the welding seam in a multistage manner, and quality of a steel pipe is improved; the device is suitable for steel pipes different in size and thickness, production range is expanded, and time and labor are saved.

Owner:TIANJIN JIEJIN METAL PROD

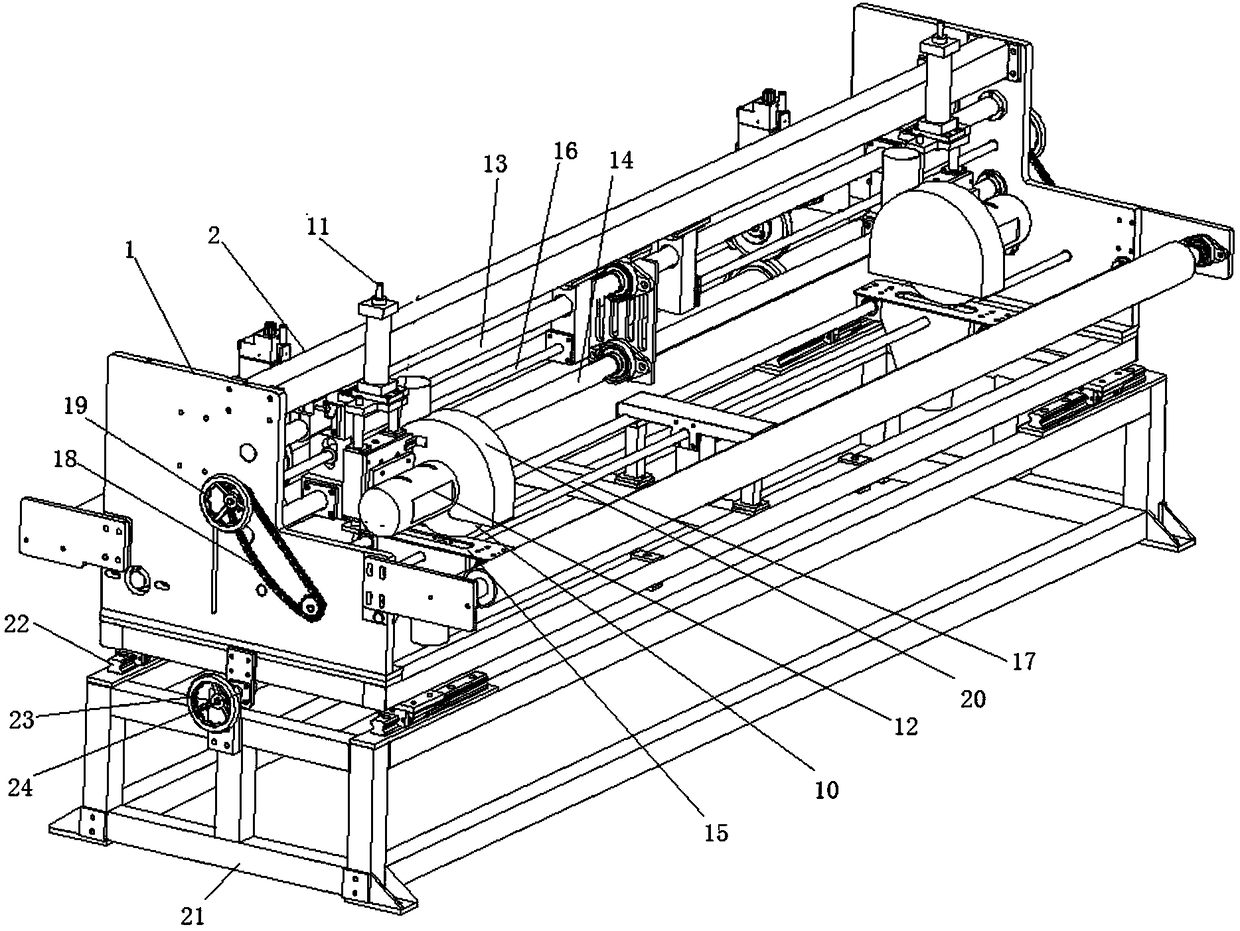

Paper splitting device

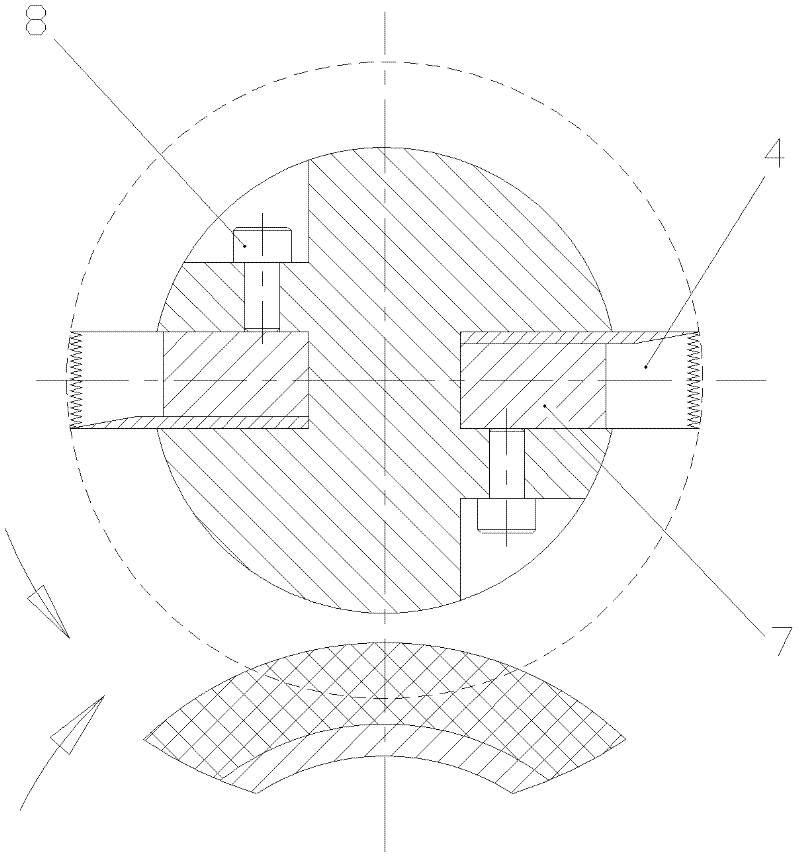

ActiveCN102442016AEven by forceGuaranteed stabilityContainer making machineryPulp and paper industryFlange

The invention relates to a paper splitting device comprising a rubber roller (1), a splitting rubber roller (2), a splitting roll shaft (3), two splitting roll shaft flanges (4), a splitting roll shaft synchronizing wheel (8), a rubber roller gear (9) and two wall boards (10), wherein two ends of the splitting roll shaft (3) penetrate through the splitting flanges (4) and are installed on the wall boards (10), one end of the splitting roll shaft (3) penetrates through the wall boards (10) and is connected with the splitting roll shaft synchronizing wheel (8); the splitting rubber roller (2) is installed on the splitting roll shaft flanges (4), a gap is formed between the splitting rubber roller (2) and the splitting roll shaft (3); the rubber roller (1) is installed on the wall boards (10) and positioned below the splitting rubber roller (2), a gap is formed between the rubber roller (1) and the splitting rubber roller (2), and one end of the rubber roller (1) penetrates through the wall boards (10) and is connected with the rubber roller gear (9). The paper splitting device provided by the invention can conveniently split needle pricked paper with accurate size, is suitable for paper of all sizes, can improve the rate of finished products in production of paper bags, and greatly reduces loss.

Owner:NANJING ZONO MACHINE EQUIP

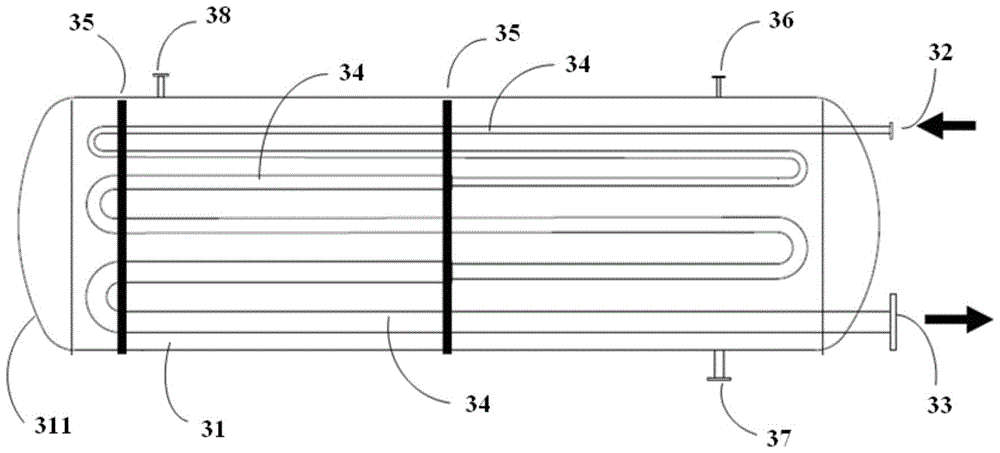

Apparatus for preparing polyamide, pressure reducing method as well as production equipment and production method for polyamide

The present invention provides a pressure reducing apparatus for preparing polyamide.The pressure reducing apparatus comprises a sealed kettle body. The kettle body is provided with a material inlet and a material outlet, wherein the material inlet is formed above the material outlet; inside the reactor body is provided with a material coil connected with the material inlet and the material outlet; the material coil is divided into a plurality of sections; the diameters of the same sections of the material coil are the same; the diameters of different sections of the material coil are gradually increased from the material inlet to the material outlet. The present invention further provides a pressure reducing method as well as production equipment and a production method for polyamide 5X. The pressure reducing apparatus provided by the present invention is capable of effectively separating water from a material, and is good in separation effect. The production equipment and the production method for polyamide 5X provided by the present invention are specific to polyamide 5X, are capable of producing many types of polyamide 5X products, and can broaden the production and application ranges of the polyamide 5X products.

Owner:CATHAY R&D CENT CO LTD +2

Preparation method of evaporation material with low refractive index

InactiveCN107285753AUniform compositionSimple and fast operationMaterials preparationRefractive index

The invention discloses a preparation method of an evaporation material with low refractive index. The preparation method comprises the steps of material preparation, material mixing, slurry drying, press forming, sintered body preparation and cleaning and packaging. The preparation method is reasonable in design and convenient to operate, materials are subjected to wet ball-milling in a planet ball mill with water as a mixing medium, shorter ball-milling time is taken, and slurry with uniform and consistent components is obtained. The evaporation material prepared with the preparation method has the advantages as follows: splashing caused by light weight of the electronic gun bombardment evaporation material can be avoided; the density is large, the gas release amount in the coating process is reduced, and thus, the membrane layer quality is improved; the surface is a diffusion reflection plane, the evaporation angels are consistent, the evaporation rate is uniform and stable, and an electronic gun can be focused easily; the surface of the evaporation material is subjected to ultra-cleaning treatment and is clean, dust cannot fall off easily, and sputtering points can be avoided during coating.

Owner:CHANGZHOU PROSRUN PHOTOELECTRIC TECH CO LTD

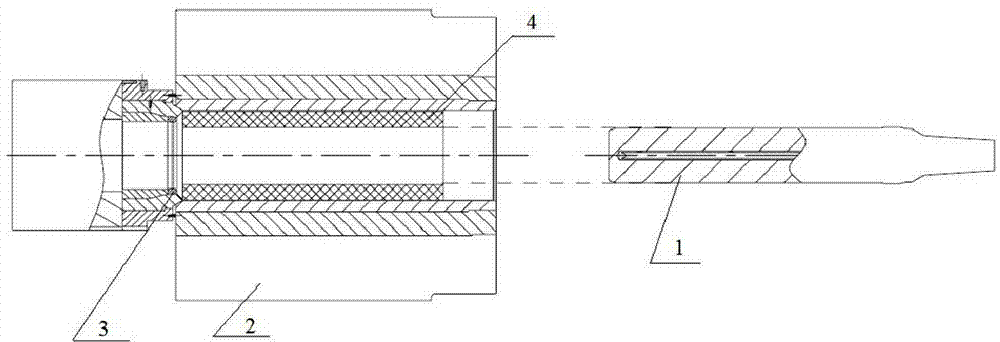

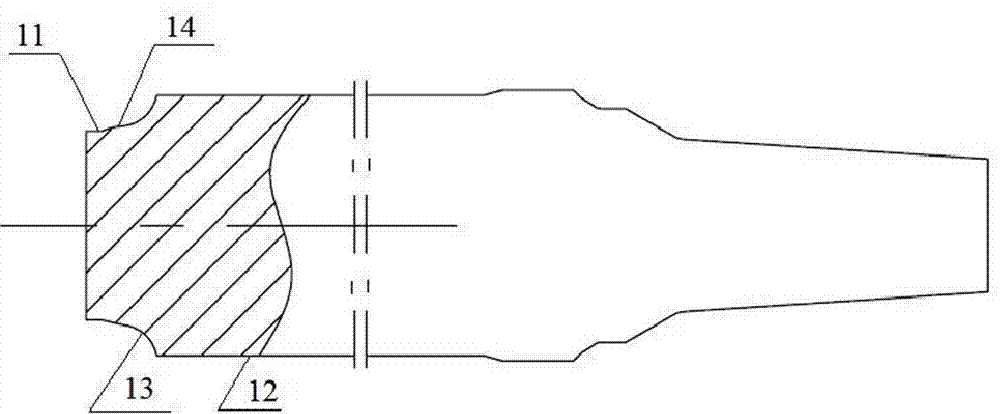

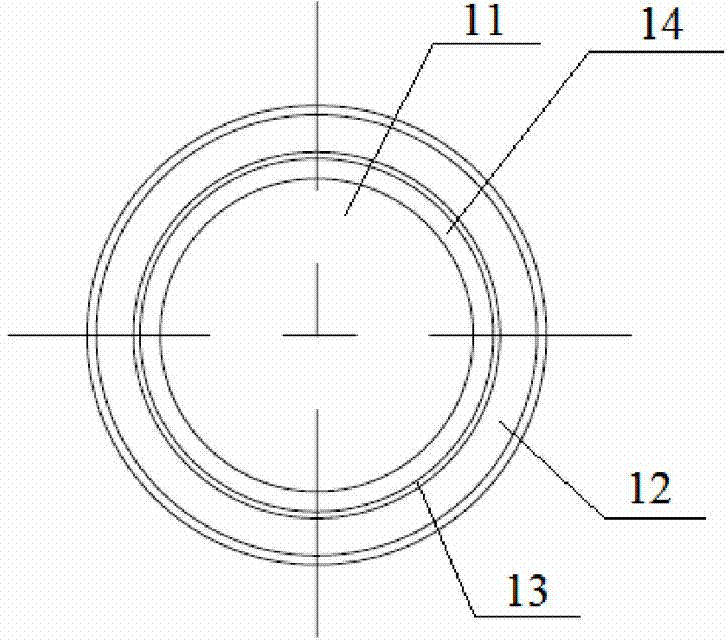

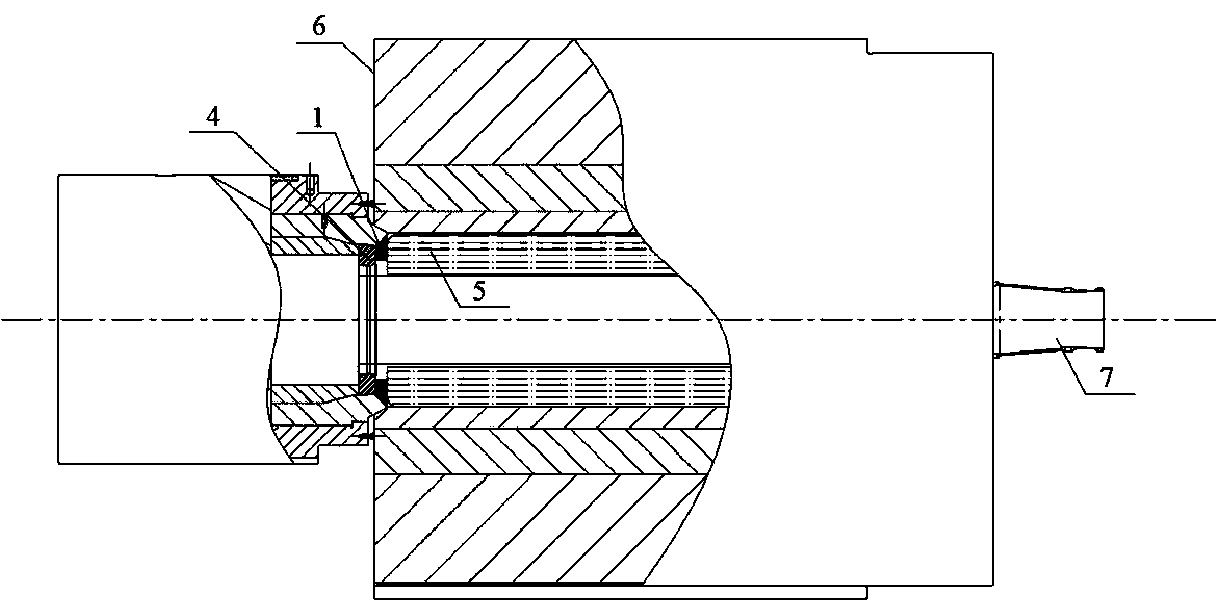

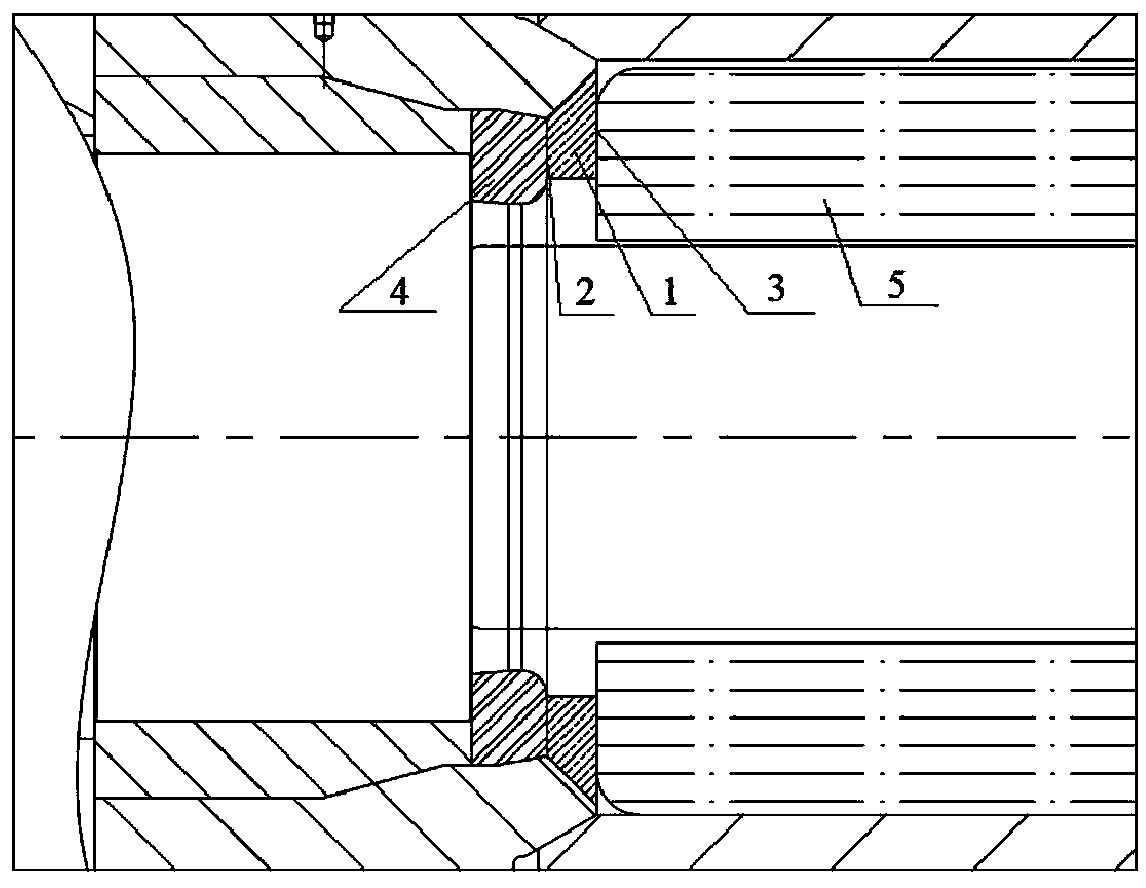

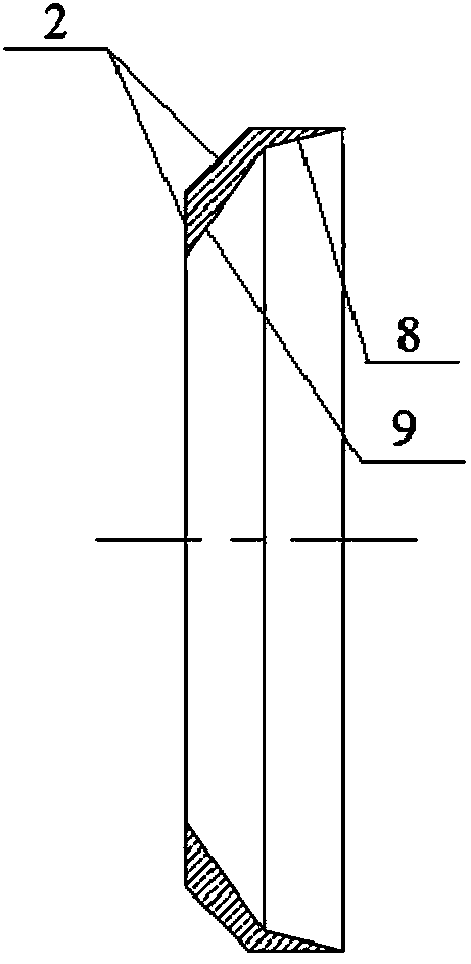

Extrusion needle and extrusion method for large-specification thin-walled pipe or hollow profile

ActiveCN103071693AExpand the scope of productionReduce extrusion processRams/plungersEngineeringMaterial Perforation

The invention discloses an extrusion needle and an extrusion method for a large-specification thin-walled pipe or a hollow profile. The extrusion needle comprises a perforation sizing section and an expansion section. The extrusion needle is characterized in that the diameter of the perforation sizing section is less than that of the expansion section; and a transition section is arranged outside the perforation sizing section; the extrusion method comprises the steps of hole drilling and boring, hole expanding and extrusion forming, in particular comprises the following steps of hole drilling and boring, hole expanding, blank heating, extrusion needle perforation sizing and automatic hole expanding, wherein the extrusion forming is finished through an extrusion action; and the needed thin-walled pipe or the hollow profile is obtained. Through adjusting the structure of the extrusion needle, the method shortens the extrusion procedure of the thin-walled pipe or the hollow profile; and the extrusion needle finishes two action processes of hole expanding and sizing, so that the production range of an extruder is widened, the loss of hole drilling / boring metals and drillers is reduced, the number of drilling / boring machine equipment is decreased, the equipment power is reduced, the tonnage of a hole expander is reduced, the hole expanding travel is shortened, the production cost is reduced, the production efficiency is improved, and the energy consumption is reduced.

Owner:嘉善创越知识产权服务有限公司

Method for producing recombined cationic antibacterial peptide by adopting co-expression anionic ligand

ActiveCN101696417AAvoid it happening againImprove product qualityMicroorganism based processesFermentationEscherichia coliPlasmid Vector

The invention discloses a method for producing a recombined cationic antibacterial peptide by adopting a co-expression anionic ligand, which is characterized in that an independent anionic ligand with net negative charges is co-expressed at the same time of expressing the cationic antibacterial peptide, namely, a cationic antibacterial peptide gene and an encoded DNA sequence of the anionic ligand are cloned to a plasmid vector and expressed in a colibacillus host cell in an independent non-fusing way, and the toxicity of the cationic antibacterial peptide to the host cell is restricted by the anionic ligand so as to improve the expression yield; and in the subsequent separation and purification processes, the step of cutting a fusing head, which consumes manpower, physical resources and financial resources, is avoided, therefore, the separation and purification efficiency and the yield ratio are improved. The invention can remarkably shorten the production cycle to one third or a half of the original production cycle and reduce the cost above 50 percent. The invention provides a high-efficiency and low-cost way for the large-scale production of the cationic antibacterial peptide.

Owner:安徽希普生物科技有限公司

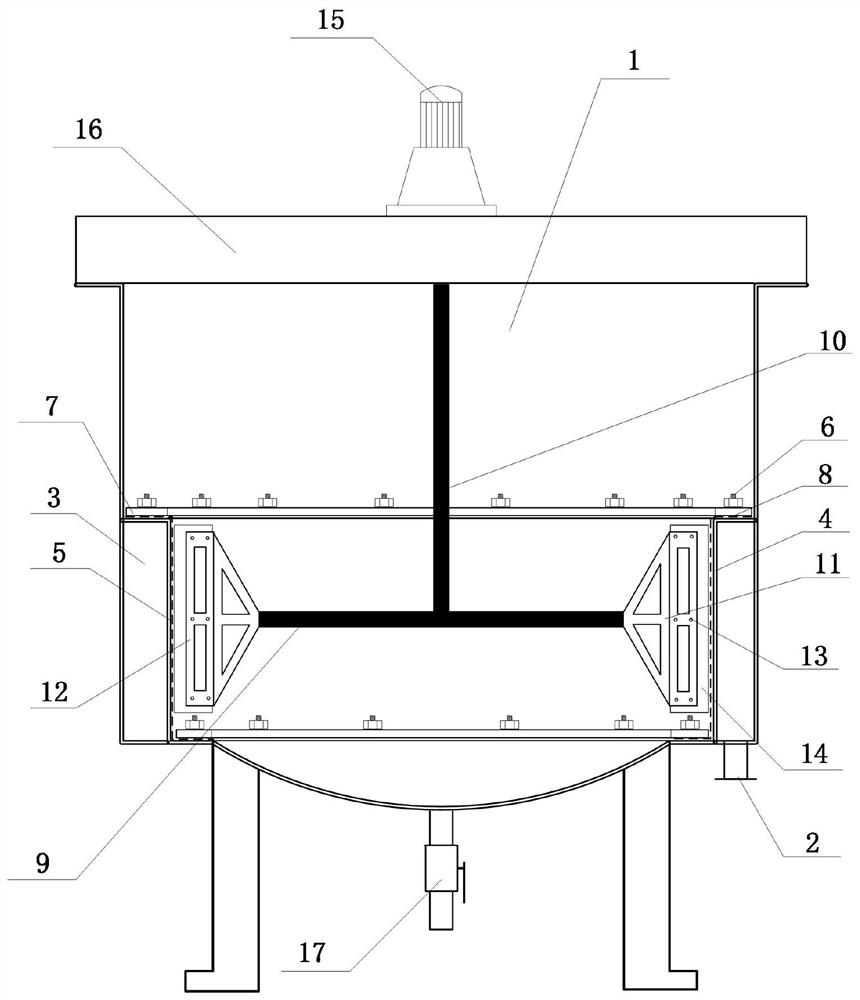

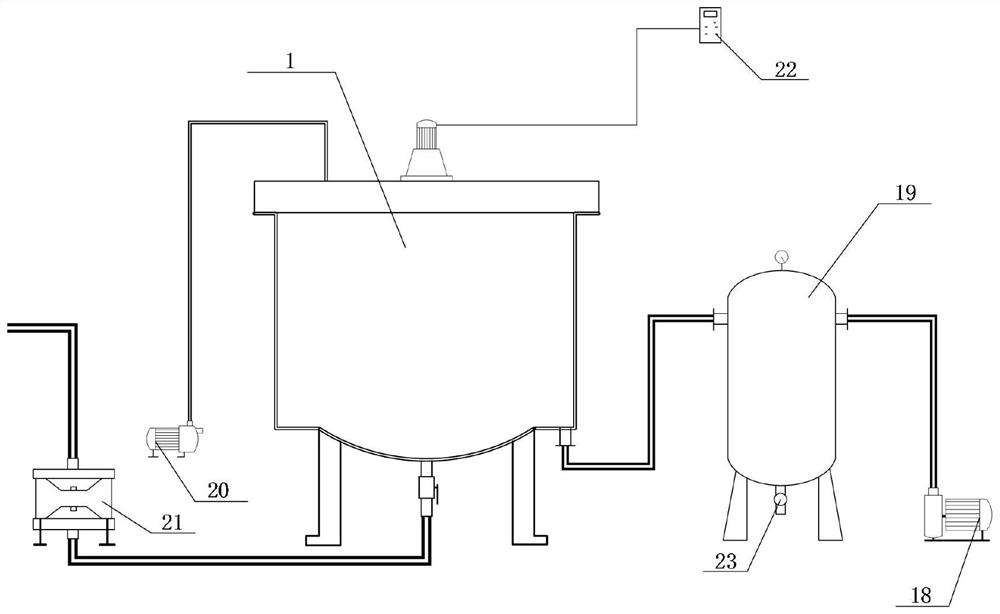

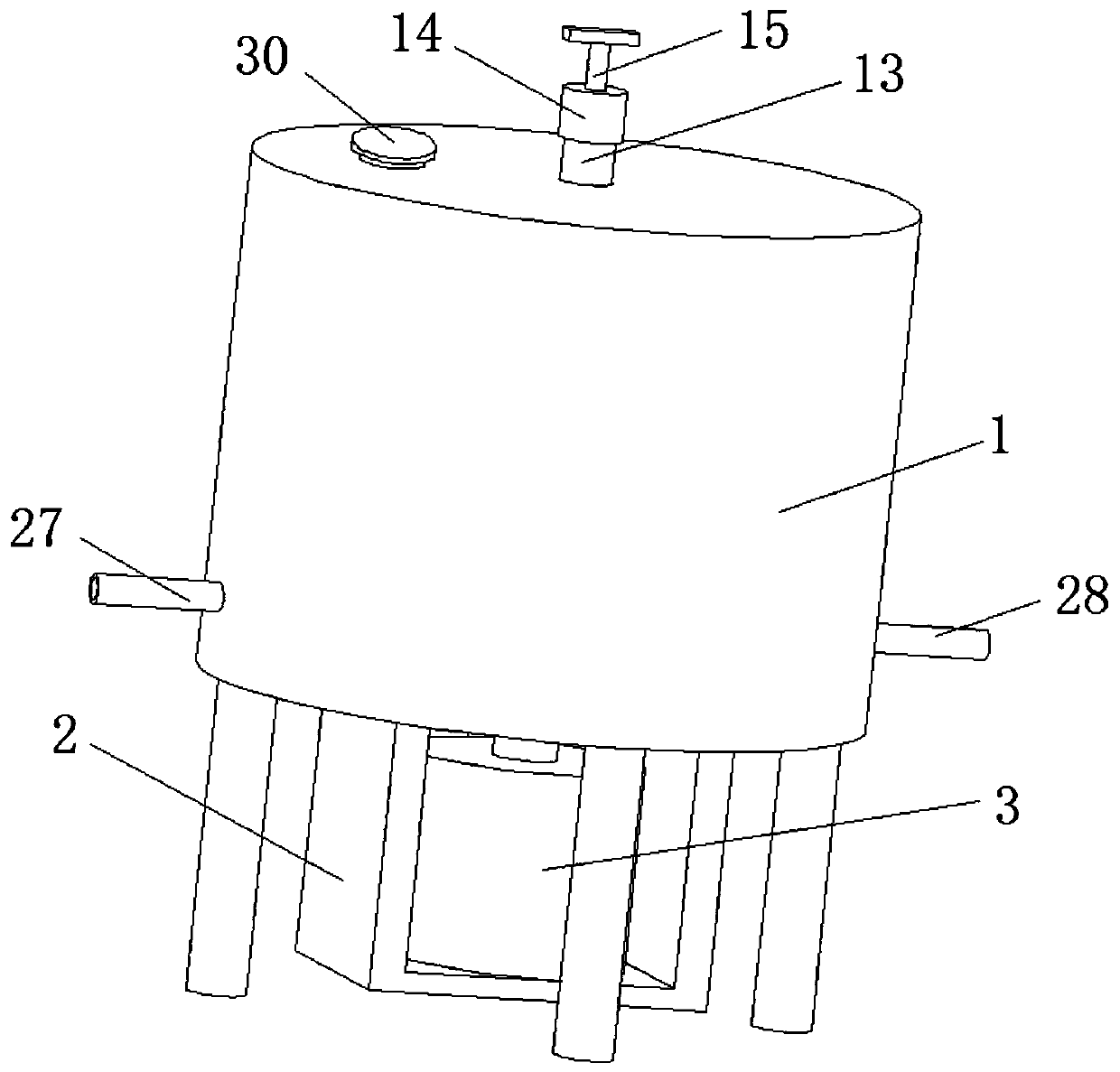

Solid-liquid separation device for organic silicon microsphere production

PendingCN112495023ASolve the problem that the flow rate is too fast and the filtering effect is poorEasy to take awayStationary filtering element filtersVapor–liquid separatorMicrosphere

The invention discloses a solid-liquid separation device for organic silicon microsphere production. The solid-liquid separation device comprises a suction filtration barrel, filter cloth and a slag scraping mechanism. A barrel body of the suction filtration barrel is a cylinder, a feeding port is formed in the top of the suction filtration barrel, a discharging port is formed in the bottom of thesuction filtration barrel, an interlayer is concavely arranged on the lower middle portion of the suction filtration barrel along the barrel wall to form a vacuum cavity, small holes are formed in the inner walls of the vacuum cavity to serve as filter plates, an extraction opening is formed in the bottom end of the vacuum cavity and connected with an inlet of a gas-liquid separator, and an outlet of the gas-liquid separator is connected with a vacuum pump; the filter cloth is arranged along the inner walls of the filter plates and is detachably connected with the barrel wall of the suction filtration barrel; and the slag scraping mechanism comprises a scraper blade paddle, scraper blades and a motor, the scraper blade paddle is horizontally and transversely arranged in the suction filtration barrel, the middle of the scraper blade paddle is connected with the motor through a stirring shaft, the two ends of the scraper blade paddle are connected with the scraper blades through clamps,the scraper blades are vertically arranged, and the scrapers make contact with the filter cloth. The problem of poor filtering effect caused by overlarge hydraulic pressure in the prior art is solved, the filter cloth is cleaned without shutdown in the suction filtration process, continuous production is realized, and the production efficiency is greatly improved.

Owner:贵州正业龙腾新材料开发有限公司

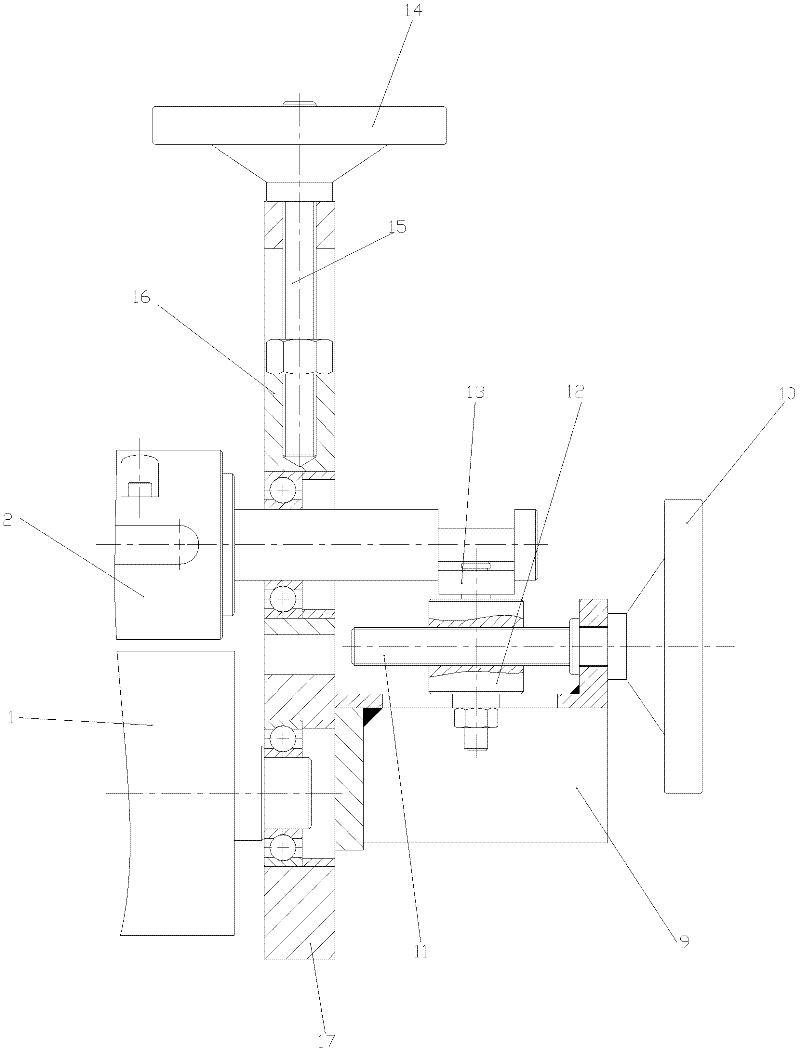

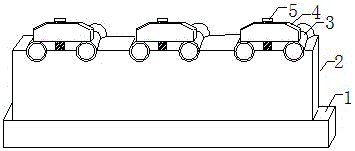

Stationary fixture device for milling machine

InactiveCN105798658ASimple structureEasy to operatePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to a stationary fixture device for a milling machine. The stationary fixture device comprises a base, a supporting base, pressing blocks, screws and parts. The supporting base is arranged on the base. The pressing blocks are arranged on the supporting base through the screws, and the parts are placed between the pressing blocks and the supporting base. The stationary fixture device is simple in structure, convenient to operate and low in cost, the product application service is improved, the production efficiency is improved, and meanwhile the production range is enlarged.

Owner:RUGAO TONGTAI ELECTRICAL POWER FITTING

Environment-friendly construction method for building decoration

ActiveCN111890517AReduce resistanceImprove applicabilityDischarging arrangementMouldsElectric machineConstruction engineering

The invention discloses an environment-friendly construction method for building decoration. A stair die comprises a machine base, wherein a partition plate is fixedly connected to the middle of the top end of the machine base; each corner at the top end of the machine base is fixedly connected with a supporting plate; the top ends of the supporting plates are fixedly connected with length adjusting mechanisms; the bottom at the outer end of the machine base is fixedly connected with an energy utilization and heat-proof and cold-proof mechanism; and two ends of the partition plate are symmetrically and movably connected with die opening and width adjusting mechanisms. According to the environment-friendly construction method, the structure is scientific and reasonable, and use is safe andconvenient; the die opening and closing and width adjusting mechanisms are arranged, a rotating motor drives a chain wheel to rotate, and the chain wheel drives a lead screw to rotate together throughthe transmission of a chain, so that a movable plate and frameworks are pushed to move, and the distance between the two frameworks and the partition plate is adjusted so as to open and close the die; and meanwhile, through the cooperation of a rolling groove and a roller, the resistance of the two frameworks during moving is reduced, the consumption of kinetic energy is reduced, and the efficiency of the movement is improved.

Owner:广东田业建设有限公司

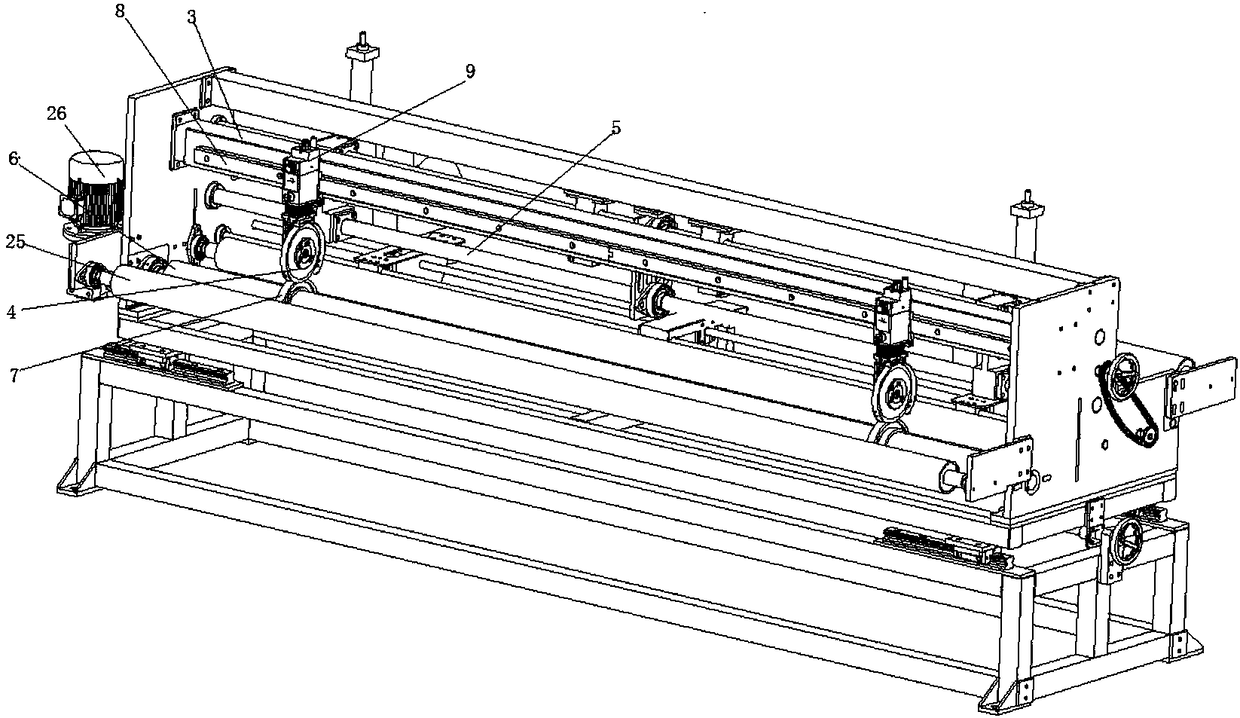

Combination edge trimmer

The invention discloses a combination edge trimmer, comprising an outer frame, and a pneumatic cutter module and a saw cutter module arranged side by side in the outer frame, wherein the pneumatic cutter module includes a pneumatic cutting blade component and an auxiliary cross beam for mounting the pneumatic cutting blade component, wherein the auxiliary cross beam is fixedly mounted between twotrimmer wall plates and is parallel to a main cross beam; the saw cutter module includes a saw blade unit and a guide rail component for mounting the saw blade unit, wherein the guide rail component is fixedly mounted between the two trimmer wall plates and is parallel to the main cross beam. The advantages of the pneumatic cutter module and saw blade cutting module are integrated herein, whereinthe pneumatic cutter module is used for cutting composite sheets less than 1.0 mm in thickness and has the advantages of low noise, few chippings, regular edge trimming and the like; the saw blade cutting module is used for cutting composite plates or sheets 1.0 mm and less thickness, and has the advantages of high efficiency, good cutting precision, good edge trimming regularity and the like.

Owner:NEWTRY COMPOSITE

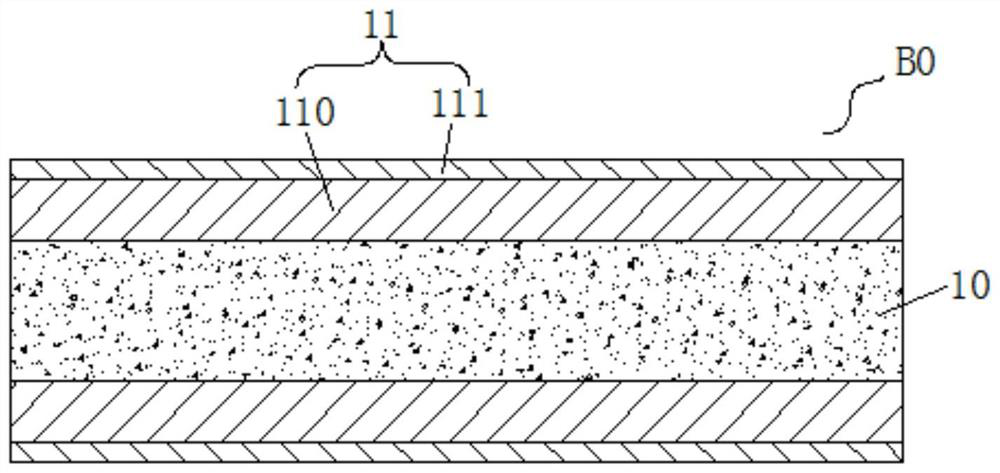

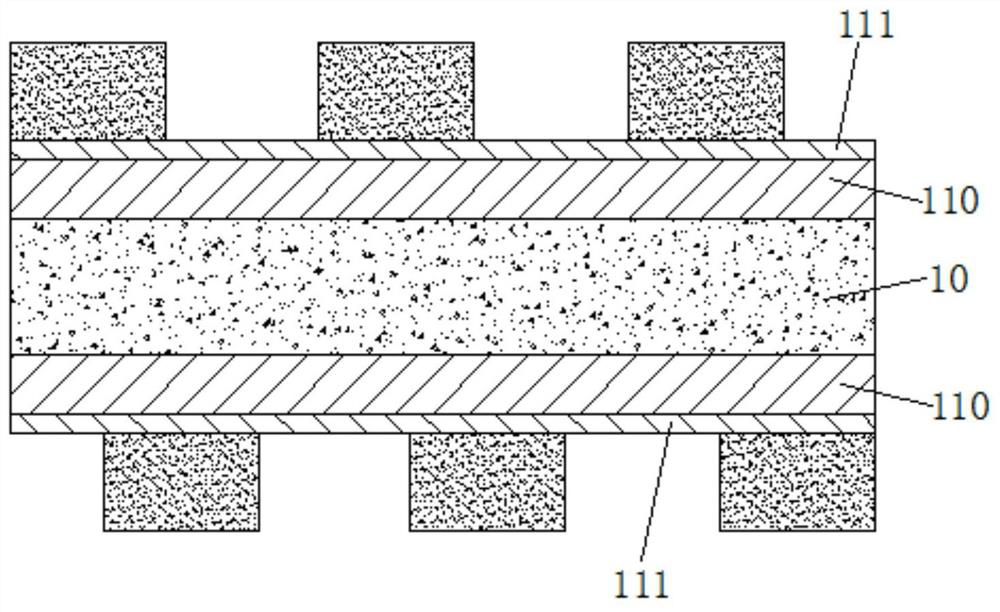

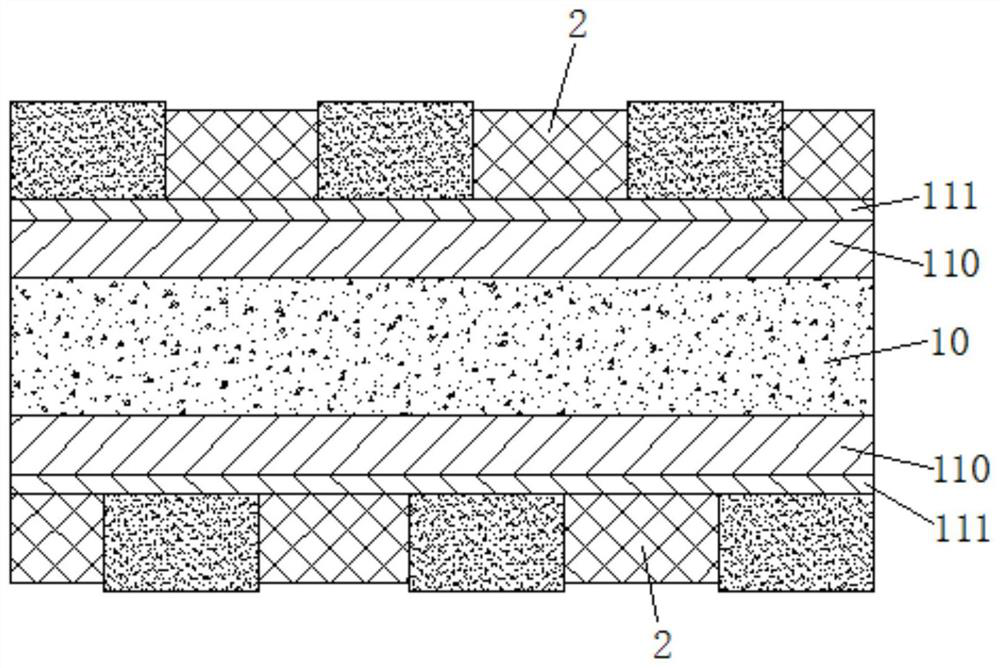

Processing technology of single-layer wireless charging coil carrier plate

PendingCN113380529AImprove reliabilityImprove efficiencyCoils manufactureCopper foilInductive charging

The invention discloses a processing technology of a single-layer wireless charging coil carrier plate. The processing technology comprises the following steps: preparing a carrier plate provided with an auxiliary substrate and two ultrathin carrier copper foils, wherein the two two ultrathin carrier copper foils are respectively laminated on the front surface and the back surface of the auxiliary substrate, and are respectively provided with a carrier copper foil and an ultrathin copper foil detachably arranged on one surface of the carrier copper foil; pasting dry films on the two ultrathin copper foils, and forming a circuit pattern after exposure and development; electroplating circuit copper layers on the two ultrathin copper foils according to the circuit pattern, then removing the dry films, and printing resin layers on the two circuit copper layers to obtain a second intermediate plate; splitting the second intermediate plate along the joint of the two ultrathin copper foils and the two carrier copper foils to obtain two third intermediate plates; and etching off the ultrathin copper foils on the third intermediate plates to obtain an effective plate of the single-layer wireless charging coil carrier plate. According to the invention, the processing technology is novel and high in production efficiency, the thickness of the manufactured single-layer wireless charging coil carrier plate is small, the reliability is good, and the coil pattern shape and wiring are not limited.

Owner:JIANGSU PROVISION ELECTRONICS CO LTD

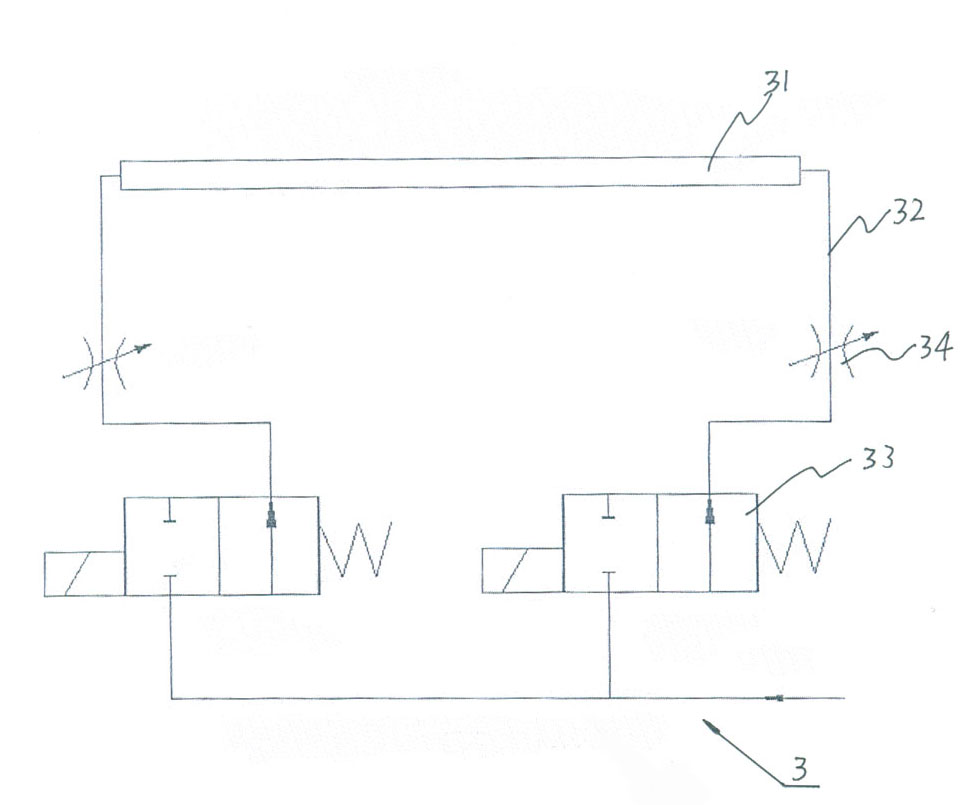

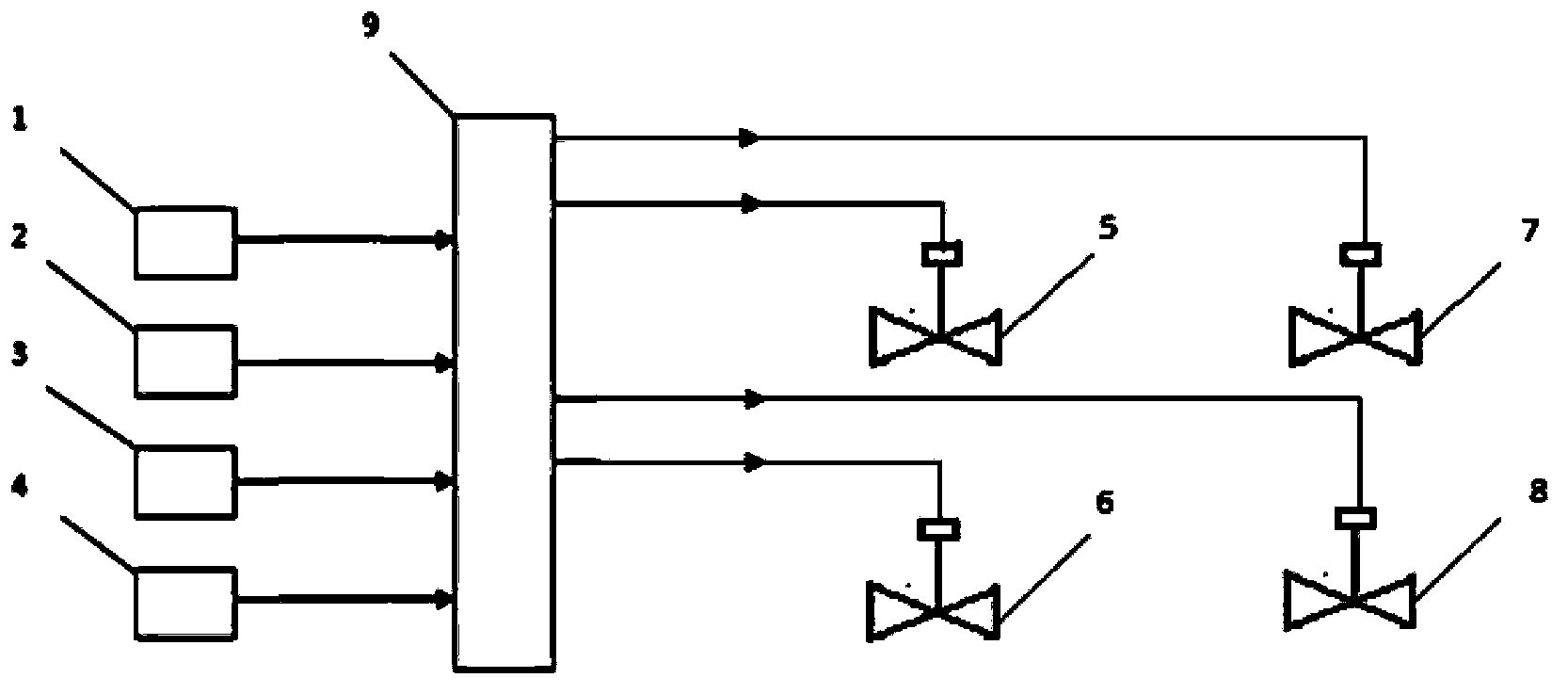

Hot rolling strip steel post-finish-rolling cooling control device

InactiveCN103846288ALow costDoes not affect production levelsTemperature control deviceWork treatment devicesProgrammable logic controllerStrip steel

The invention relates to a hot rolling strip steel post-finish-rolling cooling control device which comprises a coarse cooling upper collection pipe flow sensor, a coarse cooling lower collection pipe flower sensor, a finish cooling upper collection pipe flow sensor, a finish cooling lower collection pipe flow sensor, a coarse cooling upper collection pipe water valve, a coarse cooling lower collection pipe water valve, a finish cooling upper collection pipe water valve, a finish cooling lower collection pipe water valve and a programmable logic controller (PLC). The device is characterized in that the signal output ends of the coarse cooling upper collection pipe flow sensor, the coarse cooling lower collection pipe flow sensor, the finish cooling upper collection pipe flow sensor and the finish cooling lower collection pipe flow sensor are connected with the signal input end of the PLC, and the signal output end of the PLC is connected with the control ends of the coarse cooling upper collection pipe water valve, the coarse cooling lower collection pipe water valve, the finish cooling upper collection pipe water valve and the finish cooling lower collection pipe water valve. By means of the device, front stage cooling acceleration can be achieved according to requirements, and the product production range is expanded under the condition that the cost is not increased, and the original production level is not affected. The device is simple in structure, low in cost and convenient to operate.

Owner:武钢集团有限公司

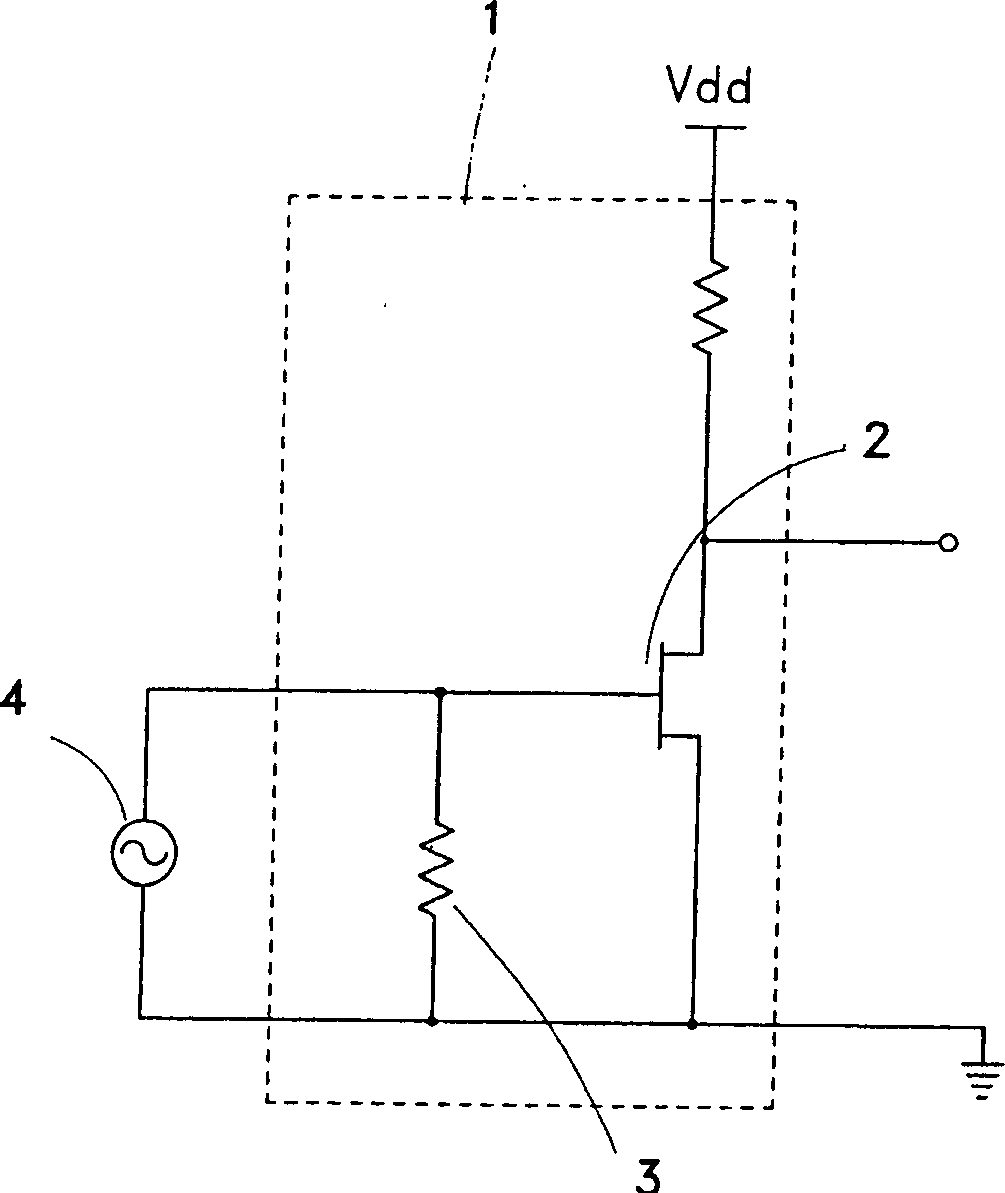

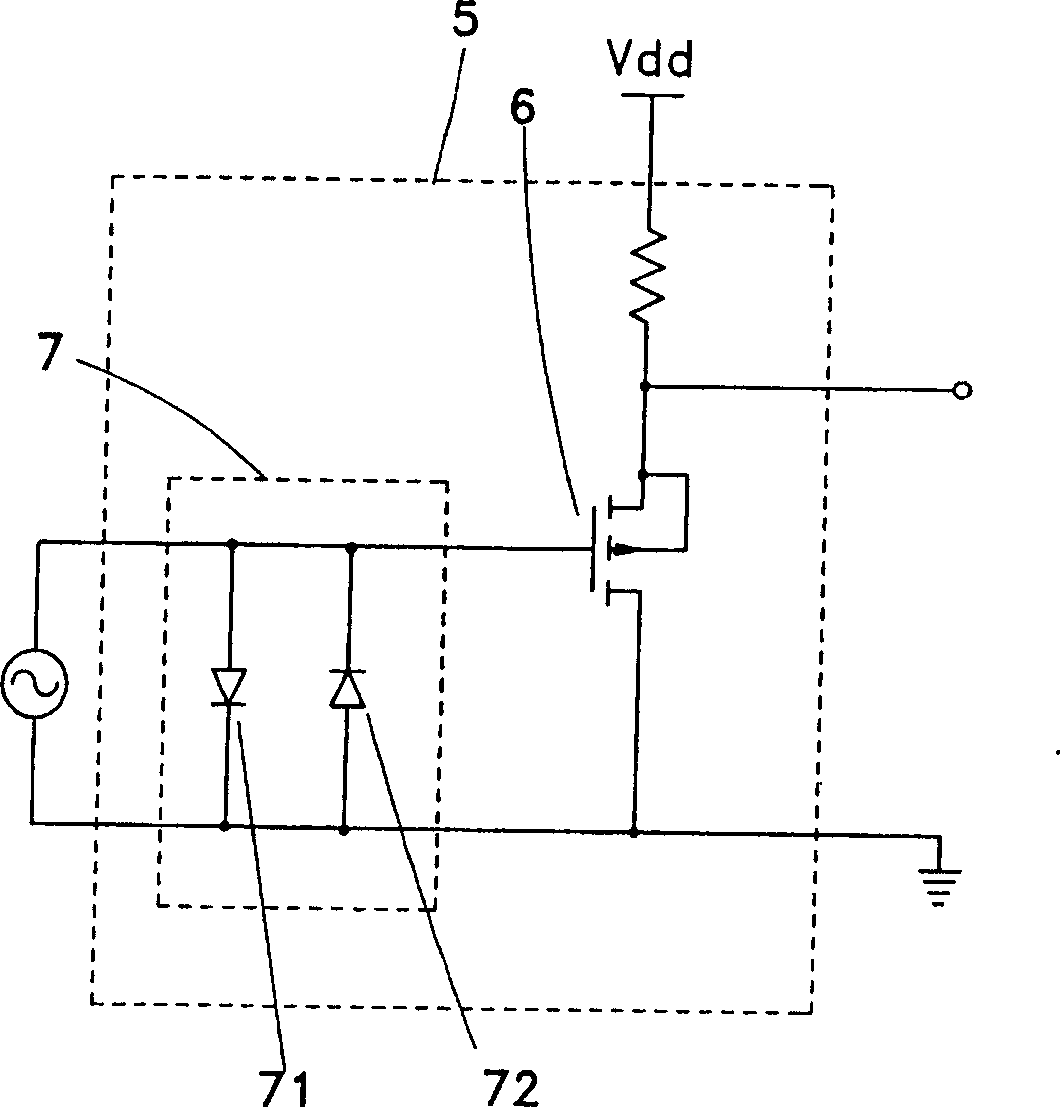

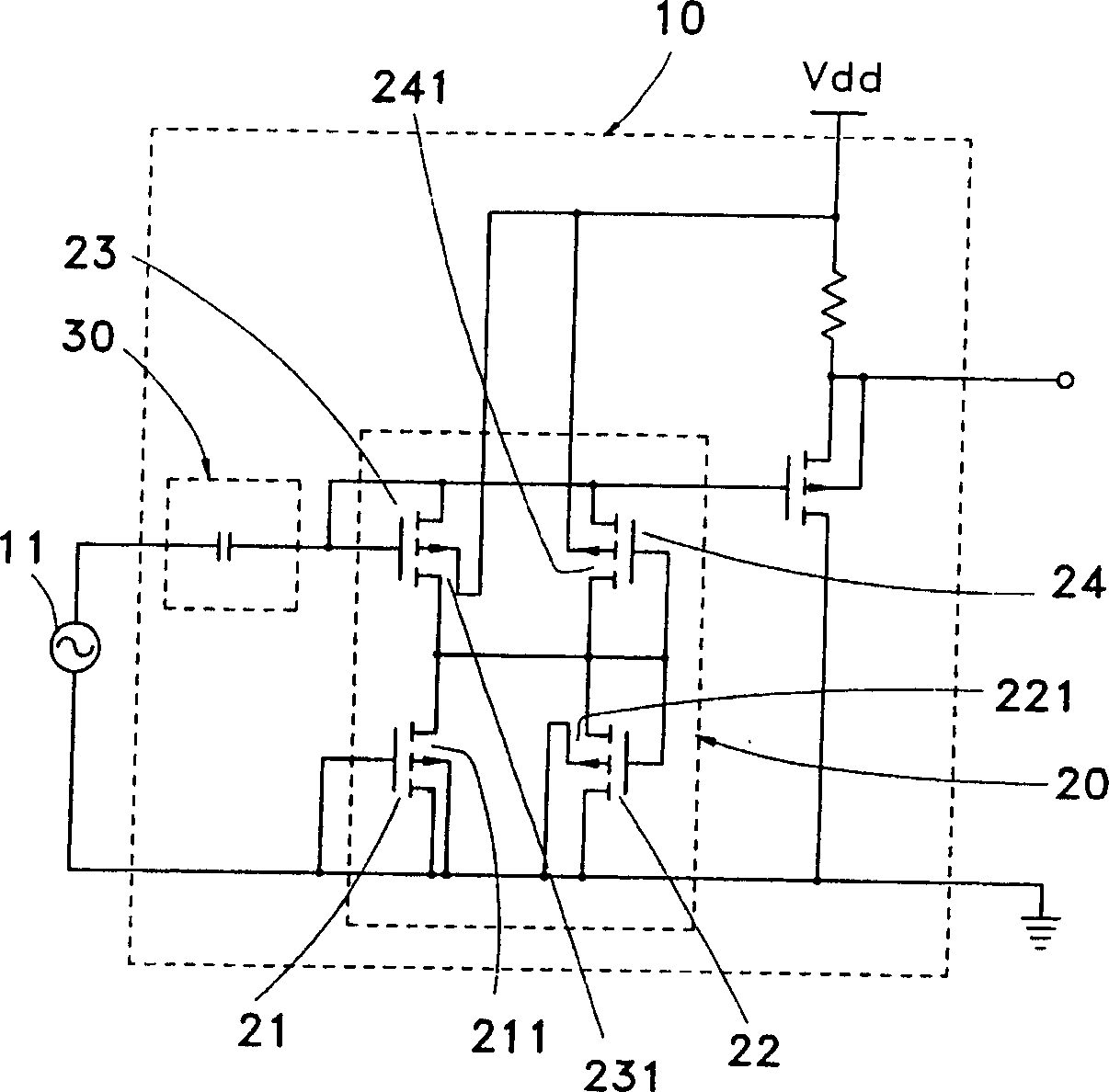

Impedance circuit of microphone preamplifier

InactiveCN1691497AImprove performanceHigh input impedanceMultiple-port networksLow frequency amplifiersAudio power amplifierMicrophone preamplifier

An impedance circuit for microphone head amplifier which set between a microphone and an amplifier to provide higher input impedance and improve the performance of the head amplifier.

Owner:MERRY ELECTRONICS (SHENZHEN) CO LTD

Roller type pulverizer for manufacturing aluminate cement

ActiveCN111495507AExpand the scope of productionIncrease economic benefitsHollow article cleaningGrain treatmentsElectric machineryPulverizer

The invention relates to the technical field of roller type pulverizers, and discloses a roller type pulverizer for manufacturing aluminate cement. The roller type pulverizer for manufacturing aluminate cement comprises a box body, wherein a motor seat is fixedly connected to the bottom surface of the box body, a motor is fixedly mounted in the motor seat, an output shaft of the motor is fixedly connected with a rotating shaft, and the upper end of the rotating shaft penetrates through the box body, extends to the inside of the box body and is fixedly connected with a rotary table. According to the roller type pulverizer for manufacturing the aluminate cement, a spring is connected with a sliding rod inserted in a sleeve hole, an oil pipe communicating with the top surface of the rotary table is used for filling pressure oil into an inner cavity of the rotary table, a lower sliding plate is moved up and down by rotating a threaded rod, the oil pressure in the inner cavity is controlled, and the sliding rod is driven to slide in the sleeve hole in a telescopic manner, so that the distance between a moving roller and a fixed roller is changed. The roller type pulverizer can meet different requirements of the cement for particle size, different minimum sizes of pulverizing can be controlled, the production range of equipment is expanded, the economic benefit is improved, and the use effect is good.

Owner:江苏中意建筑材料有限公司

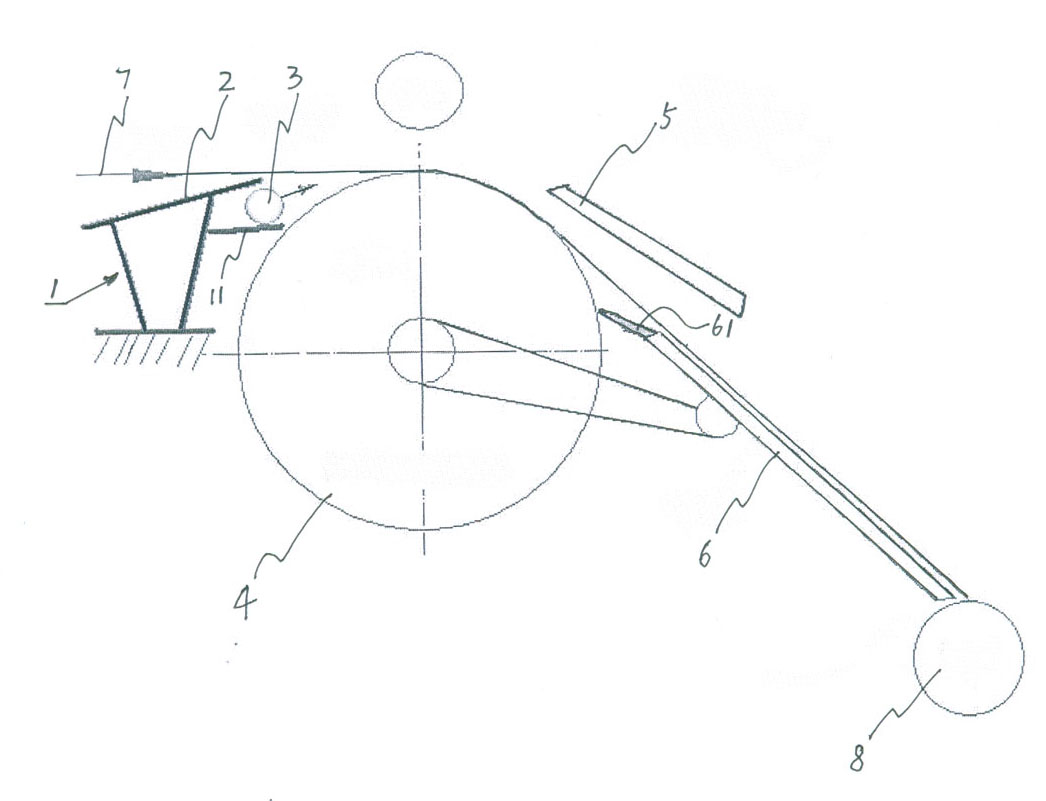

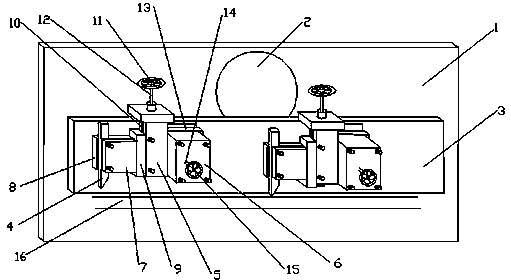

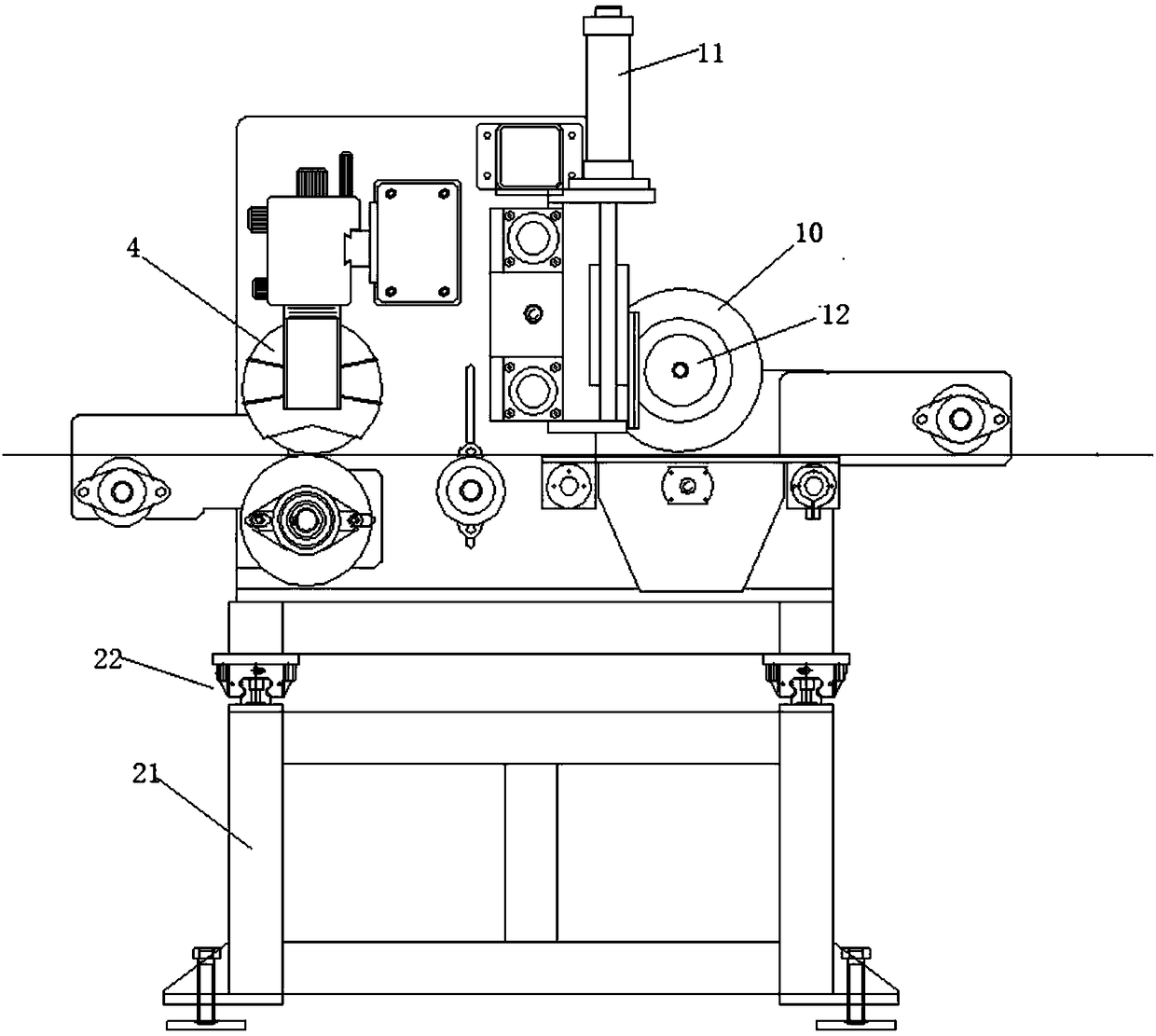

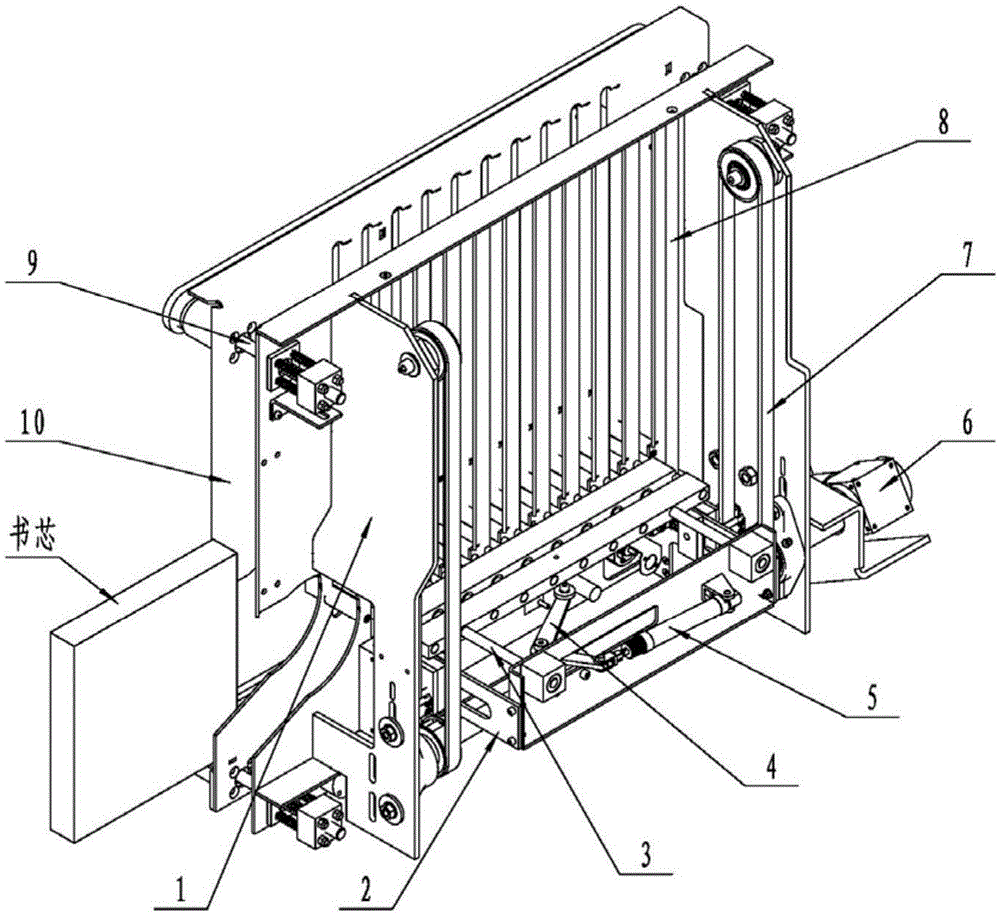

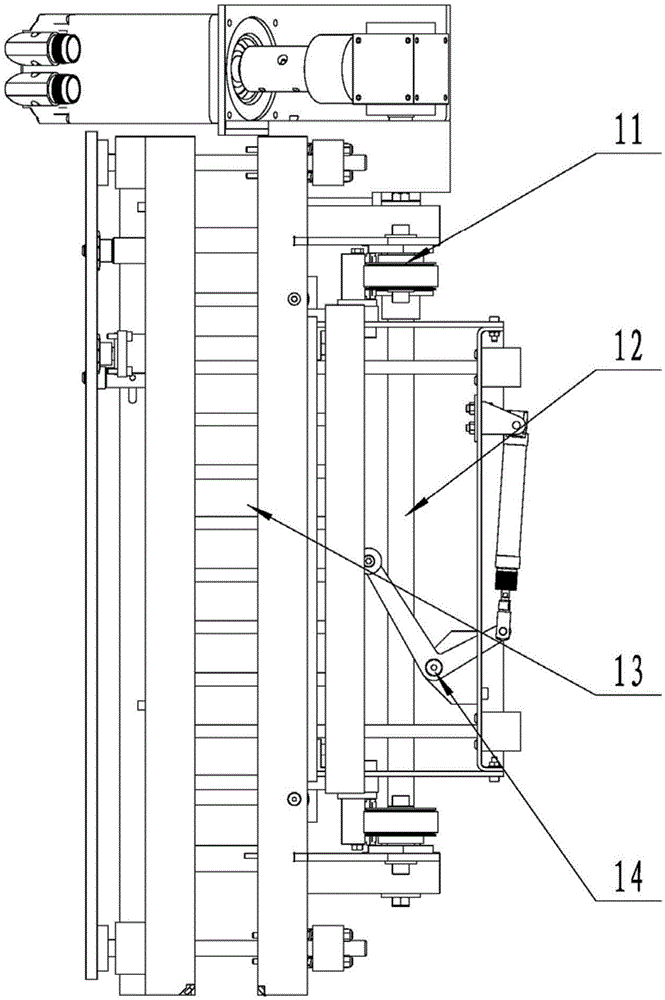

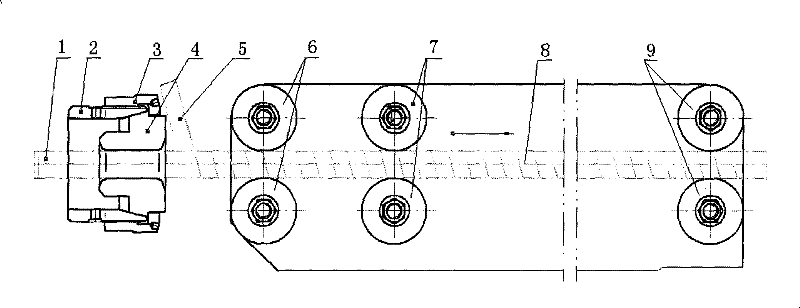

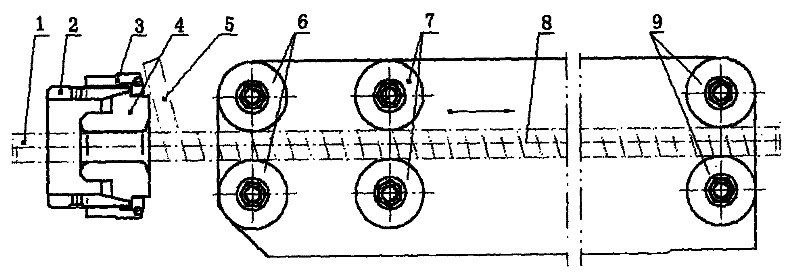

Book block feed mechanism of adhesive binding machine

PendingCN105620076AIntegrity guaranteedQuality assuranceBook making processesBookbinding adhesivePulleyEngineering

The invention discloses a book block feed mechanism of an adhesive binding machine. The book block feed mechanism comprises a rack. A base, a lifting mechanism and a transverse moving mechanism are arranged on the rack. Ejector rods are arranged on the base. The base is connected with the lifting mechanism. The transverse moving mechanism is arranged on the base. The ejector rods are connected with the transverse moving mechanism. The lifting mechanism comprises a servo motor, a rotary shaft, a synchronous belt pulley and a synchronous belt. The transverse moving mechanism comprises an air cylinder, a connecting rod and a hinge shaft.

Owner:PINGHU BIND EX MACHINERY

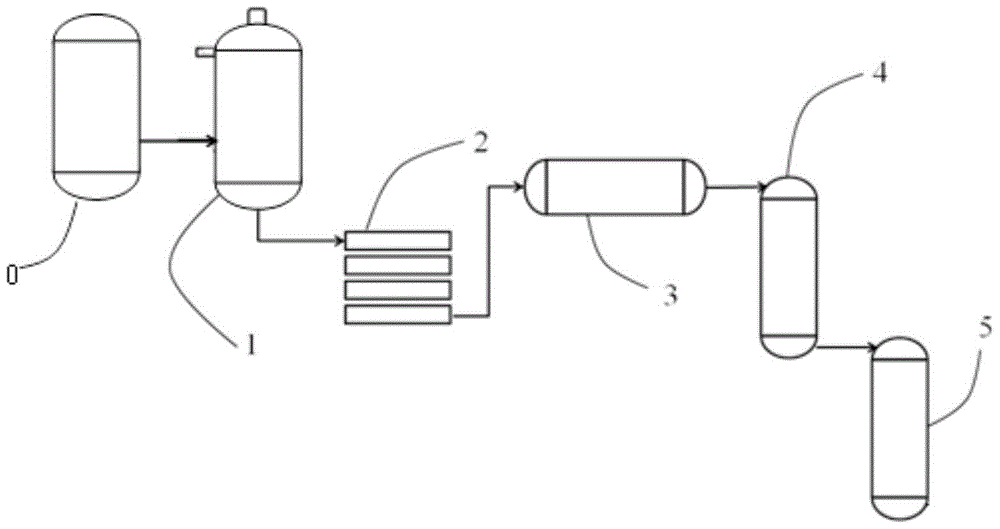

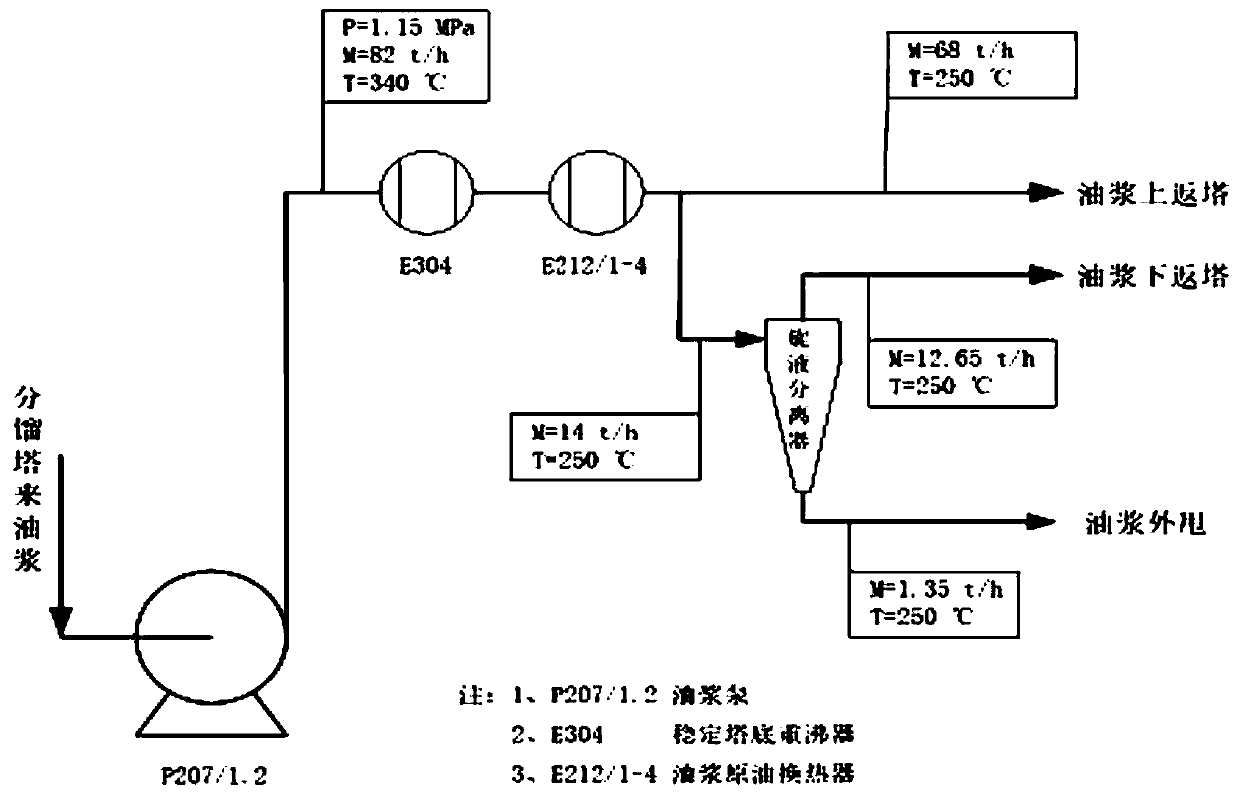

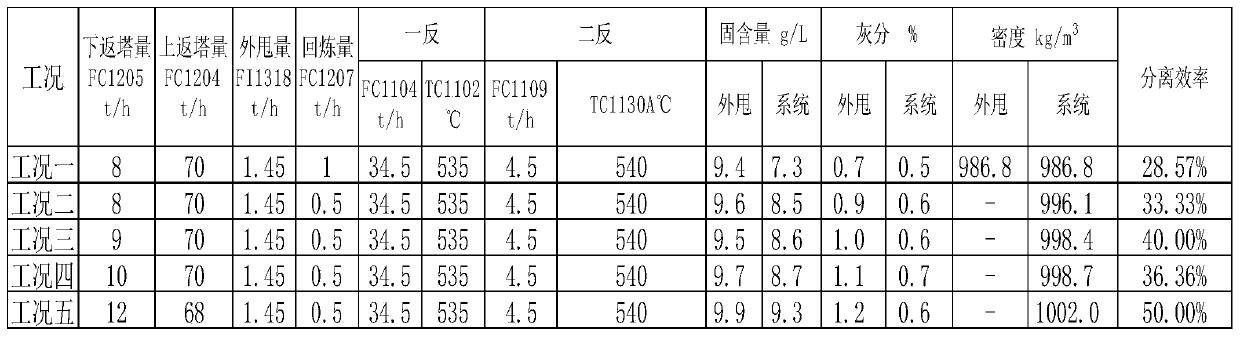

Application of hydrocyclone separation technology in MCP device

InactiveCN109722286AImprove separation efficiencyMultifunctionalTreatment with plural serial refining stagesSeparation technologyReboiler

The invention discloses application of hydrocyclone separation technology in an MCP (maximizing catalytic propylene) device. The invention involves a fractionating tower, a stable reboiler, a slurry oil crude oil heat exchanger, and a hydrocyclone separator. The steps include that: slurry oil in the fractionating tower passes through a slurry oil pump to reach high temperature and high pressure, then the slurry oil flows through the stable bottom reboiler and the slurry oil crude oil heat exchanger in order, after cooling to a certain temperature, a part of slurry oil flows back to the fractionating tower through a pipeline, and the other part of slurry oil flows into a liquid inlet of the hydrocyclone separator at certain flow, and then flows into a hydrocyclone head through a clear stream pipe outer wall, and the clear stream pipe outer wall is equipped with a spiral structure, the lower end of the hydrocyclone head is funnel-shaped, after entering the lower end of the hydrocyclone head, the slurry oil undergoes high speed rotating motion, then clear and heavy slurry oil can be separated, the clear stream returns to the upper part of the hydrocyclone separator through the clear stream pipe and flows out, and returns to the fractionating tower, and the heavy stream flows out from the bottom of the hydrocyclone separator and is then thrown out of the device. The invention has the advantages of small slurry oil viscosity, low specific gravity, high solid-liquid separation efficiency, low manufacturing cost and small space occupation.

Owner:扬州石化有限责任公司

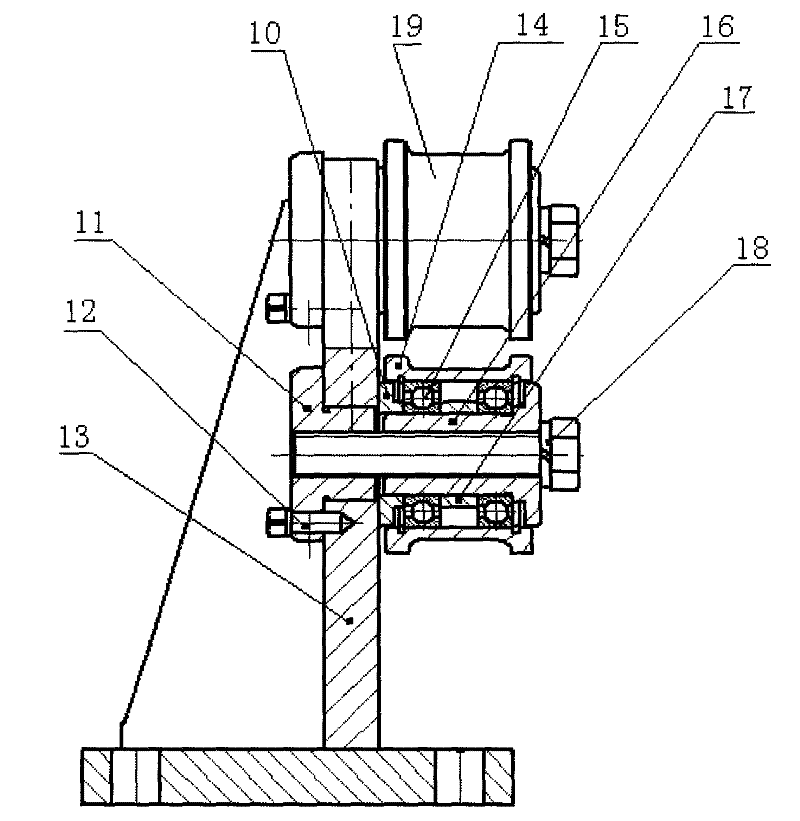

Automatic hydraulic side pressing table machine

InactiveCN107736695AHigh bonding strengthImprove efficiencyShoe gluingHydraulic cylinderAgricultural engineering

The invention discloses an automatic hydraulic side pressing machine. Its structure includes a hydraulic device, a shoe mold device and a body, the body and the hydraulic device are connected by a shoe mold device, and the hydraulic device is composed of a hydraulic cylinder, a slideway , Fixed beam and motor, the fixed beam and the hydraulic cylinder are connected with slideways, the hydraulic cylinder and the motor are connected by wires, the body and the fixed beam are connected by slides, and the shoe mold device is connected by a can The replaceable shoe mold and the mobile workbench are composed, the replaceable shoe mold and the mobile workbench are connected by a ring, the mobile workbench is movably connected to the body with a small slide, and the replaceable shoe mold is composed of a kyphosis, a It is composed of a concave arc and a front flat. The invention is suitable for rubber shoe outsole, side pressing and full rubber shoe upper and heel wrapping, improving the bonding strength of the upper and the wrapping, firm and non-gluing, and has the advantages of simple operation, The speed is high and the efficiency is high, and the present invention can replace the shoe mold and expand the production range.

Owner:陈超

Glass lubricating cushion for hot extrusion and capable of reducing extrusion force

The invention discloses a glass lubricating cushion for hot extrusion and capable of reducing extrusion force. The glass lubricating cushion is an annular piece and comprises a die orifice contact surface and a blank contact surface. The glass lubricating cushion is characterized in that the blank contact surface is divided into a guide section and a bearing section; an included angle of working surfaces of the guide section and the bearing section is 95-175 degrees; and the length ratio of the guide section and the bearing section is (0-10):(10-0). The blank contact surface is divided into the guide section and the bearing section and the inclined angle between the guide section and an annular axis is less than 90 degrees, so that initial extrusion breaking force in a hot extrusion process is reduced; meanwhile, the extrusion force of a stable phase is reduced and the production range of hot extrusion equipment is enlarged; and meanwhile, the extrusion ratio can be increased by using a larger extrusion barrel so that the quality of a product is better. Furthermore, the extrusion force is reduced so that the load and abrasion of a tool and a die are reduced, the service life is prolonged and die steel with a lower price can be used; and therefore, the cost of maintaining extrusion tool and die is greatly reduced, and the production efficiency and the economic benefit are improved.

Owner:嘉善罗星创业投资有限公司

Choerospondias axillaris fruit cake and making method thereof

A choerospondias axillaris fruit cake is made of, by weight, 80-100 parts of fresh choerospondias axillaris fruit, 30-50 parts of sweet potatoes, 3-5 parts of rock candy, 0.5-0.8 part of licorice root, 2-4 parts of honeysuckle flowers, 2-4 parts of brown sugar, 0.2-0.4 part of herba menthae, 0.2-0.4 part of poria cocos, 2-3 parts of sesame, 5-8 parts of radix puerariae and 2-3 parts of pericarpium citri reticulatae. The choerospondias axillaris fruit cake is unique in flavor and excellent in taste; on one hand, the production range of the choerospondias axillaris fruit can be expanded, and the economical value of the choerospondias axillaris fruit is improved; on the other hand, the choerospondias axillaris fruit cake serving as a snack with a unique flavor has the effect of promoting appetite and digestion, and when a consumer eats the choerospondias axillaris fruit cake, a certain physical health effect can be achieved.

Owner:黄丽

Manufacturing process and equipment for upset forging of flanges

InactiveCN101961765BReduce bending momentReduce the height of the hook shellEngine componentsHeating/cooling devicesEnergy consumptionHeating temperature

The invention relates to manufacturing process and equipment for the upset forging of flanges, relating to manufacturing process and equipment for flanges. The manufacturing process comprises the following steps of: making materials into flange metal semicircles, evenly heating and butting the flange metal semicircles by adopting upset forging equipment, wherein the pressure on an extrusion surface is 40 to 70MP and the heating temperature is 500 to 1300 DEG C; and quickly connecting the two semicircles after the extrusion through the upset forging equipment to obtain a product. The inventionhas the advantages of capability of producing various annular steel flanges and aluminum flanges with different specifications only by using the upset forging equipment and simple matched moulding beds so that the investment in equipment and the energy consumption only account for a fraction or one of dozens of that of traditional equipment, cost is saved by more than 30% and production efficiency is increased by several times.

Owner:岳炳坤

Corrugated armoring machine

InactiveCN101369474BSolve the problem that only flat armored cables can be producedExpand the scope of productionCable/conductor manufactureEngineeringMechanical engineering

The invention discloses a corrugation armouring machine comprising a shaping mechanism and two or more rolling slide bush shaping dies, the shaping mechanism is arranged at the front of a cable operation direction of the corrugation packing outgoing line port, the two or more rolling slide bush shaping dies are arranged at the front of a cable operation direction of the corrugation packing outgoing line port. The inventive corrugation armouring machine adopting this structure solves the problem that the corrugation armouring machine only can produce flat-shaped armouring cables, ensures that the products produced by the device can be suitable for applications of different industries and places, enlarges the production range, reduces the production cost, saves the energy, and the once qualification rate of the product can be ensured.

Owner:ANHUI HUAXING FIRE EQUIP GRP CO LTD

The Method of Machining Roll Involute Splines Using CNC Double-sided Milling Machine

ActiveCN105598511BShorten the timeIncrease productivityMilling equipment detailsNumerical controlEngineering

The invention relates to a spline processing method, in particular to a method adopting a numerical control double-side milling machine for processing a roller involute spline, and belongs to the technical field of machining. The specific processing method is as follows: firstly, a workpiece is clamped on a machine tool and aligned, line drawing is performed to the workpiece according to the spline tooth shape, then the spline is milled by the numerical control double-side milling machine which is provided with two main shafts, and rough milling and semi-fine milling can be performed simultaneously. With the adaption of the spline processing method, the numerical control double-side milling machine is used for processing the spline, two processing steps of rough milling and semi-fine milling can be completed simultaneously by one time clamping, the production efficiency is improved, at the same time, the processing error caused by multiple times of clamping is reduced, and the processing quality of the workpiece is improved.

Owner:邢台轧辊小冷辊有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com