Automatic hydraulic side pressing table machine

A hydraulic and automatic technology, which is applied in the field of shoes and clothing machinery, can solve the problems of shoes with lines and not conforming to the shape of human feet, and achieve the effect of firmness, fast speed and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

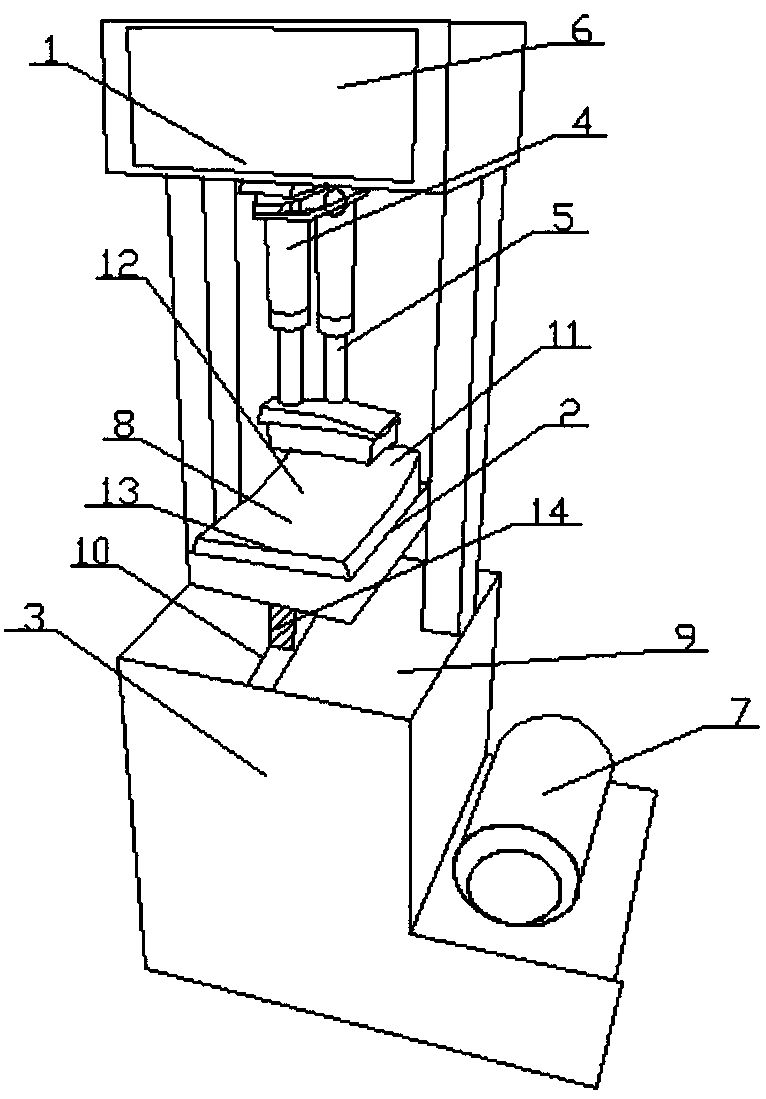

[0014] combine figure 1 , The hydraulic press is a machine that uses liquid as the working medium and is made according to Pascal's principle to transfer energy to realize various processes. A hydraulic press generally consists of three parts: the machine (main machine), the power system and the hydraulic control system. Hydraulic machines are classified into valve hydraulic machines, liquid hydraulic machines, and engineering hydraulic machines. The structure of the present invention includes a hydraulic device 1, a shoe mold device 2 and a body 3. The body 3 and hydraulic device 1 are connected by a shoe mold device 2. The hydraulic device 1 consists of a hydraulic cylinder 4, a slideway 5, a fixed beam 6 and a motor 7, the fixed beam 6 and the hydraulic cylinder 4 are connected by the slideway 5, the hydraulic cylinder 4 and the motor 7 are connected by wires, and the body 3 and the fixed crossbeam 6 are connected by a slideway 5, and the shoe mold device 2 is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com