Device for preventing galvanized plate from sticking roller and method thereof

A galvanized sheet and roll sticking technology, which is applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of fault expansion, roll damage, non-separation, etc., and reduce the number of abnormal shutdowns, The effect of expanding the scope of production and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

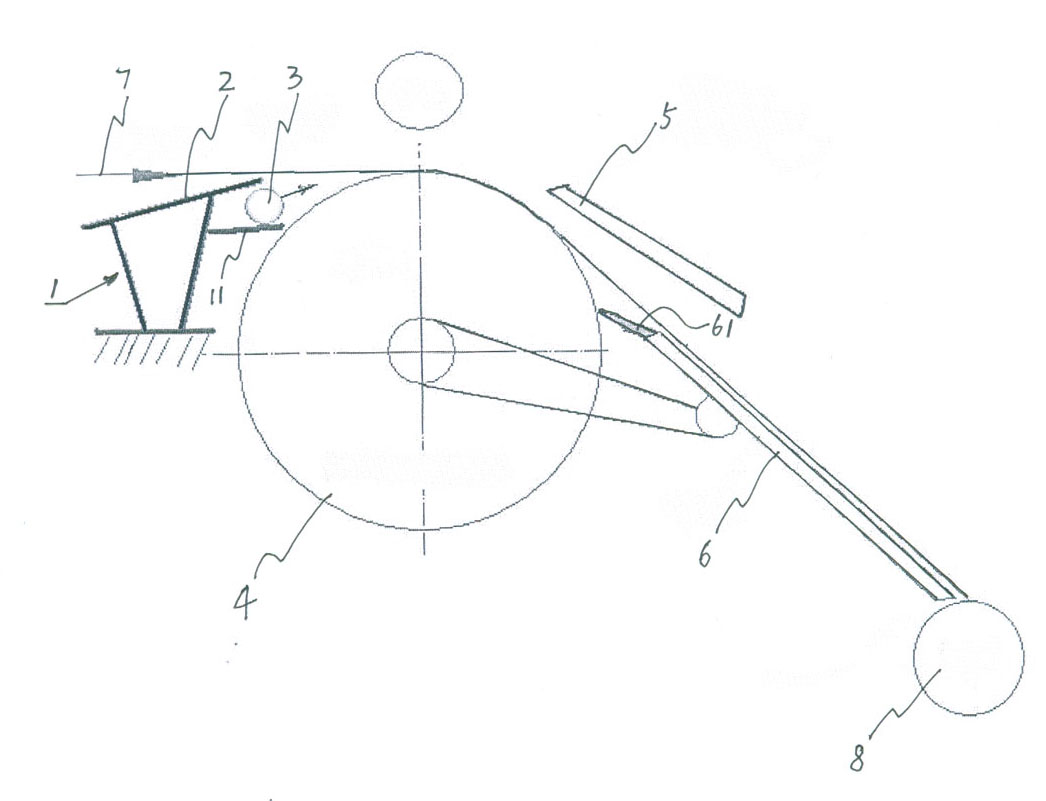

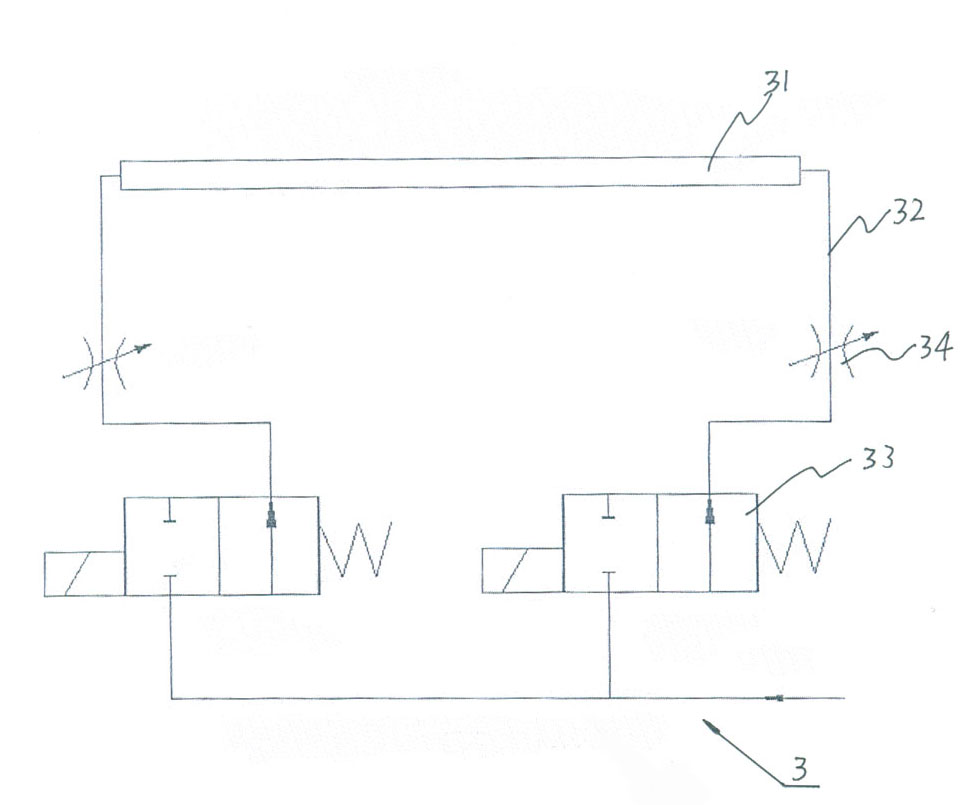

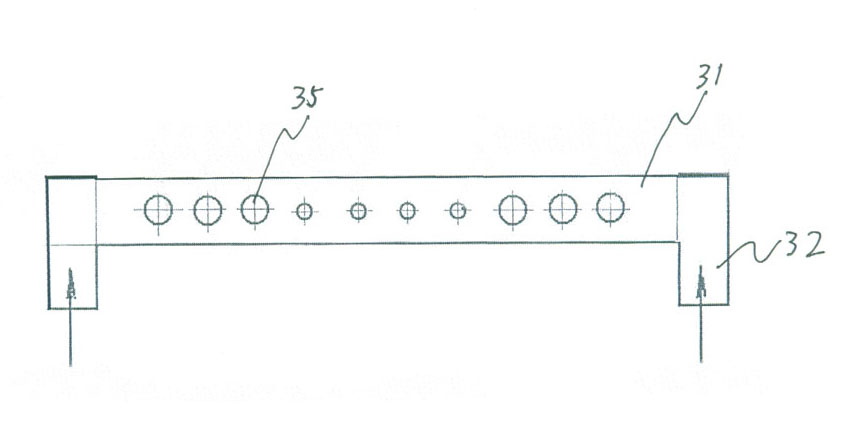

[0013] see figure 1 , which is a schematic diagram of the appearance structure of an embodiment of the device for preventing galvanized sheet from sticking to rolls proposed by the present invention. The device includes a bracket 1 mounted on the front of the work roll 4 and a front guide plate 2 installed on the top of the bracket 1, an air jet assembly 3, an upper guide plate 5 and a lower guide plate 6 at the rear of the work roll 4. In order to enable the steel plate 7 to smoothly enter the roll nip (not shown) of the coiler 8, the upper end of the lower guide plate 6 is provided with a curved portion 61 bent toward the work roll direction, and the curved portion 61 can make the lower guide plate The upper end of 6 is close to the work roll 4, so that the steel plate 7 can enter the coiler through the lower guide plate 6.

[0014] The front guide plate 2 is obliquely installed on the support 1 from the traveling direction of the steel plate 7, and a transverse plate 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com