Glass lubricating cushion for hot extrusion and capable of reducing extrusion force

A technology of glass lubrication and hot extrusion, which is applied in the field of metal thermal processing equipment and auxiliary parts of metal extrusion equipment. It can solve the problems of reducing the extrusion range of extrusion equipment, reducing the service life, and affecting product quality, so as to improve production. Efficiency and economic benefits, improved service life, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

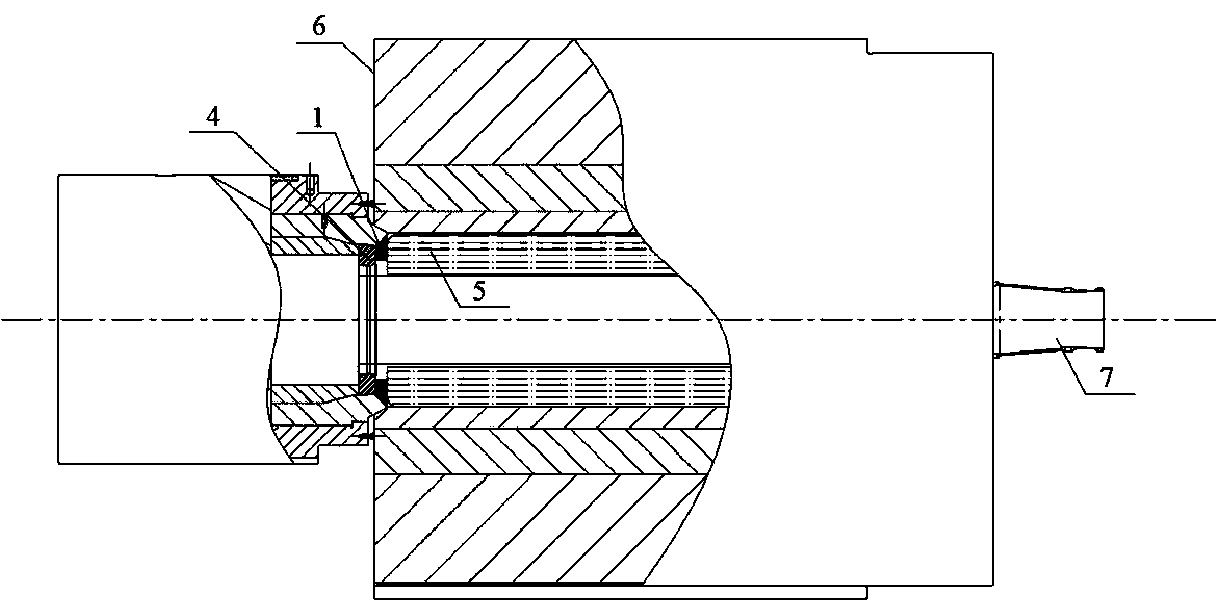

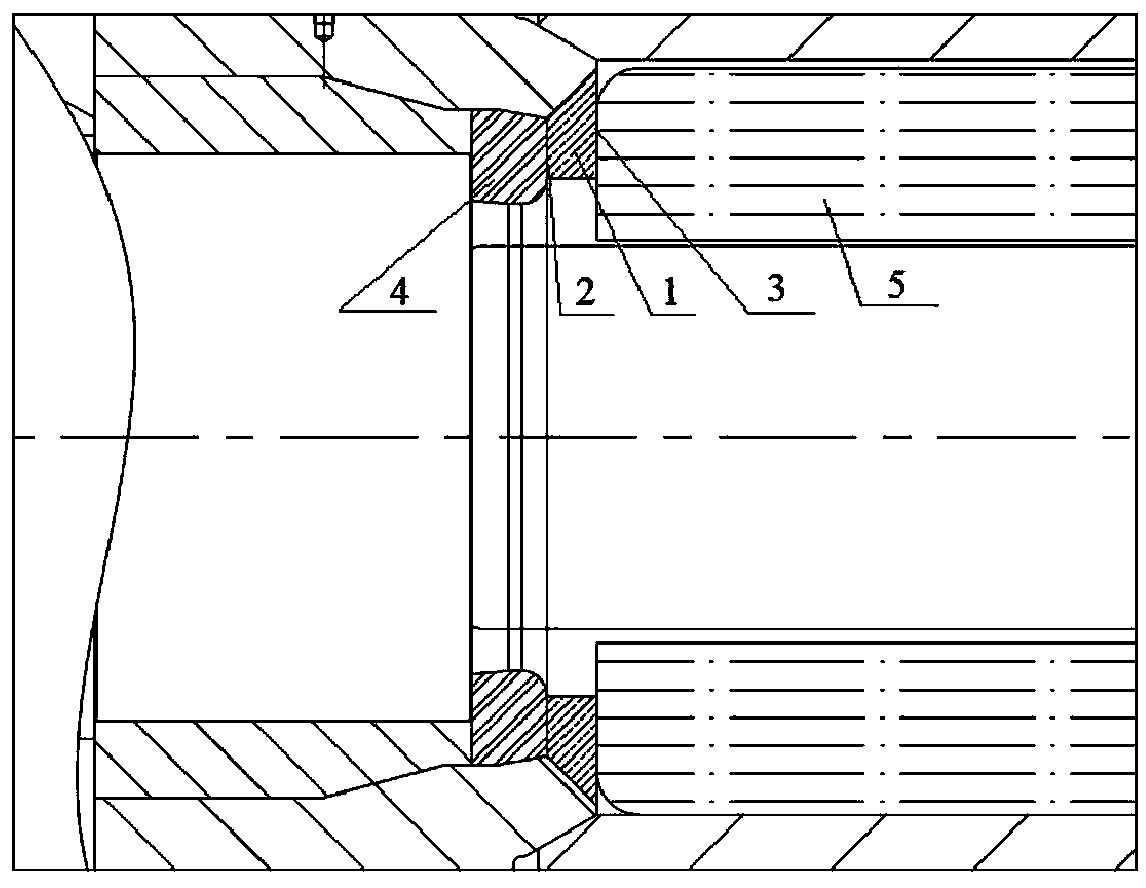

[0015] Such as Figure 1~2 As shown, the prior art glass lubricating pad 1 has a ring structure, including a die contact surface 2 and a blank contact surface 3, the blank contact surface 3 is perpendicular to the axis of the ring, and directly conflicts with the blank end surface , the billet must break through the "strong barrier" to pass through, which increases the extrusion force. Not only higher requirements are put forward for the materials of molds, extrusion cylinders and other components, but also the use of high-power extruders is required, which increases investment and increases failure rates, resulting in increased production costs.

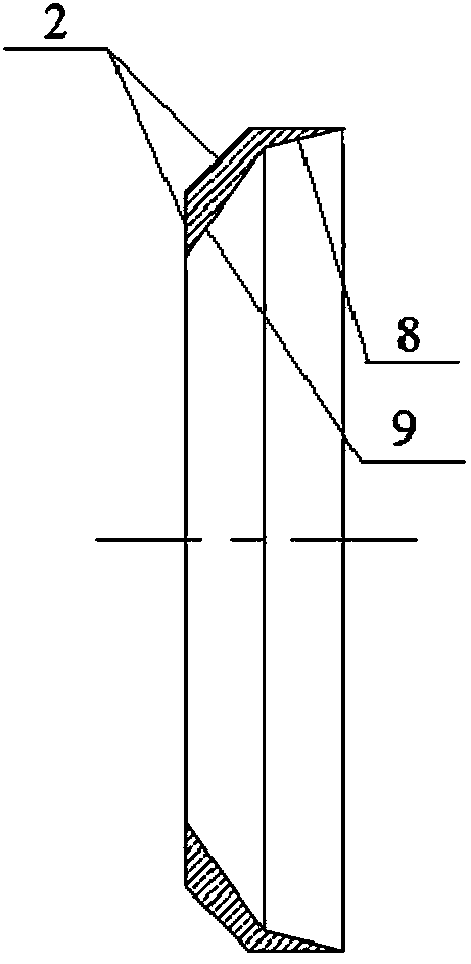

[0016] image 3 , Figure 4 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com