Hot rolling strip steel post-finish-rolling cooling control device

A technology of cooling control and hot-rolled strip steel, which is applied in metal rolling, temperature control, metal rolling, etc., can solve the problems of low alloy steel, automotive girder plates, unstable performance, slow cooling speed, etc., and achieve simple structure, Easy operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail below with reference to the drawings and specific embodiments, but the embodiments should not be understood as limiting the present invention:

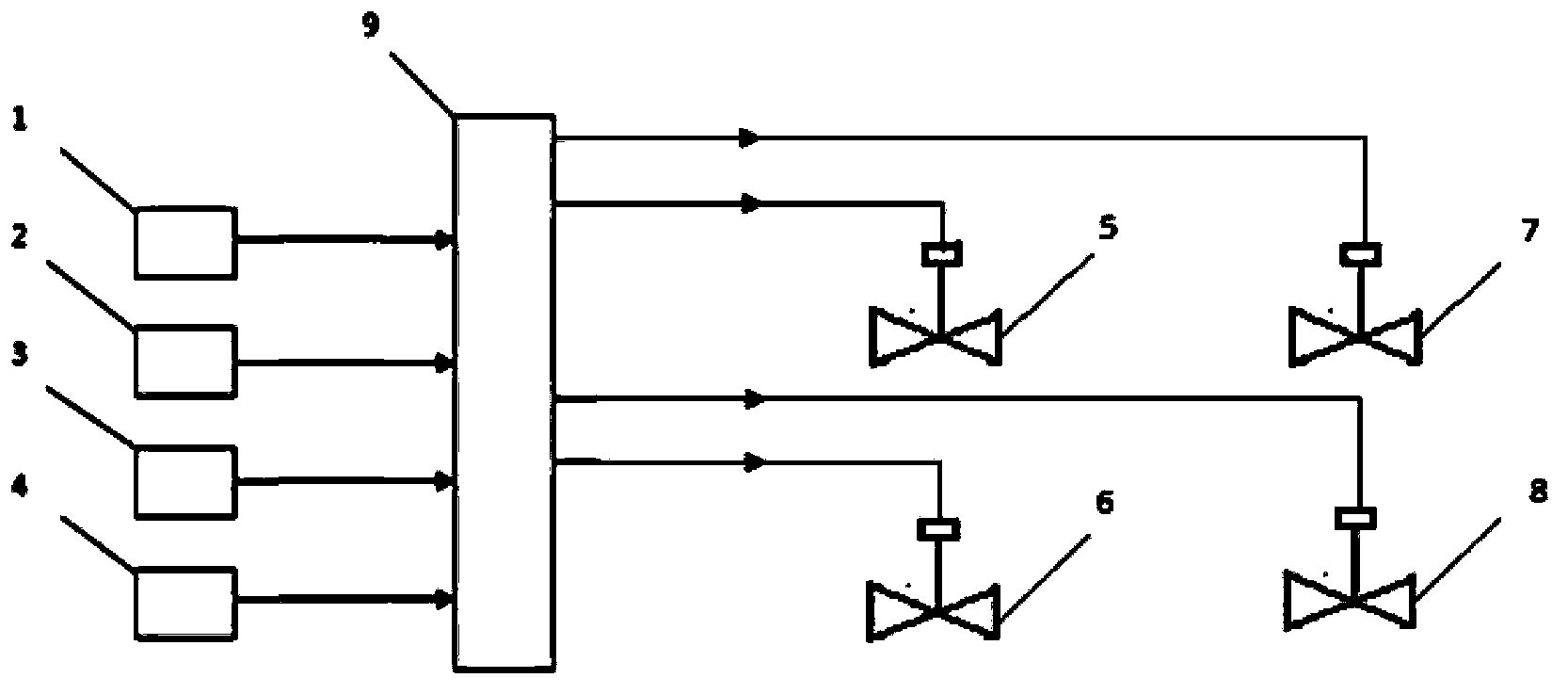

[0009] The cooling control device for the hot-rolled strip steel after finishing rolling shown in the figure includes a rough cooling upper header flow sensor 1, a rough cooling lower header flow sensor 2, a fine cooling upper header flow sensor 3, and a fine cooling lower header flow sensor Sensor 4, coarse cooling upper header water valve 5, coarse cooling lower header water valve 6, fine cooling upper header water valve 7, fine cooling lower header water valve 8 and PLC 9, coarse cooling upper header flow sensor 1 The signal output terminals of the coarse cooling lower header flow sensor 2, the fine cooling upper header flow sensor 3 and the fine cooling lower header flow sensor 4 are respectively connected to the signal input terminal of the PLC9, and the signal output t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com