Processing technology of single-layer wireless charging coil carrier plate

A technology of wireless charging and processing technology, applied in coil manufacturing, circuits, electrical components, etc., can solve problems such as application and implementation of wireless charging coil carrier boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The processing technology of the single-layer wireless charging coil carrier plate according to the present invention comprises the following steps:

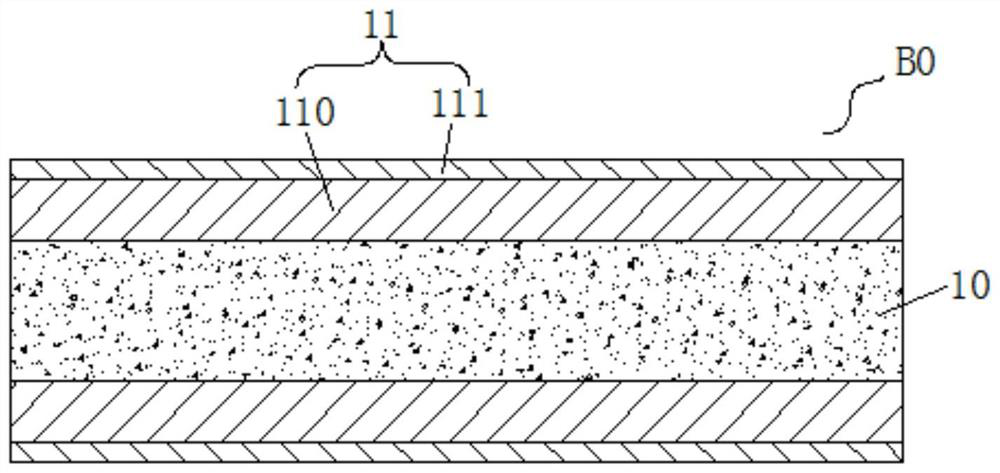

[0034] S1), see attached figure 1 As shown, a carrier board B0 is prepared, the carrier board B0 has an auxiliary substrate 10 and two ultra-thin carrier copper foils 11, each of the two ultra-thin carrier copper foils 11 has a layer of carrier copper foil 110 and a The ultra-thin copper foil 111 is detachably arranged on one surface of the carrier copper foil 110, and the two ultra-thin carrier copper foils 11 are respectively pressed by the carrier copper foil 110 on them. fit on the front and back sides of the auxiliary substrate 10;

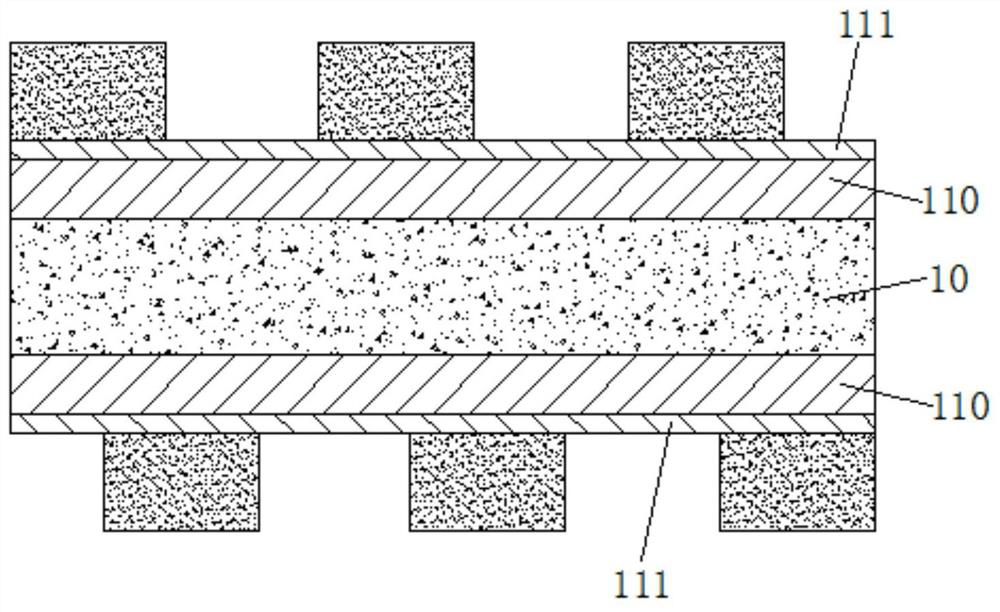

[0035] S2), paste dry films on the two ultra-thin copper foils 111 respectively, and form circuit patterns after exposure and development. For details, please refer to the attached figure 2 shown; in addition, the thickness of the dry film will be slightly greater than the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com