Hole punching cutter type hole punching device

A hole-knife and piercing technology, used in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of low production efficiency, incomplete paper cutting, and asynchronous paper feeding, so as to ensure stability. , the effect of improving product quality and output, and expanding the scope of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above-mentioned purpose, features and advantages of the present invention more comprehensible, preferred embodiments will be described in detail below together with the accompanying drawings.

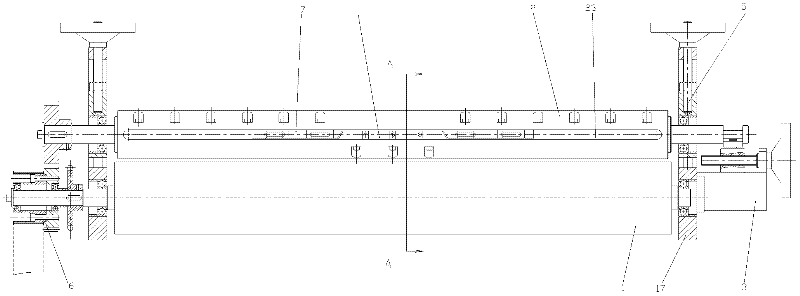

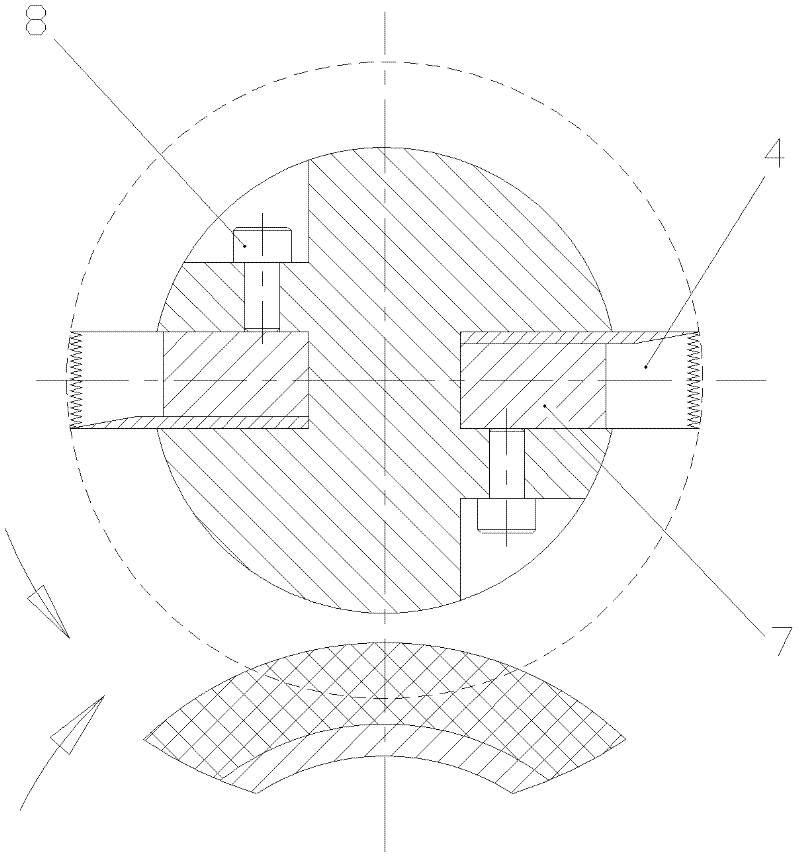

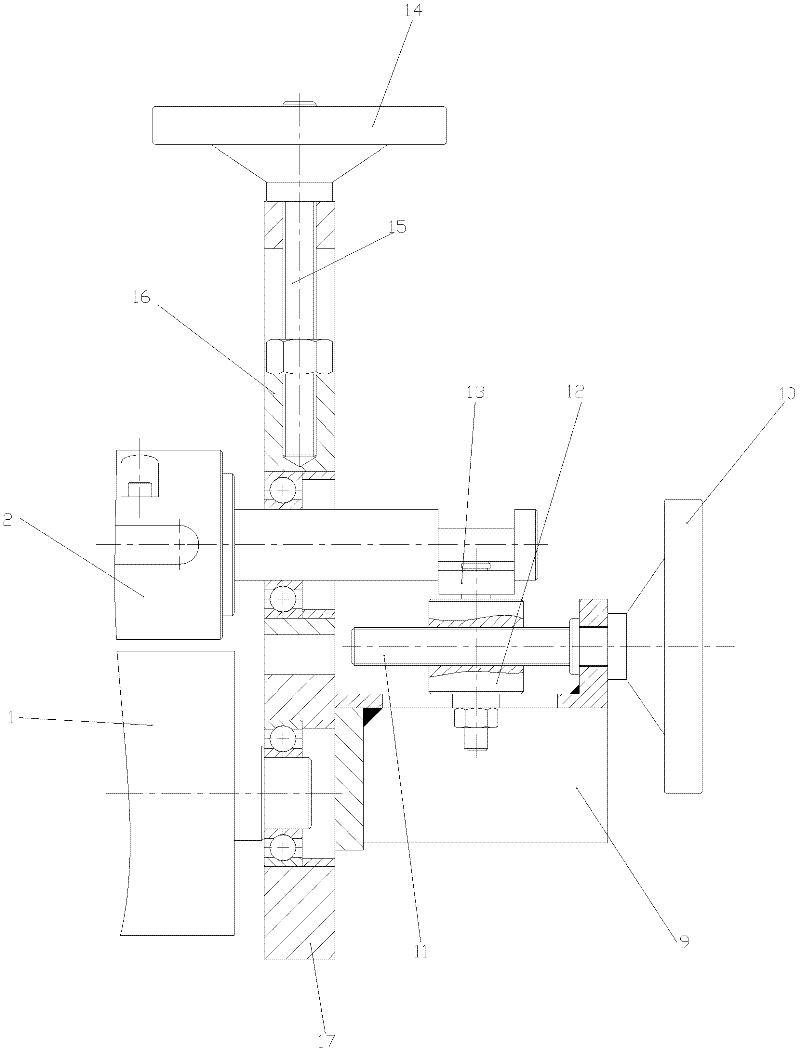

[0017] The present invention comprises a rubber roller 1, a piercing knife shaft 2, a piercing knife 4, a piercing wall panel 17, two sets of piercing knife up and down adjustment mechanisms 5, a set of piercing knife transverse adjustment mechanism 3 and a set of differential transmission mechanism 6.

[0018] Such as figure 1 , figure 2 Shown, rubber roller 1 is positioned at the below of perforating cutter shaft 2, and both are all installed on the perforating wallboard 17 that is positioned at left and right two ends. The piercing knife shaft 2 is provided with 2 equally divided mounting grooves, and each mounting groove is provided with a bow-shaped piercing knife 4, whose blade is evenly distributed jagged spikes, and passes through the piercing knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com