Casting mold manufacturing device

A technology for manufacturing equipment and casting molds, which is applied in the field of automatic production equipment for casting molds, can solve the problems of high labor intensity, low work efficiency, and low degree of automation of installers, and achieves reduction of labor intensity, improvement of work efficiency, and expansion of production. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

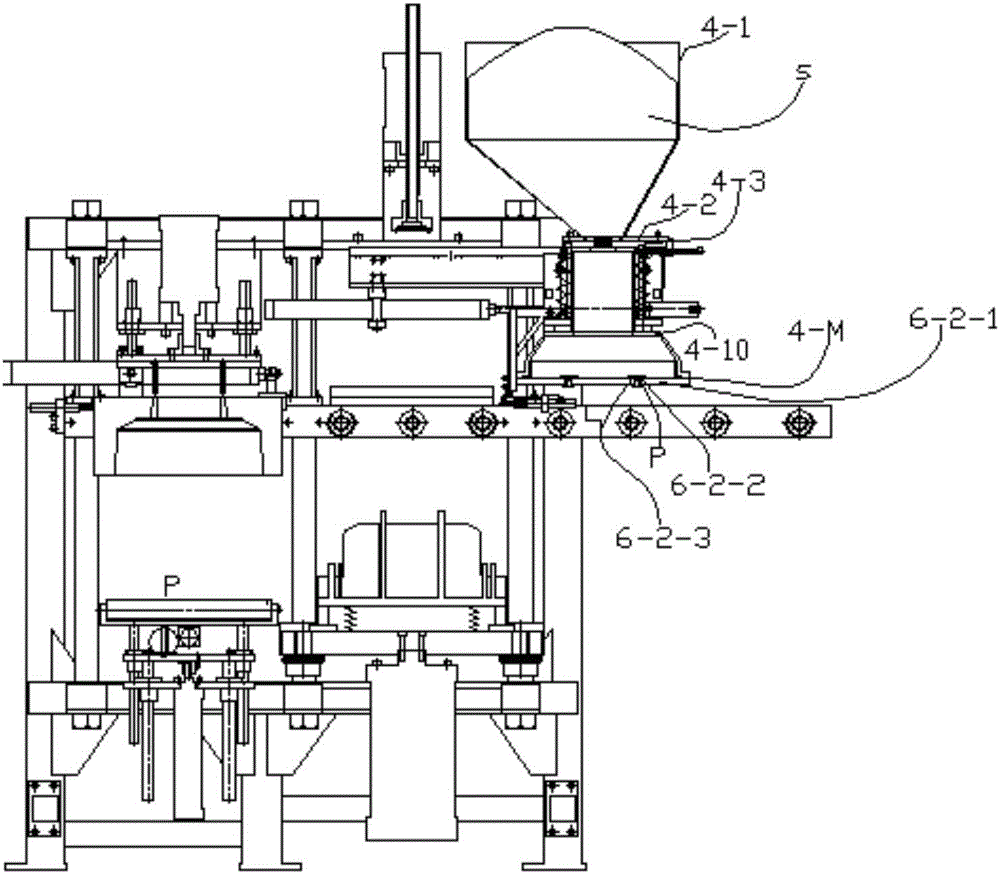

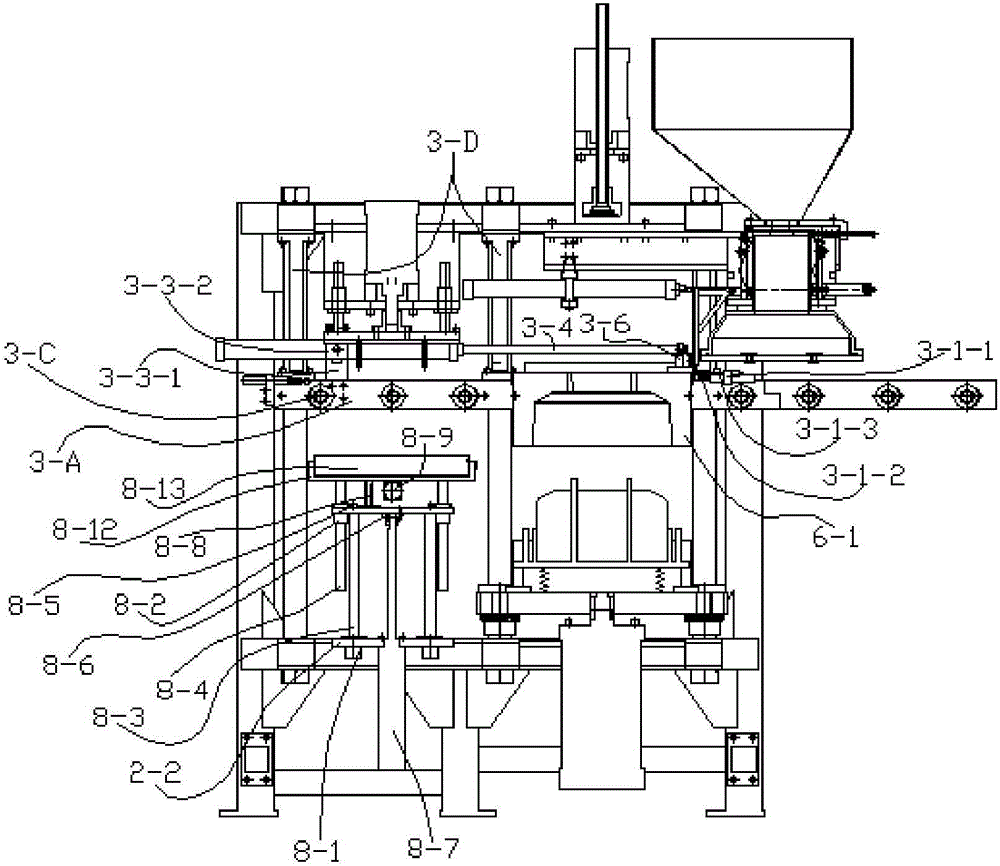

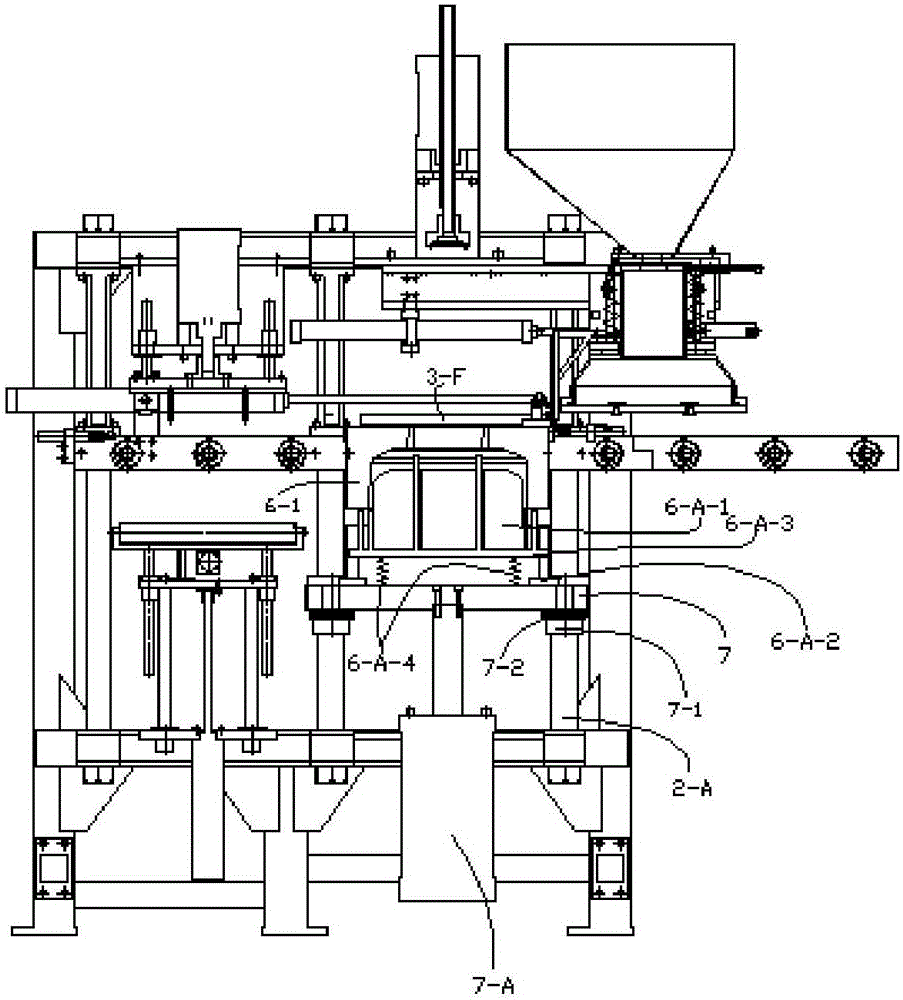

[0044] A casting mold manufacturing equipment is characterized in that: it includes a frame on which upper and lower molds and a mold connection guide wheel frame for the mold to be assembled smoothly, and a mold for moving and positioning the mold in the horizontal and vertical directions. Drive mechanism, sand shooting mechanism for mold forming and stripping and ejection mechanism for automatic mold removal;

[0045] The sand shooting mechanism includes a movable sand shooting tank, and a sand storage bucket is arranged above the sand shooting tank. The sand storage bucket is fixedly installed on the frame. A sand ejecting plate and a gate are installed, a sand shooting plate assembly is installed on the bottom surface of the sand shooting tank, and the sand shooting tank is installed on the trolley body. A ventilation system is installed above the sand tank;

[0046] The upper mold is installed on the upper mold moving bracket, and the upper mold moving bracket is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com