Solid-liquid separation device for organic silicon microsphere production

A technology of organic silicon microspheres and solid-liquid separation, which is applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of excessive hydraulic pressure and poor filtration effect, achieve low cost, reduce filter cake unloading, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings, so as to facilitate better understanding of those skilled in the art.

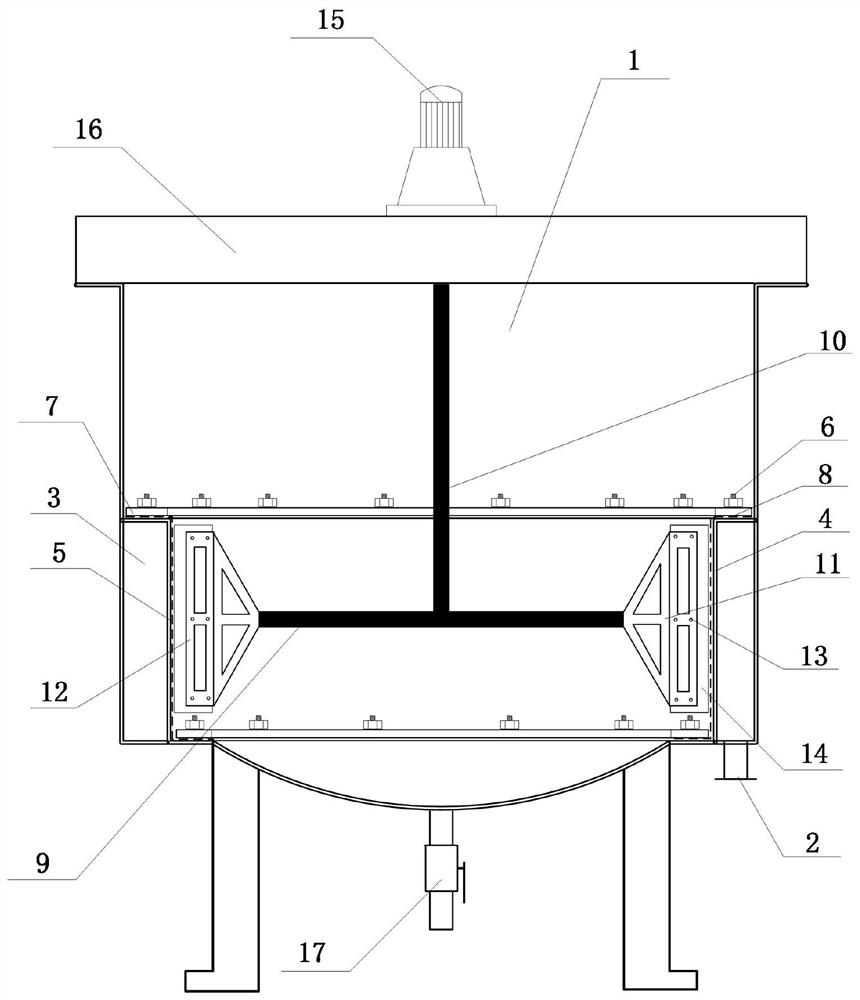

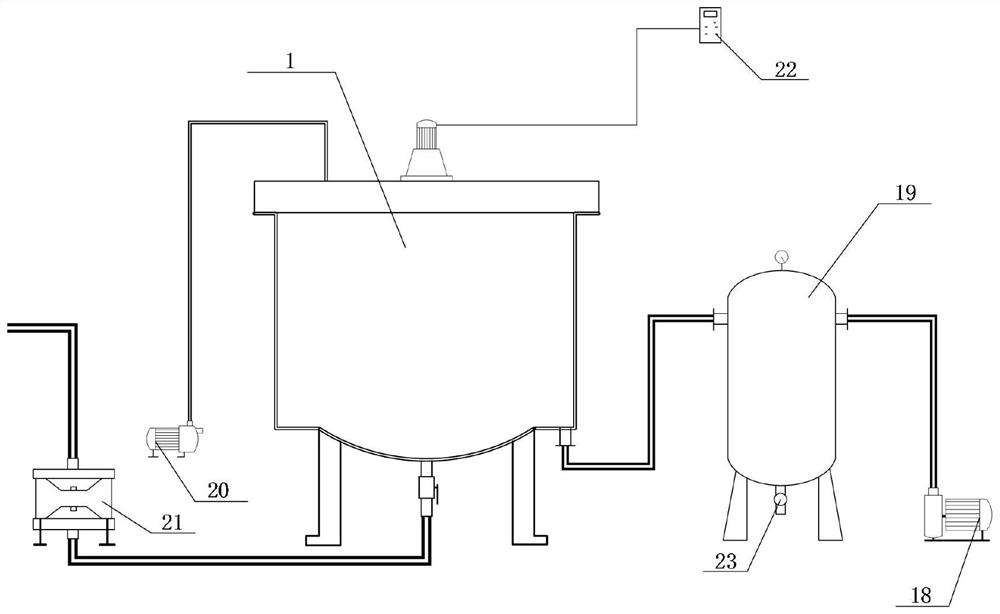

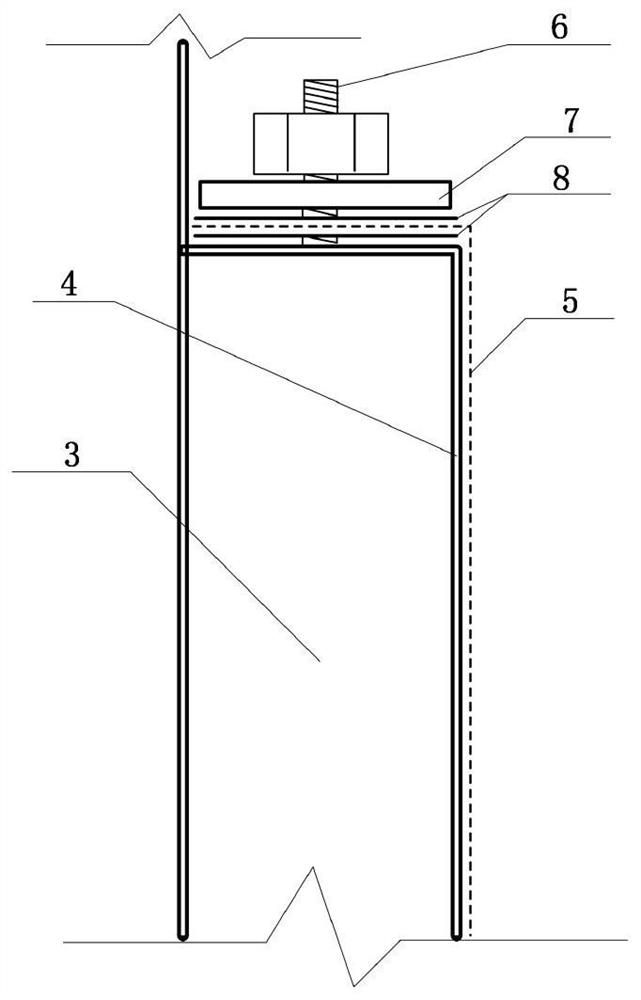

[0032] see Figure 1-3 , a solid-liquid separation device produced by organosilicon microspheres, the solid-liquid separation device comprises: a suction filter barrel 1, a filter cloth 5, a slag scraping mechanism, a gas-liquid separator 19, a vacuum pump 18, a feeding pump 20 and an outlet Feed pump 21.

[0033] The suction filter barrel 1 is made of stainless steel, the barrel body of the suction filter barrel 1 is a cylinder, and the top of the suction filter barrel 1 is provided with a feeding port, which is connected to the feeding pump 20 through a pipeline; There is a discharge port, and the bottom end of the suction filter barrel 1 is a convex spherical surface. The discharge port is arranged in the middle of the bottom end of the suction filter barrel 1, so as to facilitate the collection of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com