Combination edge trimmer

An edge trimmer and cutting blade technology, which is applied in metal processing and other directions, can solve the problems of high energy consumption, difficult control, and more flying chips for saw blade cutting, and achieve the effects of less chips, convenient adjustment, and expansion of production range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the specific implementation, features and functions of the compound edge trimming machine proposed according to the present invention are described in detail below.

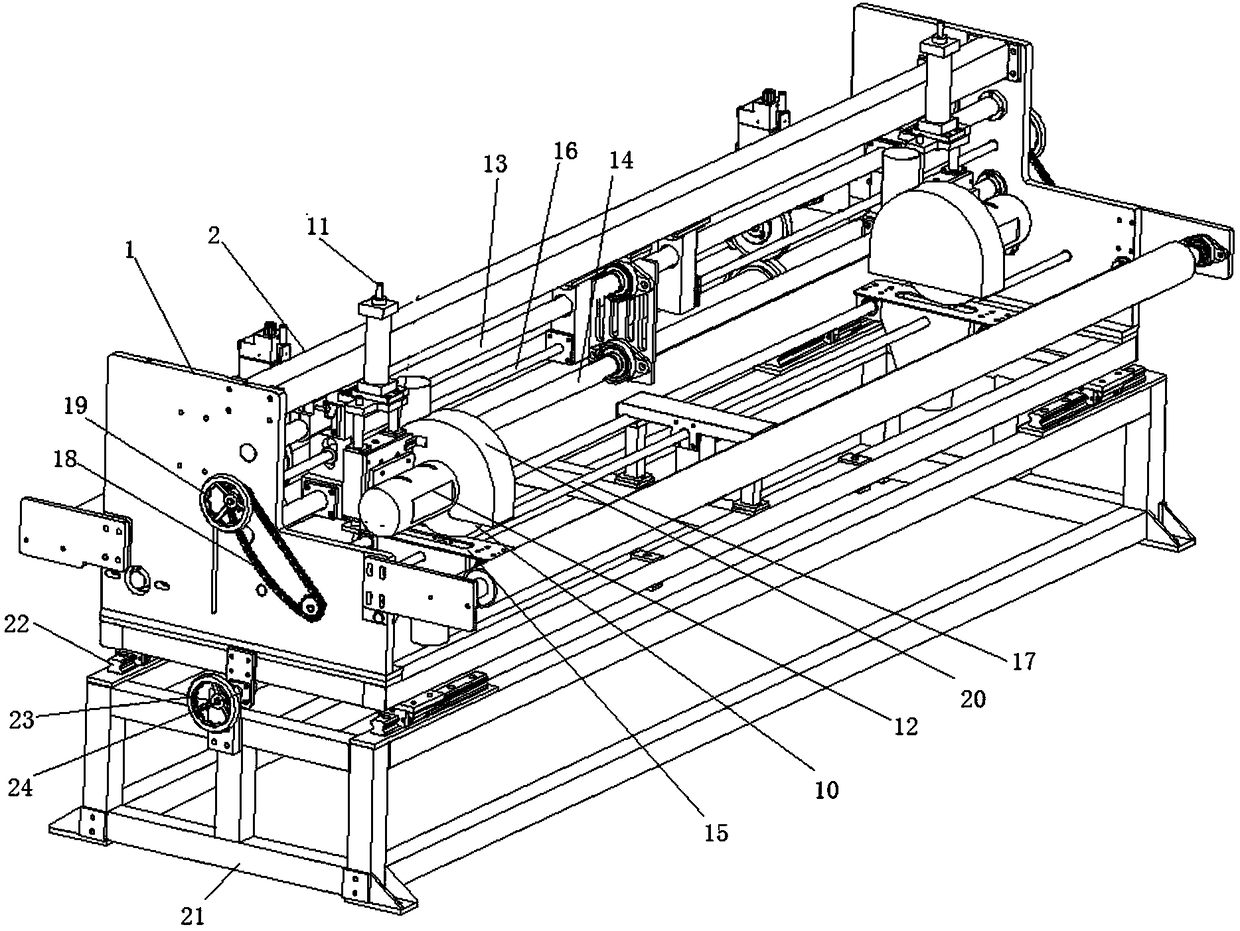

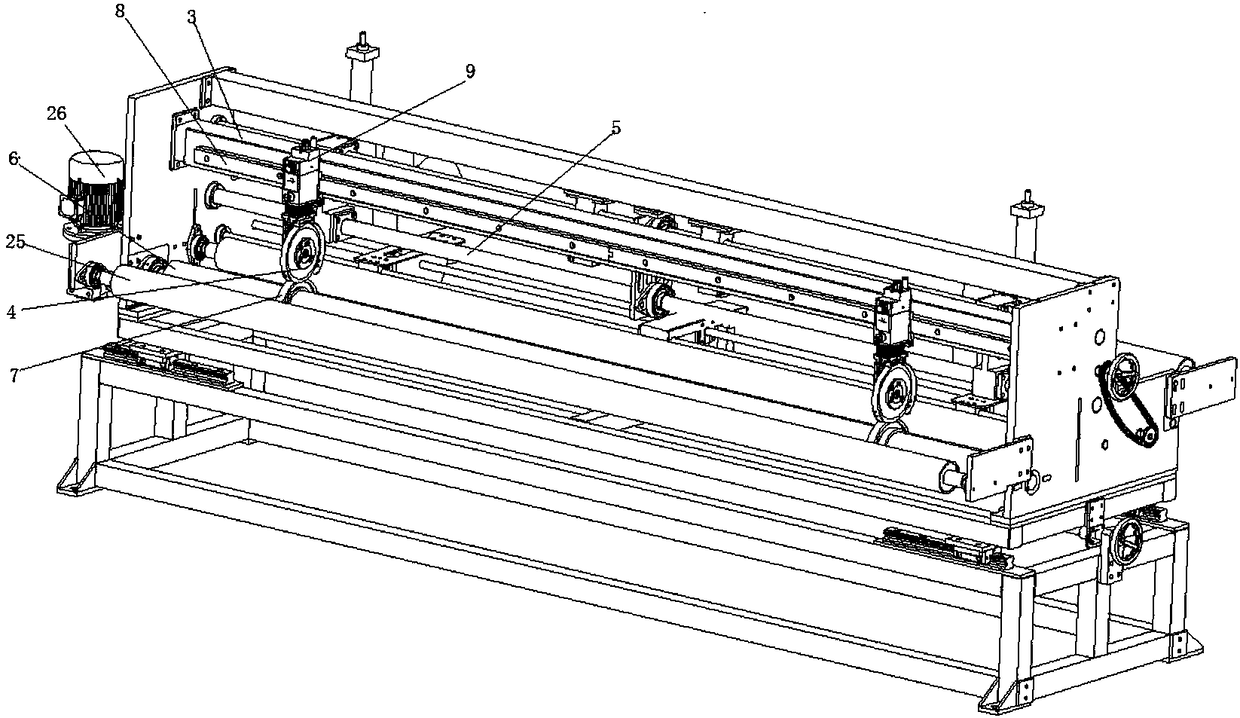

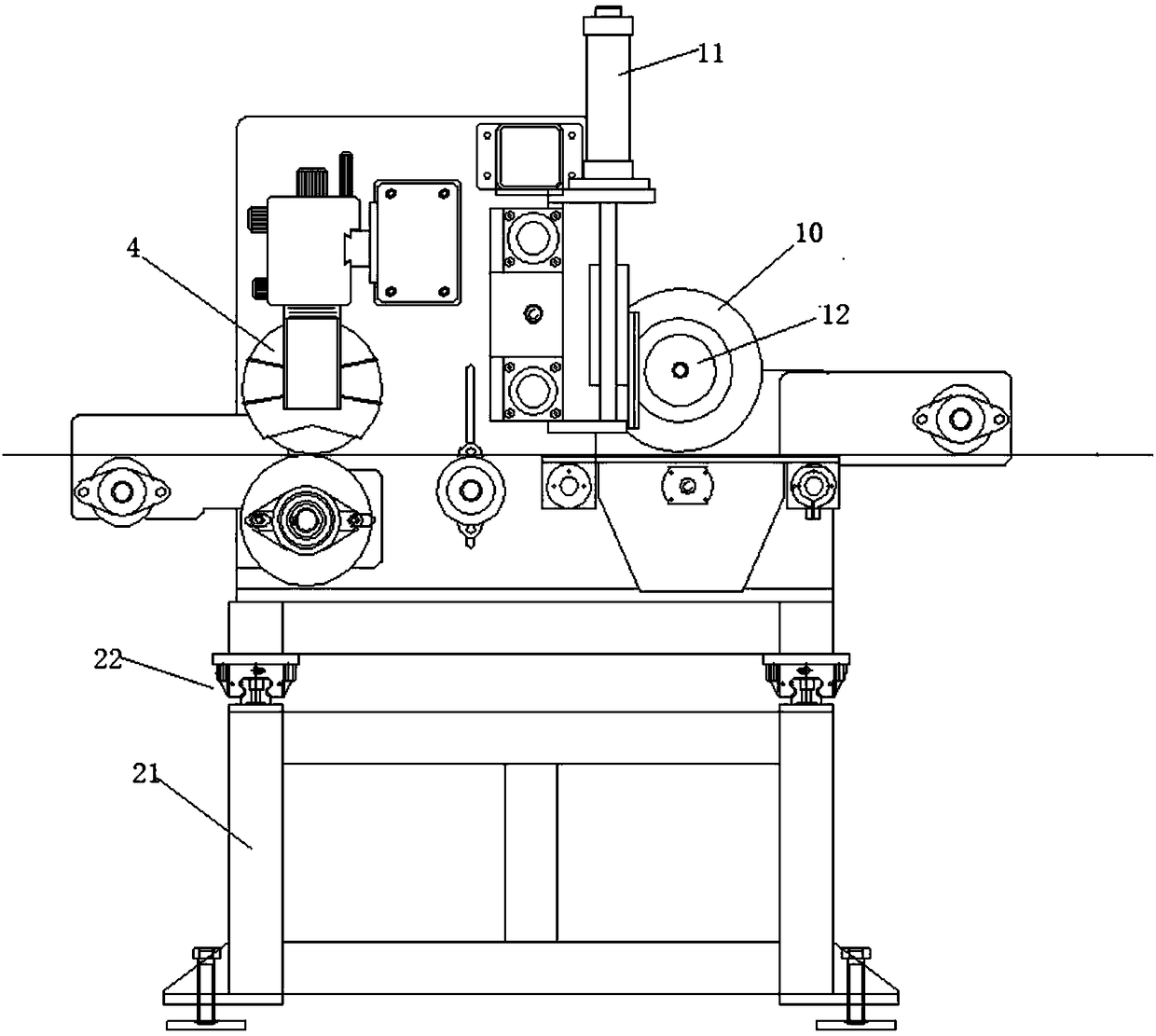

[0038] Such as Figure 1-Figure 3 As shown, the present invention discloses a composite trimming machine, comprising an outer frame, a pneumatic cutter module and a saw blade cutter module arranged side by side in the outer frame, wherein,

[0039] The outer frame includes two side trimming machine wall panels 1 arranged in parallel and a main beam 2 arranged between the two side trimming machine wall panels 1, the outer frame is used to support the whole edge trimming machine, and the beams are all fixedly arranged in the present invention Set between two trimming machine wall panels 1 and parallel to the main beam 2;

[0040] The pneumatic cutter module includes a gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com