Device for removing burrs of steel pipe welding seam

A welding port and burr technology is applied in the field of machining, which can solve the problems of burrs, affecting the quality of steel pipes, affecting flaw detection and shearing welded pipe operations, etc., to achieve the effect of expanding the scope, improving the quality and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

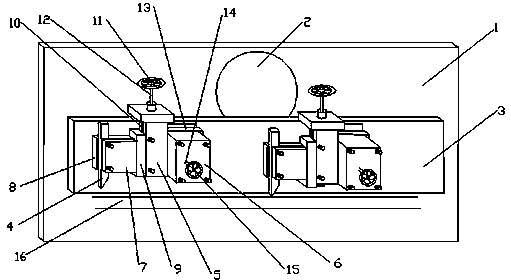

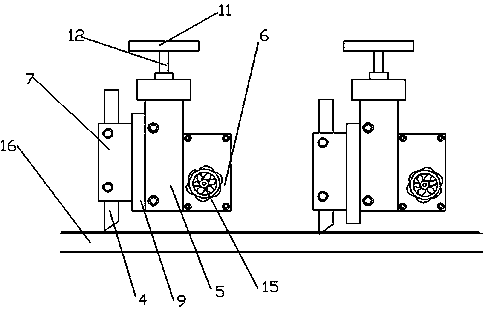

[0012] like figure 1 , 2 as shown,

[0013] The technical solution of the present invention is: a device for removing burrs from welded joints of steel pipes, comprising a first vertical plate 1, the middle part of the upper end of the first vertical plate 1 is provided with an air extraction hole 2, and the air extraction hole 2 is connected with a fan The other end of the fan is connected with a waste box, the front part of the lower end of the first vertical plate 1 is provided with a second vertical plate 3, and the second vertical plate 3 is located at the lower end of the air extraction hole 2, and the first vertical plate The plate 1 and the second vertical plate 3 are fixed on the workbench. The second vertical plate 3 is provided with a first-level burr removal device and a second-level burr removal device. The first-level and second-level burr removal devices are on the same horizontal plane. in:

[0014] The primary and secondary deburring devices include a cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com