Stationary fixture device for milling machine

A technology for fixing fixtures and milling machines, applied in positioning devices, clamping, manufacturing tools, etc., can solve problems such as difficulty in improving product accuracy, difficulty in fixing parts, and reduced use of fixtures, and achieve low cost, expanded production range, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing;

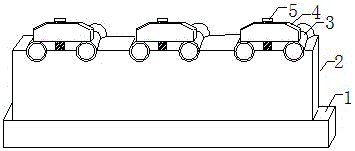

[0012] see figure 1 Shown, a kind of milling machine fixed fixture device, it comprises base 1, support base 2, briquetting block 4, screw rod 5, parts 3, described support base 2 is installed on base 1, and described briquetting block 4 is installed on by screw rod 5 On the support base 2, the parts 3 are placed between the briquetting block 4 and the support base 2, the support base 2 and the briquetting block 4 are provided with through holes, the screw rod 5 passes through the through holes, and the support base 2 is provided with a semicircular draw-in groove, and the pressure block 4 and the screw rod 5 form a group, and one to three groups can be installed on the device.

[0013] During processing, the part 3 is placed between the card slot on the support seat 2 and the pressure block 4, and the distance between the support seat 2 and the pressure block 4 is changed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com