Preparation method and device for nano porous metal or ceramic

A nanoporous, metal technology, applied in the field of porous materials, can solve the problems of difficult to widely use, limited to the laboratory stage, pollution of nano powders, etc., and achieve the effect of simple process, easy automation and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

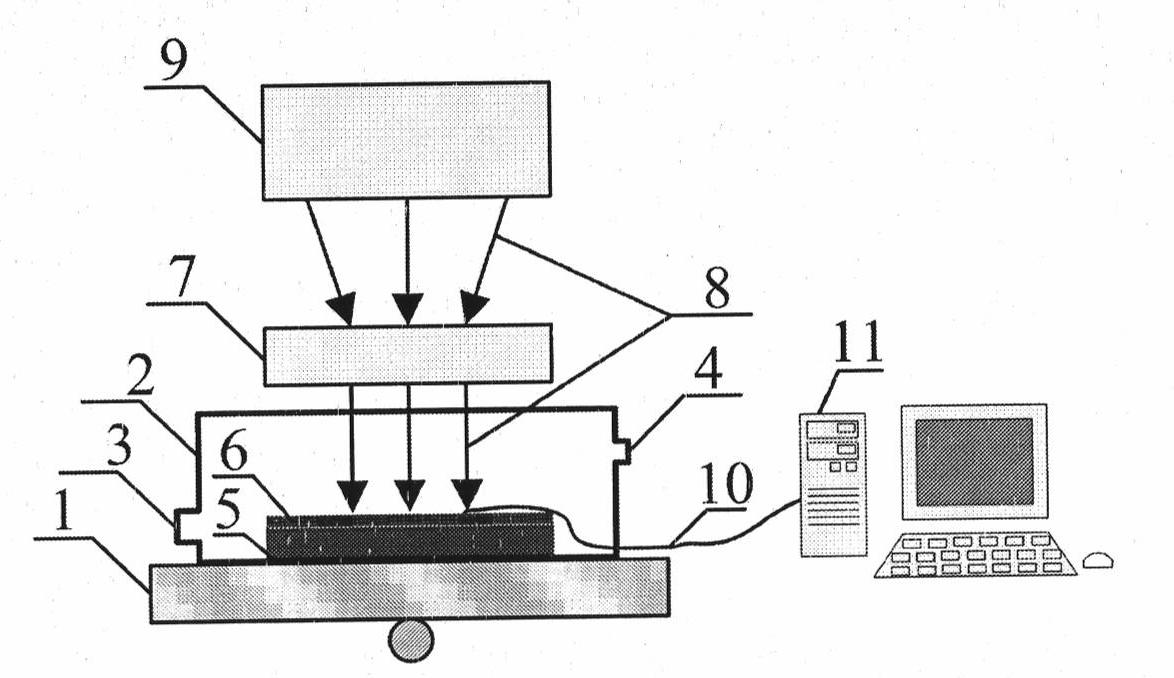

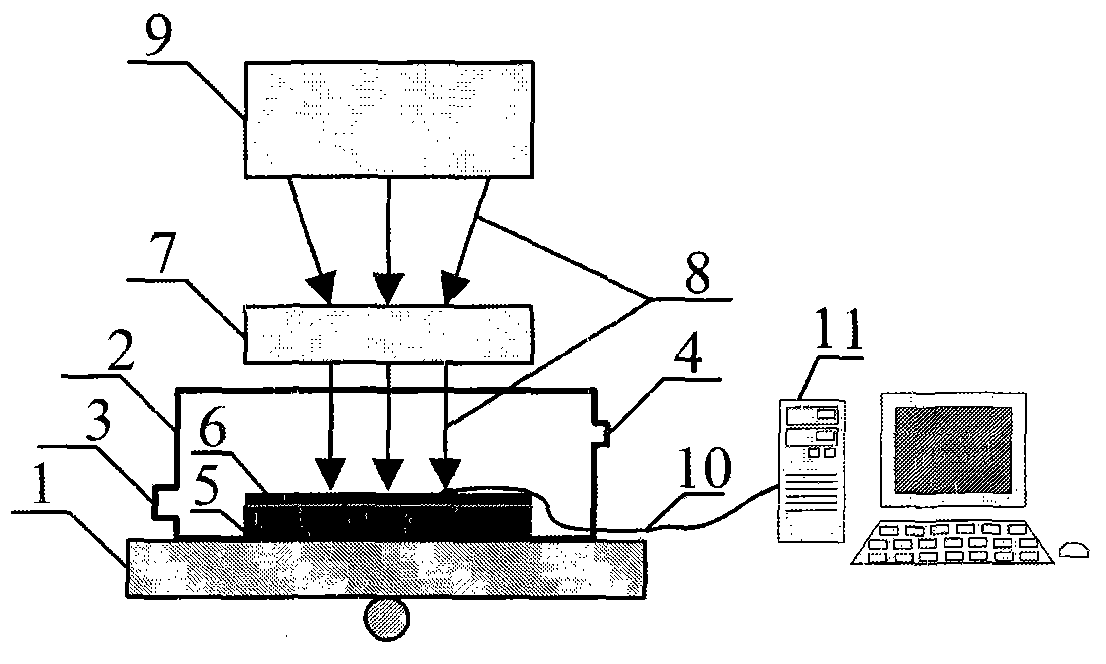

Method used

Image

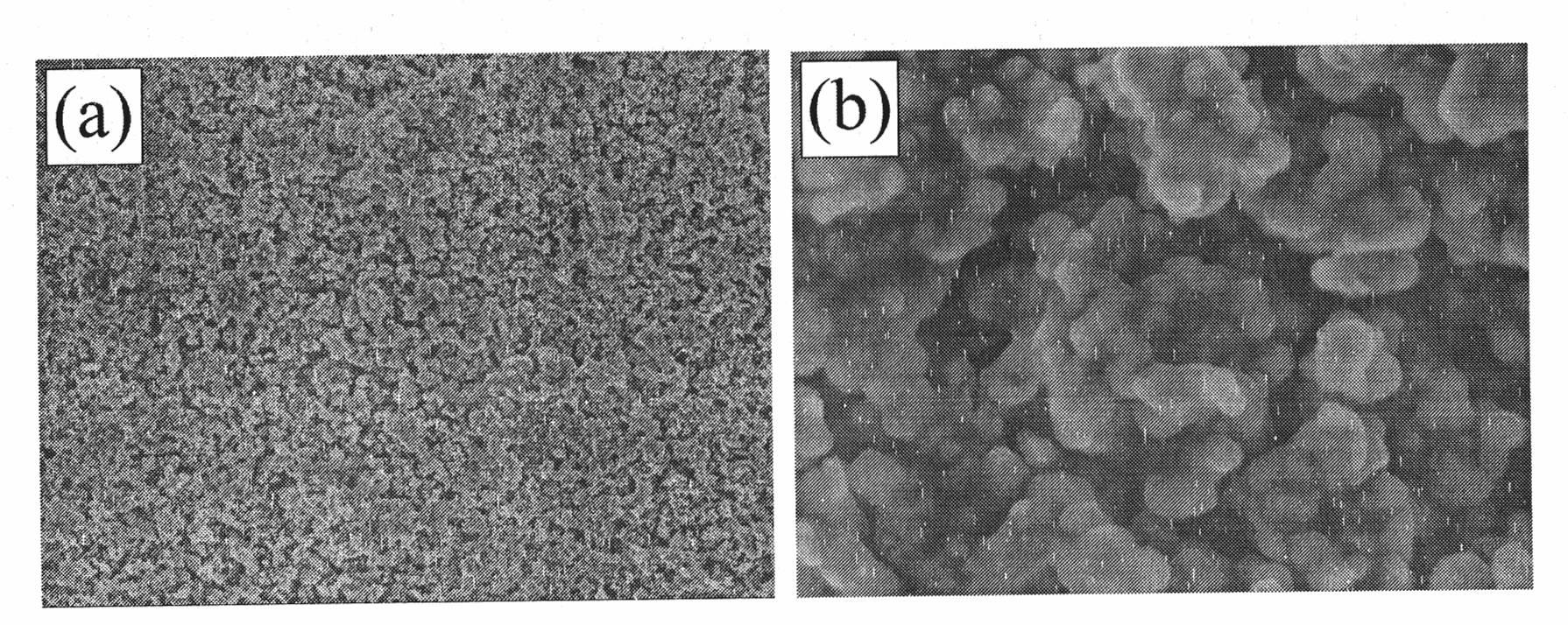

Examples

Embodiment 1

[0032] 1) Select pure Mg metal powder with a particle size in the range of 120 μm-150 μm;

[0033] 2) Select carbon steel as the substrate for pure Mg powder to adhere to, and pre-treat it: polish with metallographic sandpaper, polish with polishing paste, then pickle and clean with organic solvents to remove surface oil, and finally use ultrasonic waves in alcohol Wash, remove and dry with a drying oven;

[0034]3) Put the carbon steel treated in step 2) one by one on the heating table and heat to 50°C, apply a layer of rosin resin evenly on the surface of the carbon steel, and after it is completely melted, use a metal sieve with a mesh number of 100 Spread the micron pure Mg metal powder provided by step 1) evenly on the carbon steel substrate, let it stand and dry, so that the metal powder is bonded on the carbon steel substrate, and the thickness of the obtained metal powder is 0.1mm;

[0035] 4) Place the carbon steel coated with pure Mg powder on the surface of the pro...

Embodiment 2

[0037] 1) Select Ti alloy powder with a particle size in the range of 60 μm-100 μm;

[0038] 2) Select austenitic stainless steel as the substrate for the Ti alloy powder to adhere to, and perform pretreatment on it: polish with metallographic sandpaper, polish with polishing paste, then pickle and clean with organic solvents to remove surface oil, and finally use it in alcohol Ultrasonic cleaning, take out and dry with drying oven;

[0039] 3) Place the stainless steel treated in step 2) one by one on a heating platform and heat to 60°C, evenly apply a layer of rosin resin on the surface of the stainless steel, and after it is completely melted, use a metal screen with a mesh number of 150 ) The micron Ti alloy powder provided by ) is evenly spread on the stainless steel substrate, left to stand and dried, so that the metal powder is bonded on the stainless steel substrate, and the thickness of the obtained metal powder is 0.2mm;

[0040] 4) Place the stainless steel coated ...

Embodiment 3

[0042] 1) Select pure Ti metal powder with a particle size in the range of 50 μm-80 μm;

[0043] 2) Select austenitic stainless steel as the substrate for the pure Ti powder to adhere to, and pre-treat it: polish with metallographic sandpaper, polish with polishing paste, then pickle and clean with organic solvents to remove surface oil, and finally use it in alcohol Ultrasonic cleaning, take out and dry with drying oven;

[0044] 3) Place the stainless steel treated in step 2) one by one on a heating platform and heat to 70°C, and evenly apply a layer of rosin resin on the surface of the stainless steel. After it is completely melted, use a metal screen with a mesh number of 200 ) The micron pure Ti metal powder provided by ) is evenly spread on the stainless steel substrate, left to stand and dried, so that the metal powder is bonded on the stainless steel substrate, and the thickness of the obtained metal powder is 0.3mm;

[0045] 4) Place the stainless steel coated with p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com