Kieselguhr-based porous ceramics and method for loading Ag doped with nano TiO2 on same

A technology of nano-titanium dioxide and diatomite, which is applied in the direction of ceramic products, other household appliances, household appliances, etc., can solve the problems of affecting the photocatalyst effect, high production cost, and difficult to load evenly, and achieves small pore size, low cost, and light The effect of improving the catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Diatomite-based porous ceramics are made of the following raw materials: 850g diatomite, 100g kaolin, 50g quartz, 10g sodium polyacrylate, 5g polyvinyl alcohol, and 3500g water.

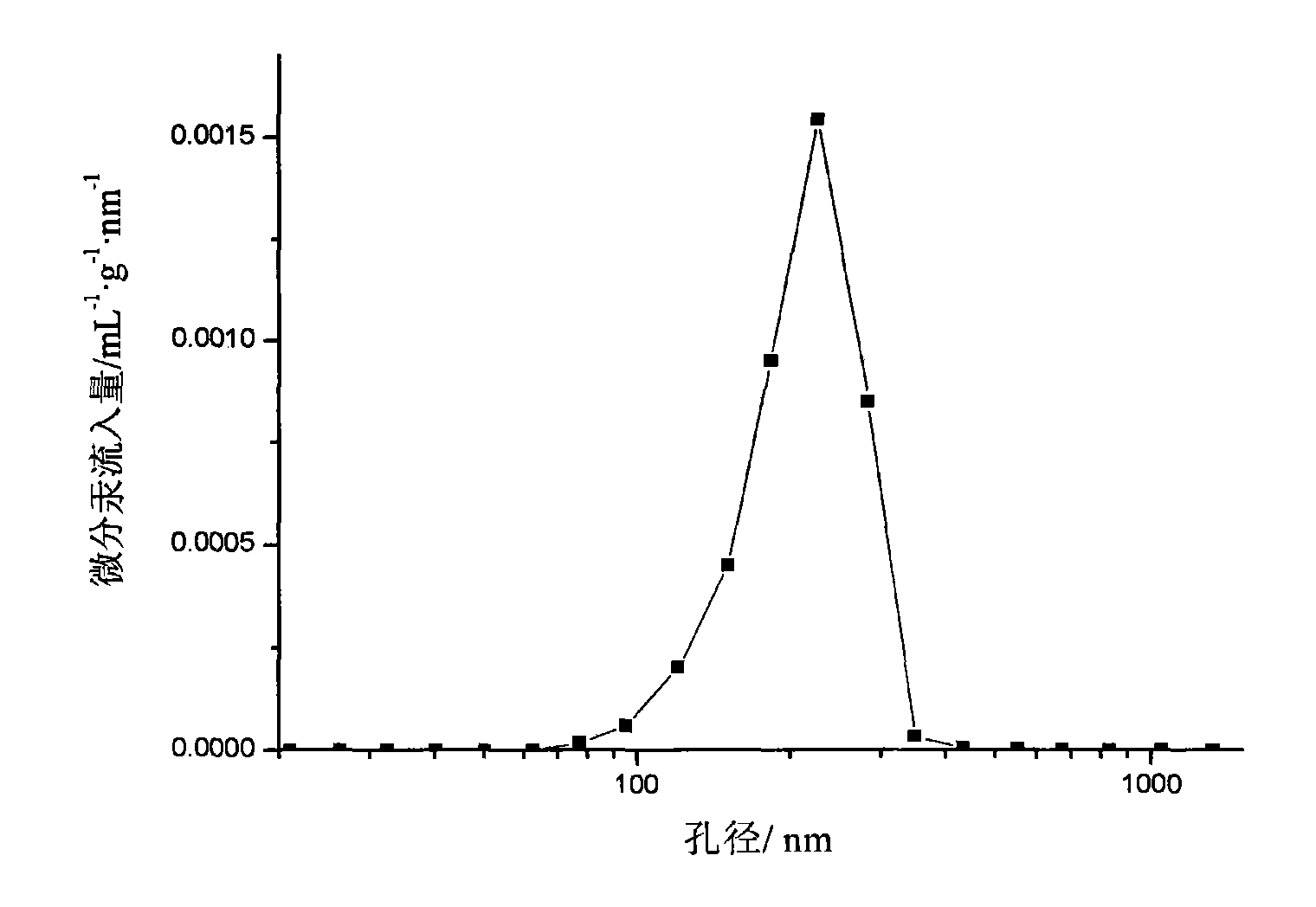

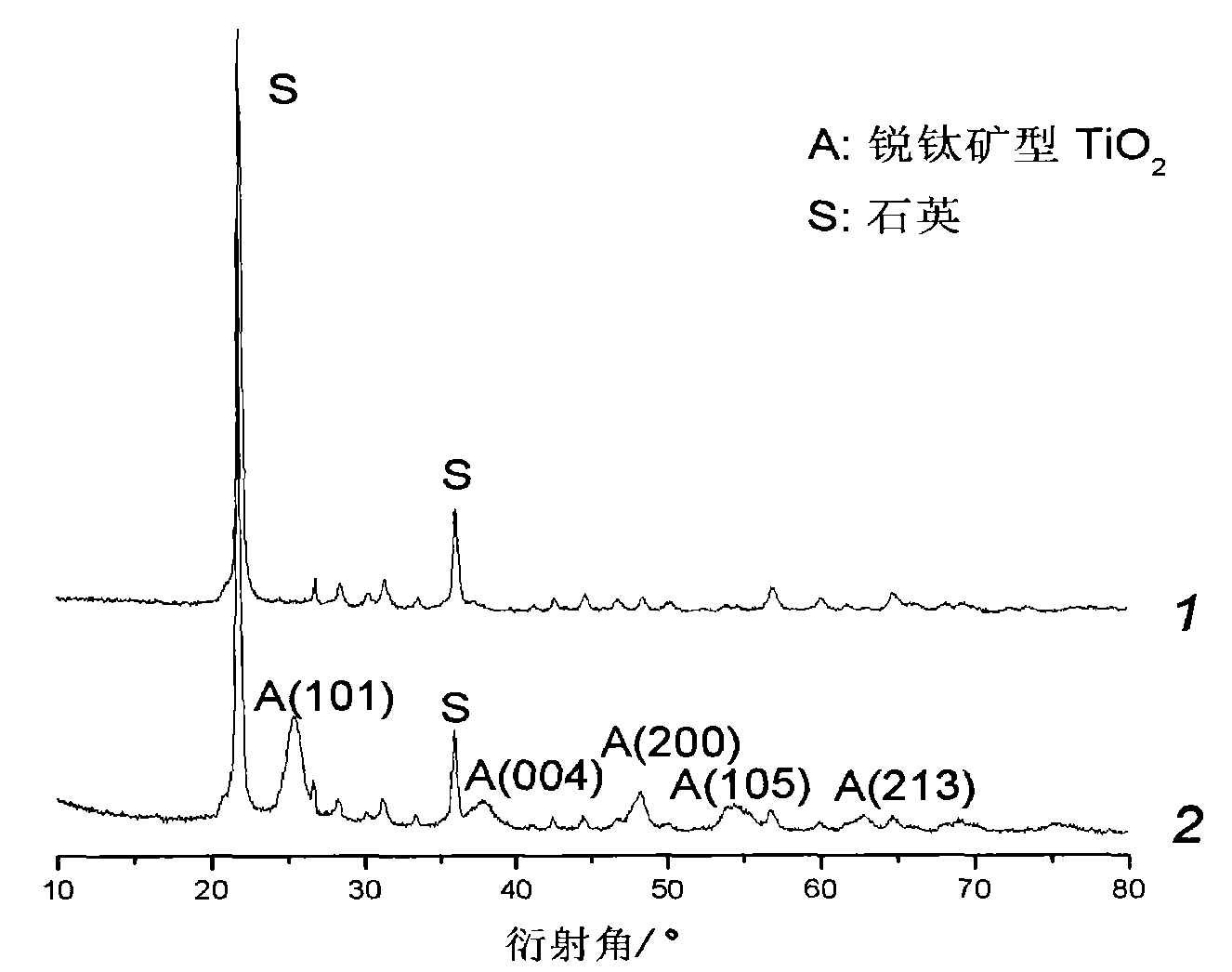

[0025] When preparing, take each raw material according to the above ratio, mix and dissolve each raw material, add it into the grinder and grind until D 50 =2μm, dried at 110°C for 3h, dispersed, molded under a pressure of 35MPa, and calcined at 950°C for 2h to obtain diatomite-based porous ceramics. figure 1 It shows that the pore size distribution of the prepared diatomite-based porous ceramics is 100-350 nm, and the pore size is fine and uniform.

[0026] The method of diatomite-based porous ceramics loaded with silver-doped nano-titanium dioxide, the raw materials used are diatomite-based porous ceramics, Ti(SO 4 ) 2 , polyethylene glycol, HCl and AgNO 3 The mass ratio of the diatomite-based porous ceramics is 100:1:0.003:0.5:0.2, and the preparation includes the following steps: (1) u...

Embodiment 2

[0028] Diatomite-based porous ceramics are made of the following raw materials: 920 g of diatomite, 80 g of kaolin, 20 g of sodium polyacrylate, 10 g of polyvinyl alcohol, and 4500 g of water.

[0029] When preparing, take each raw material according to the above ratio, mix and dissolve each raw material, add it into the grinder and grind until D 50 =5 μm, dried at 110°C for 3 hours, dispersed, molded under a pressure of 35 MPa, and calcined at 980°C for 3 hours to obtain diatomite-based porous ceramics.

[0030] The method of diatomite-based porous ceramics loaded with silver-doped nano-titanium dioxide, the raw materials used are diatomite-based porous ceramics, Ti(SO 4 ) 2 , polyethylene glycol, HCl and AgNO 3 The mass ratio of the diatomite-based porous ceramics is 100:15:0.5:2:1; the preparation includes the following steps: (1) ultrasonically cleaning the diatomite-based porous ceramics in distilled water and absolute ethanol successively, and drying; (2) drying the P...

Embodiment 3

[0032] Diatomite-based porous ceramics are made of the following raw materials: 600g of diatomite, 200g of kaolin, 120g of feldspar, 80g of calcium carbonate, 0.1g of sodium polyacrylate, 0.01g of polyvinyl alcohol, and 2000g of water.

[0033] When preparing, take each raw material according to the above ratio, mix and dissolve each raw material, add it into the grinder and grind until D 50 =6 μm, dried at 110°C for 3 hours, dispersed, molded under a pressure of 35 MPa, and calcined at 960°C for 4 hours to obtain diatomite-based porous ceramics.

[0034] The method of diatomite-based porous ceramics loaded with silver-doped nano-titanium dioxide, the raw materials used are diatomite-based porous ceramics, Ti(SO 4 ) 2 , polyethylene glycol, HCl and AgNO 3 The mass ratio of the diatomite-based porous ceramics is 100:30:1:4:2; the preparation includes the following steps: (1) ultrasonically cleaning the diatomite-based porous ceramics in distilled water and absolute ethanol su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com