Resistance wire type coal seam heating device

A heating device and resistance wire technology, which is applied in safety devices, gas discharge, and exploitation of fluids, etc., can solve problems such as complicated ground equipment, and achieve the effects of improving fracturing effect, increasing functions, and ensuring power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

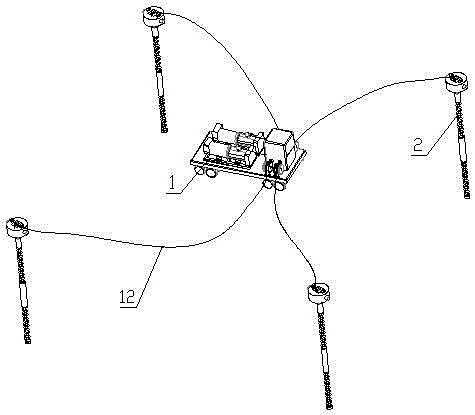

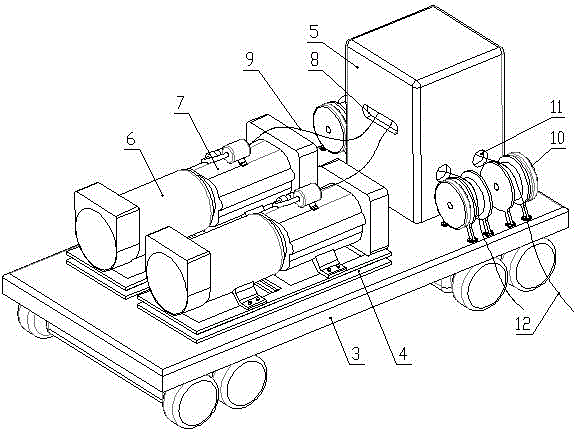

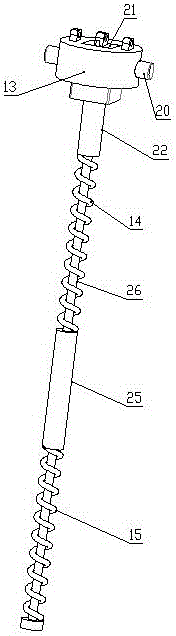

[0023] Such as Figure 1-Figure 6 As shown, the resistance wire type coal seam heating device of the present invention includes a mobile ground power generation system 1 and four downhole heaters 2; the mobile ground power generation system 1 provides electric energy for the downhole heaters 2.

[0024] The mobile ground power generation system 1 includes a flatbed truck 3, a square chassis 4, two sets of diesel generator sets and a set of control cabinets 5, and each set of diesel generator sets includes a diesel engine 6 and a generator 7, and the diesel engine 6 The power output shaft of the power output shaft and the power input shaft of the generator 7 are connected through coupling transmission, and the diesel engine 6, the generator 7 and the control electric cabinet 5 are all fixed on the square chassis 4 by bolts, and the square chassis 4 is fixed on the square chassis 4 by bolts. On the flatbed truck 3, two sets of diesel generator sets are arranged side by side at i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com