Method for preparing fuel gas by gasifying biomass materials and device thereof

A biomass and gas technology, applied in the production of combustible gas, joint combustion mitigation, and petroleum industry, etc., can solve the problems of large daily use and maintenance workload, low economic effect, large equipment investment, etc. Controllable, economical operation, high gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

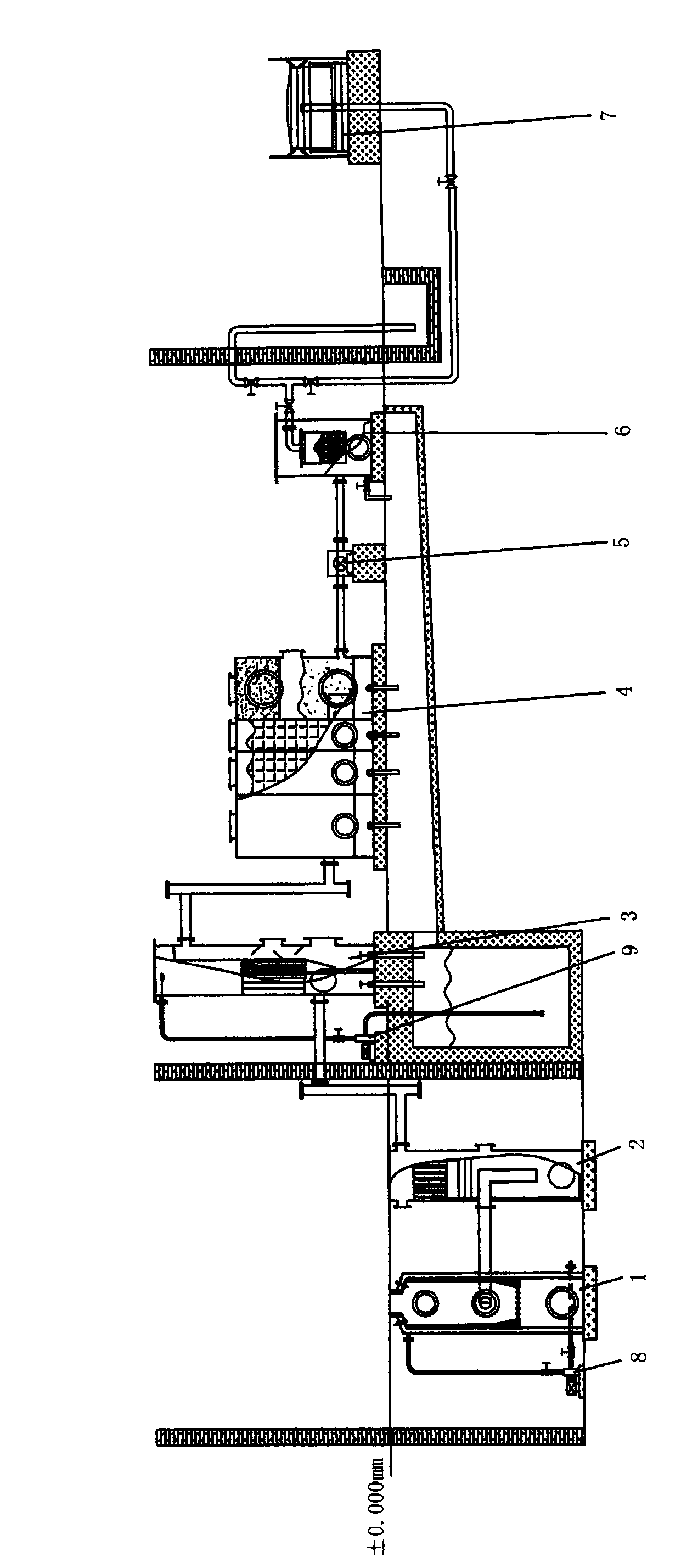

[0061] A specific embodiment of a method for producing fuel gas by gasifying biomass materials according to the present invention will be further described below in conjunction with the accompanying drawings.

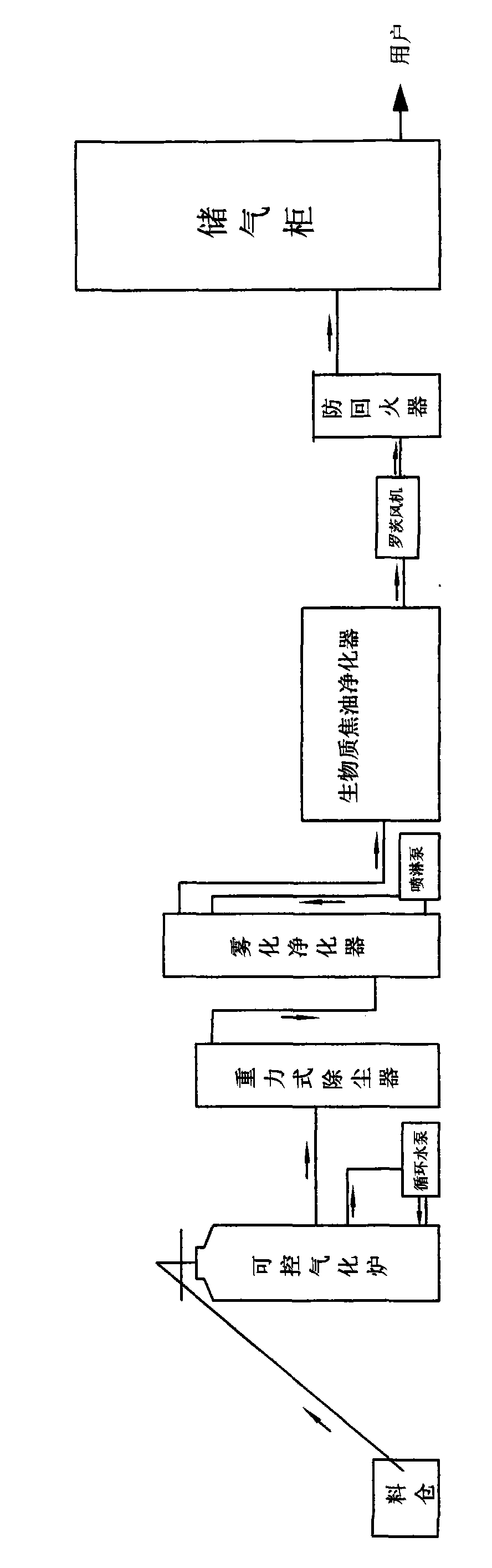

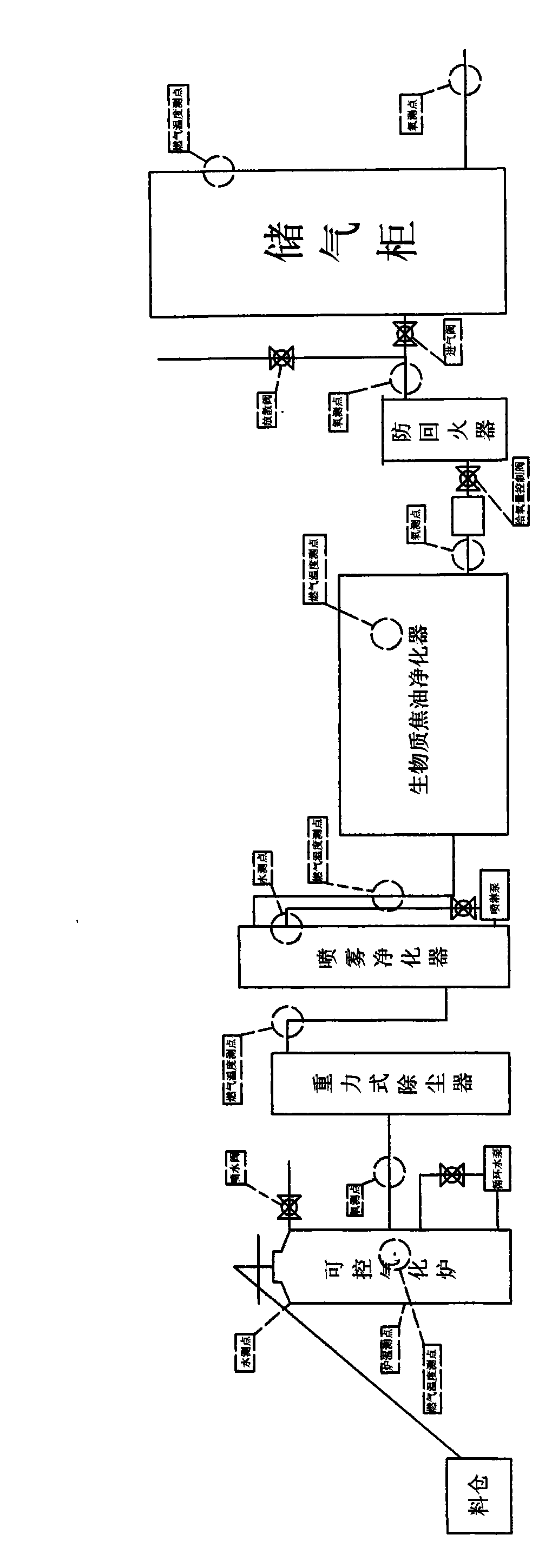

[0062] Such as figure 1 As shown, the method of the present invention mainly comprises the following steps:

[0063] Feeding-gasification-dust removal-spray purification-detarring-gas extraction and delivery-anti-tempering-gas tank storage, of which:

[0064] -Feeding: gasification materials can use various biomass materials such as wooden branches, tree roots, straw, leather shells, etc., as well as waste materials from wood processing. The pretreatment of materials is simple, but the length of long materials needs to be shortened to fit The size of the inner liner of the gasifier can also make the gasifier material can be packed tightly, increase the output of a single furnace and prevent the material layer from burning out holes during gasification. The material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com