ZSM-5 molecular sieve and preparation method thereof

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of complex preparation methods, inappropriate particle size, and environmental pollution, and achieve crystal The effects of uniformity, reduction of preparation cost, and high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

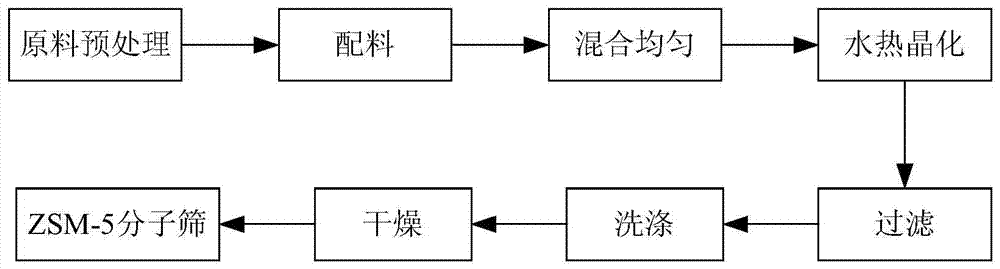

[0088] A preparation method of ZSM-5 molecular sieve, comprising the steps of:

[0089] (1) Raw material pretreatment:

[0090] Pulverize the coal gangue to obtain coal gangue powder with an average particle size of less than 10 μm; then roast the coal gangue powder at 900°C for 2 hours; 1:5 acid leaching, the temperature of acid leaching is 80°C, and the time is 2h; after that, the solid-liquid mixture of acid leaching is filtered and washed, and the solid precursor obtained is SiO in the solid precursor 2 / Al 2 o 3 The molar ratio of is 21;

[0091] (2) Mix the solid precursor, alkali and water at a ratio of 1:0.10:10 to prepare a slurry mixture, wherein the solid precursor is the acid-treated coal gangue (SiO 2 / Al 2 o 3 =21); then add 1.0wt% ZSM-5 molecular sieve purchased from Nankai University Catalyst Factory to the mixture as a seed crystal, grind to obtain a uniform slurry, and let it stand for 3 hours;

[0092] (3) Put the slurry obtained in step (2) in a reac...

Embodiment 2

[0095] A preparation method of ZSM-5 molecular sieve, comprising the steps of:

[0096] (1) Raw material pretreatment:

[0097] Pulverize the coal gangue to obtain coal gangue powder with an average particle size of less than 10 μm; then roast the coal gangue powder at 900°C for 2 hours; 1:5 acid leaching, the temperature of acid leaching is 80°C, and the time is 2h; after that, the solid-liquid mixture of acid leaching is filtered and washed, and the solid precursor obtained is SiO in the solid precursor 2 / Al 2 o 3 The molar ratio of is 21;

[0098] (2) Mix the solid precursor, alkali and water at a ratio of 1:0.10:10 to prepare a slurry mixture, wherein the solid precursor is the acid-treated coal gangue (SiO 2 / Al 2 o 3 =21); then add 1.0wt% of the ZSM-5 molecular sieve prepared in Example 1 to the mixture as a seed crystal, grind to obtain a uniform slurry, and let it stand for 4 hours;

[0099] (3) Put the slurry obtained in step (2) in a reaction kettle, conduct ...

Embodiment 3

[0105] A preparation method of ZSM-5 molecular sieve, comprising the steps of:

[0106] (1) Raw material pretreatment:

[0107] Pulverize the coal gangue to obtain coal gangue powder with an average particle size of less than 10 μm; then roast the coal gangue powder at 600°C for 20 hours; 3 solution, with a solid-to-liquid ratio of 1:5 for acid leaching, the temperature of acid leaching is 80°C, and the time is 1h; after that, the solid-liquid mixture of acid leaching is filtered and washed, and the solid precursor obtained is SiO in the solid precursor. 2 / Al 2 o 3 The molar ratio of is 16.7;

[0108] (2') Preparation of seed crystals

[0109] Take part of the solid precursor obtained in step (1), alkali and water and mix them in a ratio of 1:0.183:11.67 to prepare a slurry mixture, wherein the solid precursor is the acid-treated coal gangue (SiO 2 / Al 2 o 3=16.7), the mixture was ground to obtain a uniform slurry; then the obtained slurry was placed in a reaction kett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com