Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

697results about How to "Improve shock resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

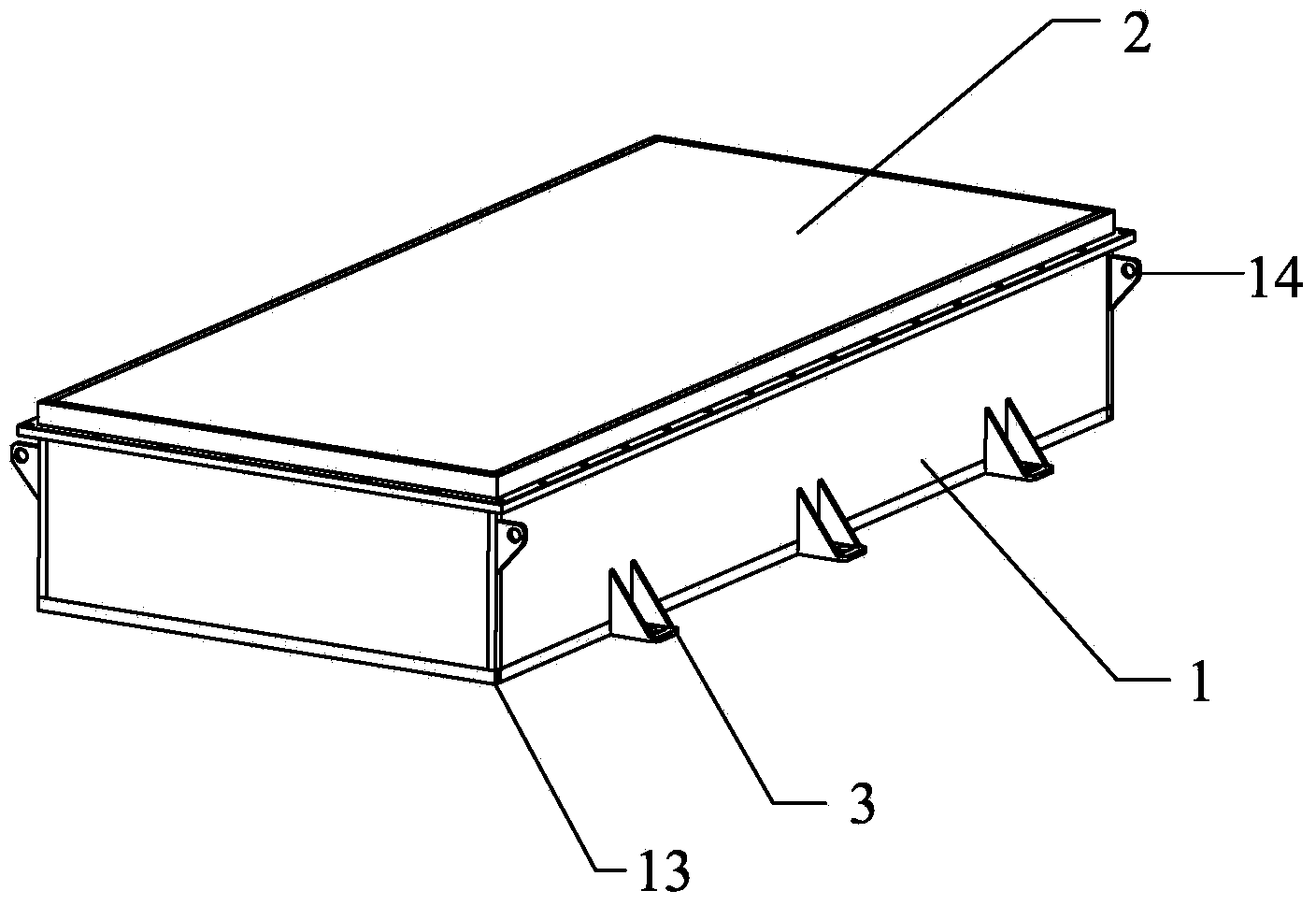

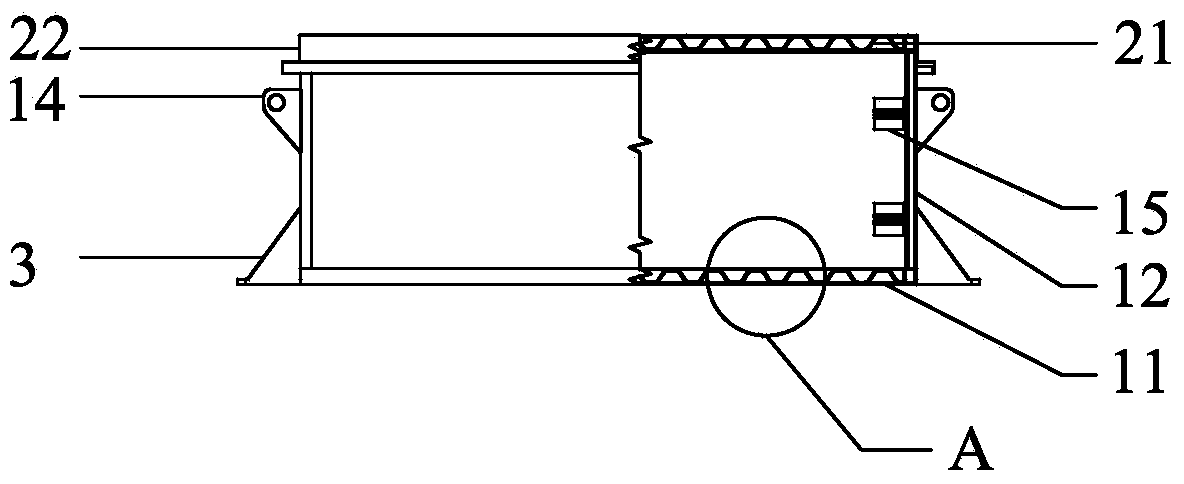

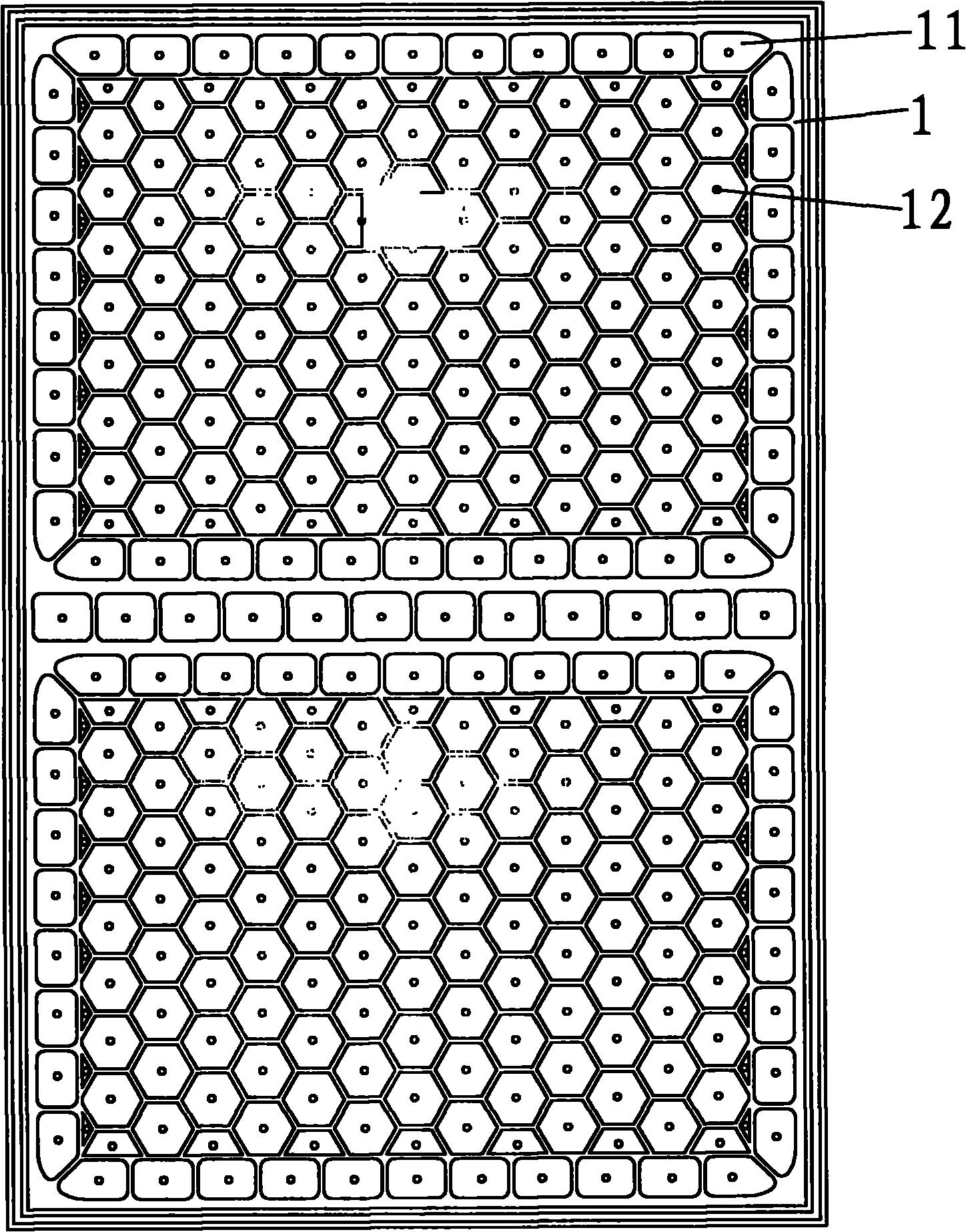

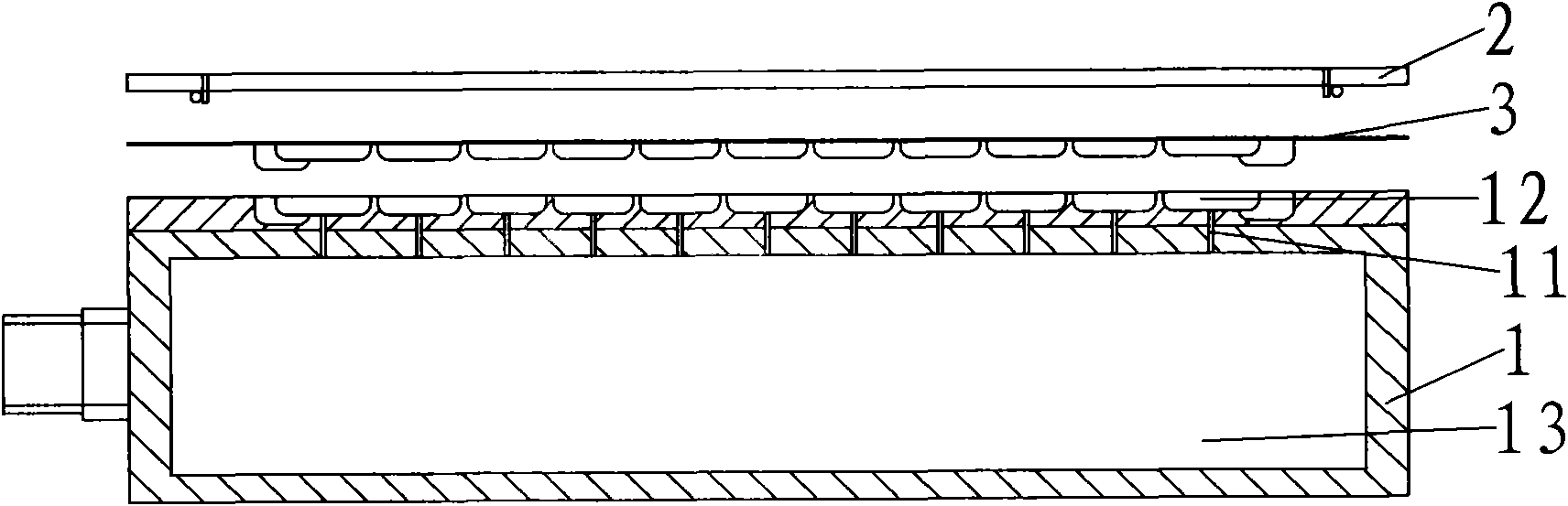

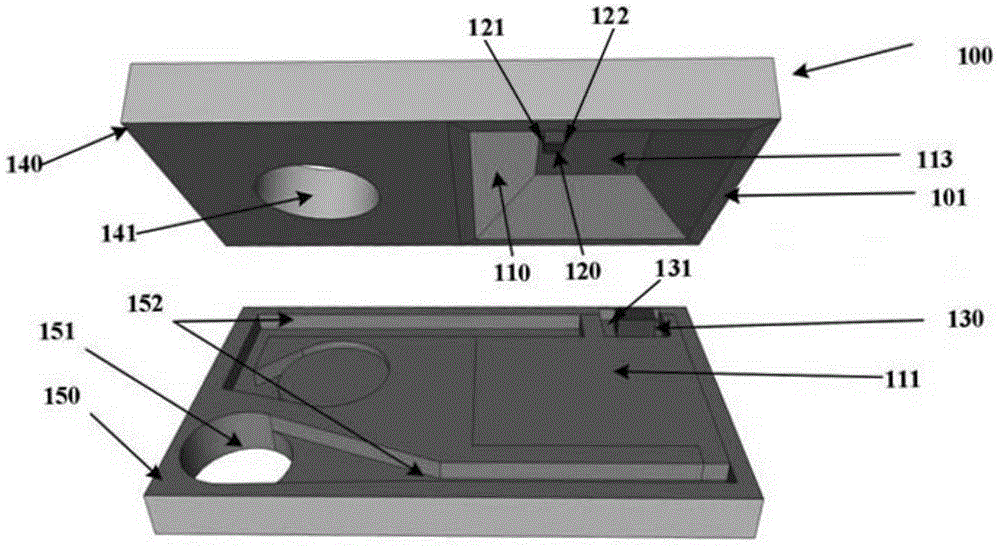

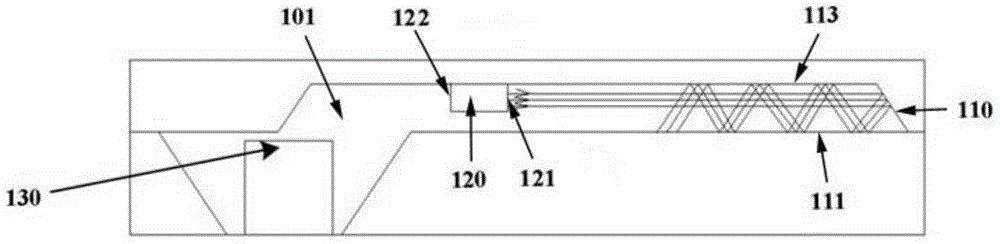

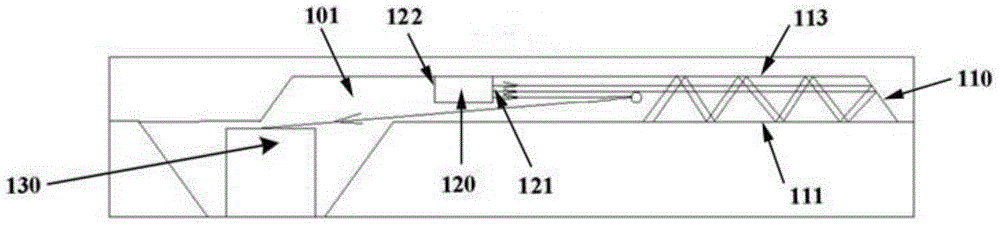

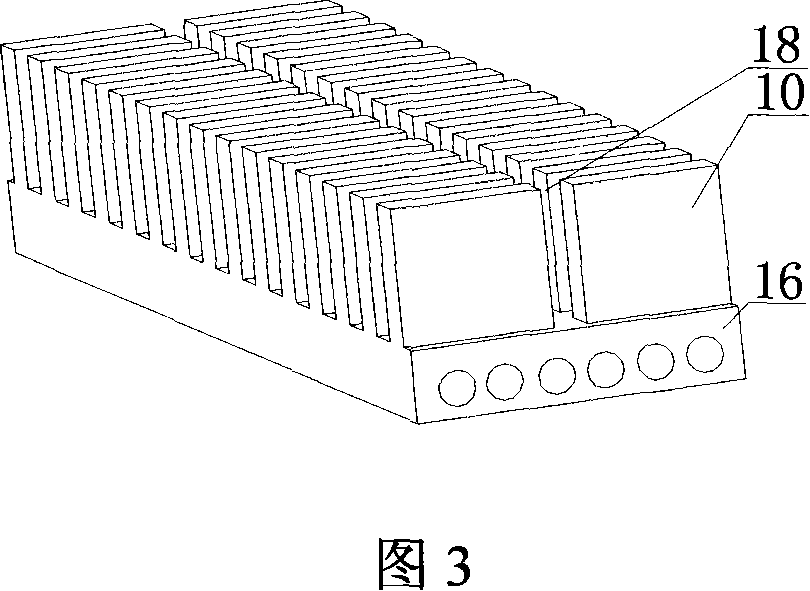

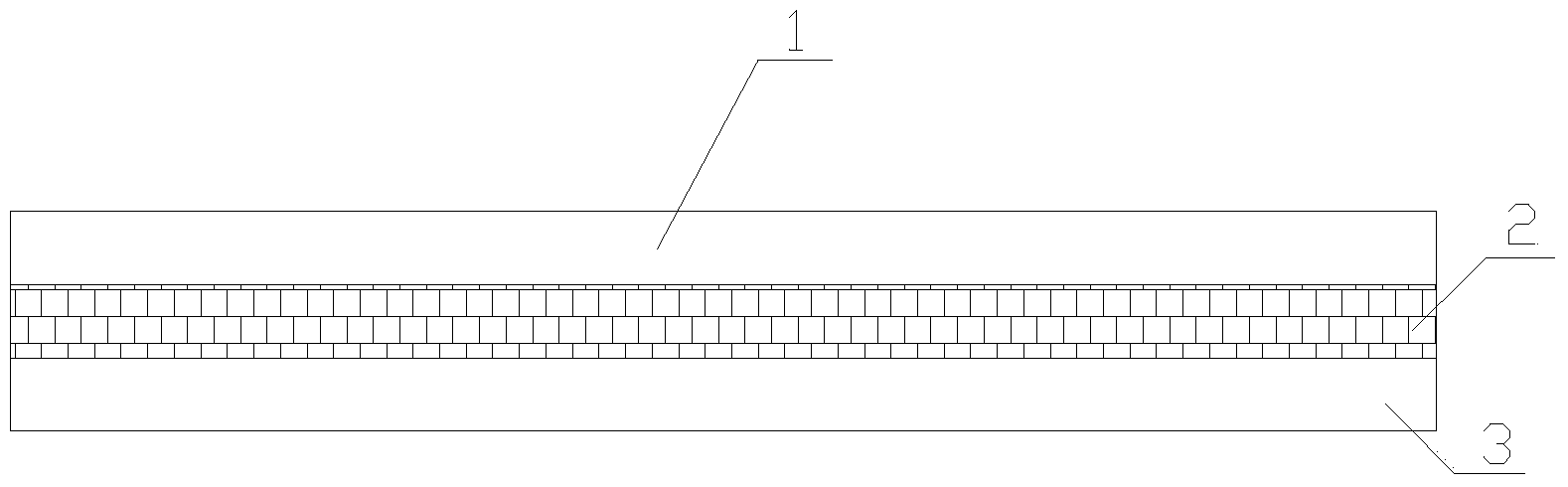

Corrugated sandwich protective structure of battery box of electric vehicle

InactiveCN103730616AUndamagedFree from destructionElectric propulsion mountingVehicle sub-unit featuresAutomotive batteryEngineering

The invention discloses a corrugated sandwich protective structure of a battery box of an electric vehicle. The protective structure comprises a box body and a box cover, wherein the box body is not closed at top, is composed of a baseplate and a baseplate wallboard fixed around the baseplate and is used for accommodating batteries; the box cover comprises a top plate and a top-plate wallboard fixed around the top plate, and the box cover and the box body are buckled so as to form a closed space. The protective structure is characterized in that the baseplate and the baseplate wallboard are respectively made of a corrugated sandwich protective plate. According to the invention, the box body and the box cover are made of the corrugated sandwich protective plates, so that the batteries can be prevented from being damaged; the corrugated sandwich protective structure has the advantages of high specific stiffness, high specific strength, high fatigue life, strong impact resistance and shock resistance, good impacting energy absorption property, light weight, and the like, thereby facilitating the promotion and application of electric vehicles and passenger cars.

Owner:DALIAN UNIV OF TECH

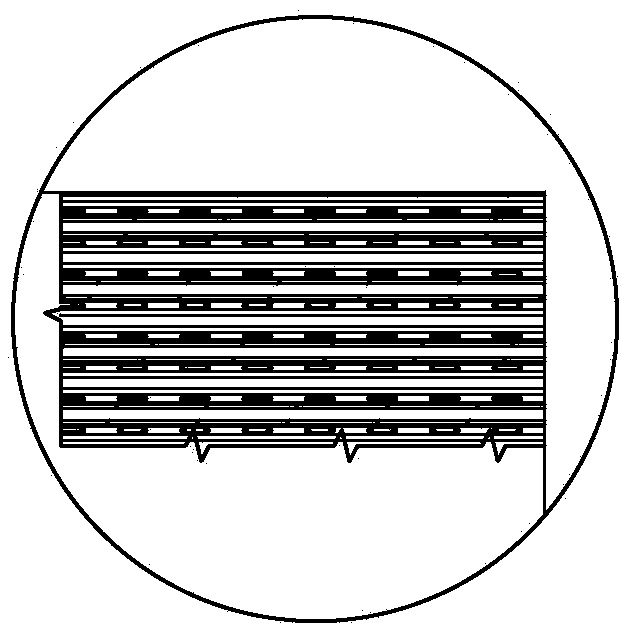

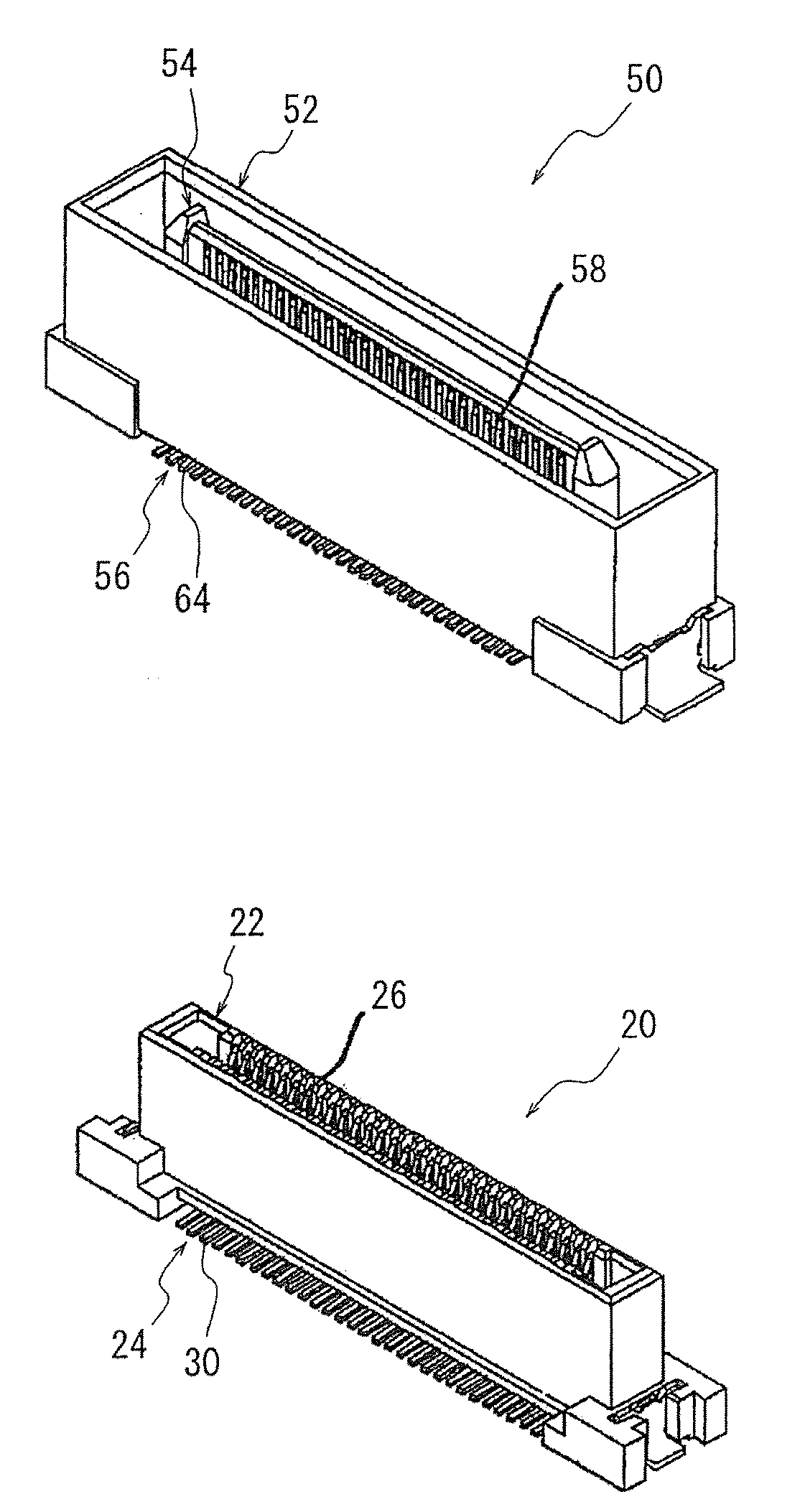

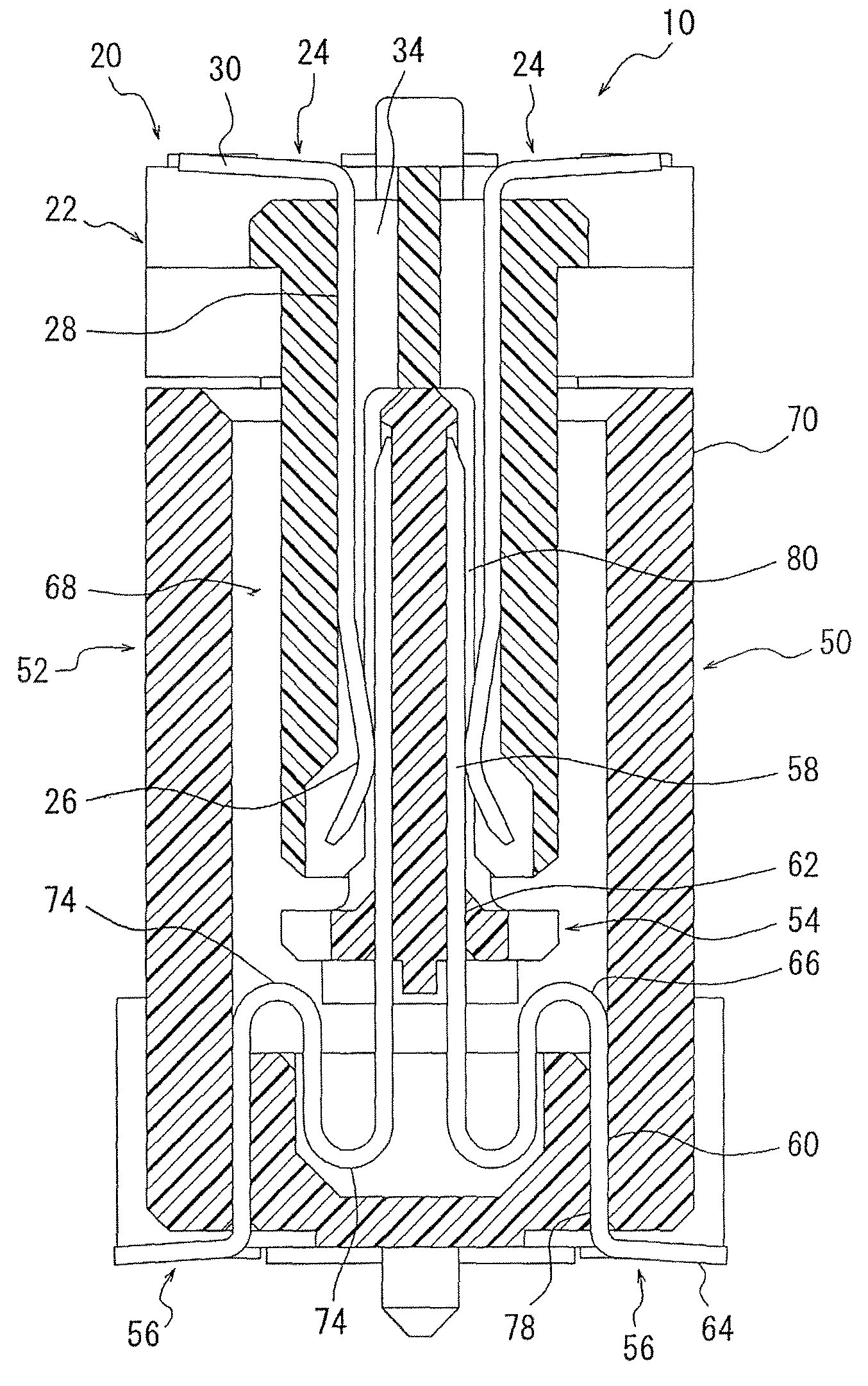

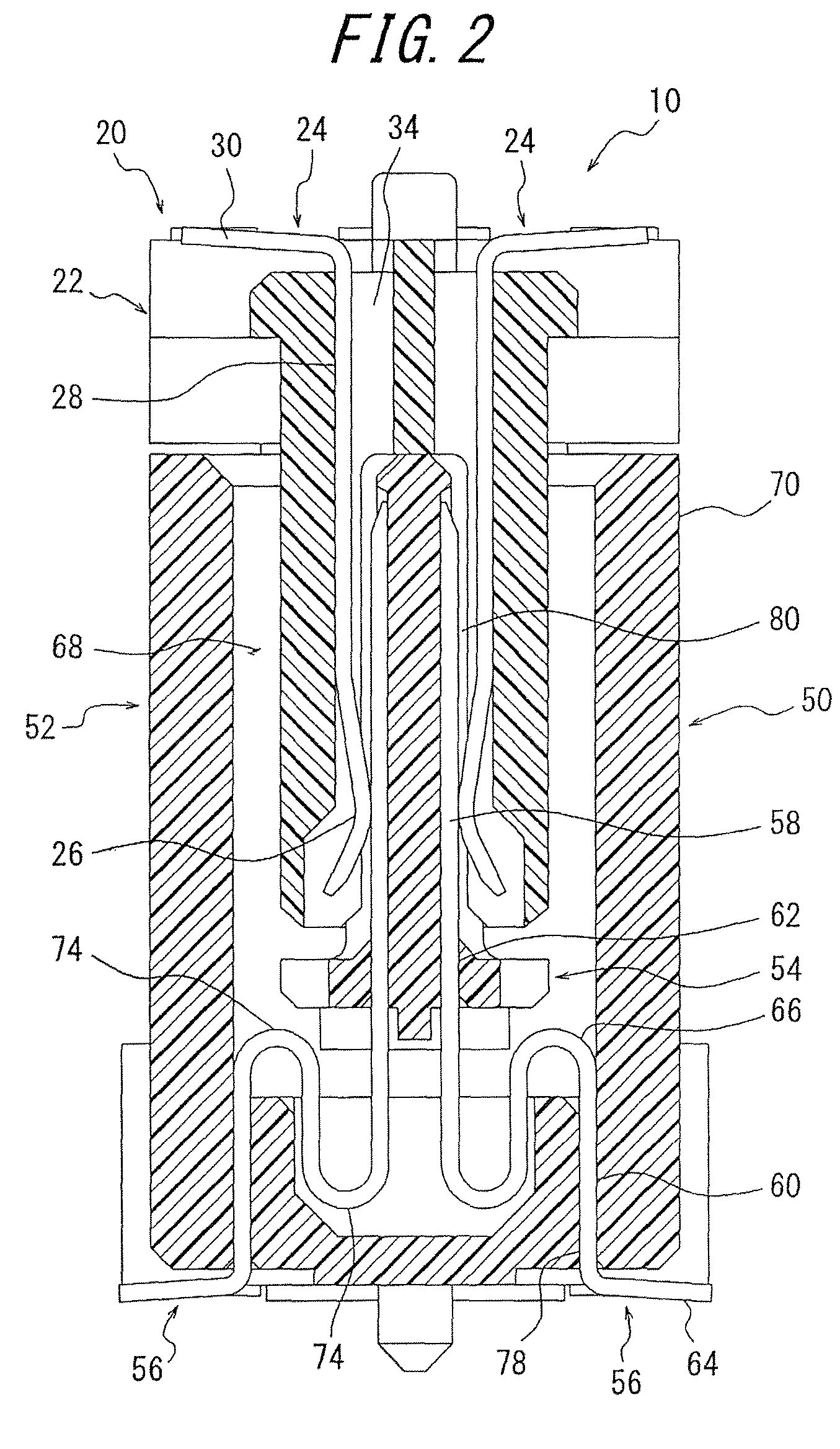

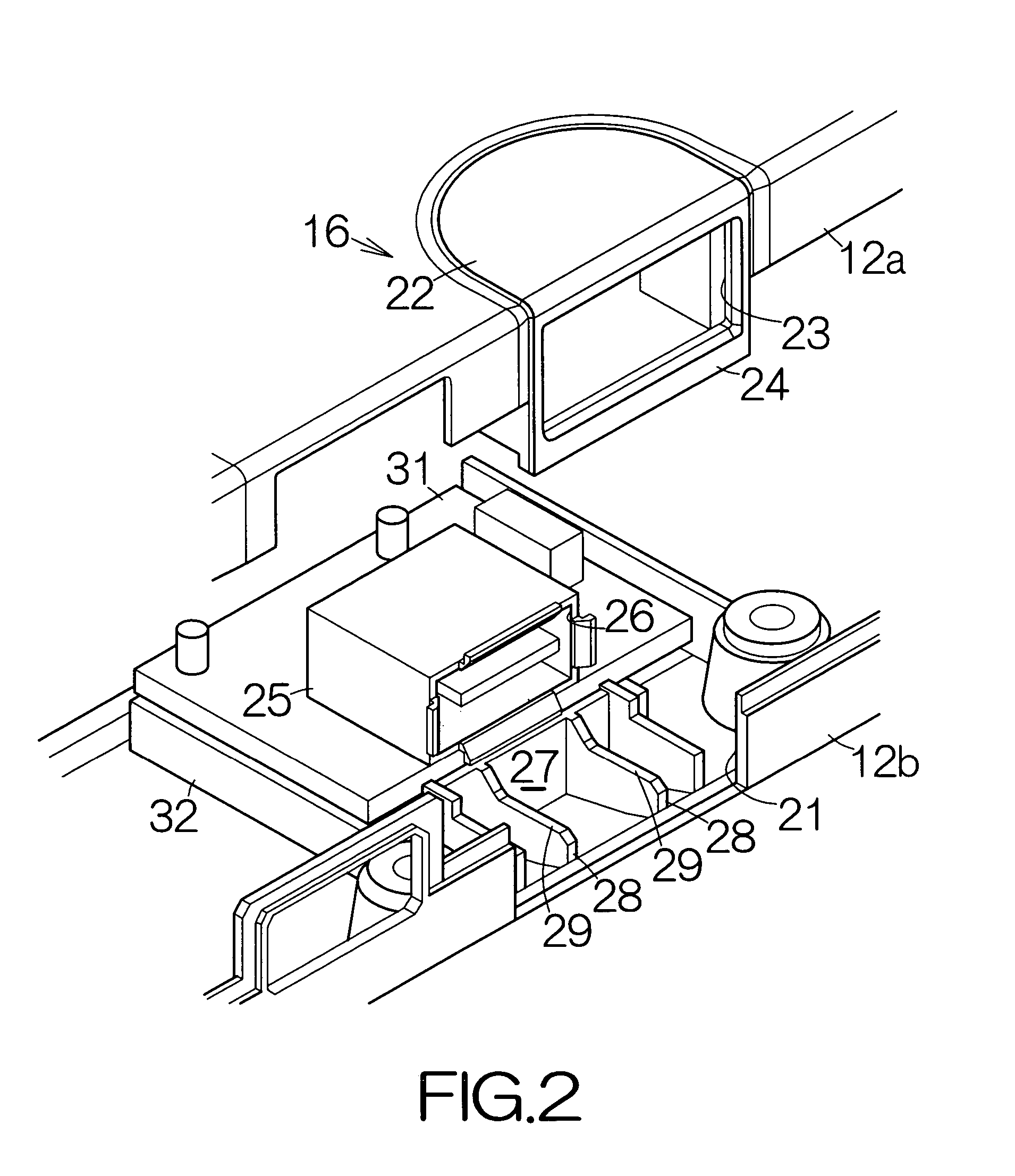

Electrical connector

ActiveUS20090239422A1Improve vibration resistanceSave spaceElectric discharge tubesSecuring/insulating coupling contact membersEngineeringElectrical connector

An electrical connector consists of a plug connector and a receptacle connector to be fitted. An insulator is supported only by plug contacts each provided between second and third fixed portions with an elastic portion having at least one snaked portion so as to be floating in a housing. The shape of the second contact portion of each of the plug contacts is substantially in the form of a plate-shaped piece so that the second contact portion of the plug contact and the first contact portion of a receptacle contact are caused to contact each other in line contact at one location, and the elastic portion is arranged within a range from a position below the second contact portion to a position below the insulator. The electrical connector thus constructed is superior in resistance to vibration, and achieves space-saving and floating of the insulator.

Owner:DDK LTD

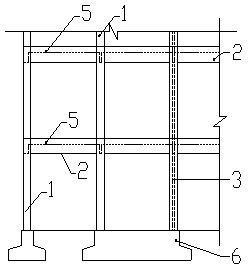

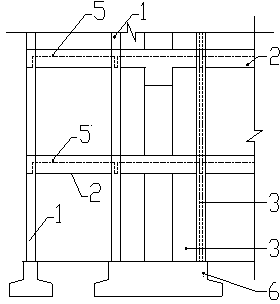

Connection structure of building composite floor slab and steel bar truss shear wall

InactiveCN103397705AFirmly connectedImprove quality controlBuilding constructionsSheet steelFloor slab

The invention relates to a connection structure of a building composite floor slab and a steel bar truss shear wall, and belongs to the field of building members. a one-way or two-way prestressed steel bar and a light steel rid are embedded in a prefabricated slab at the lower part of the connection structure; an oblong hole is formed in the end part of the light steel rib; an upper layer steel bar of the composite floor slab is paved in a notch in the upper part of the light steel rib; poured-in-place concrete is positioned at the upper part of the prefabricated slab to cover the light steel rib and the upper steel bar; a steel frame is arranged at the periphery of the shear wall, and is welded with a steel bar truss together; a pre-buried steel plate is arranged on the wall surface of the shear wall; a steel plate bracket, a reinforcing steel bar and a connecting plate all connected with the composite are welded onto the pre-buried steel plate; a concave pit is formed in the upper end of the shear wall; a short pattern steel fastener is welded on the steel frame at the lower end of the shear wall; the shear wall is connected with the composite floor slab; the composite floor slab is directly placed on the steel plate bracket of the shear wall, and is fixed in a manner that a bolt penetrates through the oblong hole in the end part of the light steel rib and the oblong hole in the connecting plate welded on the pre-buried steel plate of the wall surface of the shear wall; meanwhile, the reinforcing steel bar welded on the pre-buried steel plate of the wall surface of the shear wall is connected with the composite floor slab.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD

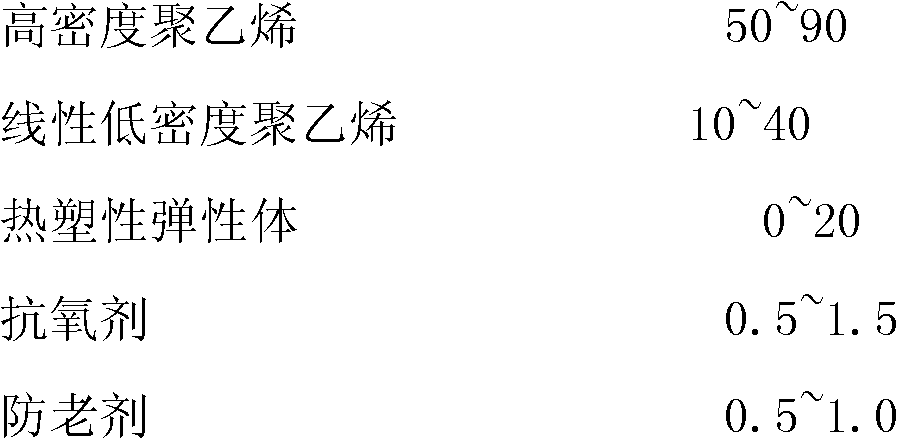

Composite macromolecular waterproof board and preparation method thereof

The invention discloses a composite macromolecular waterproof board, which consists of high density polyethylene, linear low density polyethylene, a thermoplastic elastomer, an antioxidant, an anti-ageing agent and a filler. The composite macromolecular waterproof board has high permeability resistance, high barrier property, high penetration resistance, resistance to acid, alkali and various chemical substances, high elongation and wear resistance, is free from chemical pollution, and can effectively improve the surface energy of polyethylene. The invention also discloses a method for preparing the composite macromolecular waterproof board.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

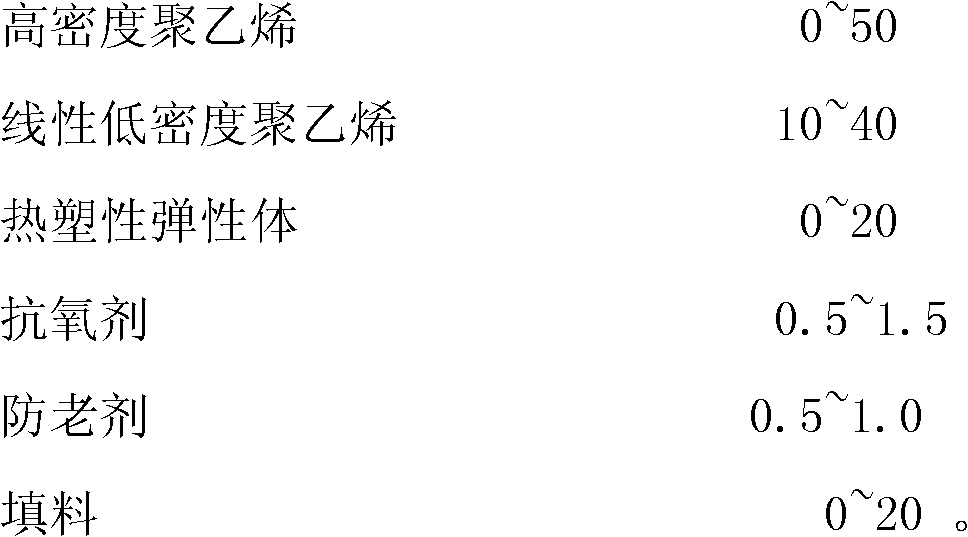

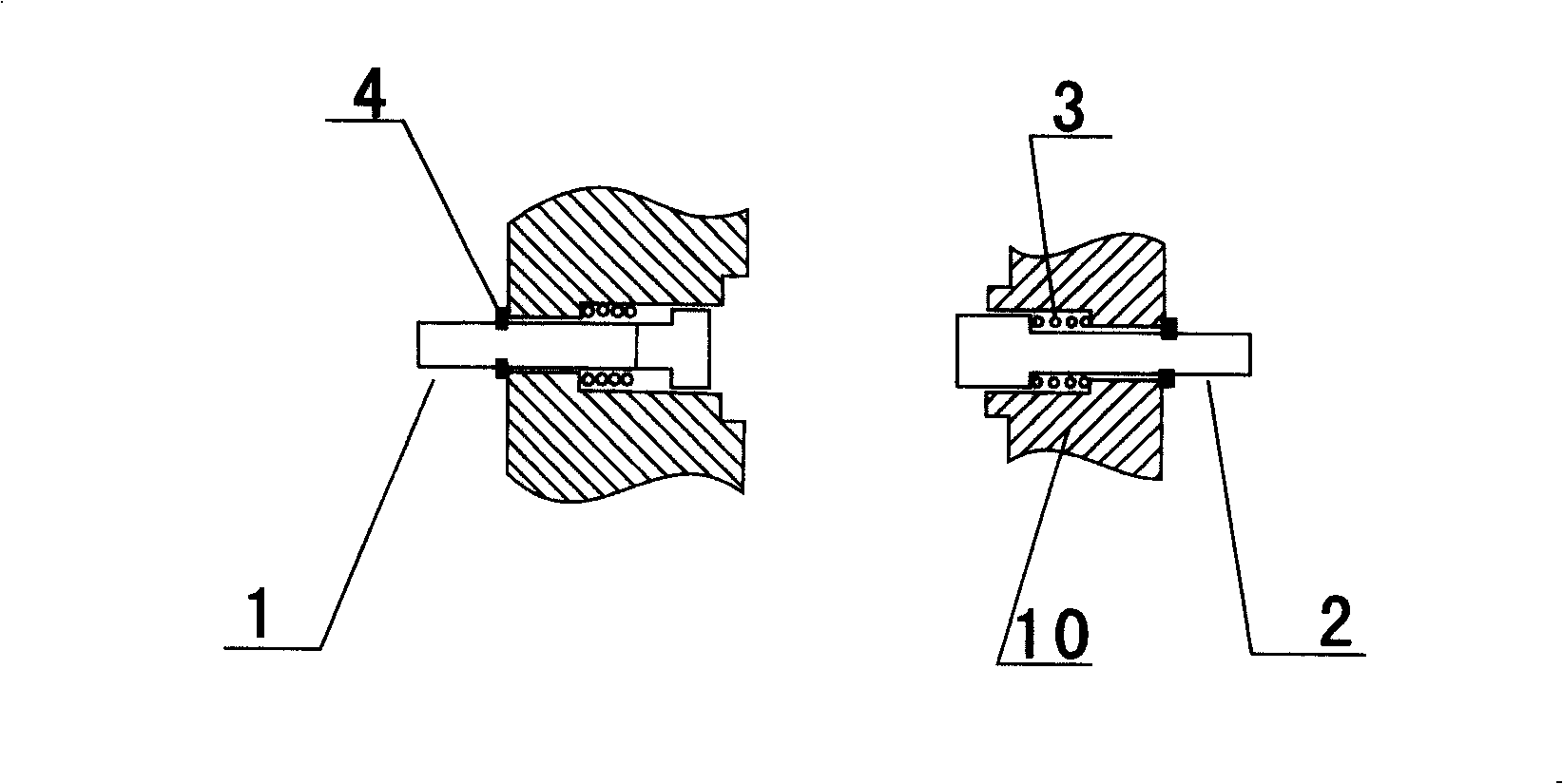

Axial elastic force-applying connection method for electric connector contact pair

InactiveCN101355208AEmission reductionSimple structureCoupling contact membersRelative displacementElectrical resistance and conductance

The invention provides a method for the axial elastic force application connection of electrical connector contact pairs. The method adopts an elastic element to apply axial external force to a contact pair consisting of a contact piece A (1) and a contact piece B (2), so as to combine the two tightly, thereby forming the electric connection with lower conductive resistance. One end of the elastic element is in contact with an insulating base so as to turn into a relative fixed end; and the other end of the elastic element directly acts on a preset fixed end face of an electric conductor contact piece, and is a relative displacement end during axial force application. The contact pair is independently formed by the end planes of the two contact pieces with simple structure. As axial elastic connection can not be affected by shock or other external factors, the connection reliability is higher. The contact pair can be formed by a positive contact piece and a negative contact piece as well, which ensures that the radial and axial directions of the contact pair are uniform in stress and contact.

Owner:徐志

Electrical connector

ActiveUS7862345B2Improve vibration resistanceSave spaceElectric discharge tubesSecuring/insulating coupling contact membersElectrical connectorElectrical and Electronics engineering

An electrical connector consists of a plug connector and a receptacle connector to be fitted. An insulator is supported only by plug contacts each provided between second and third fixed portions with an elastic portion having at least one snaked portion so as to be floating in a housing. The shape of the second contact portion of each of the plug contacts is substantially in the form of a plate-shaped piece so that the second contact portion of the plug contact and the first contact portion of a receptacle contact are caused to contact each other in line contact at one location, and the elastic portion is arranged within a range from a position below the second contact portion to a position below the insulator. The electrical connector thus constructed is superior in resistance to vibration, and achieves space-saving and floating of the insulator.

Owner:DDK LTD

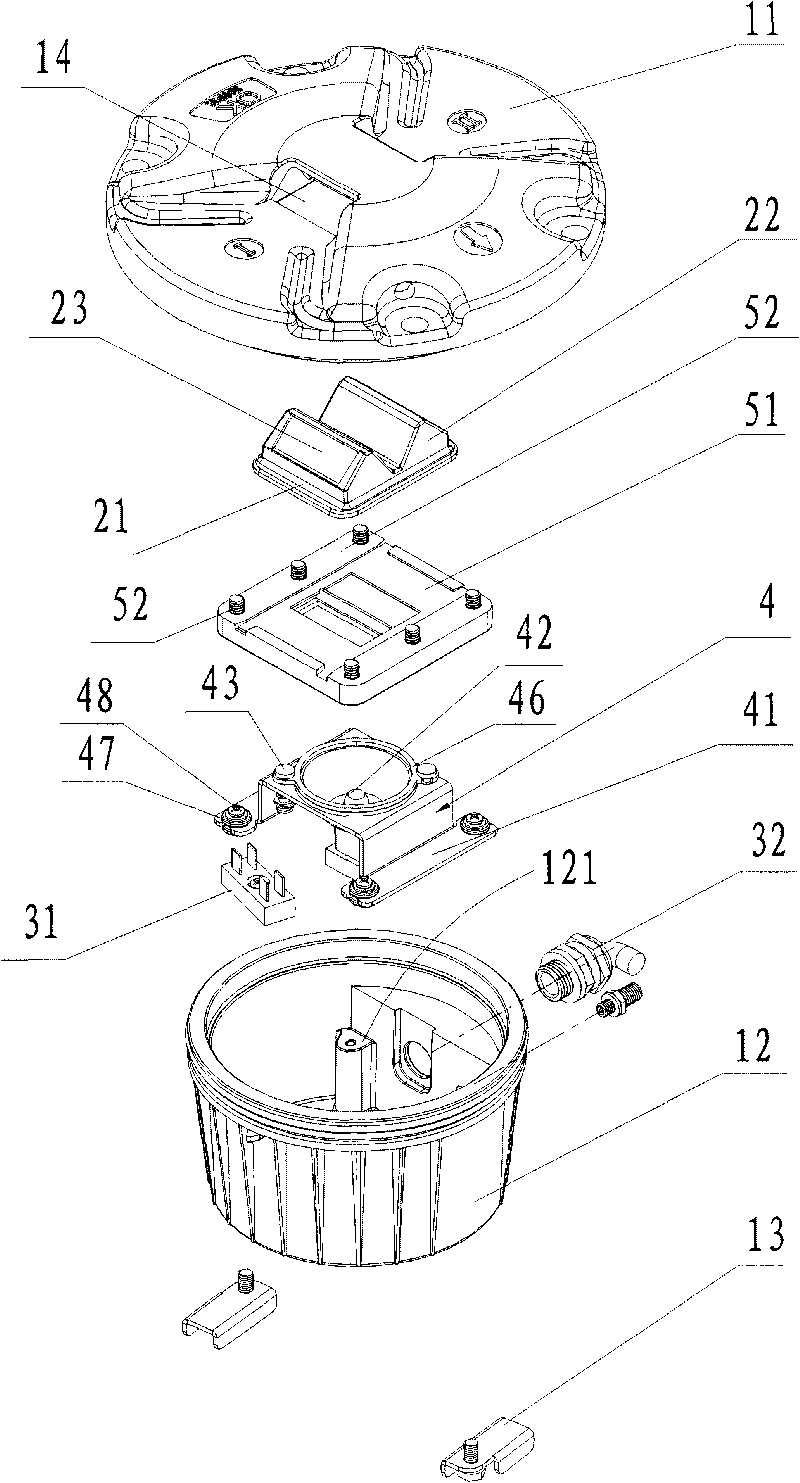

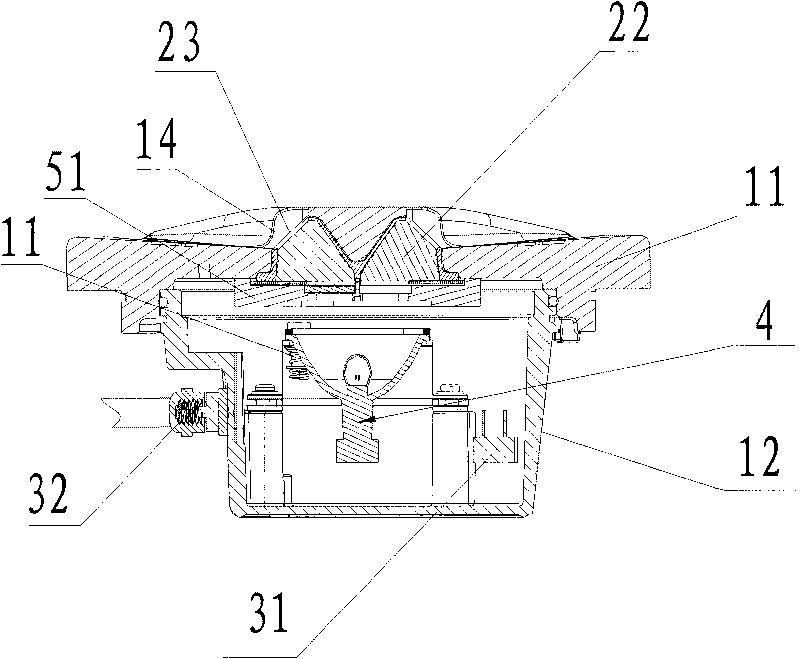

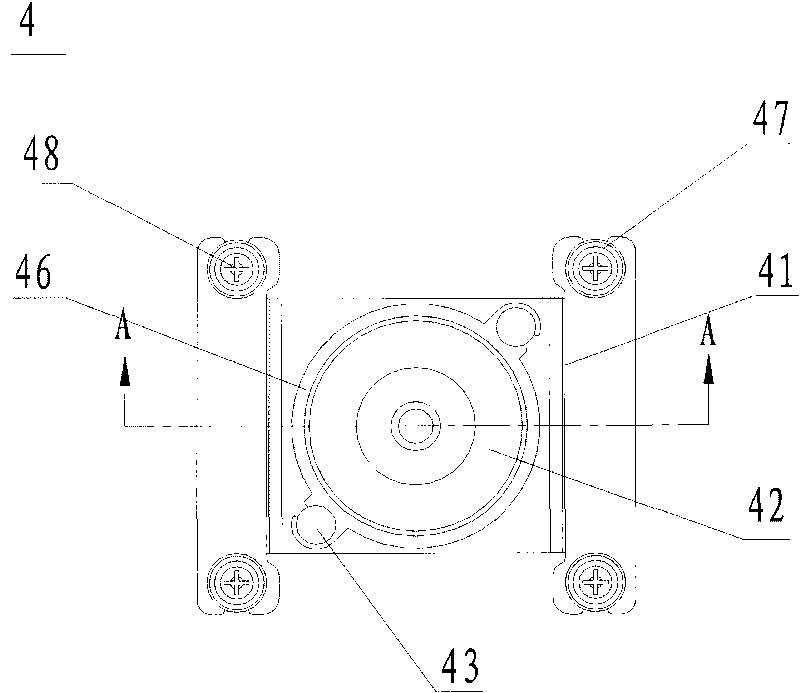

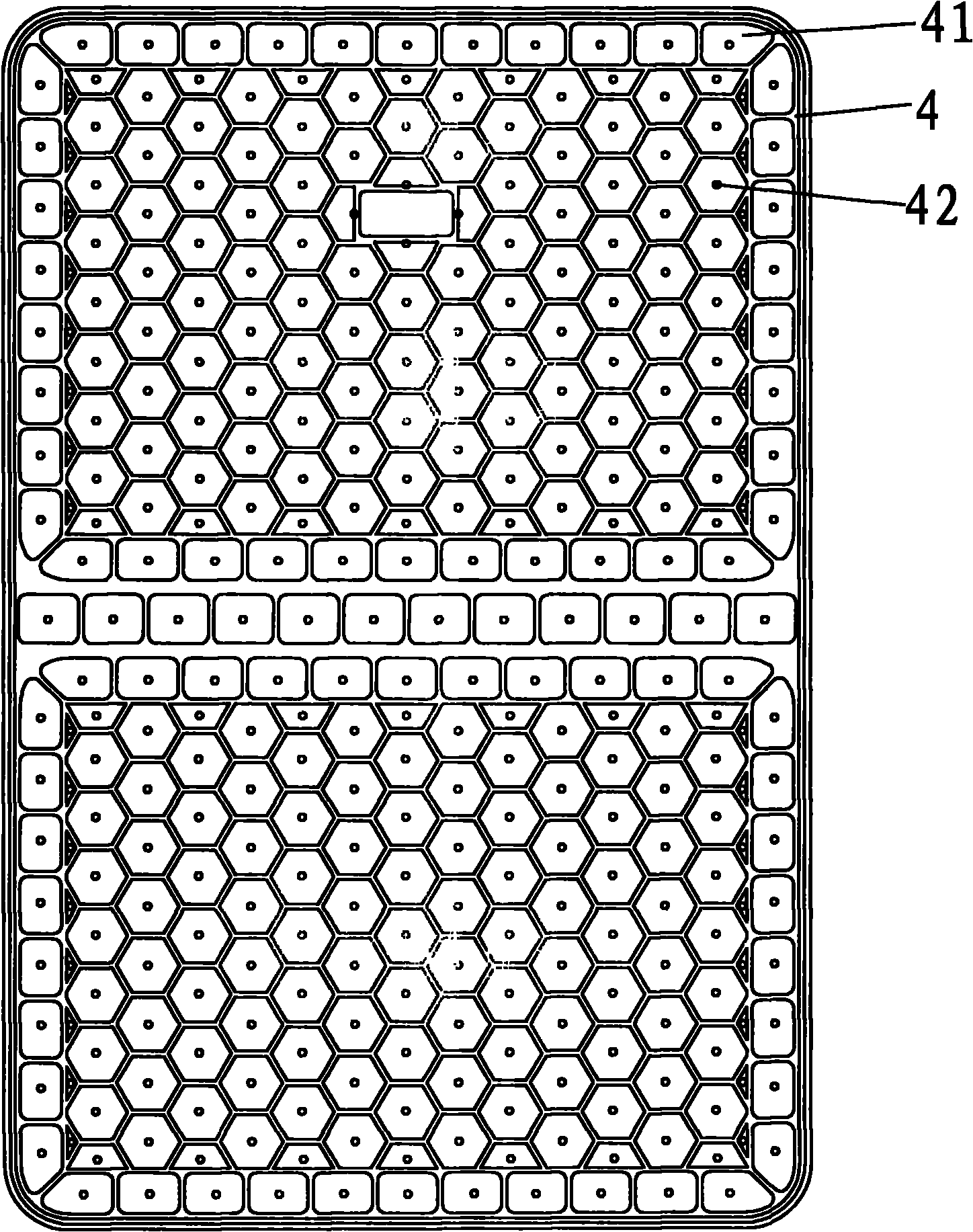

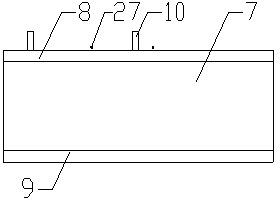

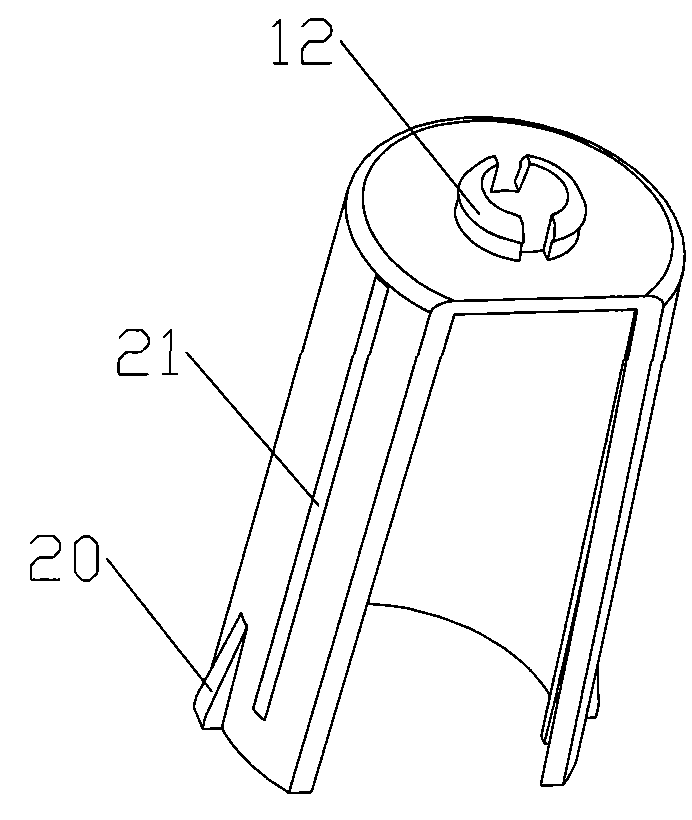

Embedded airfield runway centerline lamp

InactiveCN101761840AEasy maintenanceReduce vibrationLighting applicationsProtective devices for lightingEngineeringFlange

The invention discloses an embedded airfield runway centerline lamp, which comprises a base case (12), a face case (11), a lamp holder (41) arranged on the base case (12), and a light source (42) arranged in the lamp holder (41), wherein the upper end of the light source (42) is provided with a flange (423) exposed out of the upper end surface of the lamp holder (41). The embedded airfield runway centerline lamp also comprises a light source clamping ring (46) pressed and connected onto the flange (423) of the light source (42); two connecting parts are arranged on the external edge of the light source clamping ring (46), two connecting pieces are correspondingly arranged on the lamp holder (41), and the two connecting parts are clamped and connected on the two connecting pieces in a detachable way; in addition, the lamp holder (41) is also provided with a shock pad (47) and is connected with the base case (12) through the shock pad (47). The embedded airfield runway centerline lamp can effectively solve the problem that the tungsten halide lamp is not convenient for replacement after being damaged and the problem of the shock prevention of the tungsten halide lamp.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

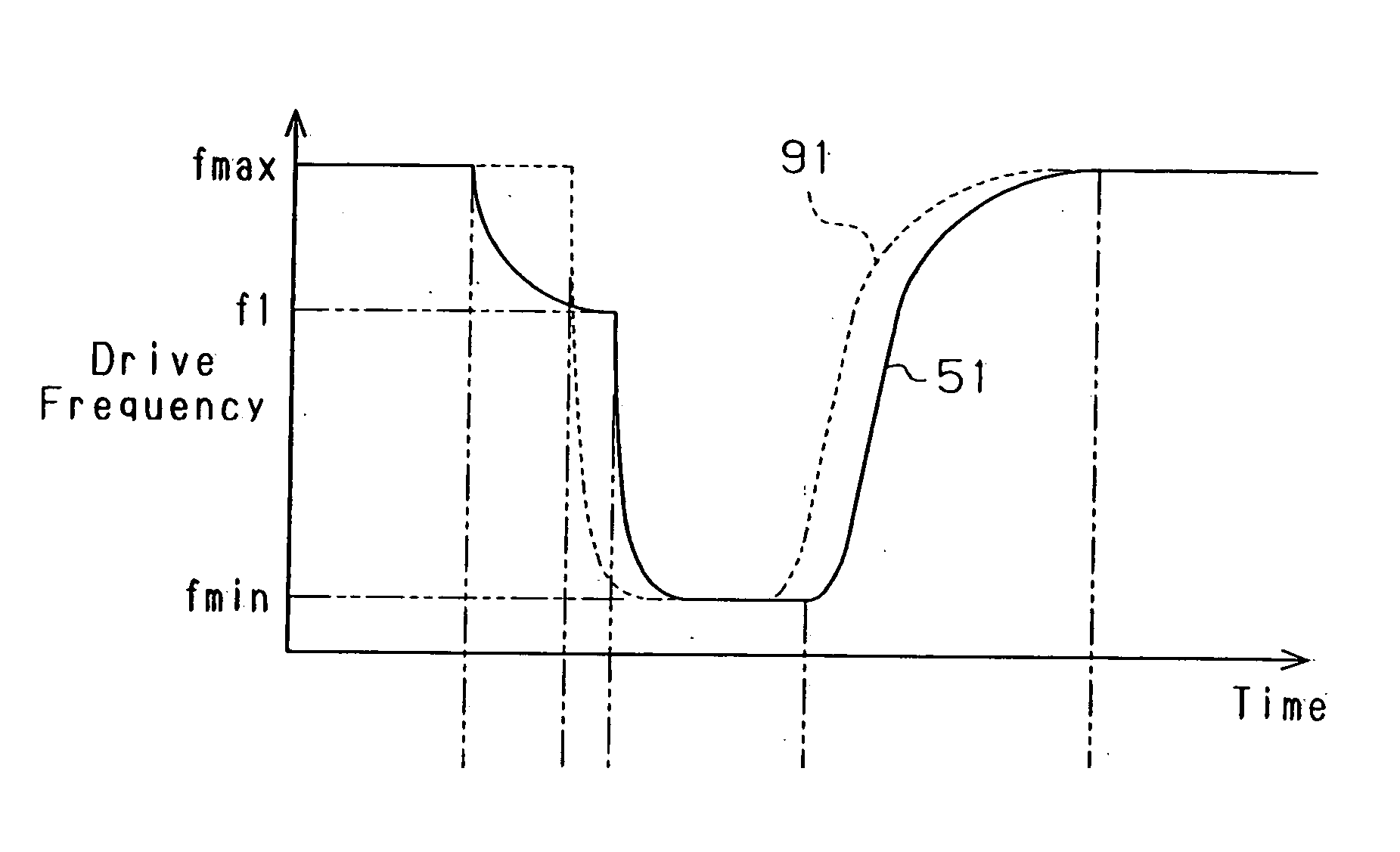

Controller of vacuum pump

InactiveUS20050031468A1Reduce rotation speedImprove shock resistanceFlexible member pumpsSemiconductor/solid-state device manufacturingFree spaceEngineering

A vacuum pump has a pump mechanism section that performs evacuation to set a space to be evacuated to a predetermined degree of vacuum and an electric motor section for driving the pump mechanism section. A controller of the vacuum pump executes deceleration control to decrease a rotational speed of the electric motor section when an increase in load torque of the vacuum pump per unit time abruptly changes upward.

Owner:KAWAGUCHI MASAHIRO +4

Manufacturing process of airbag type vibration isolating pad

InactiveCN101817233AImprove shock resistanceSimple preparation processHollow articlesForming gasPower flow

The invention relates to the airbag type package material field, in particular to a manufacturing process of an airbag type vibration isolating pad, comprising the following steps: 1) bundling a TPU chip material, broadening 2 cm for four sides on the basis of a product specification area, and cutting into a flaky material; 2) placing the flaky material in a first moulding mould; 3) pressing a platen on the flaky material and fastening the platen; 4) manufacturing a plurality of grooves on the flaky material by a molder through vacuum heating in a suction manner, wherein the heating temperature is 400+ / -10 DEG C, the running speed is 0.7m / min, the vacuum degree is 20kg and the pressure is maintained for 6s; and 5) placing the material with a plurality of independent grooves in a second moulding mould, stacking a layer of fabric to form a hollow shape, deflating gas in the second moulding to form gas chamber negative pressure, regulating a pressure valve according to the pressure requirement of the product on the airbag, switching on a welding machine, using current of 2.1A to generate high frequency current for 10s, preserving the pressure for 5s, switching off all gas inlet passages of all gas chambers, and pressing and sealing into respective independent airbags. The manufacturing process is simple, and the manufactured airbag type vibration isolating pad has good vibration isolating effect, and can effectively protect office equipment such as mobile computers and the like.

Owner:洪志强

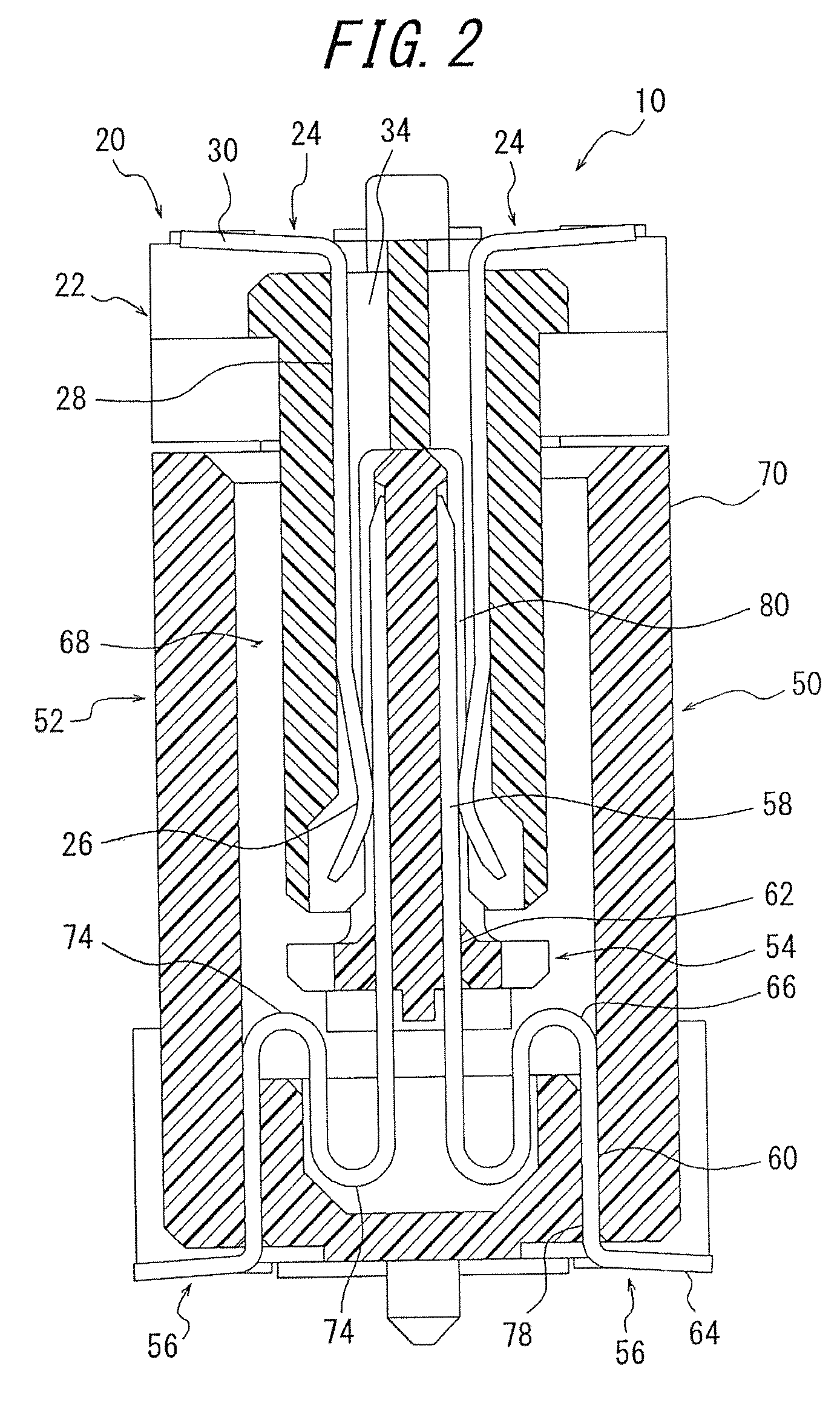

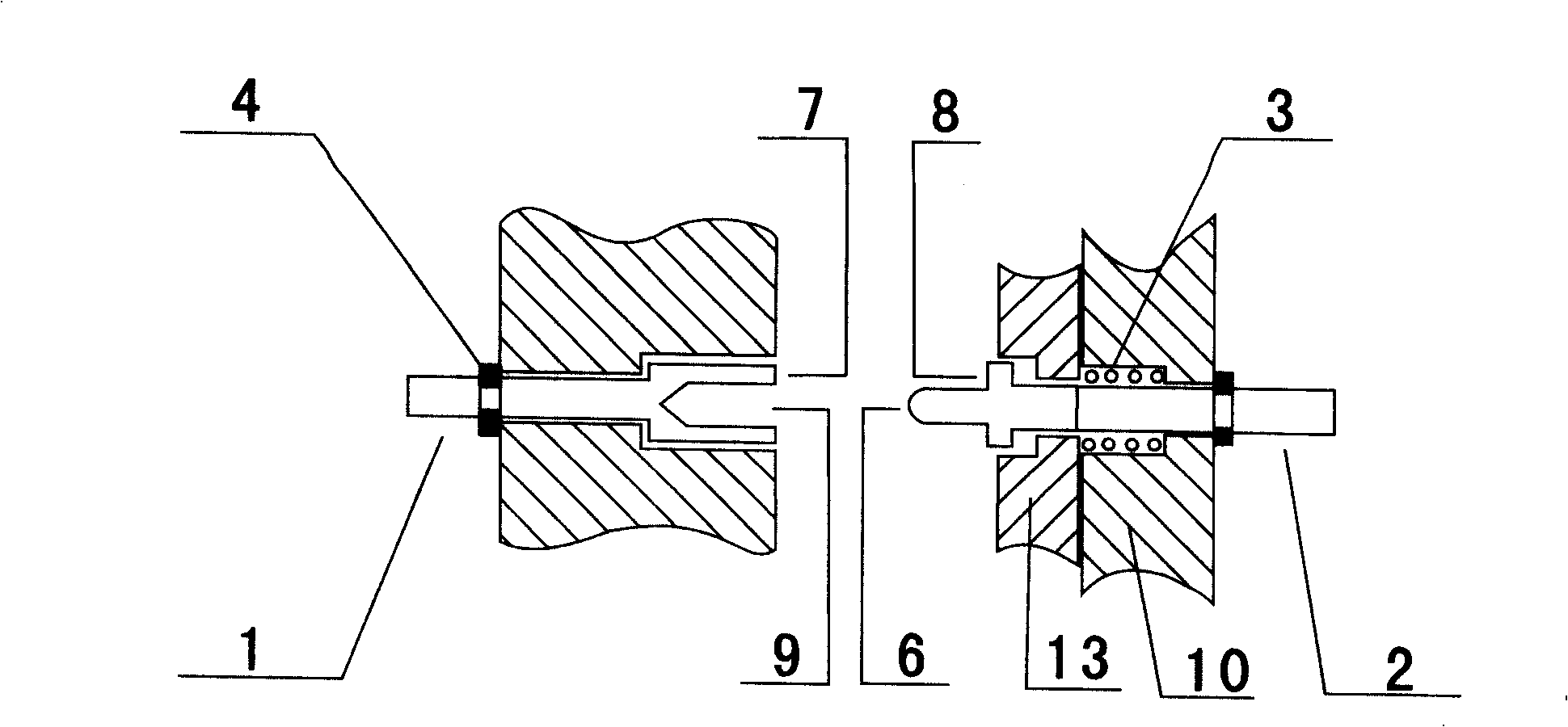

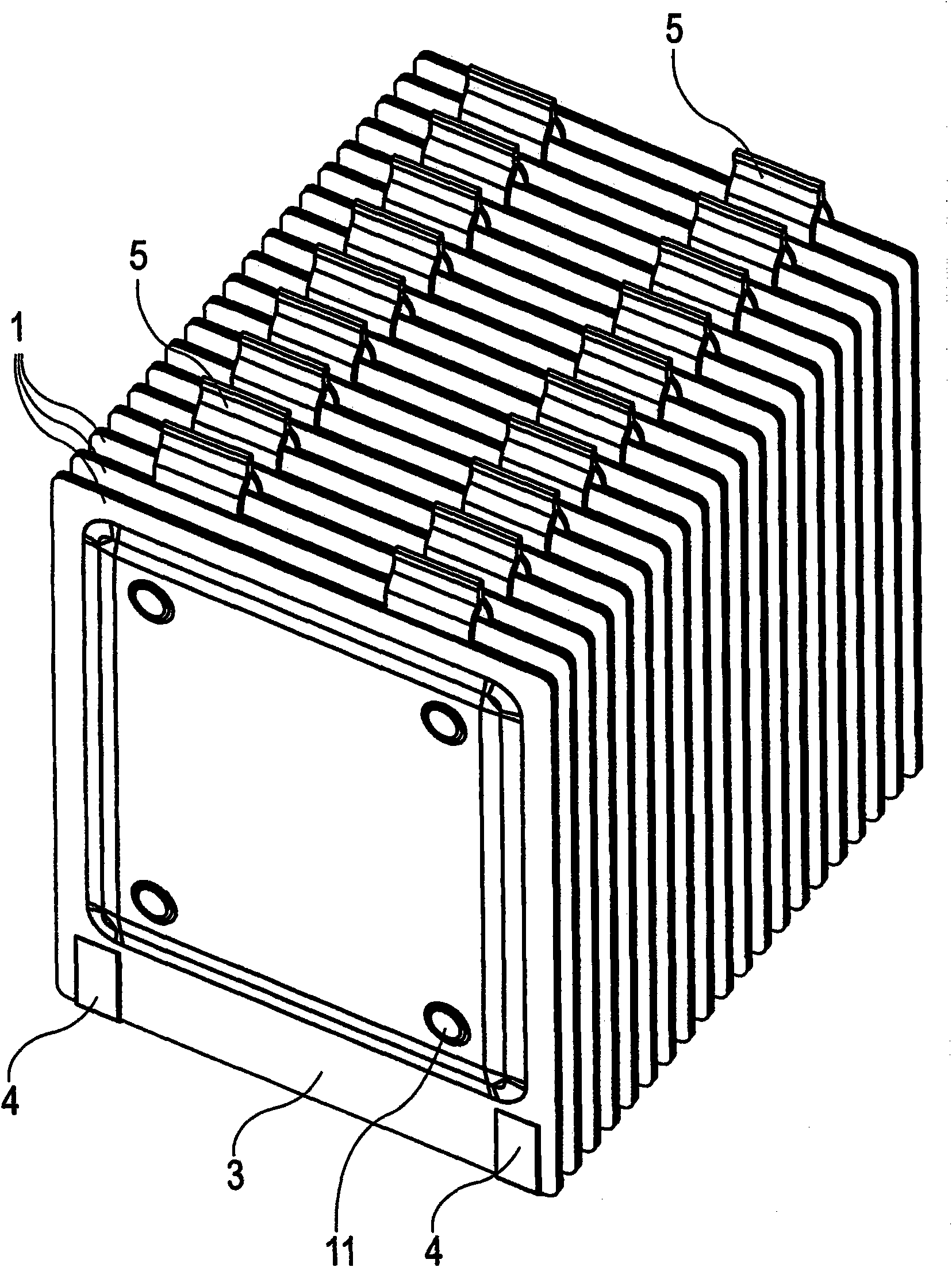

Battery, particularly for a hybrid drive

InactiveCN101772857ALow costSave installation spaceSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsTemperature controlMonomer

The invention relates to a battery (6) comprising at least one temperature control unit (7) that is configured as a cooling plate, and at least two galvanic individual cells (1), each having a metal housing (2), wherein the metal housing (2) has an extension (3), which can be accommodated at least partially in a respective recess (8) of the temperature control unit (7).

Owner:DAIMLER AG

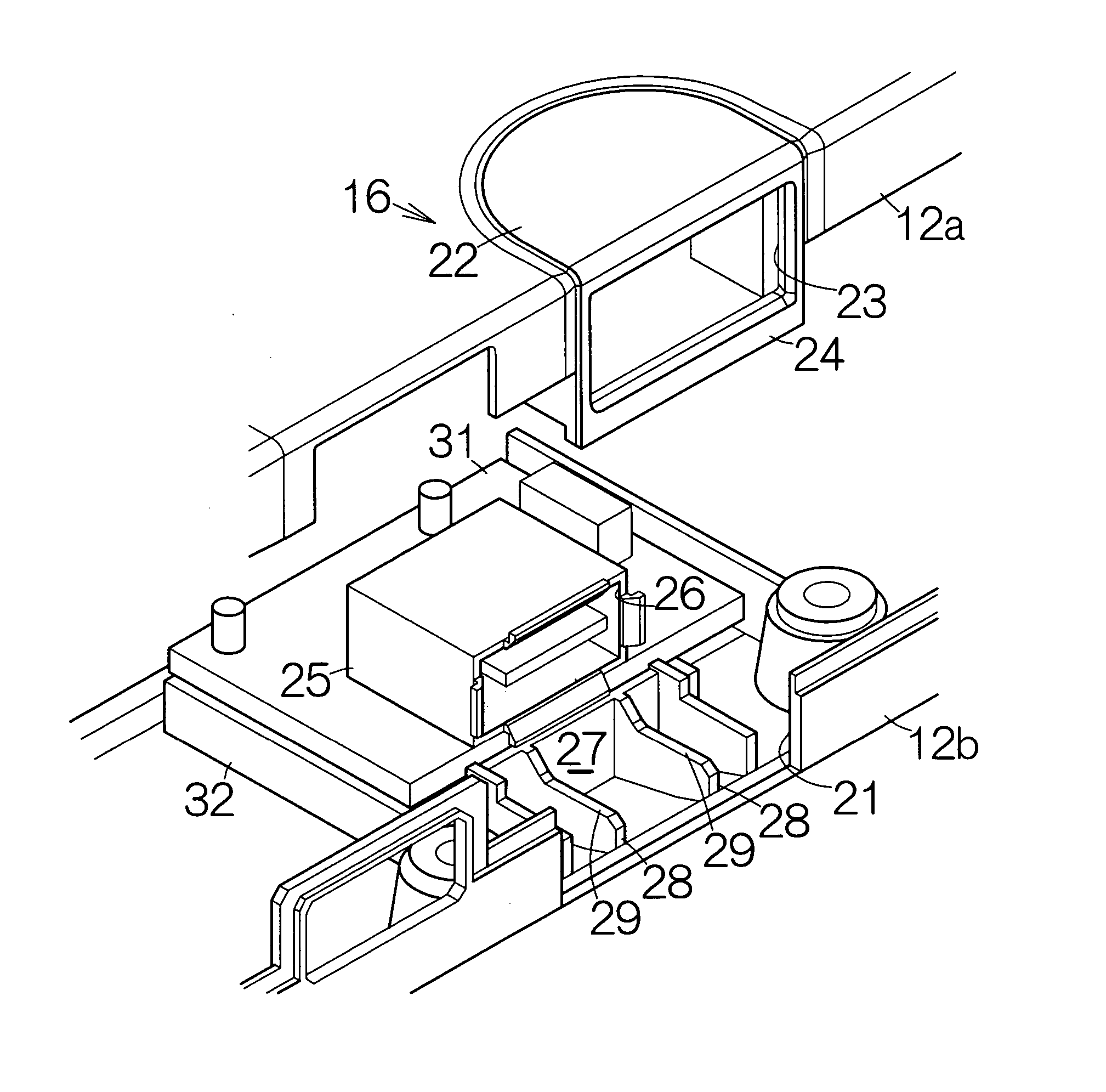

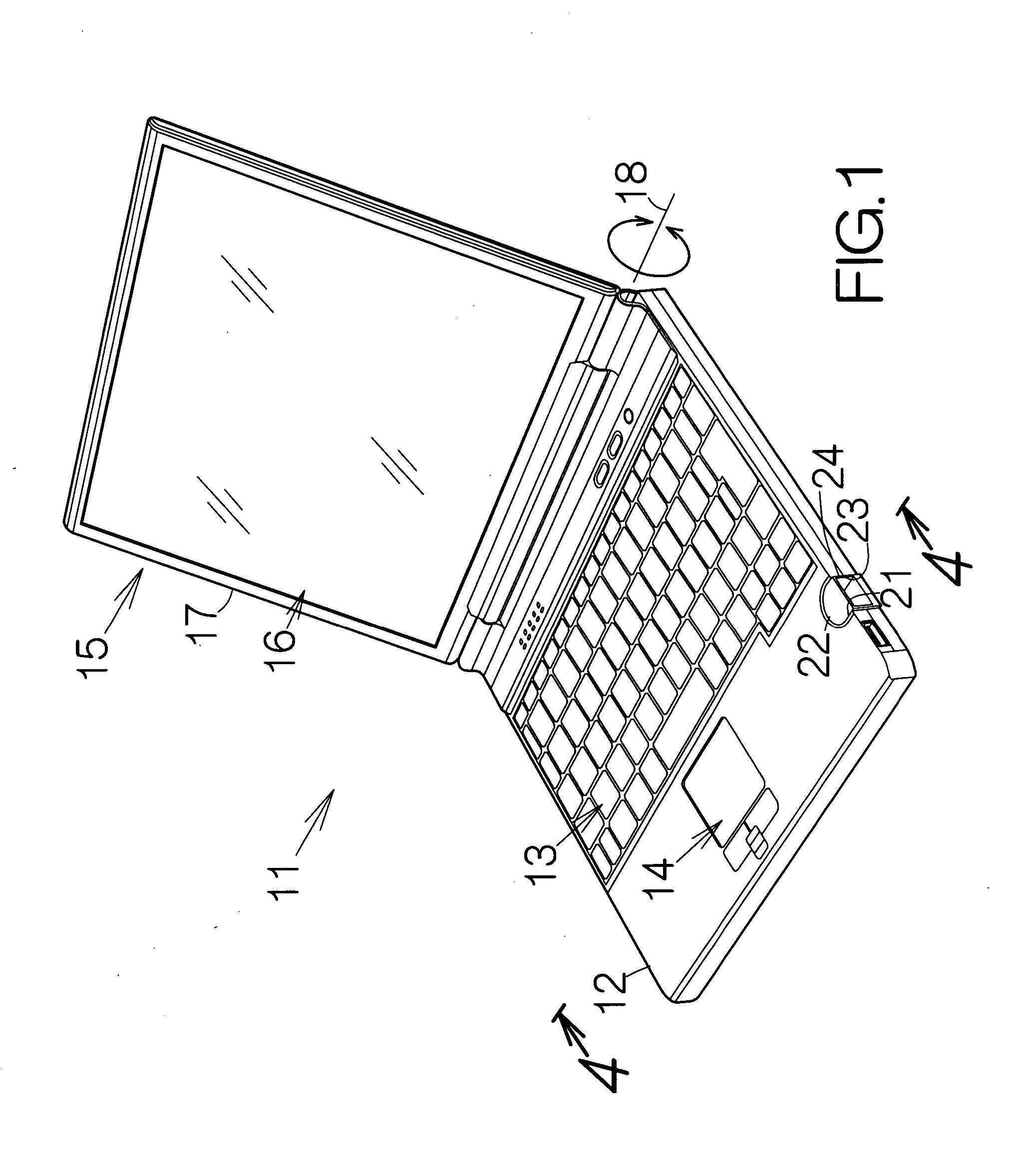

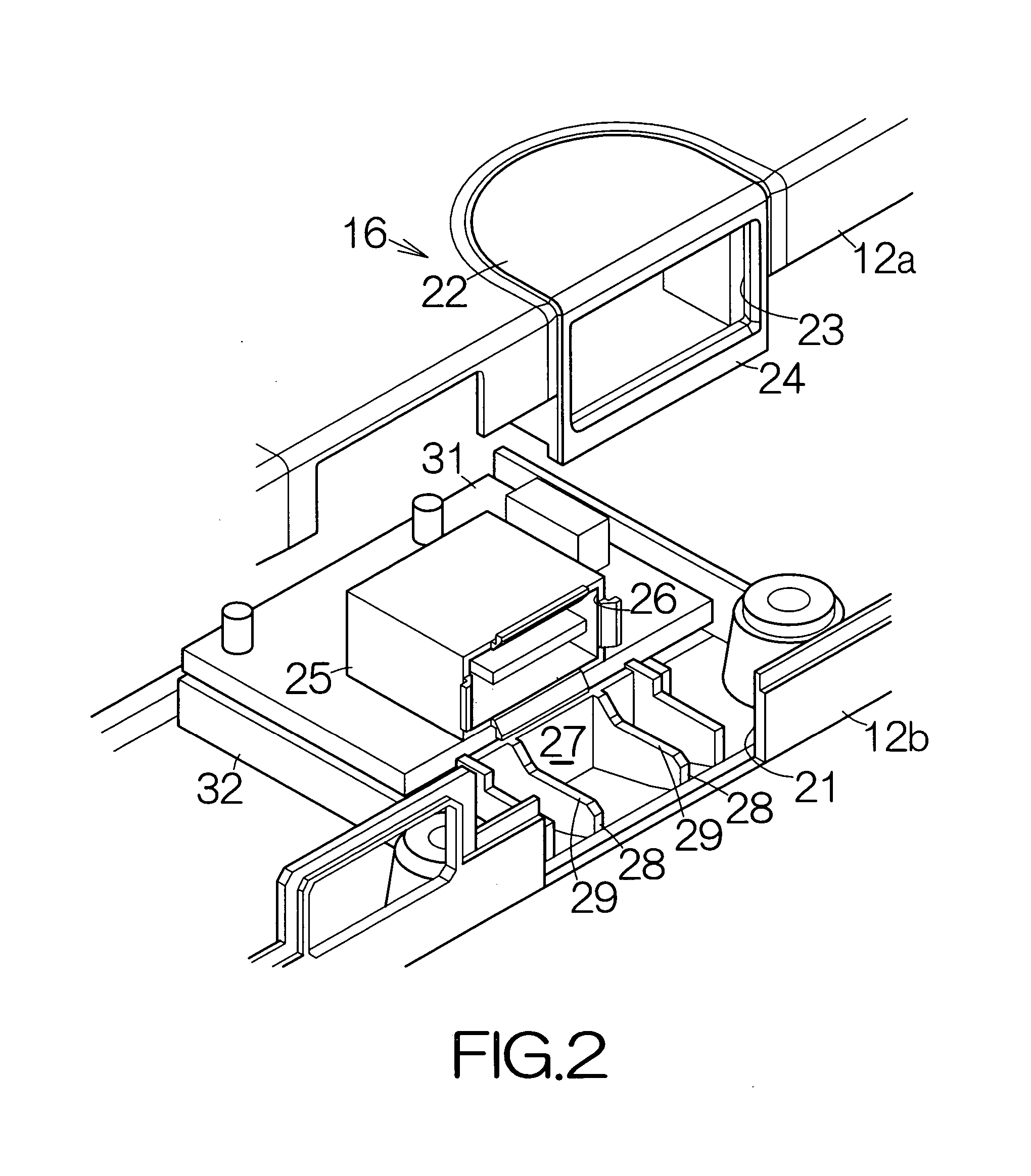

Electronic apparatus with connector of changeable attitude

InactiveUS7175443B2Improve shock resistanceSuppress generationIncorrect coupling preventionComputer periphery connectorsEngineeringPrinted circuit board

Owner:FUJITSU LTD

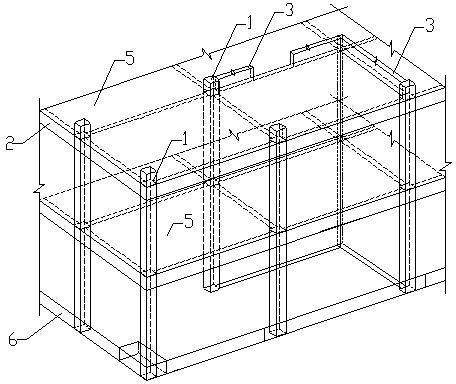

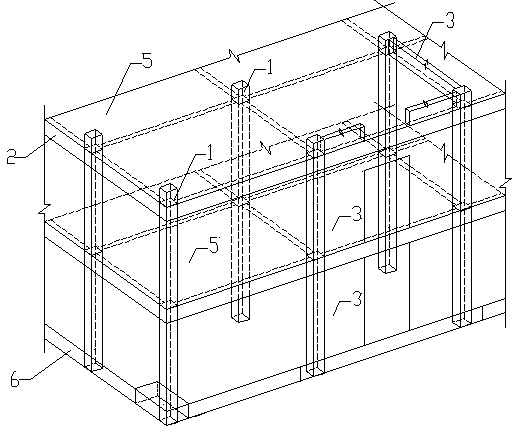

Shock-proof prefabricated steel tube shear wall mixed structural building

ActiveCN103388357ABolt-and-solder connections for easy connectionHigh compressive strengthWallsShock proofingFloor slabSteel columns

The invention relates to a shock-proof prefabricated steel tube shear wall mixed structural building which belongs to the field of buildings. The building is provided with a foundation, wherein the foundation is respectively connected with the lower ends of shear walls and steel columns; the upper ends of the shear walls and the steel columns are connected with steel beams; the shear walls and the steel beams are connected with composite floor slabs; single shear walls on a plane are combined and connected together to form a shear wall barrel body; a vertical upper section of shear walls is connected with a vertical lower section of shear walls; stair treads are connected with supporting beams; and self-bearing masoning filler walls and main body structural components are connected together. The integrity and vibration strength of the connected structural components are reliable, so that the building is safe, economic and durable; steel structural components and steel concrete combined components have good connecting performances, so that the working environment of the operating personnel is improved to the maximum extent, the construction period is shortened, and the construction cost is lowered; and moreover, the structural components of the building are made by steel materials with higher strength, so that a large span is realized, and the building is easy to reconstruct and update after a plurality of years and has high durability.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD

Device and method for detecting particles in air and wearable equipment comprising device

The invention discloses a device and a method for detecting particles in air and wearable equipment comprising the device. The device comprises an upper part, a lower part, at least one light emitting element and at least one light sensing element, wherein the upper part and the lower part are made of silicon base materials; a measurement chamber formed between the upper part and the lower part comprises side surfaces, an upper surface and a lower surface; the upper surface and the lower surface are parallel to each other; the side surfaces are inclined relative to the upper surface; each light emitting element is arranged in the measurement chamber and comprises a first side surface with an emitting port; the emitting port is used for emitting light which is parallel to the upper surface and faces the side surfaces; each light sensing element is positioned in the measurement chamber and is adjacent to a second side surface, opposite to the first side surface, of the corresponding light emitting element; light emitted by each light emitting element is scattered to the corresponding light sensing element by virtue of particles; each light sensing element is used for detecting a signal of light scattered to the corresponding light sensing element by virtue of particles to obtain a particle detection result.

Owner:北京洛可可科技有限公司

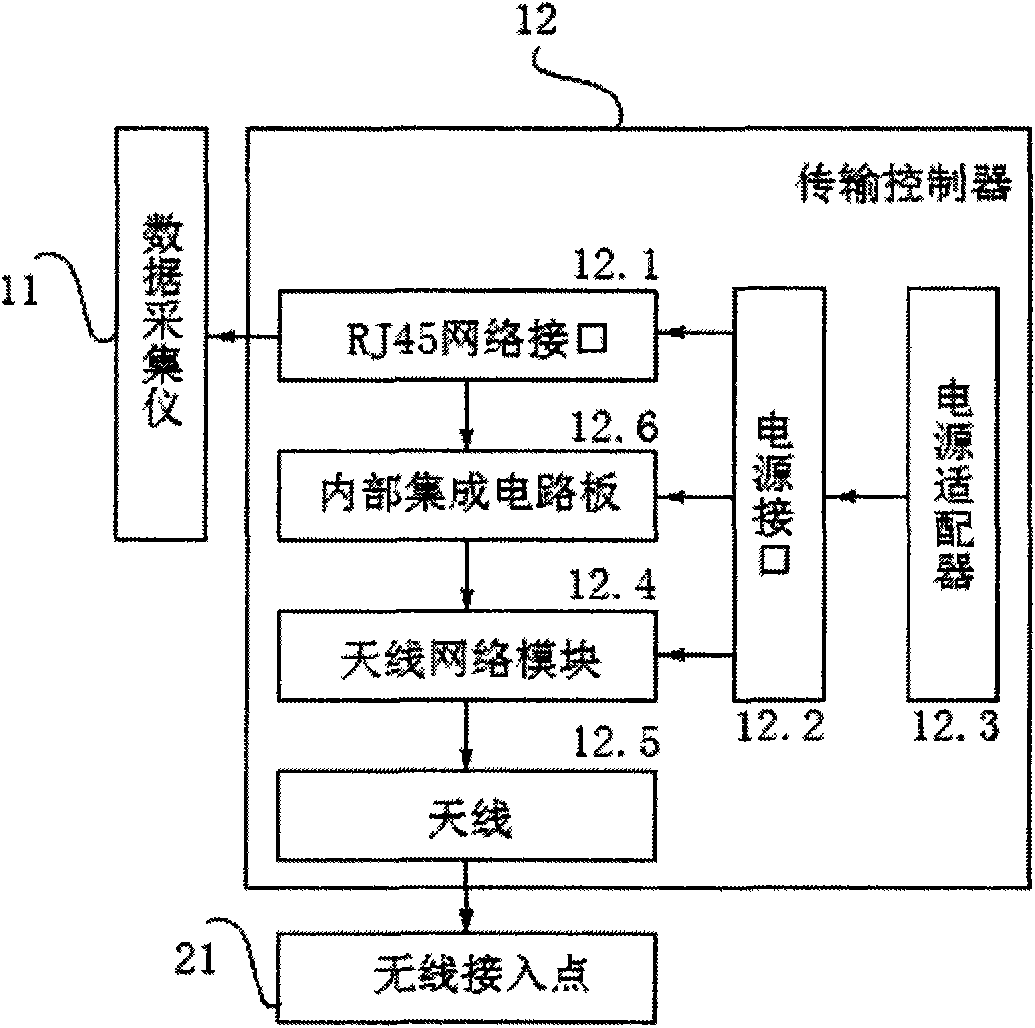

Geotechnical engineering field monitoring high-speed remote wireless transmission device and method thereof

InactiveCN101599212AFlexible networkingImprove scalabilityTransmission systemsWireless transmissionData acquisition

The invention discloses a geotechnical engineering field monitoring high-speed remote wireless transmission device and a method thereof, relating to the technology of high-speed remote wireless transmission; the device comprises a data acquisition and transmission control module (10), a high-speed remote wireless transmission module (20) and a data transmission reception control module (30) which are sequentially connected back and forth; the three functional modules are respectively formed by a data acquisition instrument (11), a transmission controller (12), a wireless access point (21), a wireless network bridge (22), a relay network bridge (23), a switch (31), a control terminal computer (32) and a remote transmission control software (33) which are connected back and forth. The device has ultra high transmission rate and ultra remote transmission distance, the networking is flexible, the expansibility is strong, the adaptability is strong, the data safety is high, therefore, the device and the method solve the difficult problems of remote real-time high-speed wireless transmission of geotechnical engineering monitoring data and realizes real-time high-speed remote monitoring of deformation of buildings in geotechnical engineering under a severe environment.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Building adopting aseismatic precasted reinforcing steel truss shear wall composite structure

ActiveCN103397696ABolt-and-solder connections for easy connectionHigh compressive strengthStrutsWallsFloor slabSteel frame

The invention relates to a building adopting an aseismatic precasted reinforcing steel truss shear wall composite structure, and belongs to the architectural field. The building adopts the scheme that reinforcing steel truss concrete shear walls provided with steel frames and composite floor slabs with prestressed concrete sheets are precasted; a foundation is connected with steel columns and the shear walls; the steel columns are connected with steel beams; the steel beams are connected with the composite floor slabs and the shear walls; the shear walls are connected with the composite floor slabs; an upper section of each shear wall is connected with the lower section of each shear wall; the steel columns are connected with the shear walls; the steel beams are combined and connected with the shear walls. According to the invention, the safety, economy and durability of the building can be ensured in virtue of the reliable integrity and seismic resistance of the connection between the structural elements; the steel structural elements and the steel concrete composite members have favorable connection performance, the labor environment for operators is improved, the construction period is shorted and the construction cost is reduced furthest; besides, the large span can be realized as the building structural elements are made of steel materials with higher strength, so that the building is easy to refit and renovate after several years, and the high durability is realized.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD

Wireless self-networking group detection based mudslide early warning sensing device, system and method

InactiveCN103646514AReliable forecast in advanceNo post-wiring requiredAlarmsEarly warning systemSocial benefits

The invention discloses a wireless self-networking group detection based mudslide early warning sensing device, system and method. The system comprises an RTU (remote terminal unit) and multiple mudslide monitoring early warning sensing devices, wherein each mudslide monitoring early warning sensing device is taken as a MESH network node, the RTU has a concentrator for data collection integrated therein, and the RTU is in wireless communication connection with all the mudslide monitoring early warning sensing devices through the concentrator. The wireless self-networking group detection based mudslide early warning sensing device, system and method, based on multiple sensors, cooperatively realize mudslide monitoring early warning and have remarkable social benefits.

Owner:湖南华中灾害预警研究开发有限公司

FCC waste catalyst-coal ash ceramsite and production method thereof

ActiveCN107459339ALow bulk densityHigh bulk densityCeramic materials productionClaywaresPetrochemicalEngineering

The invention discloses a method for producing ceramsite from an FCC waste catalyst. The main raw materials used in the method are the FCC waste catalyst, coal ash and petrochemical alkali waste neutralizing liquid. The method comprises the steps of treating the FCC waste catalyst with liquid alkali, uniformly mixing the treated FCC waste catalyst with coal ash, finally adding a proper amount of the petrochemical alkali waste neutralizing liquid in proportion, and carrying out processes of balling, drying and calcination, so as to obtain the ceramsite. The ceramsite is produced from waste of thermal power plants and petrochemical engineering enterprises, so that the waste treatment problem of the relevant enterprises is solved, and meanwhile, the ceramsite with reliable quality and high strength can be obtained.

Owner:山东京泰再生资源有限公司

Electronic apparatus with connector of changeable attitude

InactiveUS20060019513A1Improve shock resistanceSuppress generationIncorrect coupling preventionComputer periphery connectorsPrinted circuit boardElectronic equipment

A connector is mounted on a printed circuit board in an enclosure. A member is interposed between the enclosure and the printed circuit board so as to hold the printed circuit board on the enclosure. The member allows change in the attitude of the printed circuit board relative to the enclosure. When the connector is coupled to the other connector, the connector receives a force from the other connector in the electronic apparatus. The force induces the change in the attitude of the connector and the printed circuit board. The change in the attitude in this manner enables consumption of the energy of the force within the member. Generation of stress can be suppressed in a bonding member such as a solder coupling the connector with the printed circuit board, for example. Generation of cracks can be prevented in the solder. Shockproof is improved for the connector.

Owner:FUJITSU LTD

EVA (Ethylene vinyl-acetate) film and manufacturing method thereof

ActiveCN103205212AHigh transparencyGood transparencyFilm/foil adhesivesSynthetic resin layered productsPolyolefinSilane coupling

The invention provides an EVA (Ethylene vinyl-acetate) film used for laminated glass which is prepared from raw materials in percentage by weight as follows: 69-89.5% of ethylene-vinyl acetate copolymer, 10-30% of polyolefin plastomer, 0.2-0.4% of a silane coupling agent, 0.2-0.5% of an optical stabilizer and 0.1-0.4% of an antioxidant. The content of vinyl acetate in the ethylene-vinyl acetate copolymer is 32-33%. The EVA film consists of an upper layer, a middle layer and a lower layer, wherein the upper and lower layers are prepared from the ethylene-vinyl acetate copolymer, the silane coupling agent, the optical stabilizer and the antioxidant. The middle layer is prepared from the polyolefin plastomer. The EVA film provided by the invention is not only high in strength and transparency, but also good in sound insulating and shockproof performance. The invention further provides a preparation method of the EVA film, and the process is simple and easy to control.

Owner:GUANGDONG ANDELI NEW MATERIALS CO LTD

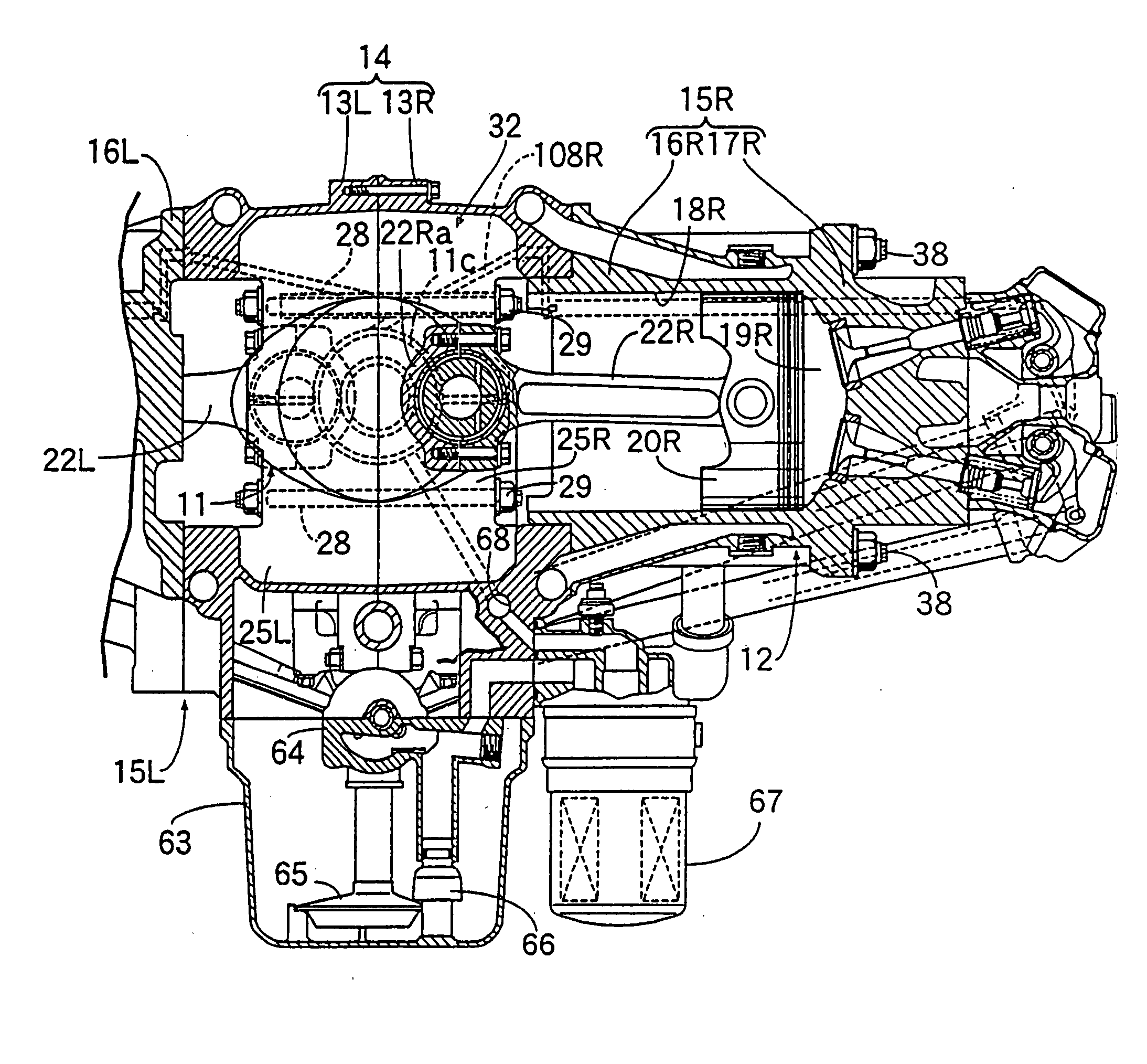

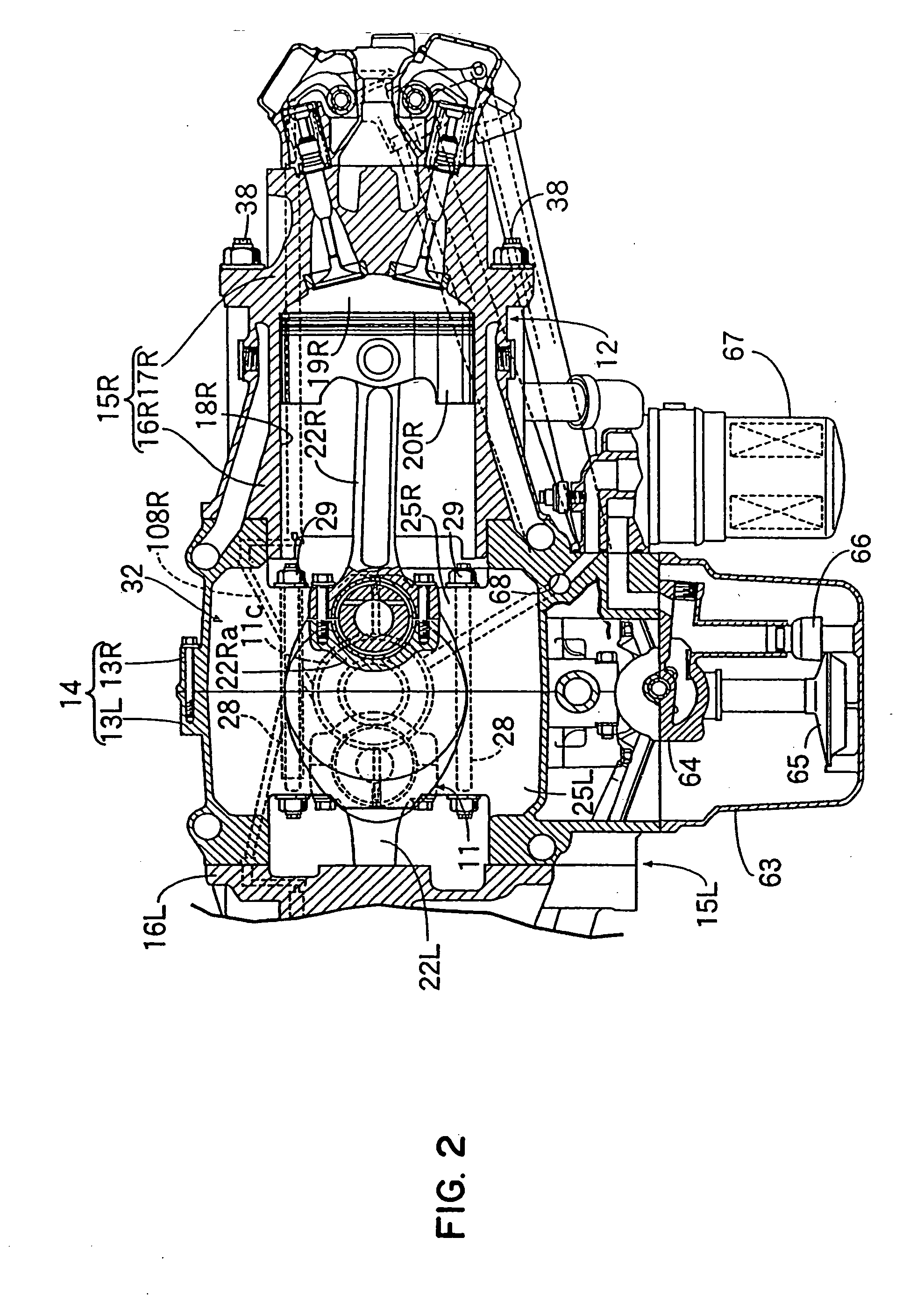

Vibration prevention structure in engine

InactiveUS20060042585A1Improve shock resistanceEasy to changeRotating vibration suppressionCasingsPropellerCrankcase

In an engine having a propeller mounted on one end of a crankshaft, the vibrations on an end portion of the crankshaft opposite to the propeller are effectively suppressed with a pair of vibration pendulum type weights arranged outside the crankcase whereby it is possible to easily perform a change of the vibration suppression structure in conformity with the property of the propeller.

Owner:HONDA MOTOR CO LTD

Parallel-flow evaporator for automobile air conditioner

InactiveCN101149195AImprove heat transfer efficiencyImprove shock resistanceEvaporators/condensersHeat transfer efficiencyEvaporator

This invention relates to a parallel evaporator for vehicle air conditioner. It includes integral type fin flat-tube, fin, multi-holes flat-tube, upper collecting pipe, lower collecting pipe, baffle, inlet pipe and outlet opening. Several parallel and communicated integral type fin flat-tubes are composed of multi-holes flat-tubes and fins. The multi-holes flat-tube and fin are emerged together. The superior end of flat-tube connects to the upper collecting pipe. It inferior end connects to the lower collecting pipe. The upper collecting pipe is divided into fluid inlet-outlet cavity and fluid turning cavity by inner baffle. The fluid inlet-outlet cavity is divided into fluid inlet and outlet cavities by inner baffle. The right side of fluid inlet cavity has inlet pipe. The left side of fluid outlet cavity has outlet pipe. The lower collecting pipe is divided into left and right fluid turning cavities by inner baffle. This invention increases the integral heat transferring efficiency and anti-shock capacity of the parallel fluid evaporator. It also reduces the output air temperature difference of each point at the air output side.

Owner:上海精励汽车科技有限公司

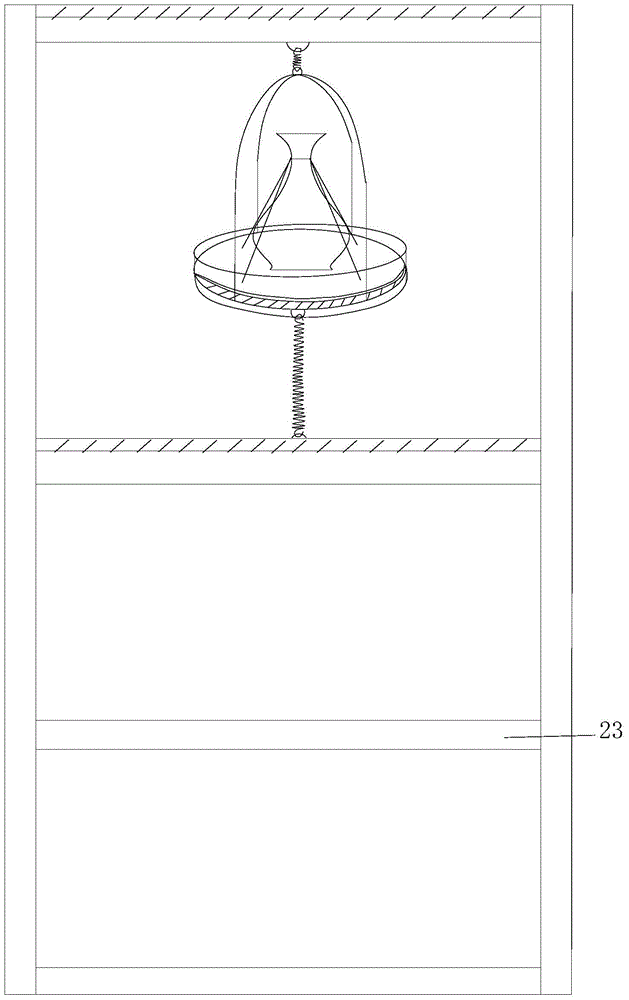

Shockproof suspension shock absorption control method and device for museum cultural relic system

ActiveCN104825015AGuaranteed stiffness and stabilityEffective vibration controlShow cabinetsShow shelvesEngineeringResponse spectrum

The invention discloses a shockproof suspension shock absorption control method and a device for a museum cultural relic system. Compared with traditional shockproof measures such as improvement of a section of a structural member, improvement of a reinforcement ratio so as to enhance the shockproof ability and additional arrangement of a shock isolation table device, while the shock isolation and shock absorption control cost is not obviously increased and the shockproof ability is effectively improved, time-history analysis and response spectrum analysis calculation are carried out on a museum main body structure-cultural relics integrated system, the earthquake acting force of the museum cultural relic system can be effectively controlled, and huge expenditure is reduced; and as the control method adopted by the system is easy to execute, the cost of the device is comparatively low, large-area promotion and execution of the museum cultural relics are facilitated, damages on the museum cultural relic system by the high-intensity earthquake action can be effectively reduced, and losses are reduced as much as possible.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

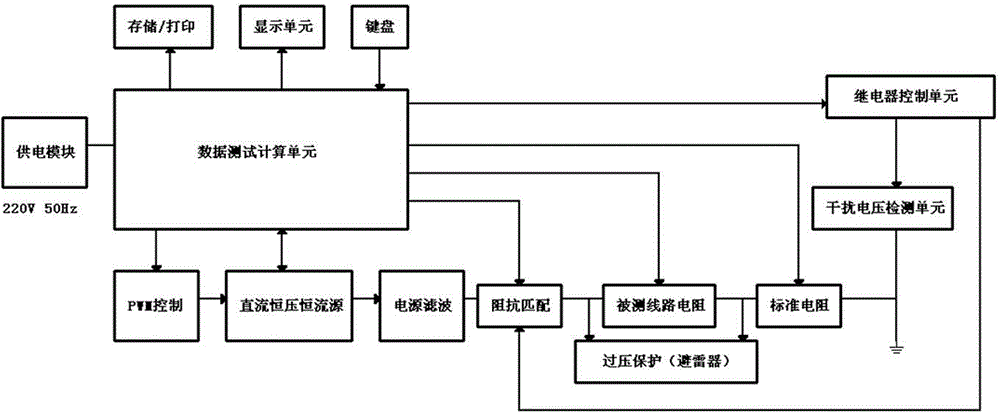

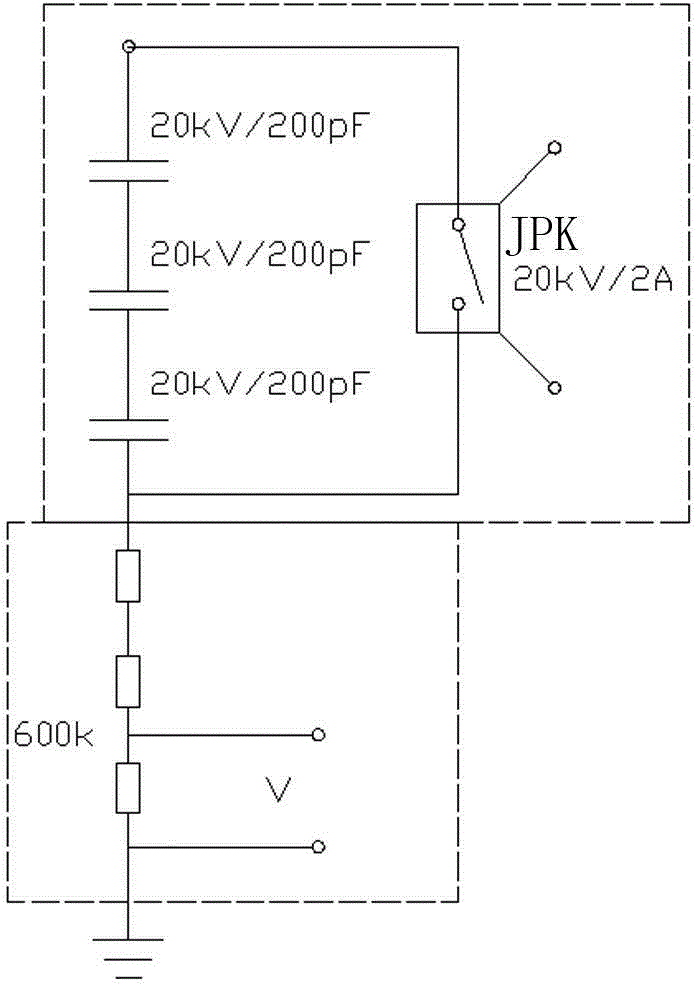

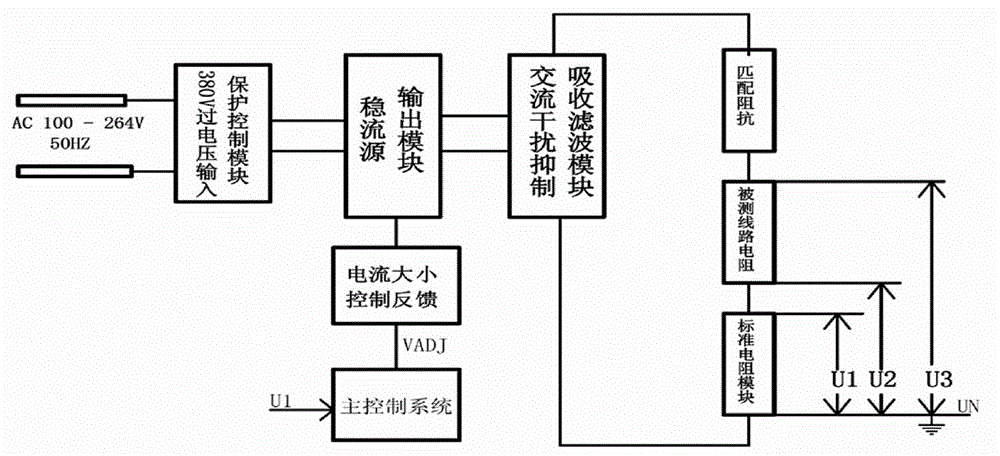

High tension transmission line comprehensive tester and testing method

The invention relates to a high tension transmission line comprehensive tester which is structurally characterized in that a data testing calculation unit is connected with a power supply module, a pulse width modulation (PWM) control unit, a direct current constant voltage constant current source, an impedance matching unit, a standard resistor, a measured line resistor, a relay control unit, a storage and printing unit, a display unit and a keyboard. The PWM control unit, the direct current constant voltage constant current source, a power supply filtering unit, the impedance matching unit, the measured line resistor and a standard resistor are sequentially connected. The relay control unit is connected with an interference voltage detection unit and the impedance matching unit. The resistance-capacitance voltage dividing principle is utilized to measure the static induction voltage under 20kV, a disperse Fourier development technology is adopted to test line loop resistance, digital filtering is utilized to remove alternating current components, only direct current components are measured, and direct current voltage of the line can be still measured accurately after alternating current is overlapped. The tester provides accurate data for fixed value setting of a line automatic device and ensures that a power system runs safely and reliably.

Owner:STATE GRID CORP OF CHINA +1

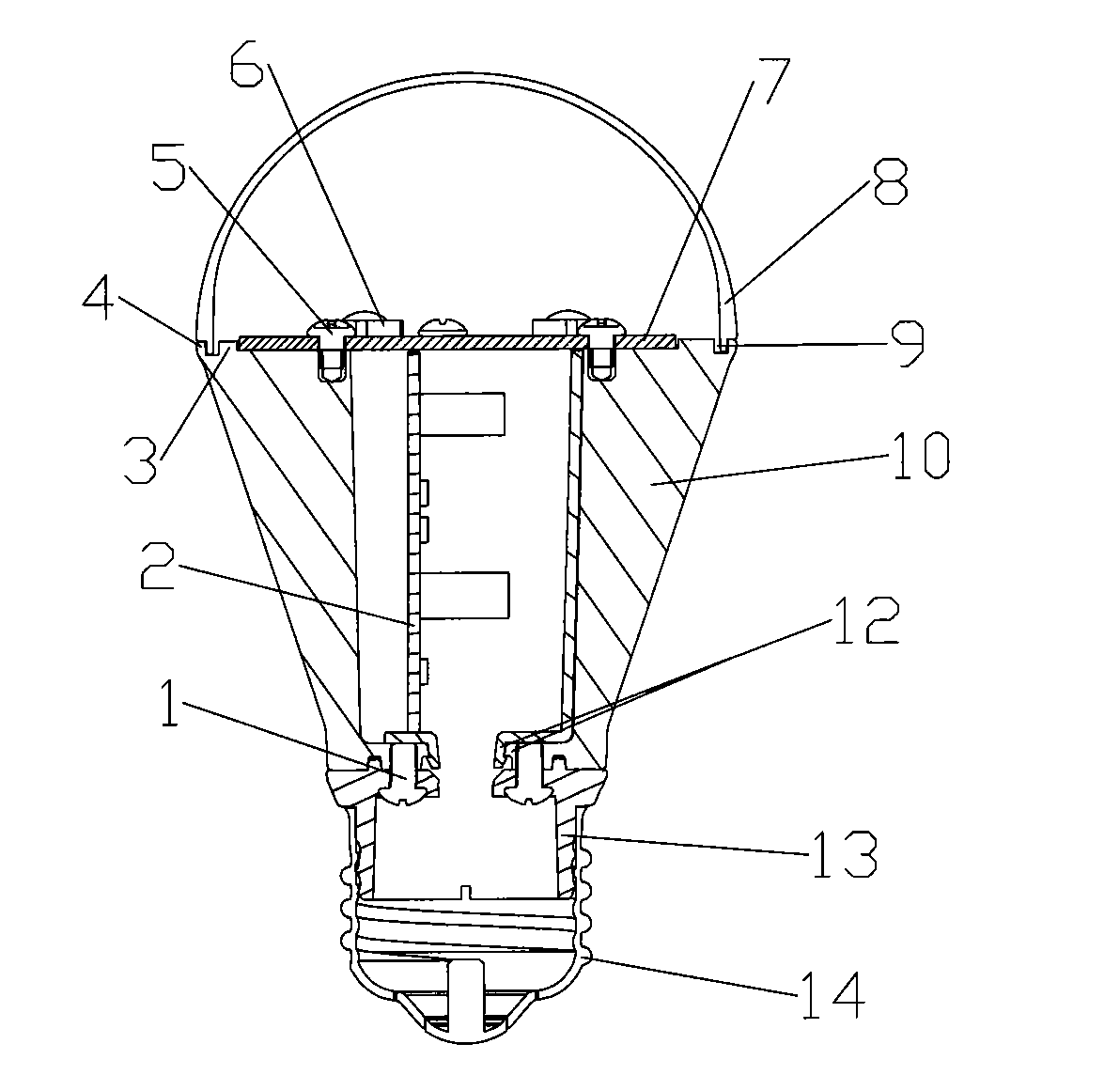

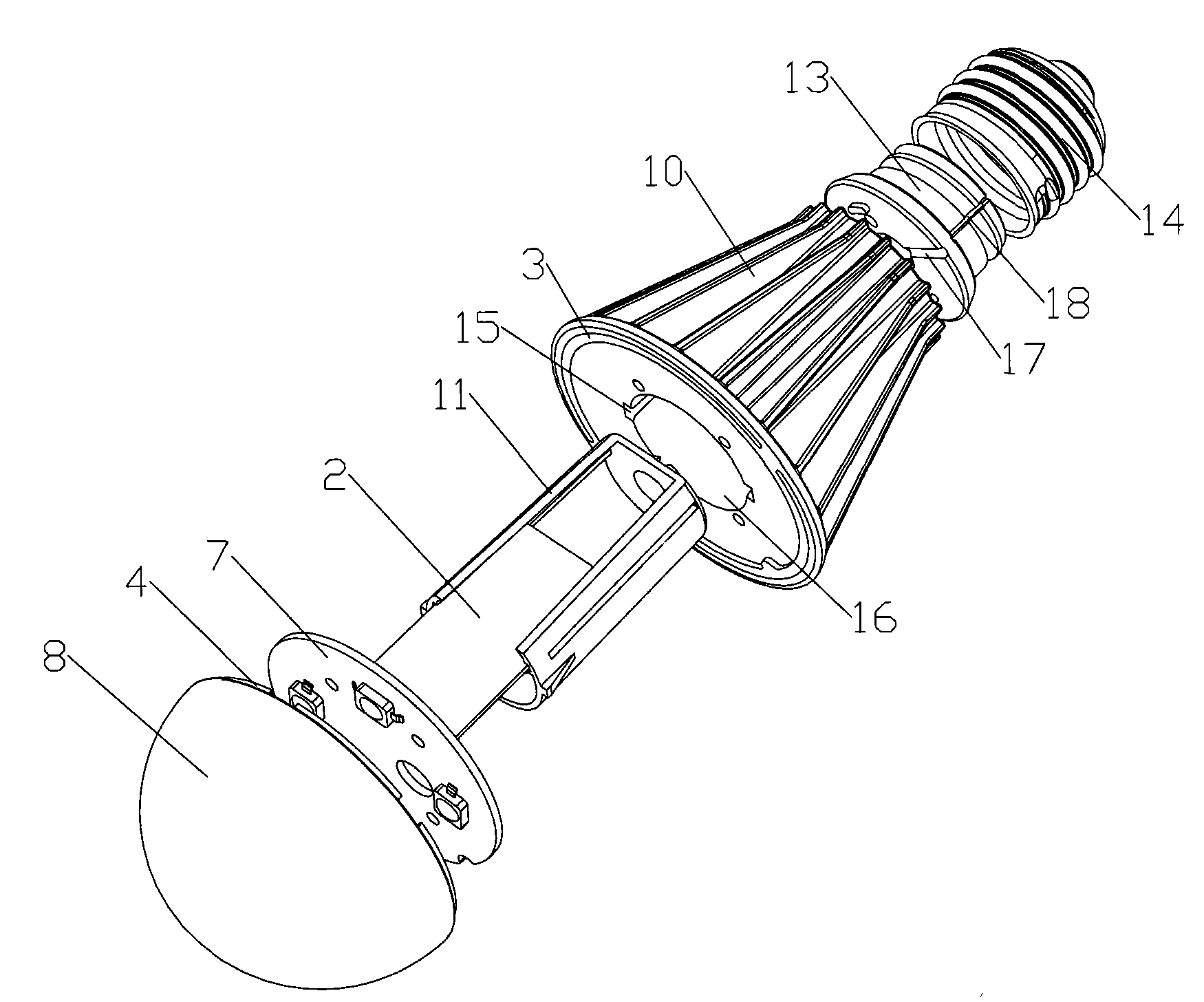

LED bulb

InactiveCN102003627ASimple structureAvoid leakage hazardsPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention discloses a light emitting diode (LED) bulb and aims to provide the LED bulb which has high anti-shock performance and high radiating performance and is convenient to install and maintain. The LED bulb of the invention comprises a lamp shade, a radiator, an aluminum base, an LED, a circuit board, a connecting piece and a lamp holder, wherein the lamp shade is connected with the radiator; the radiator is connected with the connecting piece; the connecting piece is connected with the lamp holder; the LED is welded on the aluminum base; a cavity is reserved in the radiator; the opening of the cavity is upward; a sheath is arranged in the cavity of the radiator; hooks are arranged at the positions corresponding to the lower end of the sheath and the lower end of the radiator so as to form a fastener structure; and the sheath and the radiator can be connected with each other through the fastener structure. The LED bulb has high anti-shocking performance and radiating performance, is convenient to install and maintain, and is a regeneration product of the convention LED bulb.

Owner:TIANJIN JINYA ELECTRONICS

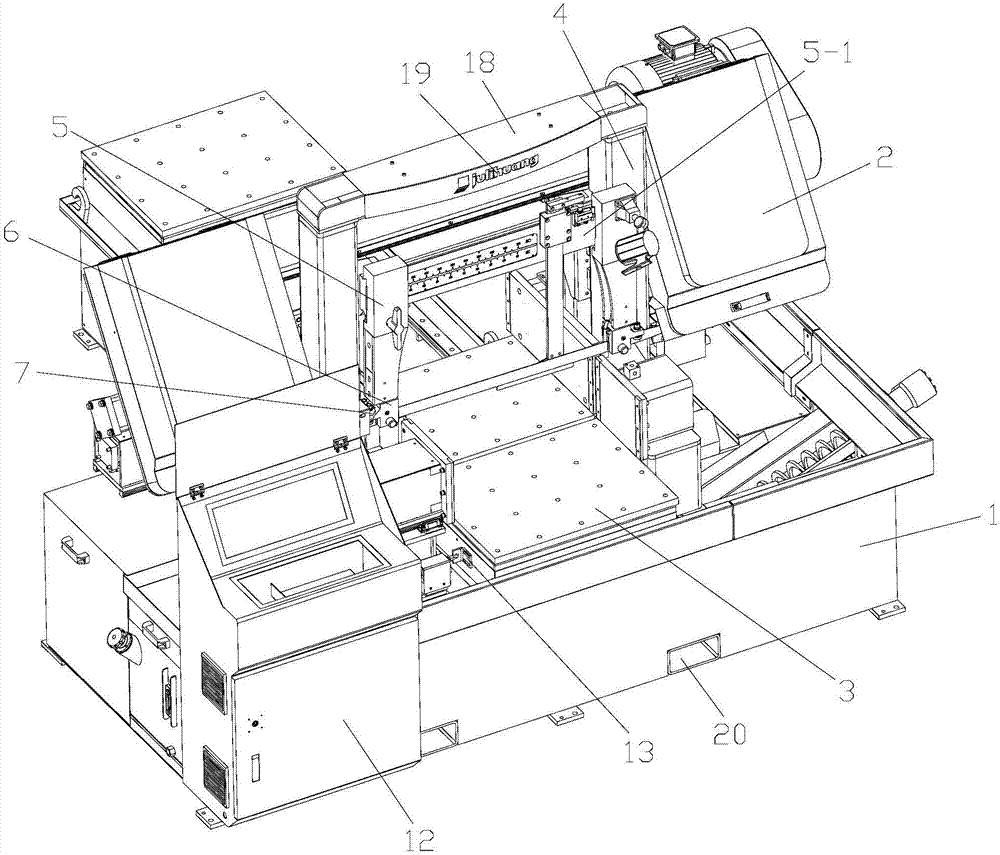

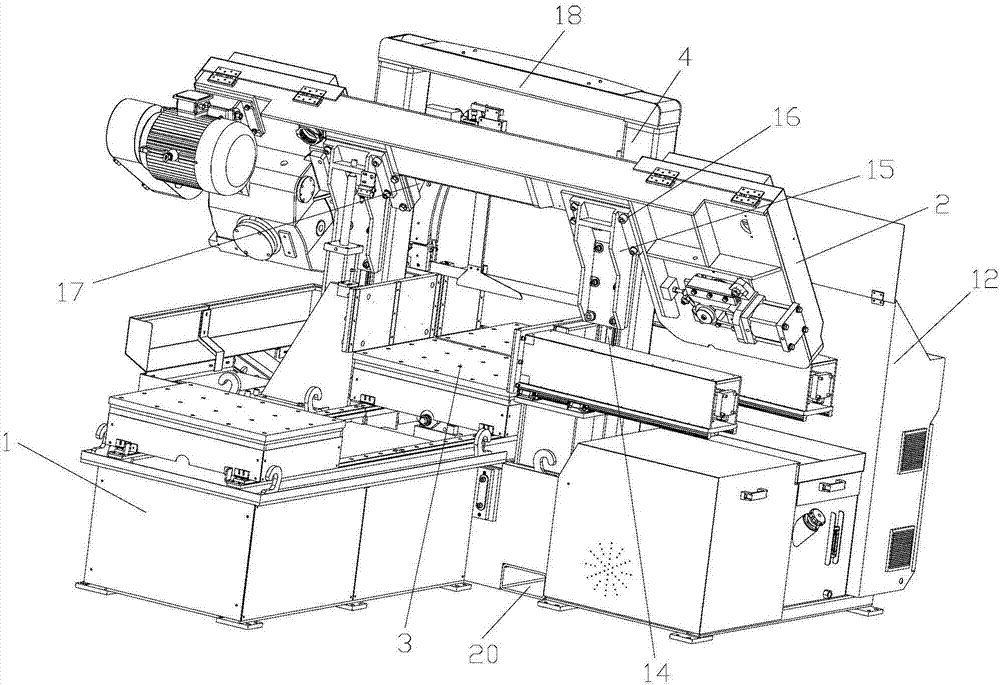

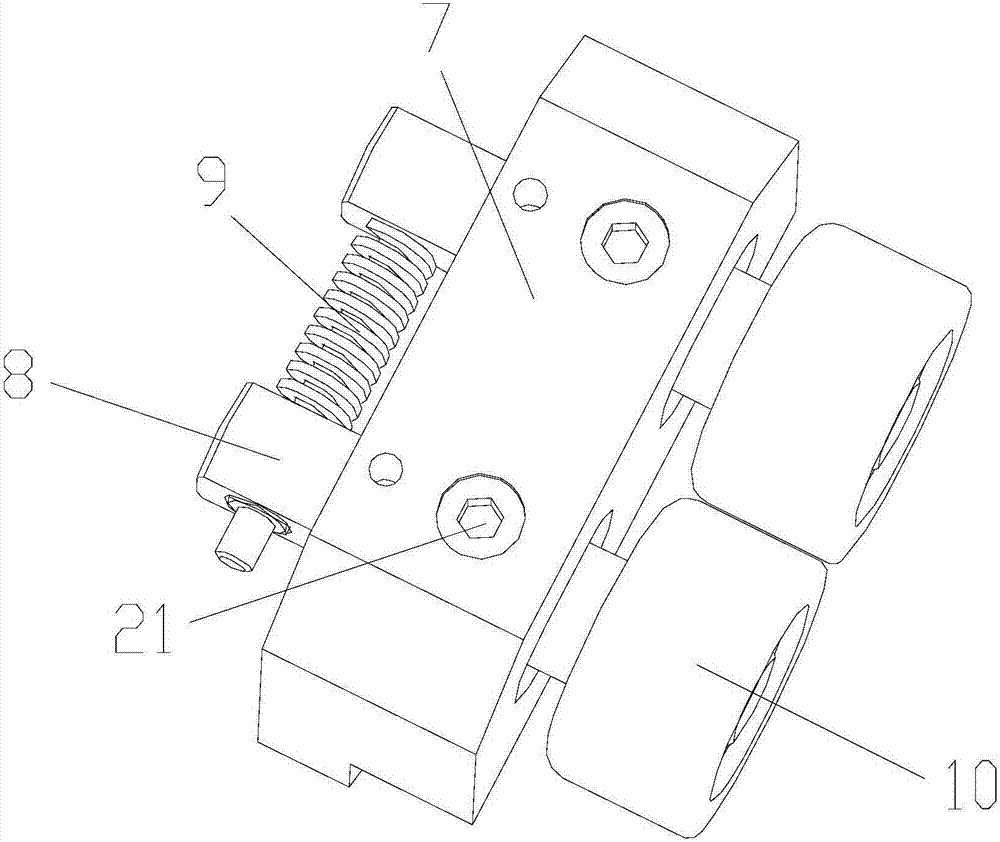

Band sawing machine

ActiveCN107096959AExtended service lifeGuaranteed accuracyMetal sawing devicesMetal sawing accessoriesWorkbench

A bank sawing machine comprises a machine body, wherein a saw frame is arranged on the machine body; a workbench is arranged in the saw frame; two vertical columns are arranged in the saw frame; guiding arms are arranged between the two vertical columns; a guiding seat is mounted on each guiding arm; a shockproof seat is mounted on each guiding seat; two swinging shafts are arranged in each shockproof seat; a spring is arranged between the front parts of every two swinging shafts; two rolling wheels are connected onto the rear parts of every two swinging shafts; and a saw belt clearance is left between every two rolling wheels. The bank sawing machine provided by the invention has the beneficial effects that the shock of a saw belt can be reduced and even eliminated when the bank sawing machine is in use; the shockproof effect is obvious; the service life of the saw belt is prolonged; the material section precision is improved; and the saw cutting noise is reduced.

Owner:浙江锯力煌工业科技股份有限公司

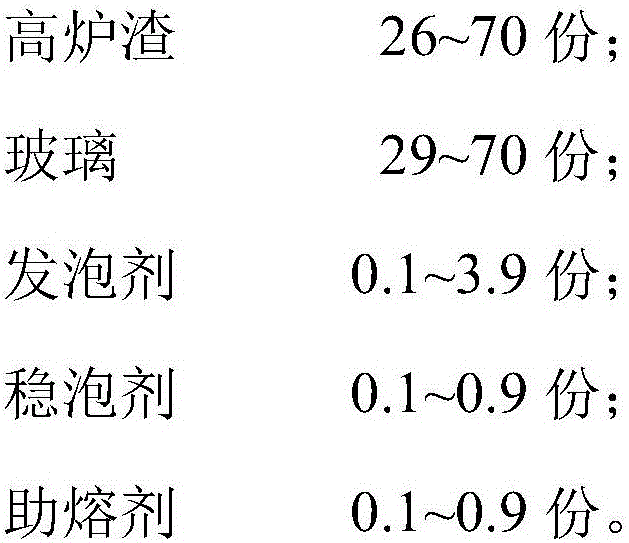

Method for producing foamed glass by melting blast furnace slag

The invention discloses a method for producing foamed glass by melting blast furnace slag. The method comprises the following steps: using the blast furnace slag as a main raw material to produce the foamed glass, wherein the blast furnace slag is metallurgical furnace slag produced online in the ironmaking process of a blast furnace; after acquiring the blast furnace slag from a slag discharge opening of the blast furnace, directly mixing with other raw materials in a high-temperature molten state; finally preparing the foamed glass. The method uses melting blast furnace slag with a high content of glass body as the main raw material, makes full use of residual heat of the melting blast furnace slag and secondary resources, and achieves purposes of energy conservation and environmental friendliness.

Owner:武汉钢铁有限公司

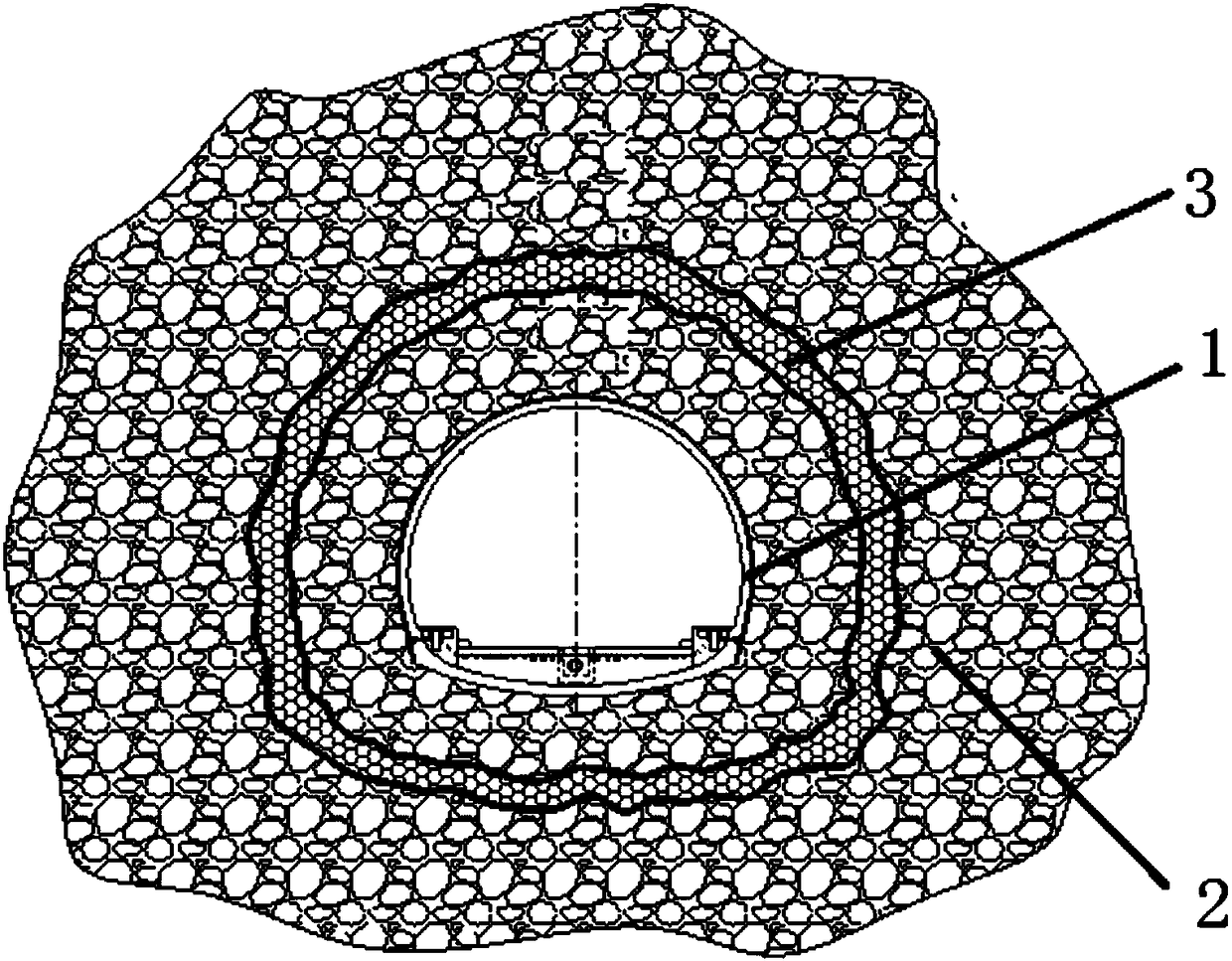

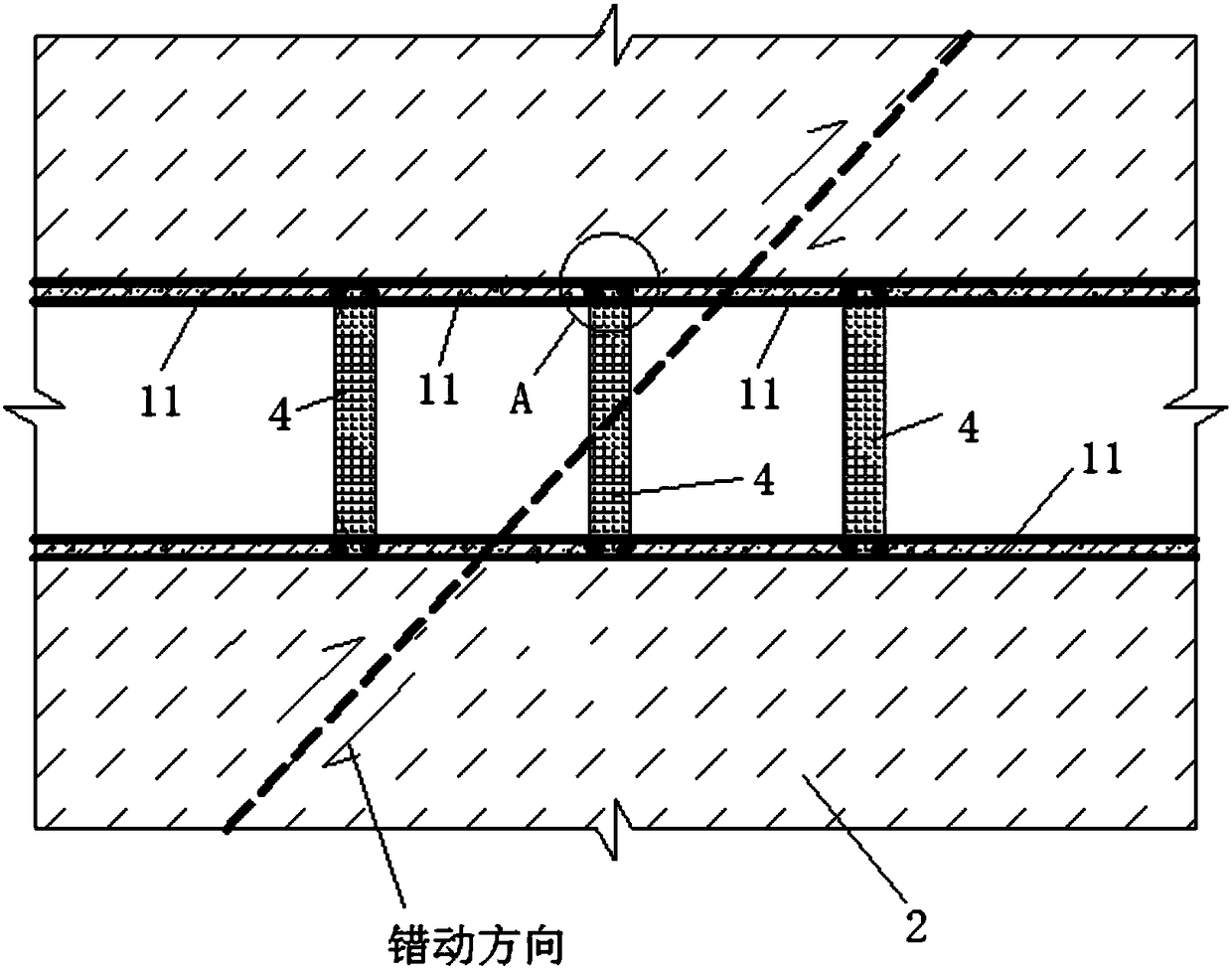

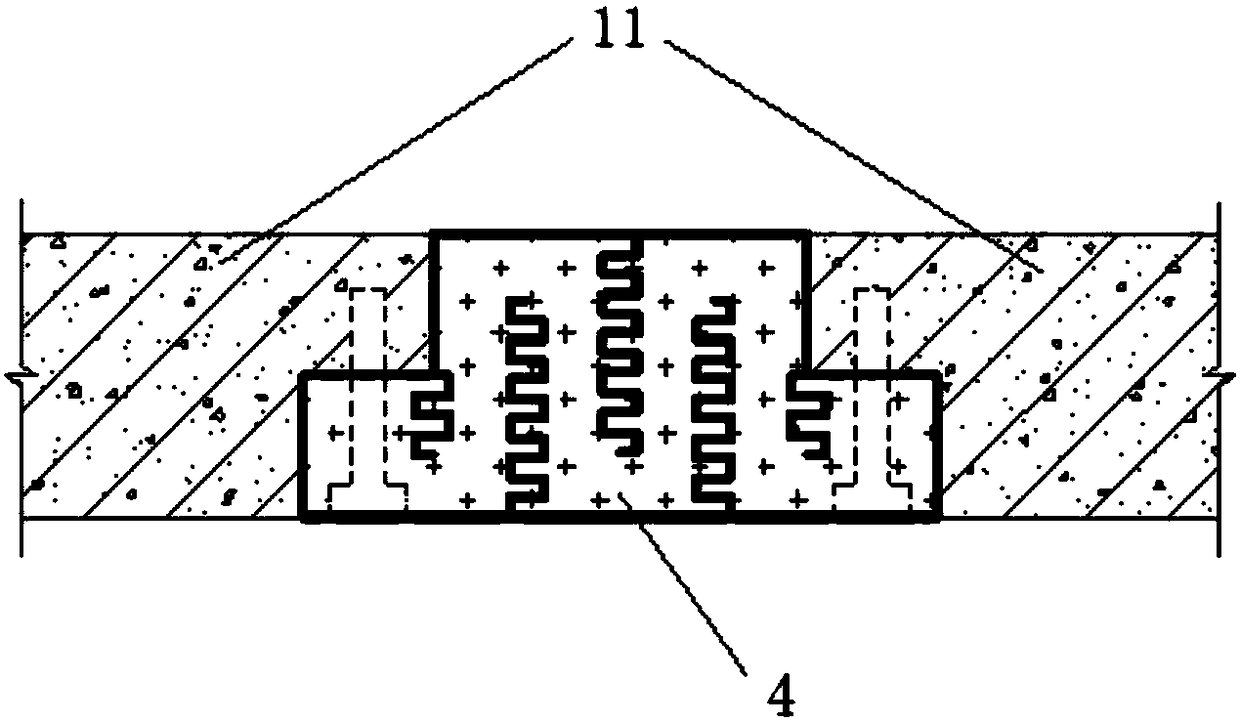

Active fault spanning aseismic structure and construction method thereof

PendingCN108547633AImprove securityReduce vertical displacementUnderground chambersTunnel liningEarthquake resistanceActive fault

The invention relates to an active fault spanning aseismic structure and a construction method thereof. A damping ring is arranged in the surrounding rock of the lining structure at a fault fracture zone, the lining structure is located in the inner round of the damping ring, and a certain spacing distance exists between the lining structure and the damping ring; left, right and upper sides of thetunnel cross section at the fault fracture zone are expanded relative to the tunnel cross section of the stable section; the lining structure penetrating through the fault fracture zone is of a vertical segmental structure, and two adjacent lining segments are connected through a folded flexible joint in the deformation joint. The damping ring is adopted to weaken the earthquake action, and partsof seismic wave energy is absorbed to consume and reduce the earthquake energy; the whole lining structure is converted to the lining segment from, flexible chaining connection capable of bearing large deformability between the two adjacent lining segments is adopted, so that the staggered displacement is mainly absorbed by the flexible chaining connection, and the earthquake resistance and damping performance of the tunnel structure is improved. According to the structure, earthquake resistance and diastrophism resistance are combined, and the whole safety of a tunnel can be greatly improved.

Owner:SOUTHWEST JIAOTONG UNIV

Quakeproof silencing cotton and preparation method thereof

InactiveCN104228238AThe overall thickness is thinStrong hardnessLamination ancillary operationsSynthetic resin layered productsEnvironmental resistancePolyester

The invention provides quakeproof silencing cotton and a preparation method thereof. The quakeproof silencing cotton comprises an upper non-woven fabric layer, a double-component cotton layer and a lower non-woven fabric layer which are sequentially arranged from top to bottom and are adhered to one another by polyene glue, wherein the double-component cotton layer is prepared from polypropylene fibers and vacuum polyester staple fibers, and the mass ratio of the polypropylene fibers to the vacuum polyester staple fibers is 6 to 4. The produced double-component cotton is thin and has non-toxic and environmental-friendly effects; furthermore, the silencing, heat-insulation and quakeproof effects of the cotton are enhanced; meanwhile, the upper and lower surfaces of the cooled double-component cotton is adhered to the non-woven fabric layers by the polyene glue, and the adhered product is subjected to hot roller pressing molding, so that the silencing cotton is high in rigidity, low in thickness and high in durability.

Owner:HUBEI TIANYUN NOISE REDUCTION & ANTIVIBRATION NEW MATERIAL

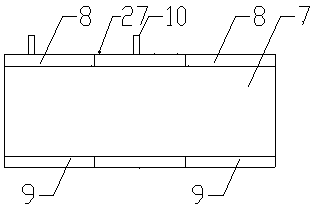

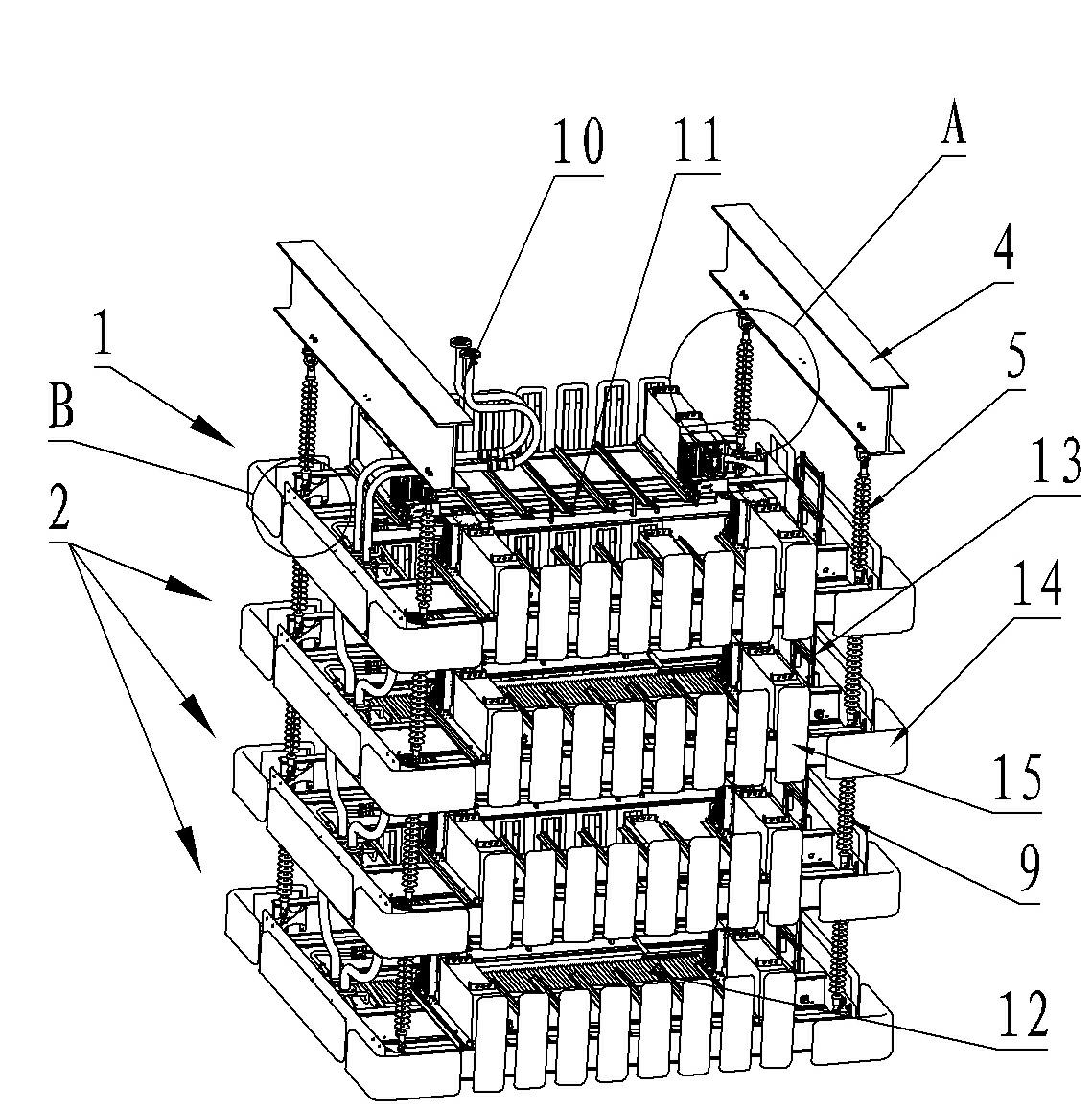

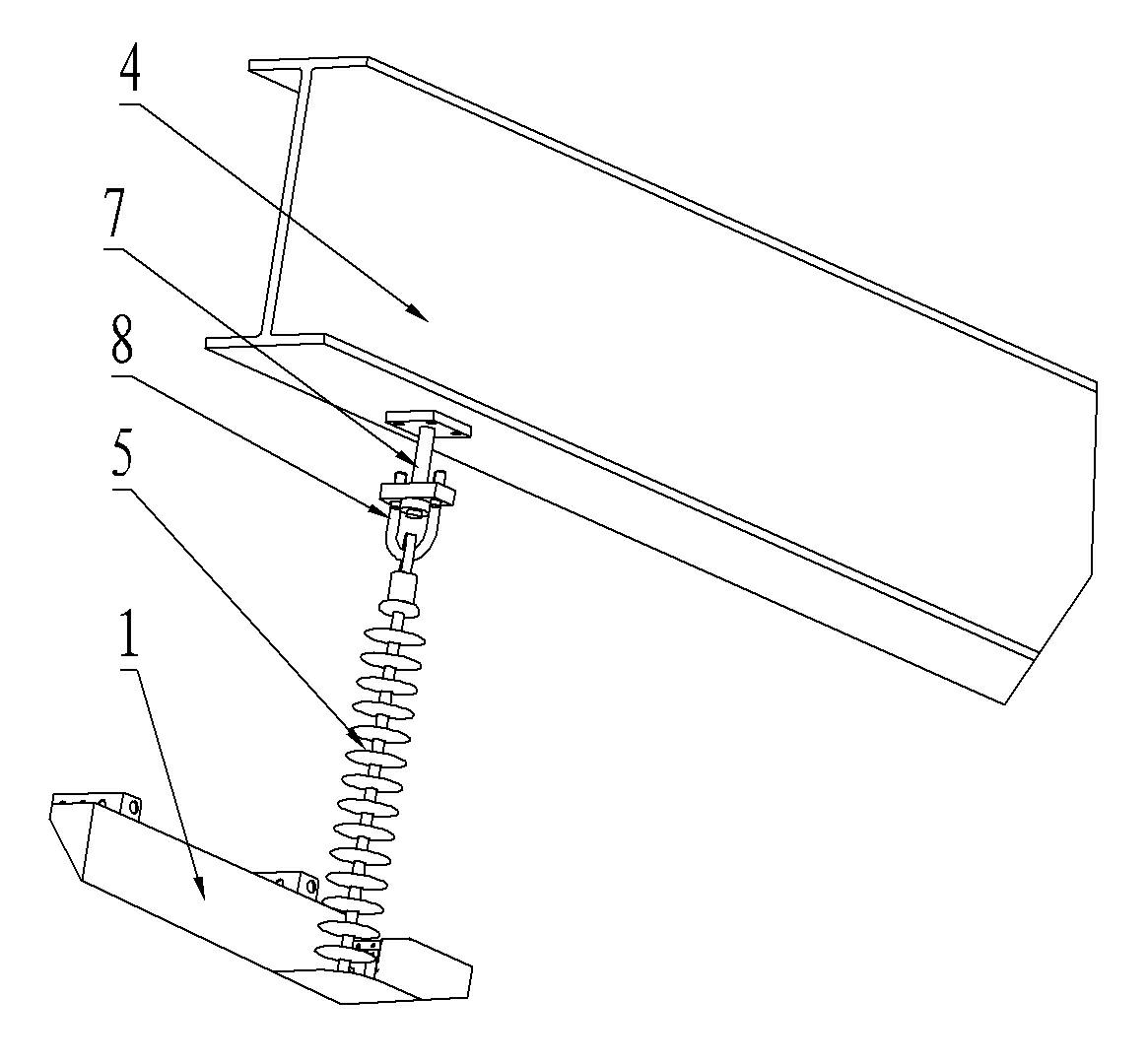

Flexible direct current transmission suspended type valve tower, assembly method and suspension connection structure thereof

InactiveCN102611097AImprove shock resistanceConvenience layersDc network circuit arrangementsElectrical apparatus contructional detailsEngineeringMechanical engineering

The invention relates to a flexible direct current transmission suspended type valve tower, an assembly method and a suspension connection structure thereof. According to the invention, a top layer valve group is suspended on a steel beam of a building through the suspension connection structure; the suspension connection structures are connected between the top layer valve group and an adjacent lower valve group and between every two adjacent lower valve groups; the suspension connection structure comprises an insulator, a U-shaped bolt fastened with one end of the insulator, and an 8-shaped ring hinged with the other end of the insulator, so that all the lower layer valve groups can be sequentially suspended below the top layer valve group, the valve tower forms an integral suspended structure, and the overall shock resistance of the valve tower is further improved; and as the valve tower ensures that all layers of the valve groups are suspended below the steel beam of the building through the 8-shaped rings, the external insulators and the U-shaped bolts, the valve tower can be conveniently and rapidly assembled on site, and the work efficiency of valve tower assembly is improved.

Owner:XJ ELECTRIC +1

Polycrystalline silicon battery pack

InactiveCN104465833AHigh strengthImproves UV resistancePhotovoltaic energy generationSemiconductor devicesUltraviolet lightsEngineering

The invention discloses a polycrystalline silicon battery pack. The polycrystalline silicon battery pack is formed by sequentially stacking first tempered glass, a first glue film, a polycrystalline silicon battery string, a second glue film, a reflecting plate, a third glue film and second tempered glass from top to bottom through a lamination technology, a nanometer titania film layer is arranged on the upper surface of the first tempered glass in a thermocompression bonding mode, a uvioresistant coating is arranged on the lower surface of the first tempered glass in a thermocompression bonding mode, and an elastic rubber layer is arranged on the upper surface of the second tempered glass in a thermocompression bonding mode. In this way, the polycrystalline silicon battery pack has good strength, ultraviolet light resisting performance and vibration resisting performance, the attenuation phenomenon can be effectively delayed, and the service life is long.

Owner:CHANGSHU GAOJIA ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com