Parallel-flow evaporator for automobile air conditioner

An automotive air conditioner and parallel flow technology, which is applied to evaporators/condensers, refrigeration components, refrigerators, etc., can solve the problems of large outlet air temperature difference, decreased heat exchange efficiency of parallel flow evaporators, and poor shock resistance, etc. The effect of reducing wind temperature difference, improving anti-vibration ability and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following is a further description of the invention in conjunction with the accompanying drawings and embodiments. The manufacturing technology of this product is easy to implement for people in the field.

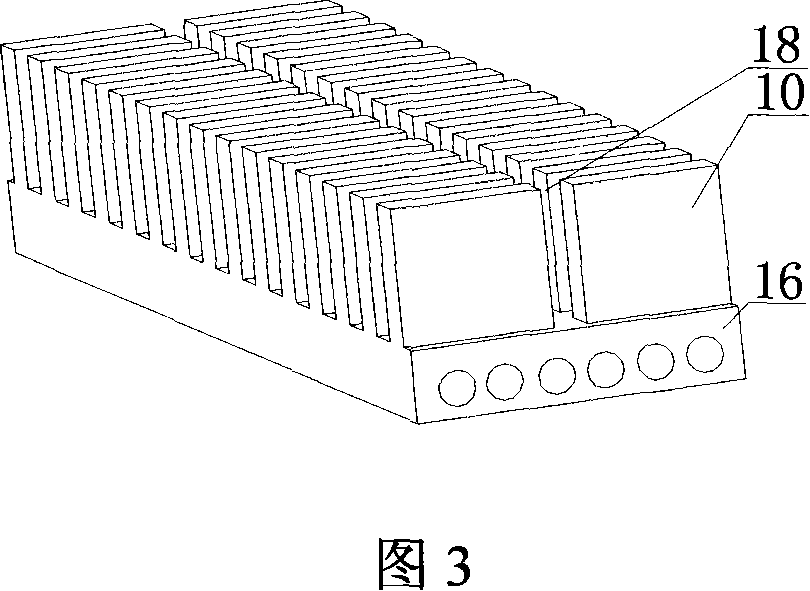

[0013] Referring to Fig. 1, a parallel flow evaporator for automobile air conditioners includes: integral fin flat tube 1, fin 10, porous flat tube 16, upper header 2, lower header 13, end plate 17, and baffle 7. Diaphragm 14, diaphragm 15, inlet pipe 8, outlet pipe 9, fluid inlet and outlet cavity 3, fluid diversion cavity 4, outlet cavity 5, inlet cavity 6, left fluid diversion cavity 11, right fluid diversion cavity 12, It is characterized in that: the integral finned flat tube 1 is divided into two groups of front and rear, and the two sets of integral finned flat tubes are arranged parallel to each other, and they are communicated with each other through the upper header 2 and the lower header 13; The upper header 2 is divided into a fluid inlet and outlet cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com