Sulfur-containing polypropylene composite fiber enhanced sulfur concrete and preparation method thereof

A technology of sulfur concrete and composite fiber, which is applied in the field of concrete for building construction, can solve the problems of poor adhesion, decline in concrete mechanical properties, inability to strengthen and toughen, etc., to improve strength, prevent the expansion of micro-cracks, and improve toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The sulfur-containing polypropylene composite fiber-reinforced sulfur concrete of the present invention and its preparation method will be further described in detail below in conjunction with specific examples.

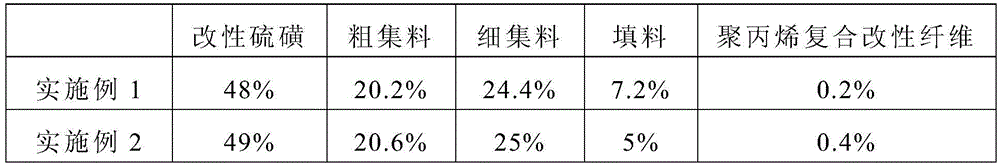

[0023] Taking the sulfur-containing polypropylene composite fiber-reinforced sulfur concrete of Examples 1-6, the components of the concrete in each example are shown in Table 1 in terms of mass percentage.

[0024] Table 1:

[0025]

[0026]

[0027] Above-mentioned is the concrete preparation method of strength, comprises the following steps:

[0028] 1) Self-made compatibilizer polypropylene grafted sulfur:

[0029] After mixing polypropylene, sulfur, and initiator dicumyl peroxide, plasticize and knead in an internal mixer at 180-230°C for 30-60 minutes, and melt graft to obtain compatibilizer polypropylene-grafted sulfur;

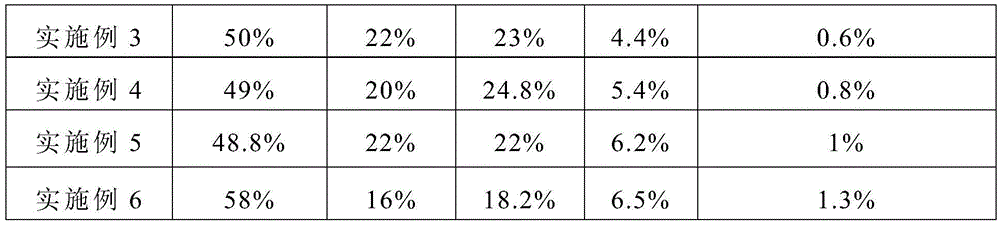

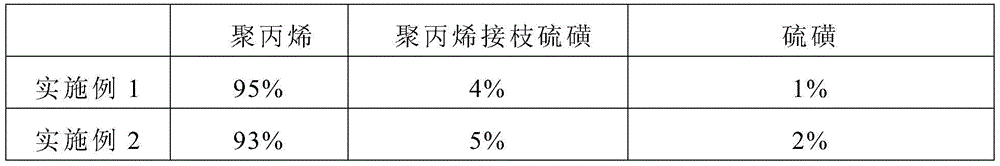

[0030] The raw materials in step 1) were selected according to the manner in Table 2 for Examples 1-6 respectively.

[0031]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com