Application of a modified sulfur in improving the compressive strength, anti-corrosion and/or anti-permeability of sulfur concrete and sulfur mortar

The technology of sulfur concrete and sulfur mortar, which is applied in the field of building materials, can solve the problems of poor corrosion resistance, permeability resistance and acid corrosion resistance of silicate concrete, and achieve excellent acid corrosion resistance and permeability resistance, The effect of good integrity and easy access to materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

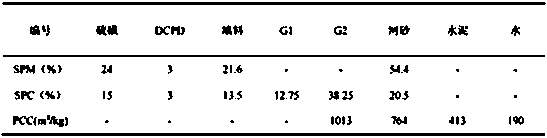

[0034] The preparation of high-strength modified sulfur concrete, in terms of mass percentage, sulfur is 15% of the total mass, wherein the modifier DCPD accounts for 3% of the sulfur mass, cement accounts for 13.5% of the total mass, and river sand accounts for 20.5% of the total mass, Granite coarse aggregate accounts for 51% of the total mass.

[0035] Step 1: Melt the sulfur at 140°C, then weigh 3% of its mass of DCPD and add it to react for 2 hours.

[0036] Step 2: At 140°C, uniformly mix the modified sulfur obtained in Step 1 with the corresponding preheated cement filler.

[0037] Step 3: At 140°C, add preheated river sand and granite to the mixture obtained in Step 2, stir evenly, vibrate for 60 seconds, pour into the preheated cast iron test mold, and disassemble after cooling at room temperature for 1 day mold.

[0038] The 3d compressive strength of this modified sulfur concrete specimen reaches 82.5MPa, and the mixture has good fluidity.

Embodiment 2

[0040] Preparation of high-strength modified sulfur mortar, in terms of mass percentage, the sulfur content is 24% of the total mass, wherein the modifier DCPD accounts for 3% of the sulfur mass, cement accounts for 21.6% of the total mass, and river sand accounts for 54.4% of the total mass .

[0041] Step 1: Melt the sulfur at 140°C, then weigh 3% of its mass of DCPD and add it to react for 2 hours.

[0042] Step 2: At 140°C, uniformly mix the modified sulfur obtained in Step 1 with the corresponding preheated cement filler.

[0043] Step 3: At 140°C, add preheated river sand to the mixture obtained in Step 2, stir evenly, vibrate for 60 seconds, pour into the preheated cast iron test mold, and remove the mold after cooling at room temperature for 1 day.

[0044] The 3d compressive strength of this modified sulfur mortar specimen reaches 62.3MPa, and the flexural strength reaches 11.9MPa.

Embodiment 3

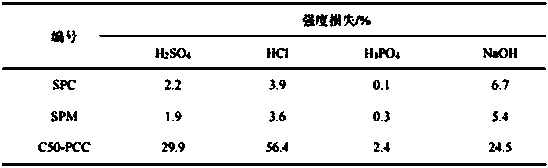

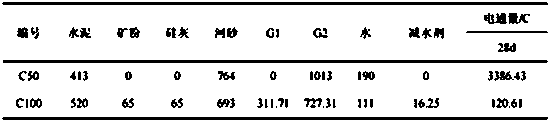

[0046] This experiment is a study on the permeability of modified sulfur concrete and modified sulfur mortar. The ASTM C1202 standard test method, that is, the electric flux method, is used to comprehensively evaluate the chloride ion permeability resistance of ordinary concrete, modified sulfur concrete, and modified sulfur mortar. Cured to 28d age under standard conditions, the modified sulfur concrete was cured at room temperature for 1d, then taken out, placed in a vacuum saturation device, vacuumed for 3h, then pumped with water for 1h, and then soaked for 18h. The cathode and anode of the specimen are respectively equipped with 3% NaCl solution and 0.3mol / L NaOH solution, and then apply a DC voltage of 60V in the axial direction of the concrete specimen, and record the Q value of the electricity passing through the specimen within 6 hours. It is used to measure the compactness of concrete and the ability to resist chloride ion penetration. According to the ASTM C1202 st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com