Fire-resistant sulfur concrete

A technology of sulfur concrete and concrete, which is applied in the direction of building components, building insulation materials, construction, etc., and can solve problems such as poor performance and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

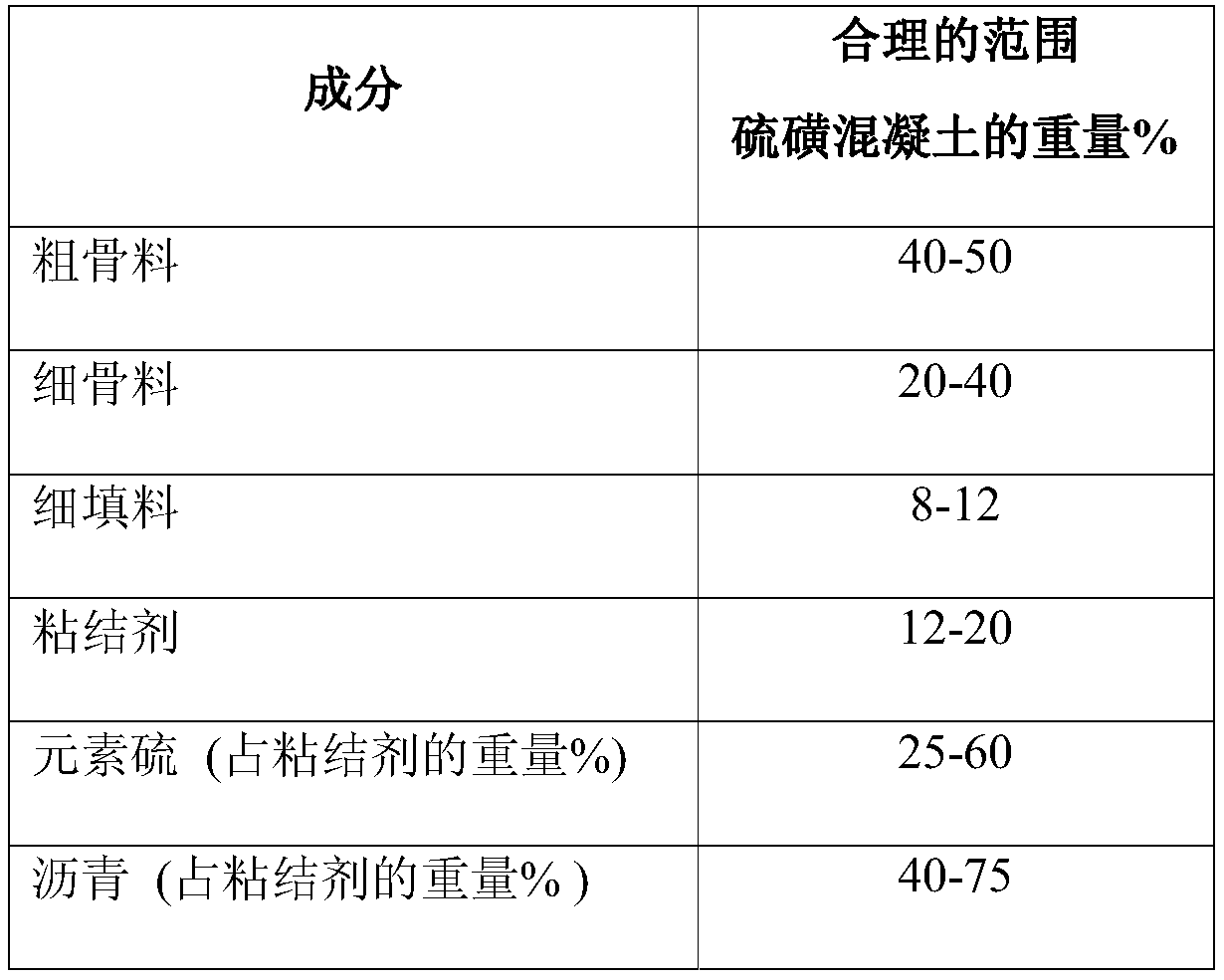

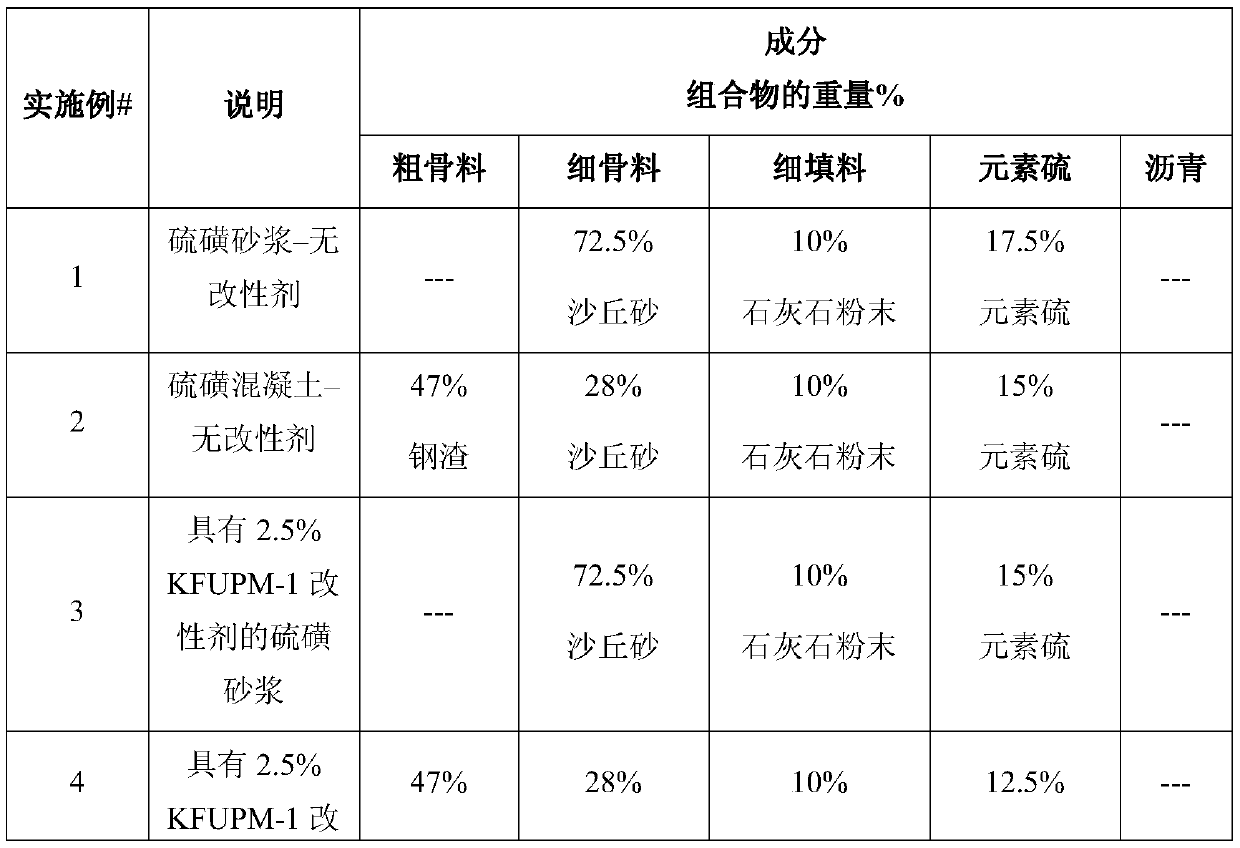

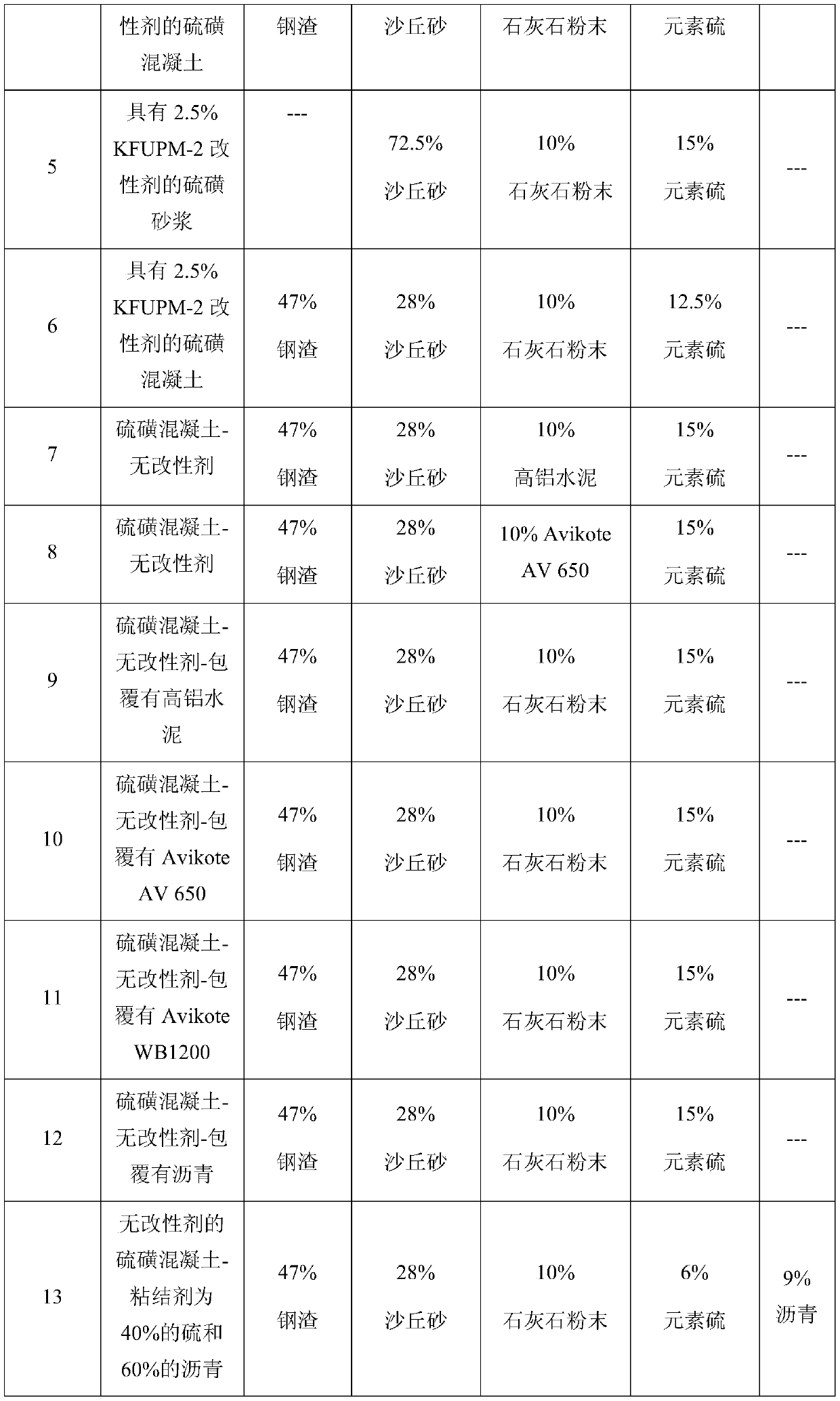

[0038] Several test mixtures of sulfur concrete were prepared. The weights of the mixture ingredients in the test mixture are shown in Table 2.

[0039] Table 2: Example mixtures.

[0040]

[0041]

[0042]

[0043] For Examples 3 to 6, two types of sulfur binders (ie, KFUPM-1 and KFUPM-2) developed by the inventors were used. In Examples 13 to 14 bitumen from a local refinery was used. The molded samples were held at about 130°C for at least 6 hours, after which the samples were allowed to gradually cool to room temperature.

[0044] A series of experiments were carried out with different examples incorporating sulfur to determine their fire resistance. Slab samples were prepared using Examples 1 to 14 detailed in Table 1 and exposed to flame. Table 3 describes the condition of the samples before and after exposure to the flame. As illustrated in Table 3, most of the systems evaluated exhibited low fire resistance. However, samples prepared with the composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com