Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Won't disintegrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

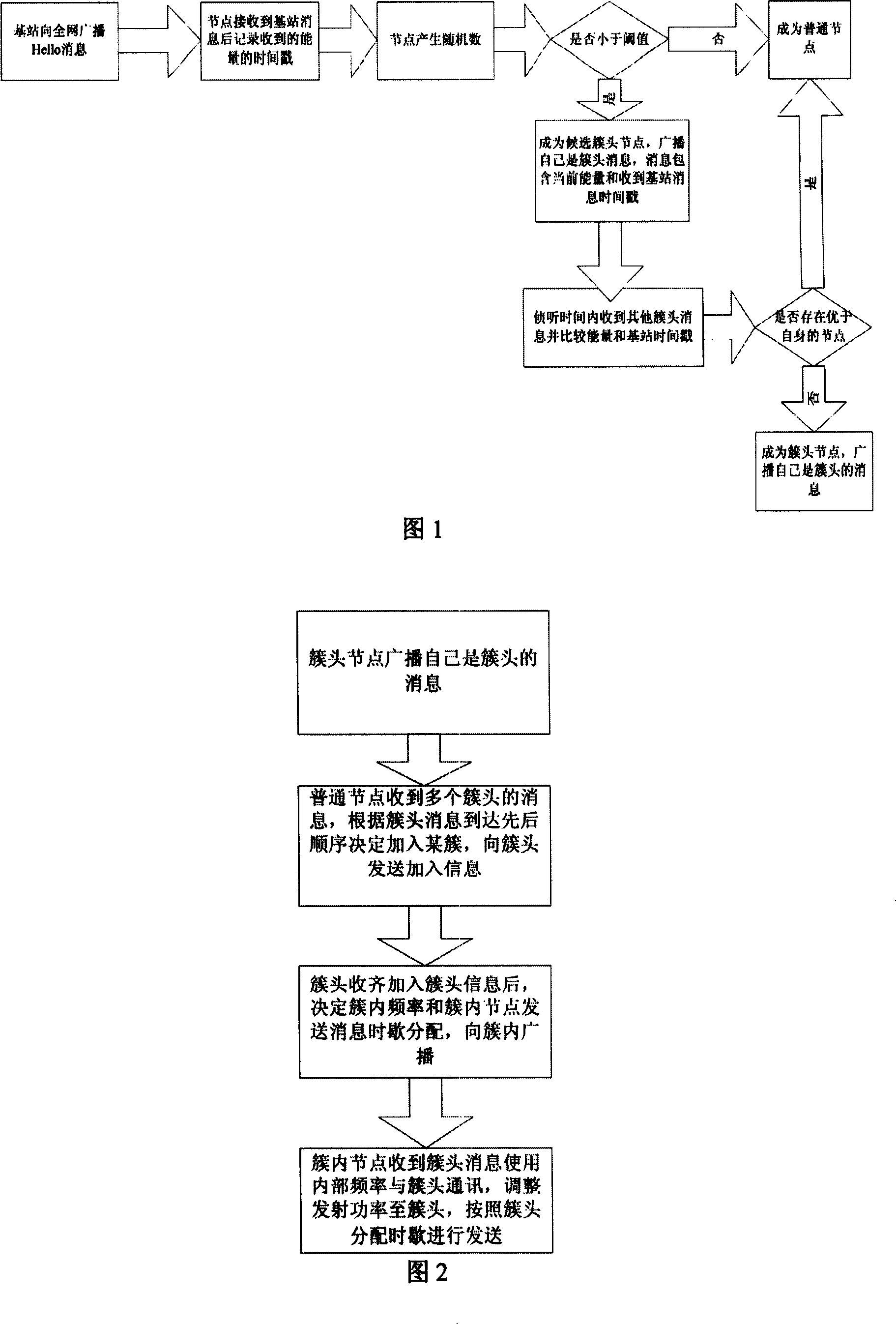

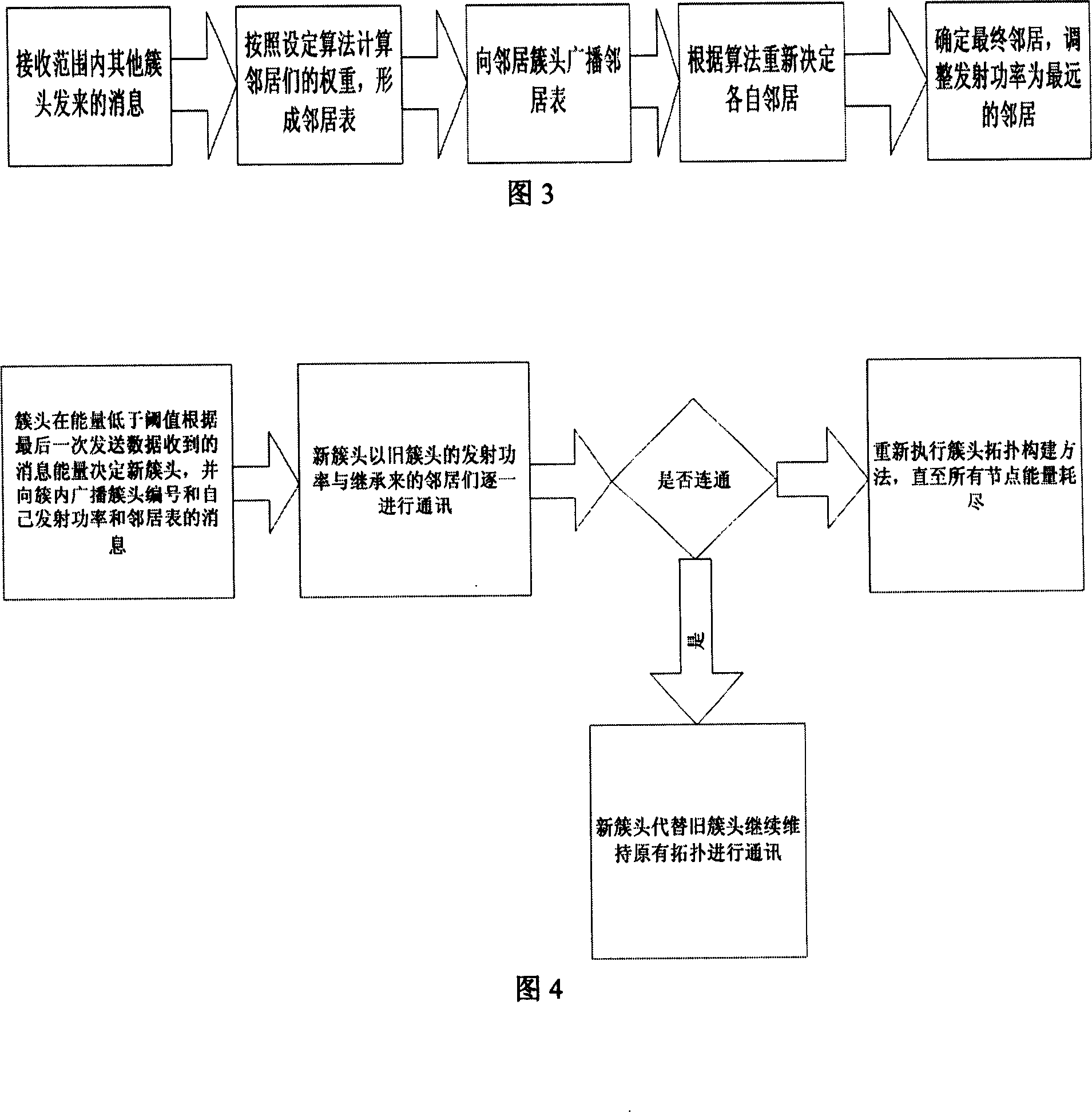

High-efficiency controlling method of wireless sensor network topology

InactiveCN101013987ARevise the assumption of flat distribution of nodesExtend the life cycleEnergy efficient ICTTransmission control/equalisingWireless sensor networkingSensor node

The invention relates to one efficient wireless sensor network topological control method, which combines topological control cluster division method and power control method and comprises the following steps: a, dividing the network clusters and selecting cluster head point; b, forming cluster inner network; c, processing power control on cluster point to form final network topological structure; after failure, re-establishing network topological structure.

Owner:NANJING UNIV OF POSTS & TELECOMM

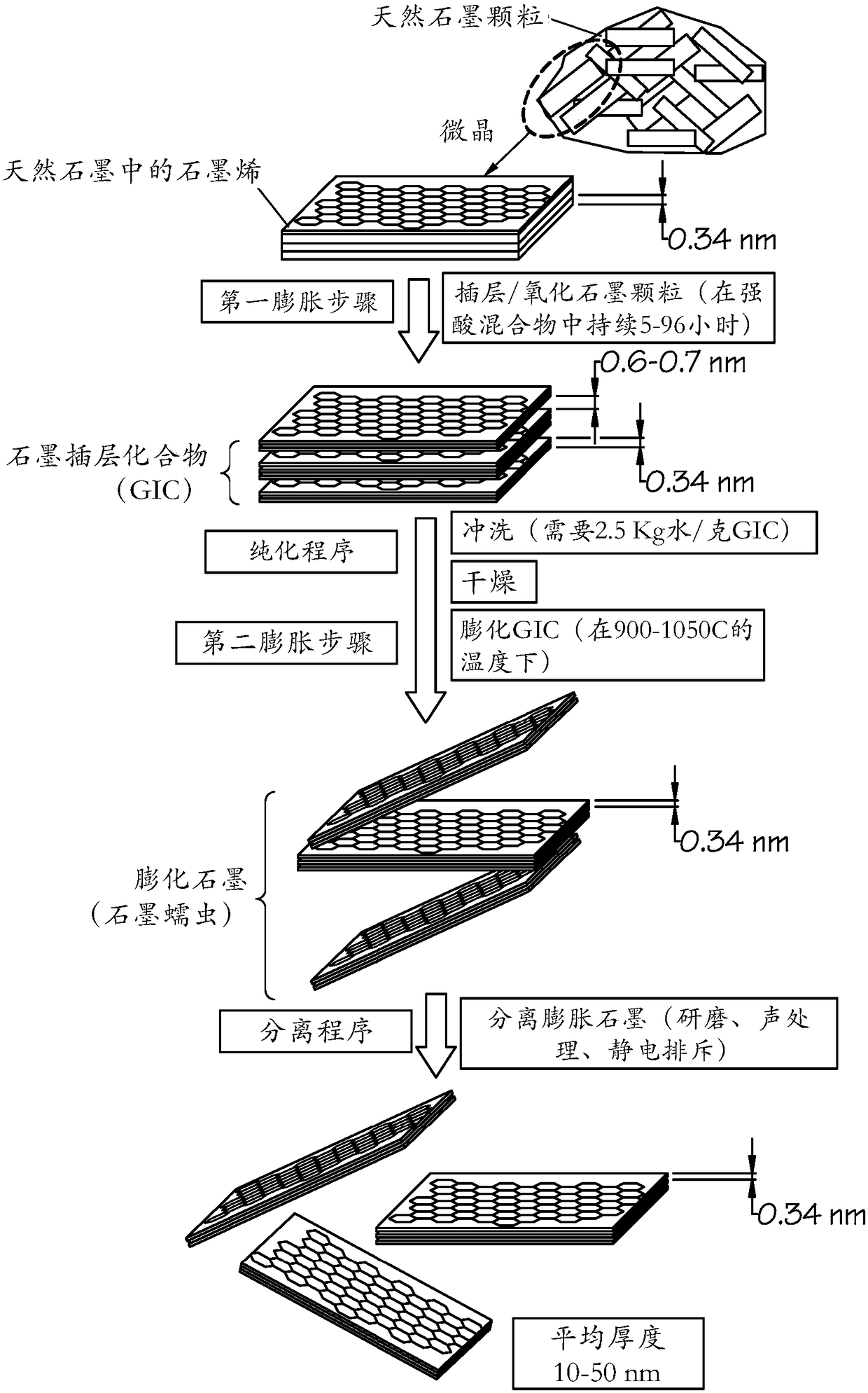

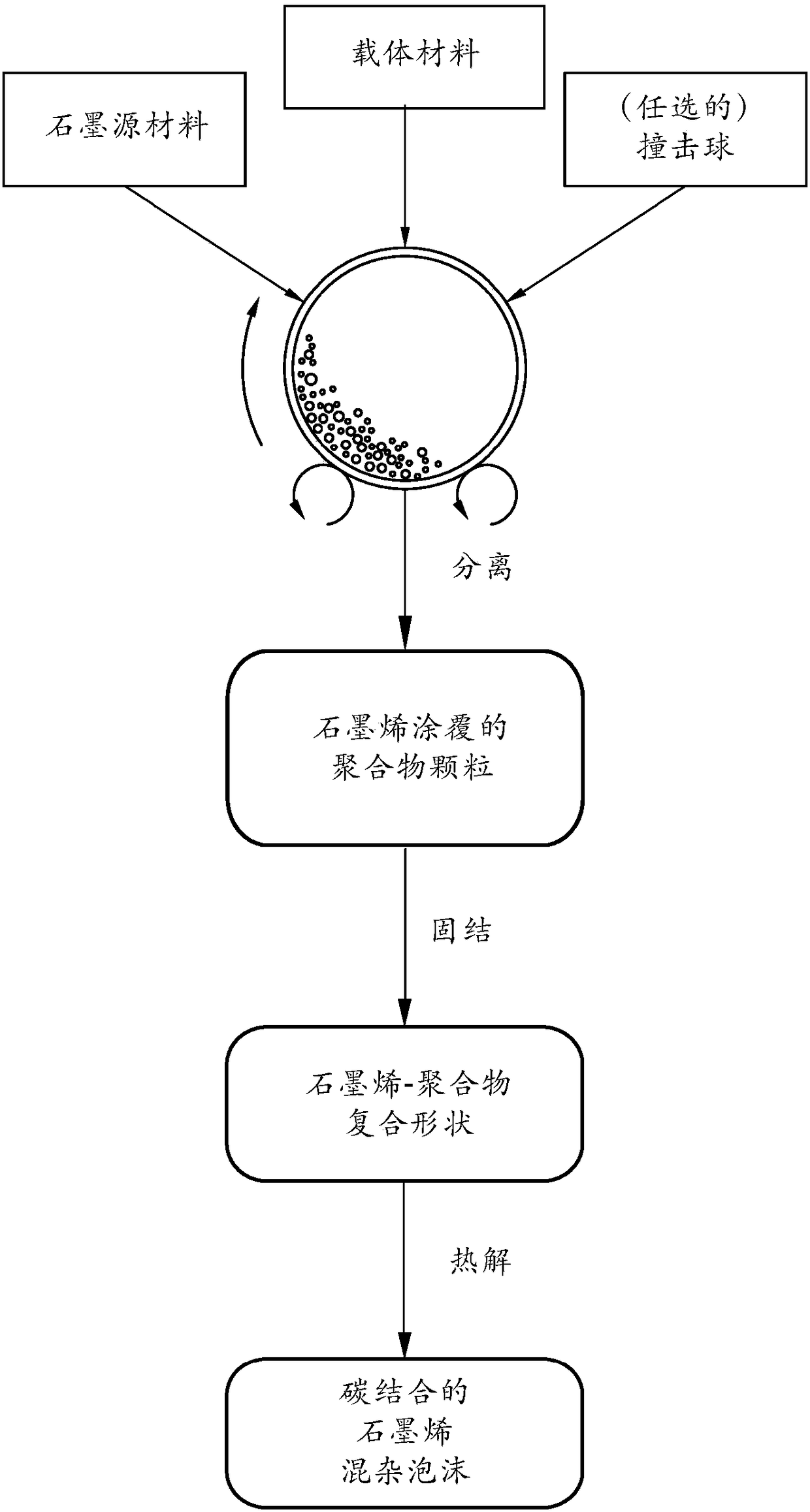

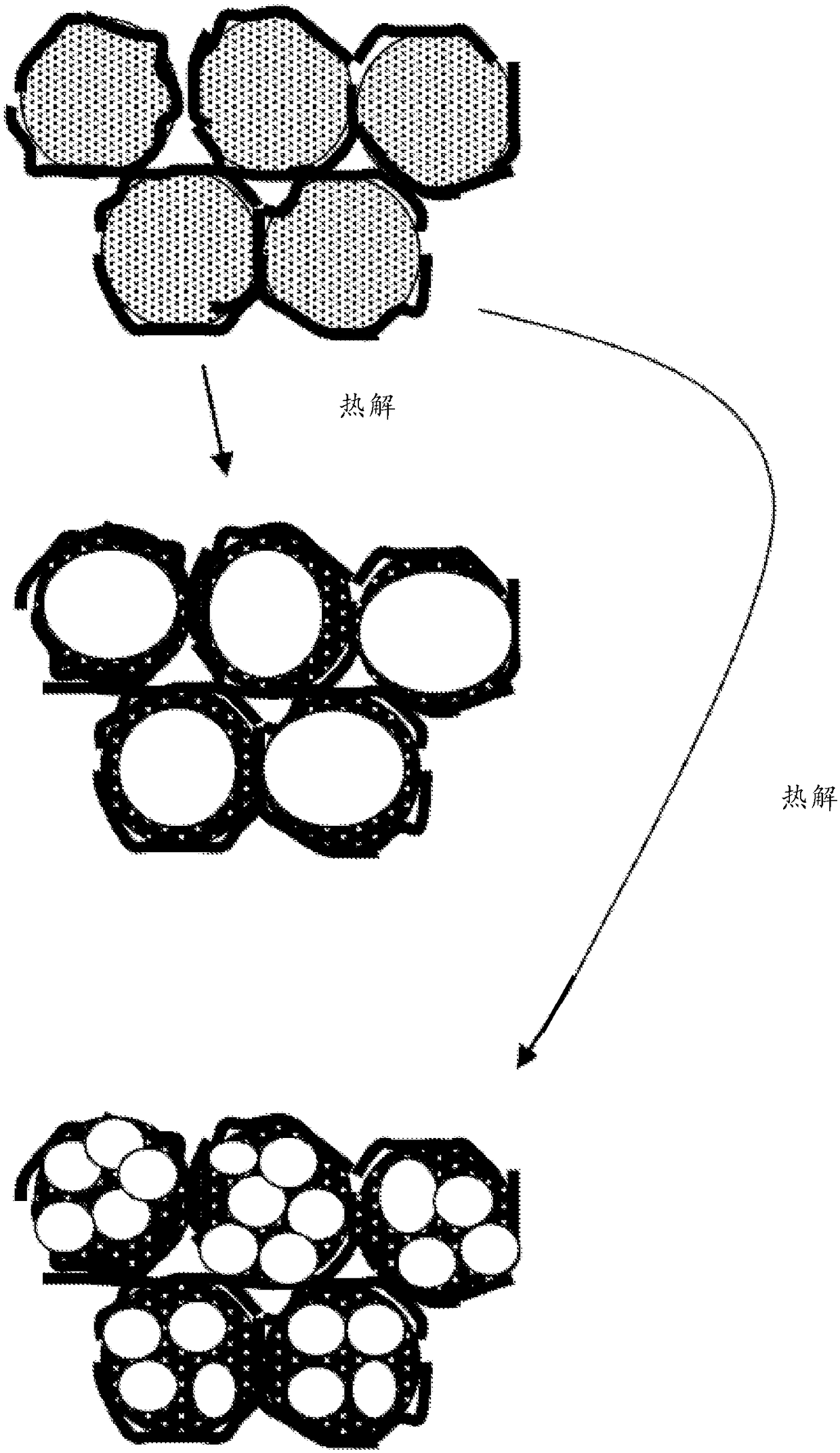

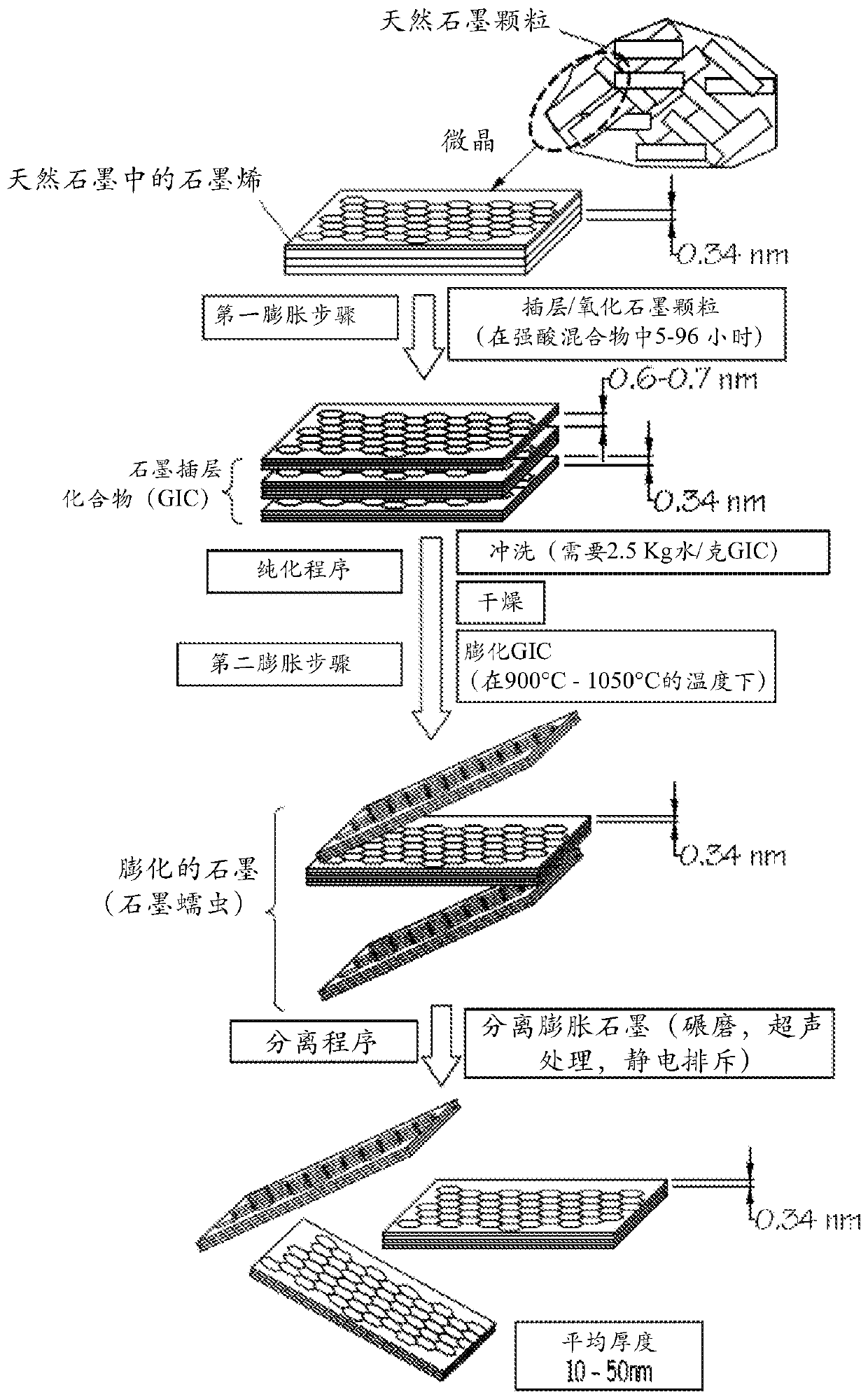

Graphene-Carbon Hybrid Foam

ActiveCN108602046AWon't disintegrateMaterial nanotechnologyOther chemical processesDoped grapheneIodide

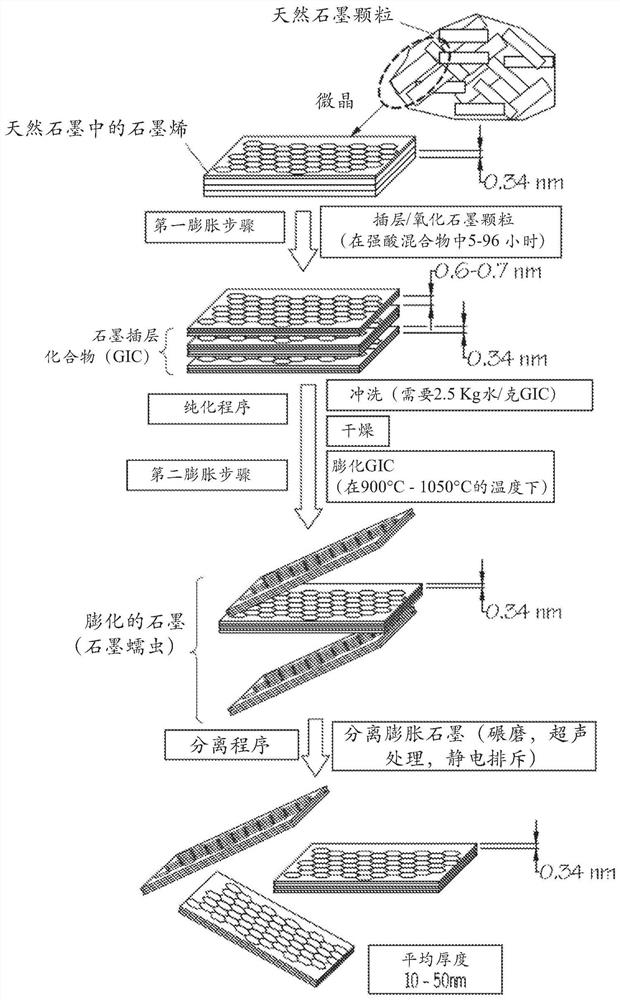

Provided is an integral 3D graphene-carbon hybrid foam composed of multiple pores and pore walls, wherein the pore walls contain single-layer or few-layer graphene sheets chemically bonded by a carbonmaterial having a carbon material-to-graphene weight ratio from 1 / 100 to 1 / 2, wherein the few-layer graphene sheets have 2-10 layers of stacked graphene planes having an inter-plane spacing doo2 from0.3354 nm to 0.40 nm and the graphene sheets contain a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.01% to 25% by weight of non-carbon elements wherein said non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenatedgraphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof. Also provided are a process for producing the hybrid form, products containing the hybridfoam, and its applications.

Owner:NANOTEK INSTR

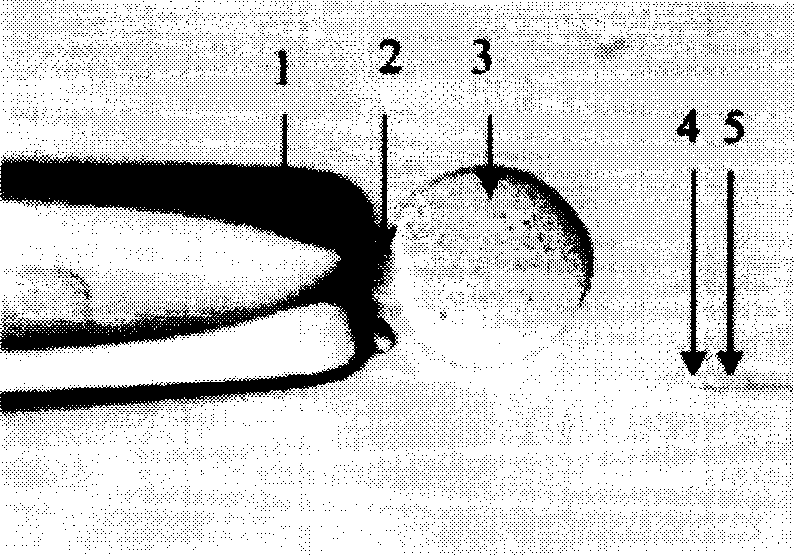

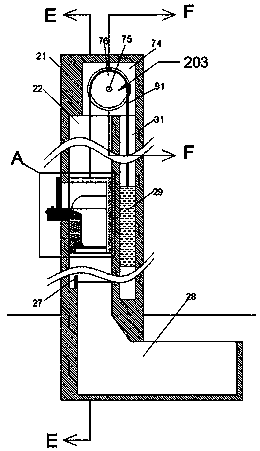

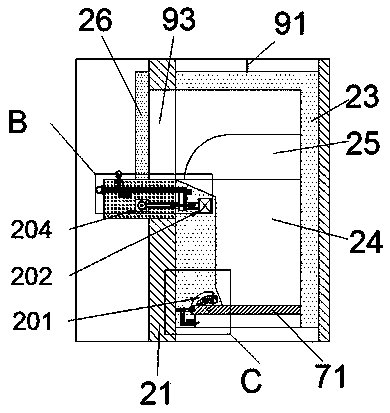

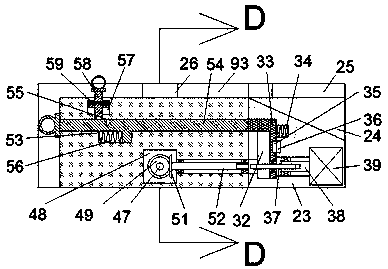

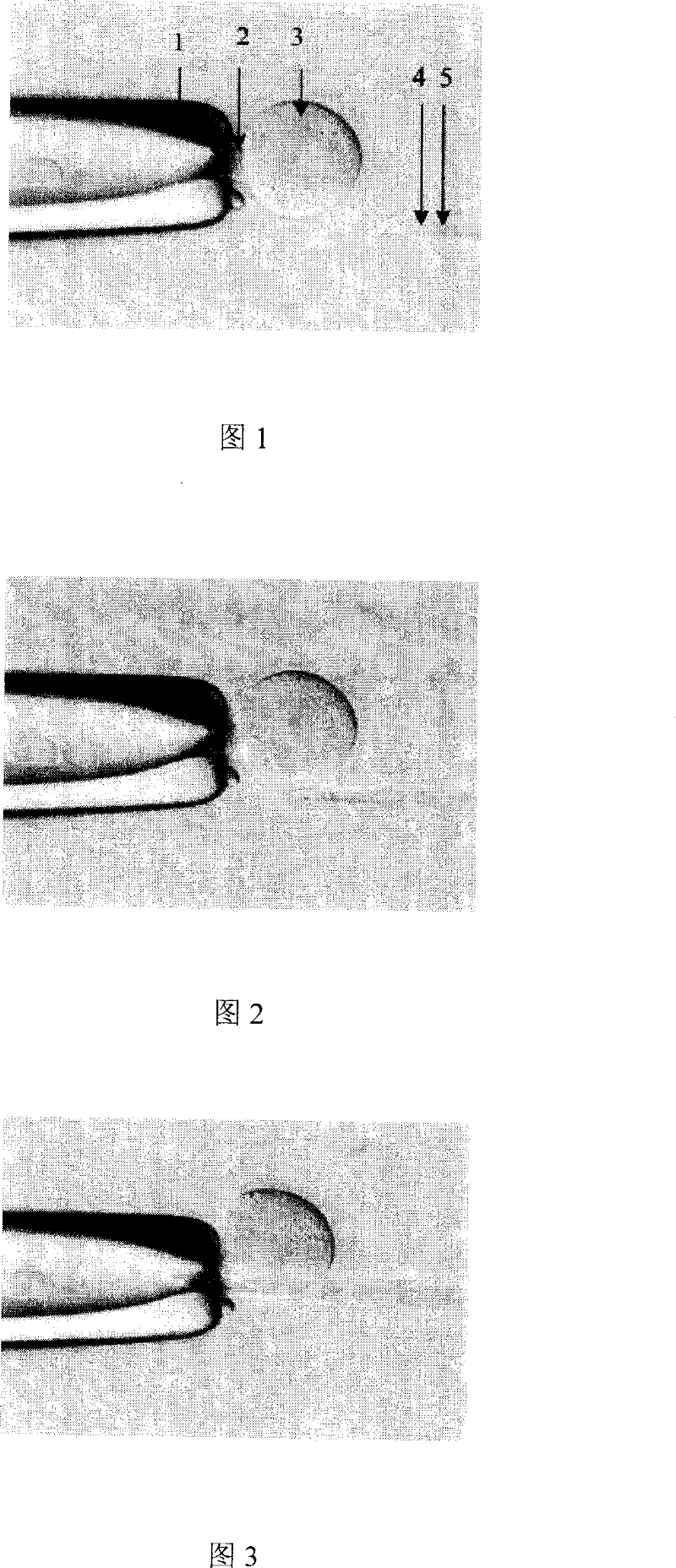

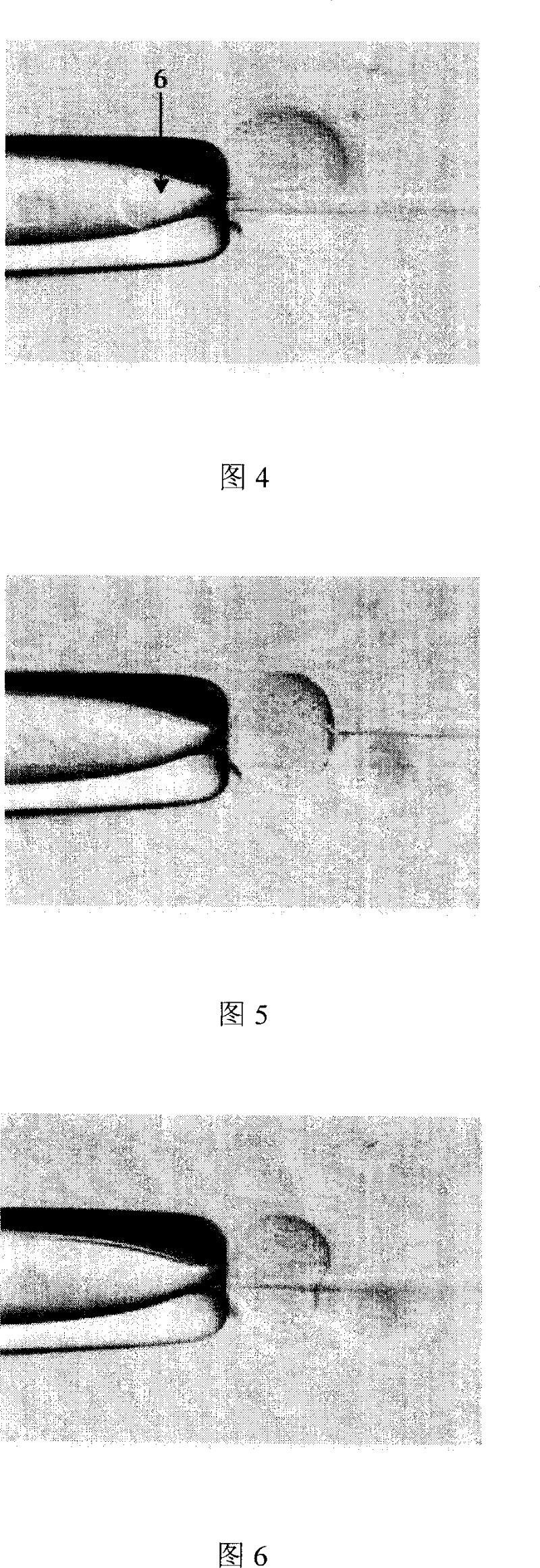

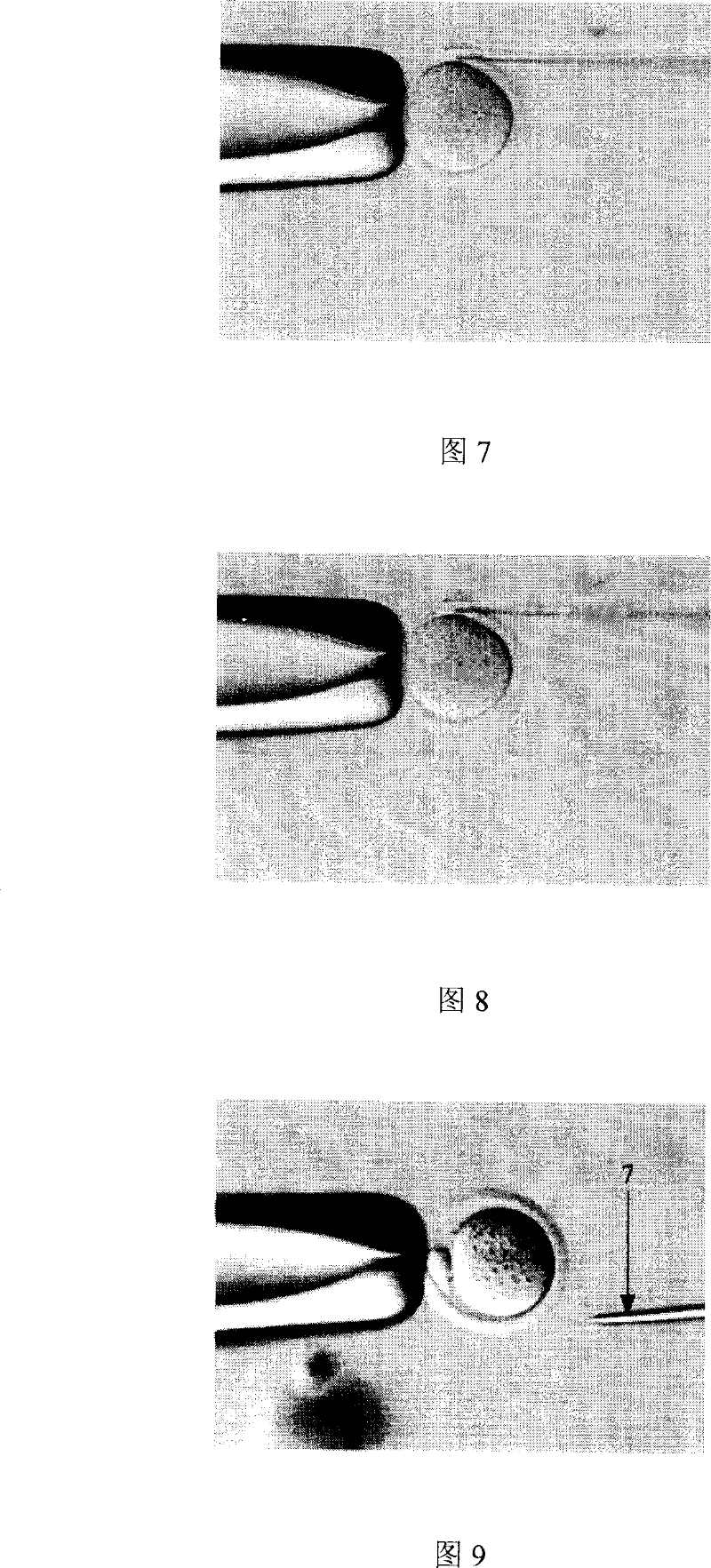

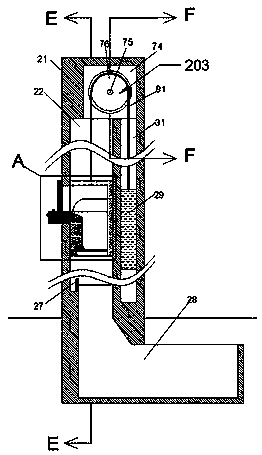

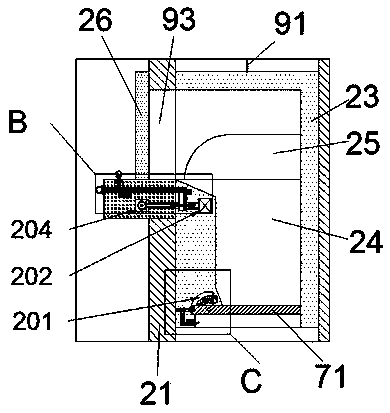

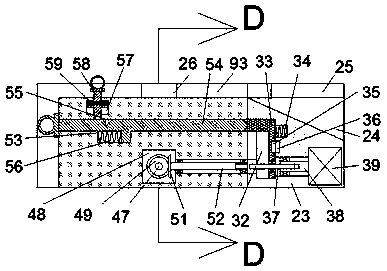

Transplantation method for nucleus

InactiveCN1807616ASimple and efficient operationShorten the timeRecombinant DNA-technologyOocyteBiological substances

This invention discloses a simple and effective microoperation nucleolus transplant method. This invention has the following steps: extruding the inject pin that has absorbed biology substance before on the ovum cell to form the transparent strip gauffer between the inject pin and ovum holding pin, then sticking and penetrating into the transparent strip gauffer with the inject pin to enter the opening of the ovum holing pin, then pulling the inject pin out from the surrounding gap of the ovum and adding the negative pressure in the ovum holing pin to absorb the pole body and object karyoplasms into the ovum holing pin, and then adjusting the place of the ovum cell with ovum holing pin to make its center at the same horizontal line with the needle-point of the inject pin, fixing up the ovum cell again, injecting the biology substance in the inject pin into the cell cytoplast or the surrounding gap of the ovum. This invention can complete the micro stoning and nucleus injecting processing at one time rapidly without special device; it has little damage to the ovum and can be used extensively in the cell project such as animal clone and transfer gene and so on.

Owner:SHANDONG UNIV

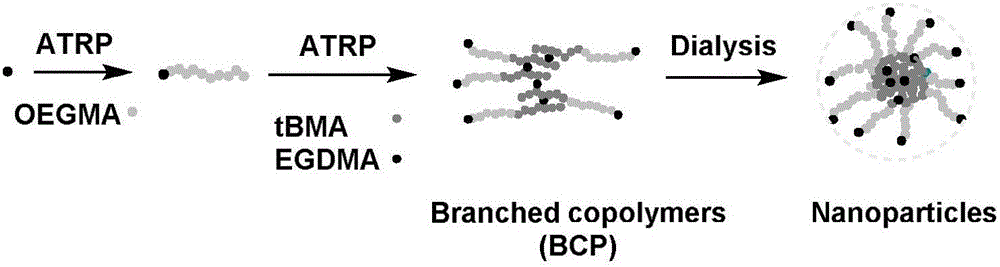

Ultra-mild crosslinking hyperbranched structure polymer nanometer slow-release material and preparation method and application thereof

ActiveCN104987470AWon't disintegrateIncrease loading capacityBiocideFungicidesPolymer scienceWater insoluble

The invention discloses an ultra-mild crosslinking hyperbranched structure polymer nanometer slow-release material and a preparation method and application thereof. Raw materials of the polymer nanometer slow-release material comprise monomers A, monomers B, bifunctional crosslinking agents, initiators, catalysts and ligands, wherein the molar ratio of the monomers A, to the monomers B, to the bifunctional crosslinking agents, to the initiators, to the catalysts and to the ligands is (30-50):(20-90):(0.8-1):1:1:2. The polymer nanometer slow-release material has the advantages that the size is controllable, synthesis is convenient, self-assembly is not needed, the object matter loading capacity is high, the polymer nanometer slow-release material is suitable for mass production and low in toxicity, and various functional groups can be led in. The polymer nanometer slow-release material has high loading capacity and good stability. The polymer nanometer slow-release material can be used for loading and slowly releasing non-water-insoluble active substances.

Owner:ANHUI ZHONGBANG BIOLOGICAL ENG

Paper cup

ActiveCN111792146AWon't disintegrateReduce scaldingLayered productsDomestic containersFiberThermal insulation

The invention relates to the field of paper products, in particular to a paper cup. The paper cup comprises a cup body, the cup body comprises a paper cup wall, an inner heat-resistant water-proof film, an adhesive glue filling gap, a cup bottom plate, a cup base, a thermal insulation fiberboard and a thermal insulation fiber mat, the inner heat-resistant water-proof film is arranged on the innerside of the paper cup wall, the adhesive glue filling gap is arranged between the paper cup wall and the inner heat-resistant water-proof film, the adhesive glue filling gap is filled with high temperature resistant edible adhesive glue, the lower side edge of the inner heat-resistant water-proof film is stuck to the circular cup bottom plate in a sealed mode, the lower side edge of the paper cupwall surrounds the cup bottom plate to be rolled into a cylindrical shape, and an intersecting edge of the paper cup wall is bonded by the adhesive glue in a sealed mode. According to the paper cup, various paper structures are used to install a strainer mechanism capable of isolating and blocking solids such as tea leaves in the cup body additionally to achieve the self-strainer effect, users areprevented from drinking tea leaves by mistake when drinking tea, and convenience of the paper cup is greatly improved.

Owner:山东新思路生活科技有限公司

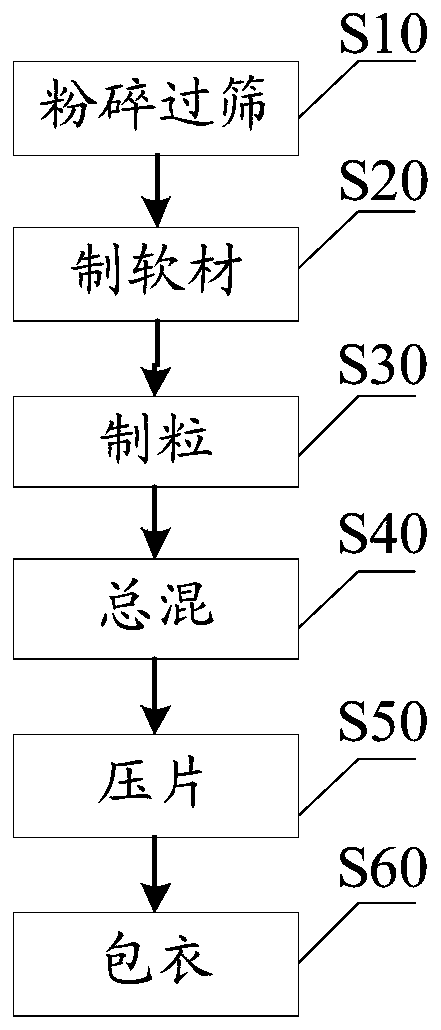

Nattokinase enteric-coated tablet and preparation method thereof

InactiveCN109718219AReduce oxidation rateAvoid destructionPeptide/protein ingredientsPharmaceutical non-active ingredientsAdhesiveMedicine

The invention discloses a nattokinase enteric-coated tablet and a preparation method thereof, and relates to the technical field of pharmaceutical preparations. The enteric-coated tablet includes a core tablet and a enteric coating layer; the core tablet is prepared by, by weight, 30-35 parts of nattokinase, 10-15 parts of a radix astragali extract product, 35-55 parts of a filler, 4-15 parts of an adhesive, 0.1-3 parts of a lubricant, and 2-10 parts of a disintegrating agent; and the enteric coating layer includes 3-6 parts of a coating material. The preparation method includes crushing and sieving, soft material making, granulation, total mixing, tabletting and coating. The enteric-coated tablet has the efficacy of adjusting blood pressure and dissolving thrombus, and can prevent the formation of the thrombus.

Owner:WUHAN POLYTECHNIC UNIVERSITY

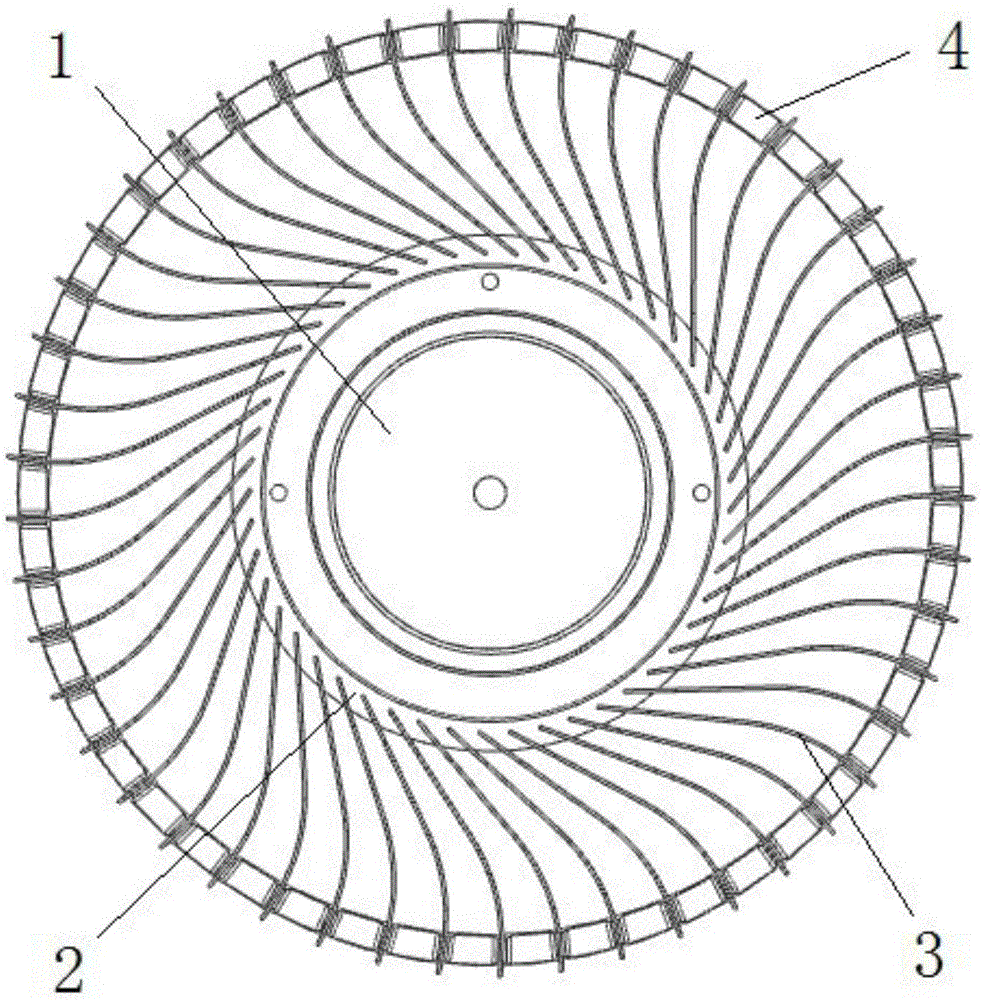

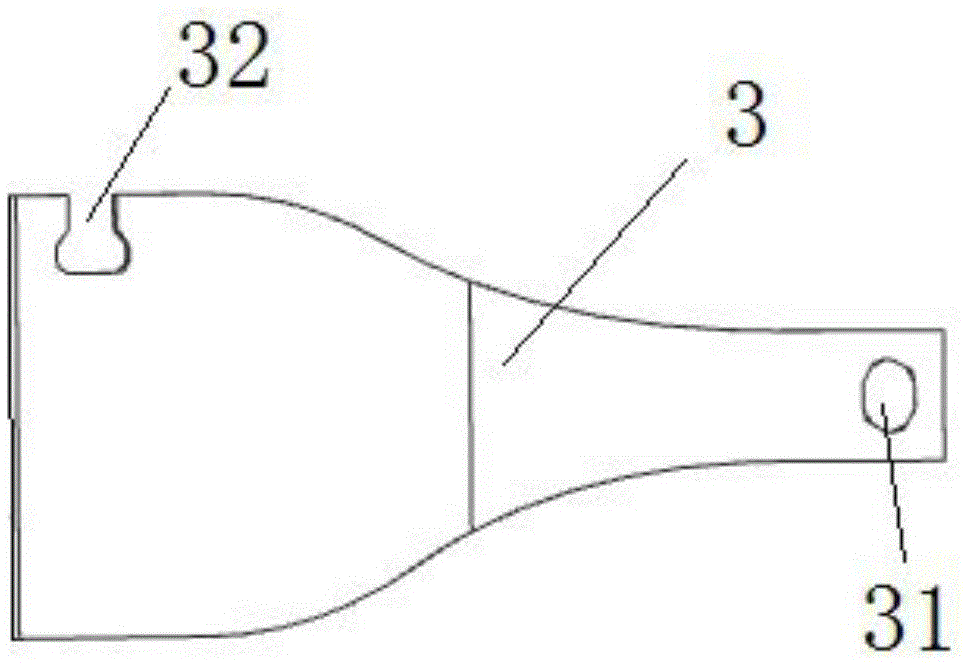

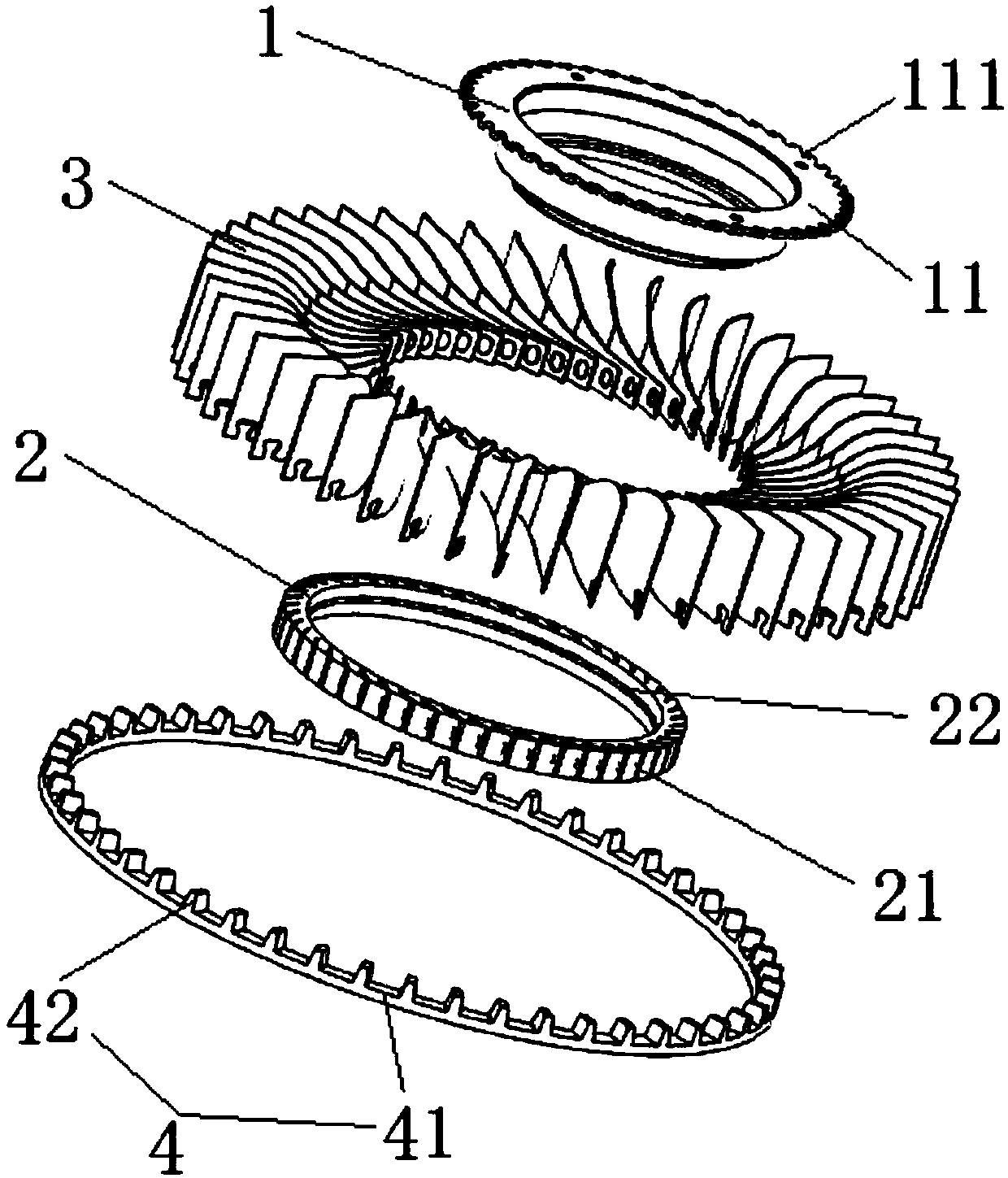

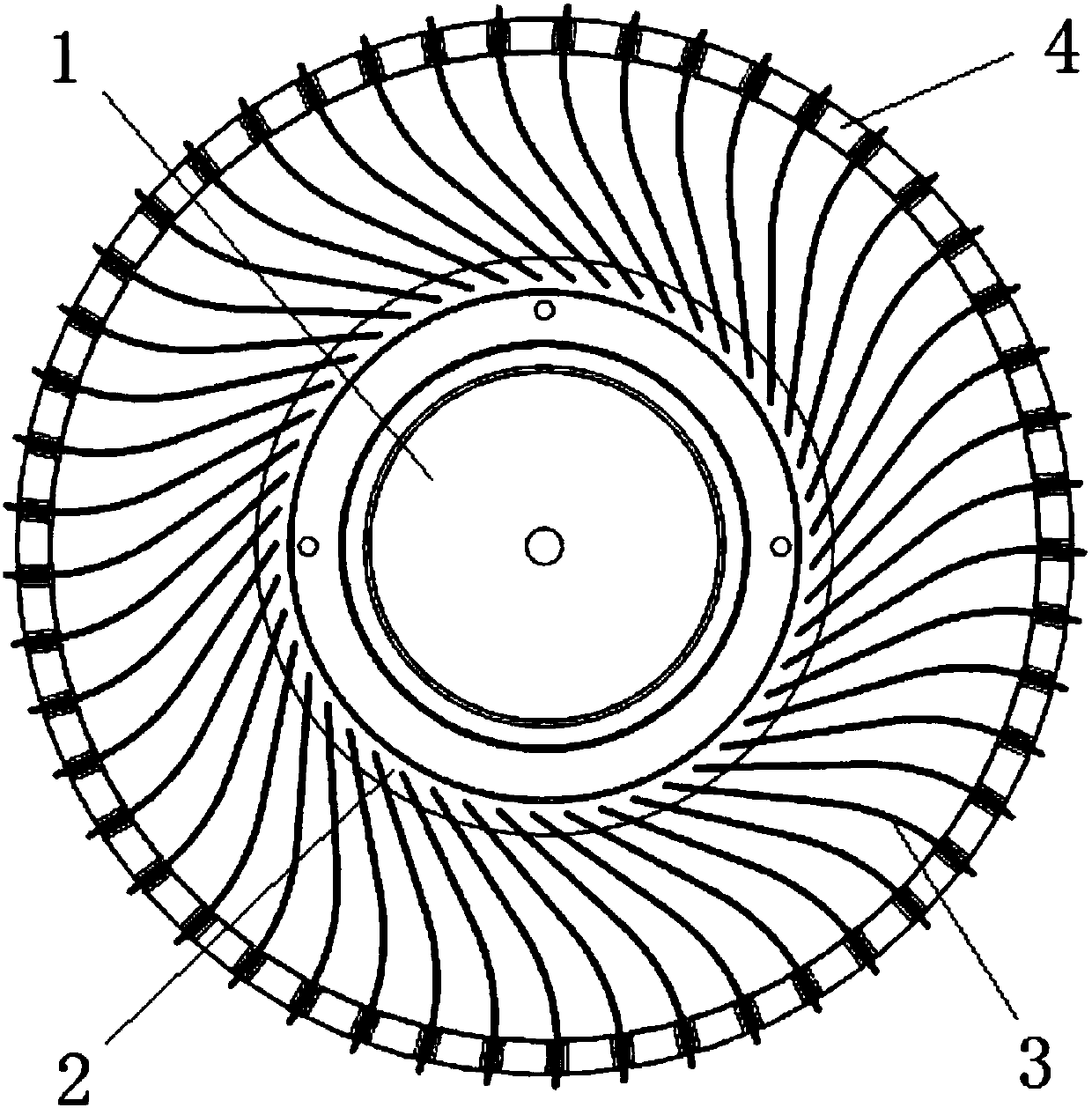

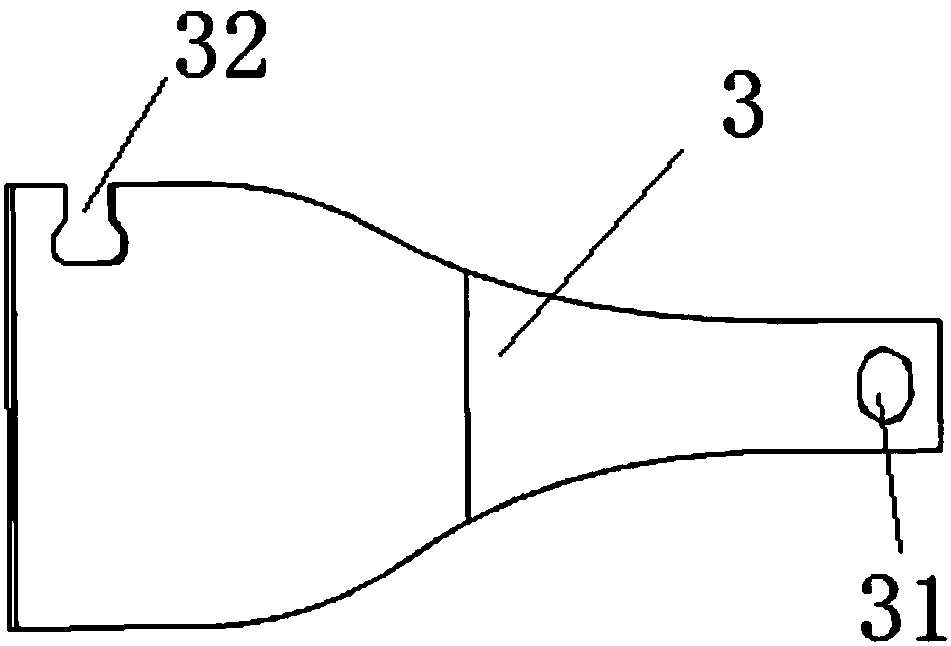

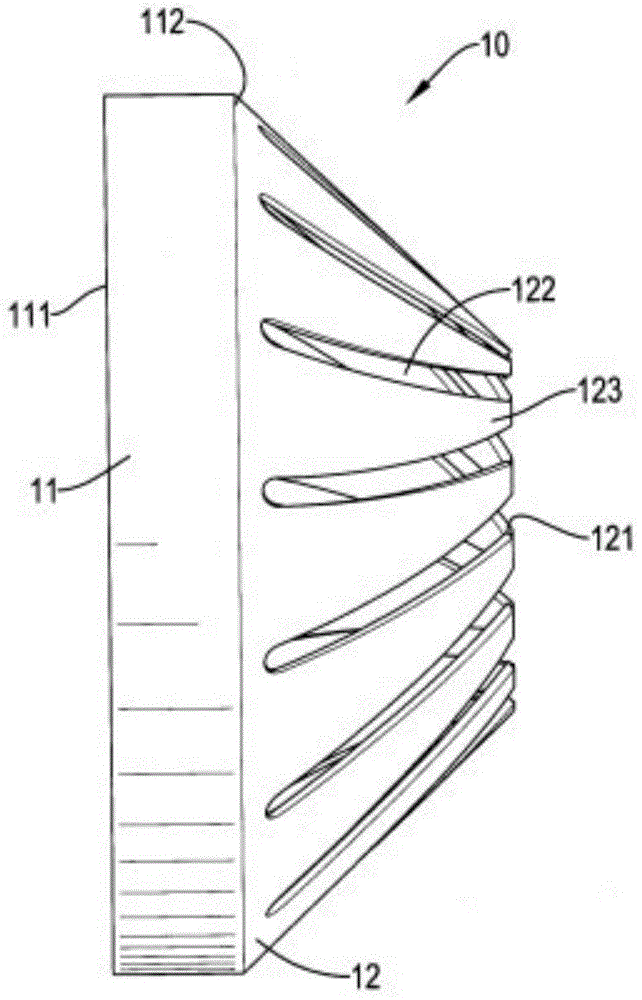

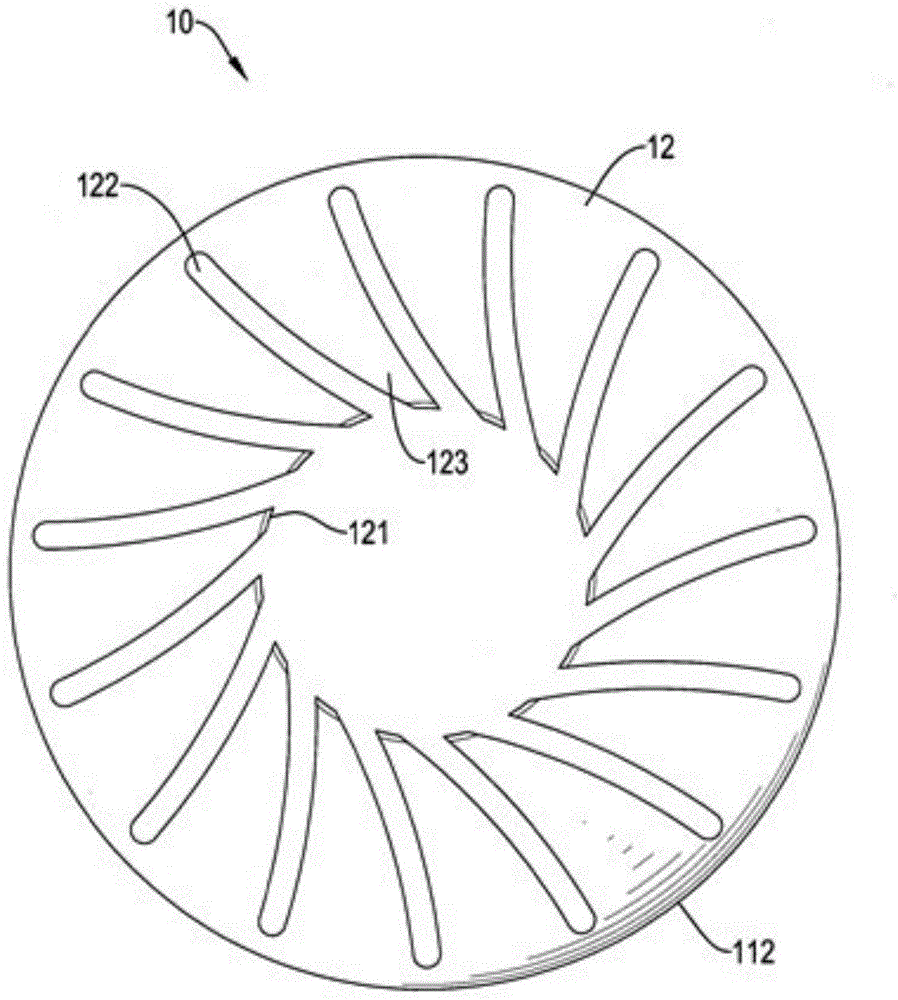

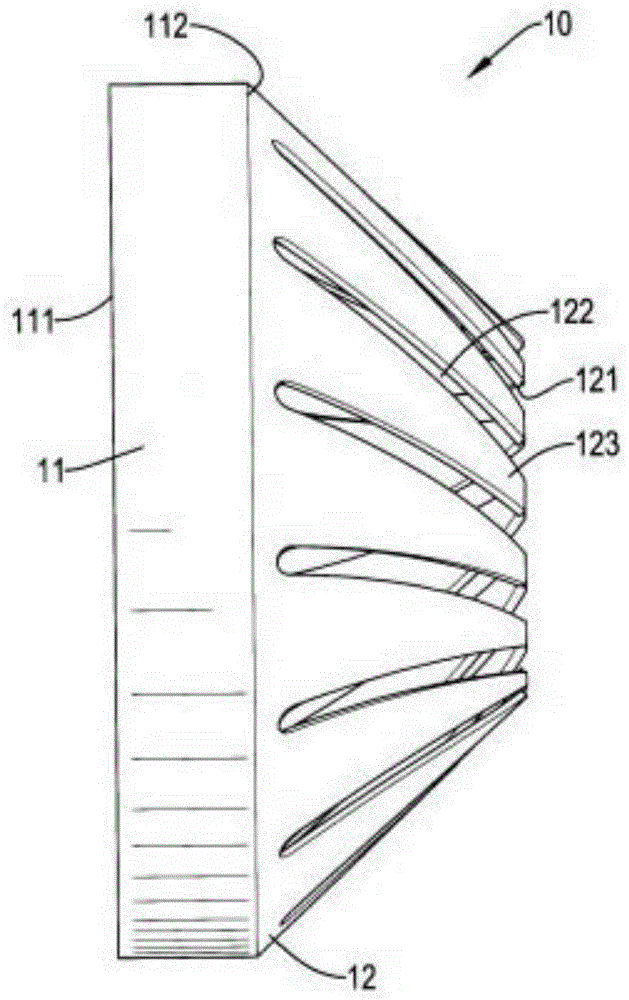

CPU (Central Processing Unit) cooling fan

ActiveCN105545776ALarge air volumeImprove cooling effectPump componentsDigital data processing detailsAir volumeCooling effect

The invention belongs to the technical field of computer accessory processing and relates to a CPU (Central Processing Unit) cooling fan. The CPU cooling fan comprises a fixing plate, an inner fixing ring covering the edge of the fixing plate, a plurality of fan blades annularly and evenly distributed on the outer side of the inner fixing ring, and an outer fixing ring fixed to the outer sides of all the fan blades. The fan blades are of a folded structure. The outer fixing ring is provided with an annular base part and upright parts protruding out of the base part, wherein outer clamping seams perpendicular to the base part are formed in the upright parts. The outer sides of the fan blades are provided with clamping claws clamped in the outer clamping seams. According to the CPU cooling fan, air can be thrown out of the side face of the cooling fan in the radial direction through the fan blades of the folded structure, the air volume is large, and the cooling effect is good.

Owner:安徽刚毅电子科技有限公司

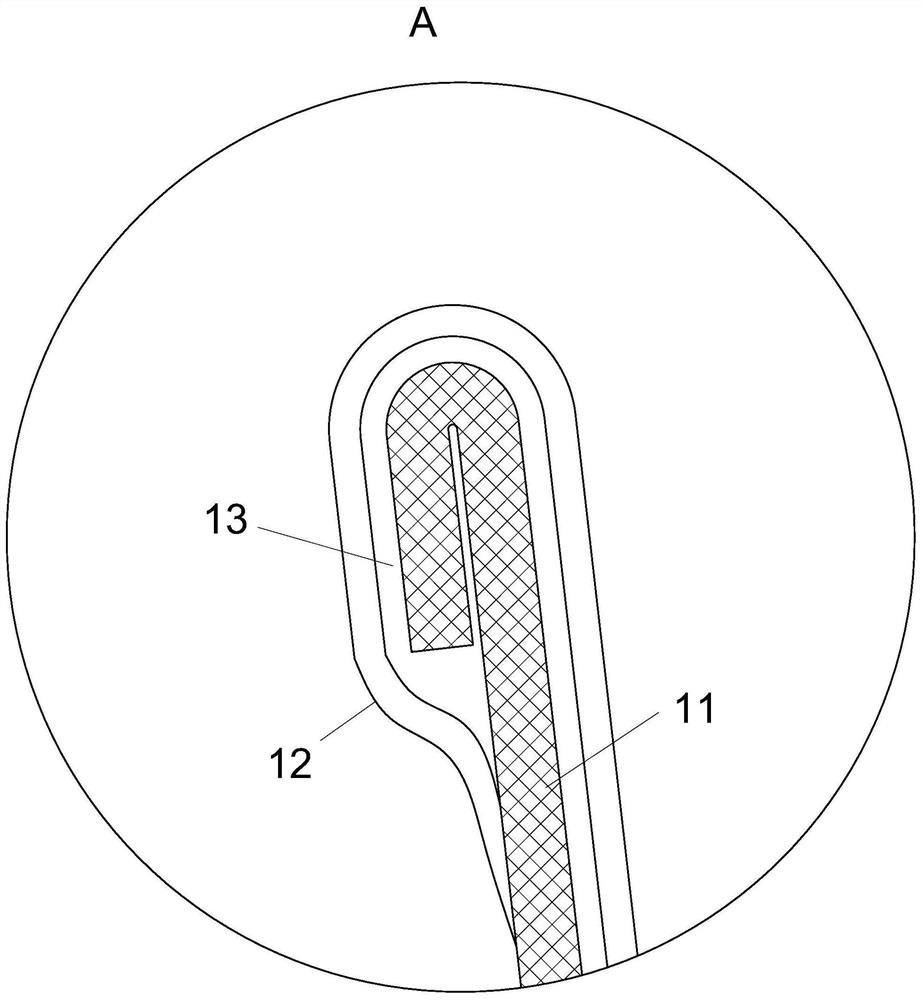

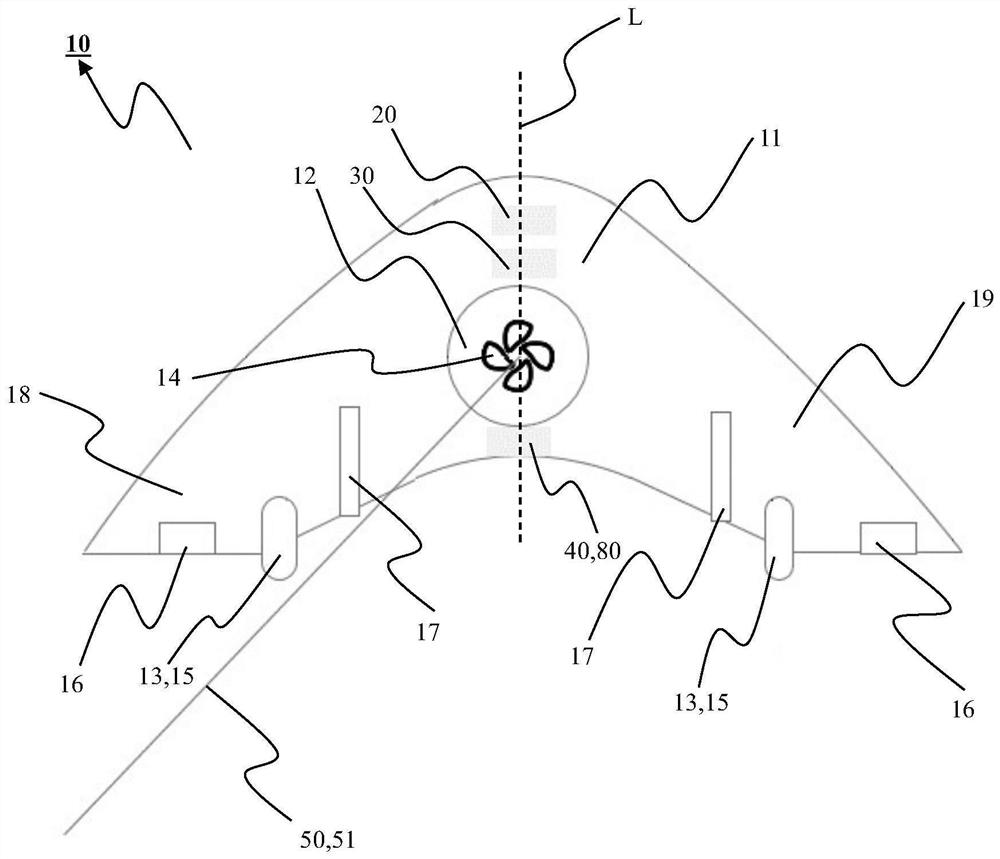

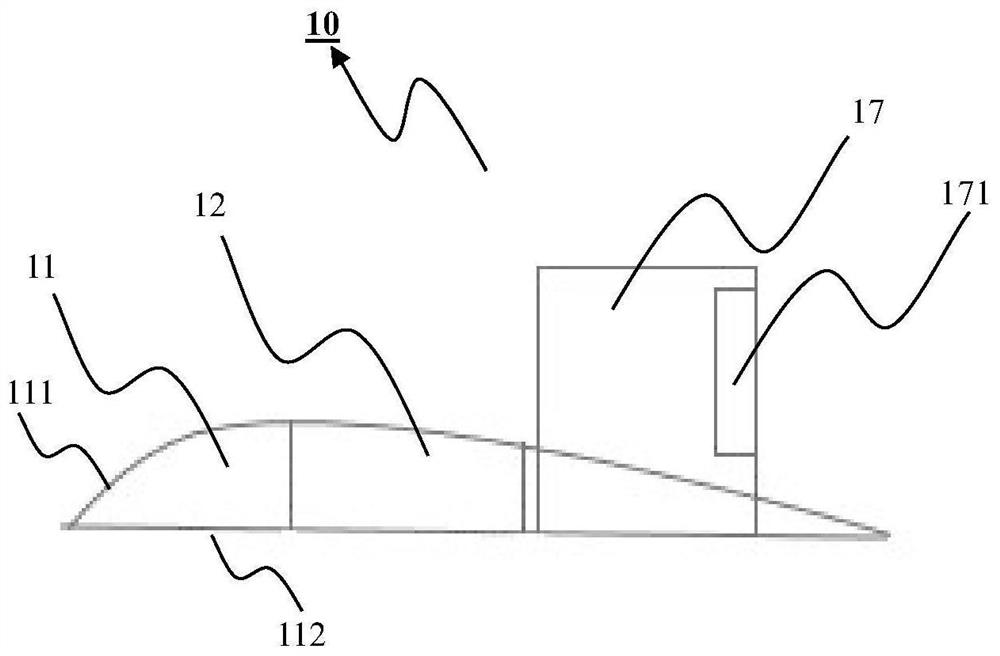

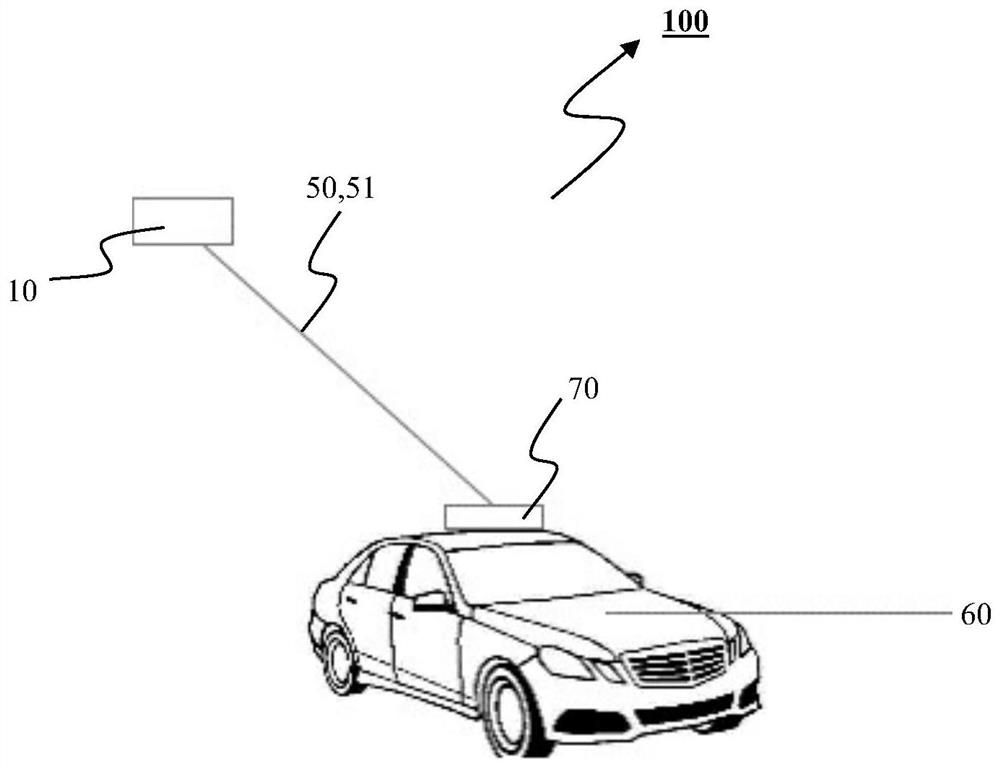

Tethered aircraft, flight system including same, and control method thereof

PendingCN111806678AImprove battery lifeImprove stabilityAircraft stabilisationPower plant typeFlight vehicleClassical mechanics

The invention relates to the field of unmanned aerial vehicles. Specifically, the invention relates to a tethered aircraft (10). The tethered aircraft comprises an aircraft body (11), at least one take-off and landing duct (12) arranged in the aircraft body (11), a lift rotor wing (14) located in the take-off and landing duct (12), at least one thrust duct (13) arranged in the aircraft body (11),and a thrust rotor wing (15) located in the thrust duct (13), wherein the aircraft body (11) has an integrally streamlined geometric design such that the left side portion of the aircraft body (11) forms a left fixed wing (18) and the right side portion of the aircraft body (11) forms a right fixed wing (19). The invention also relates to a flight system including the aircraft and to a control method for such the flight system. The aircraft disclosed by the invention can still take off, recover and stably follow up when the vehicle is in a high-speed running state, and has good cruising ability.

Owner:DAIMLER AG

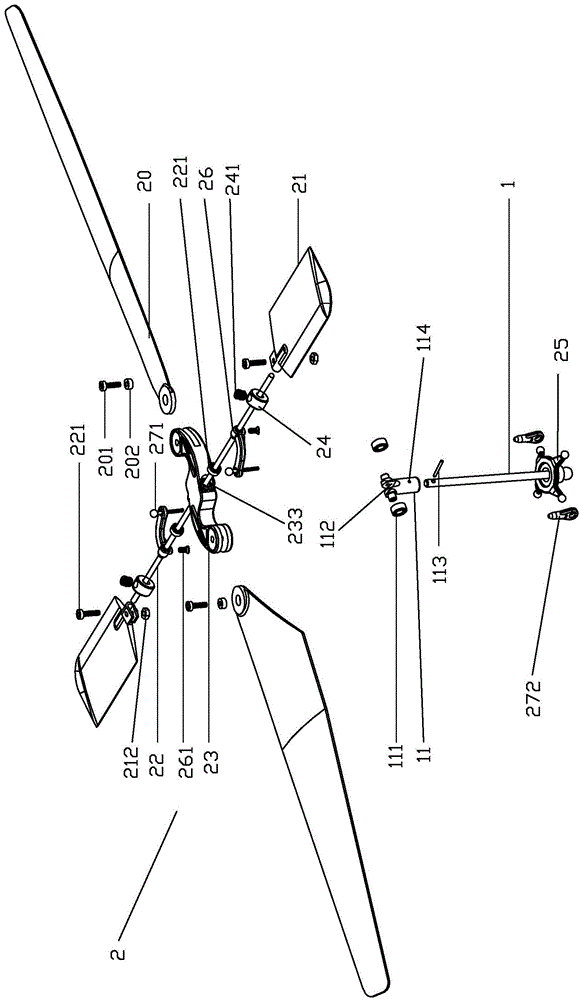

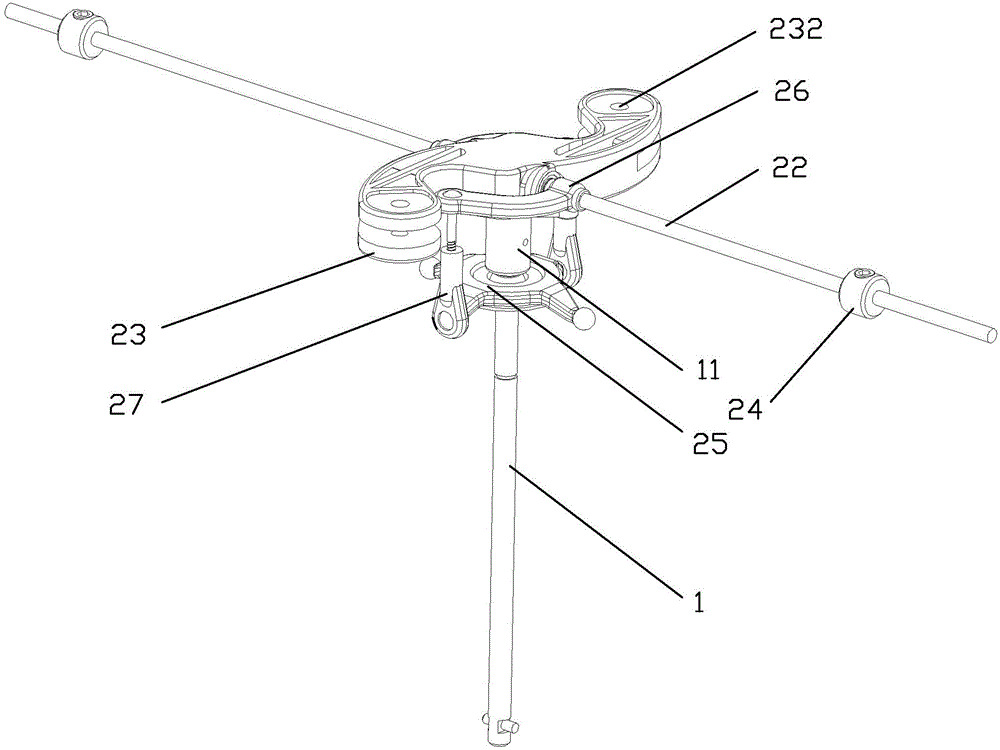

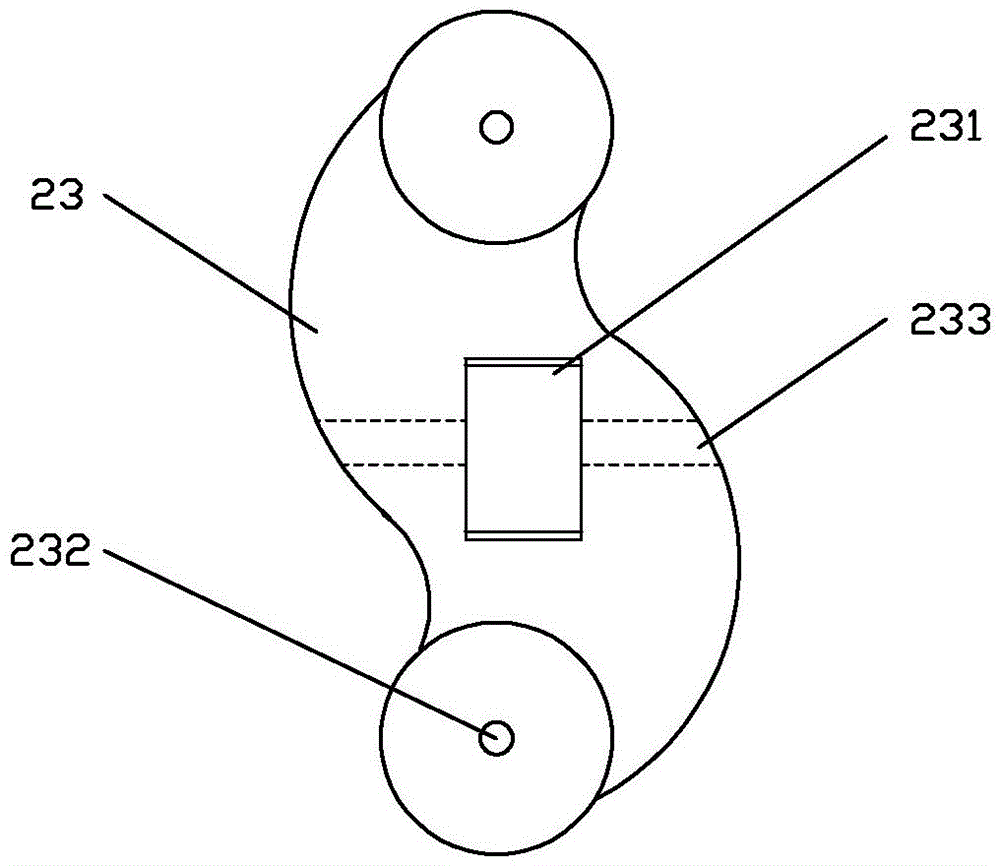

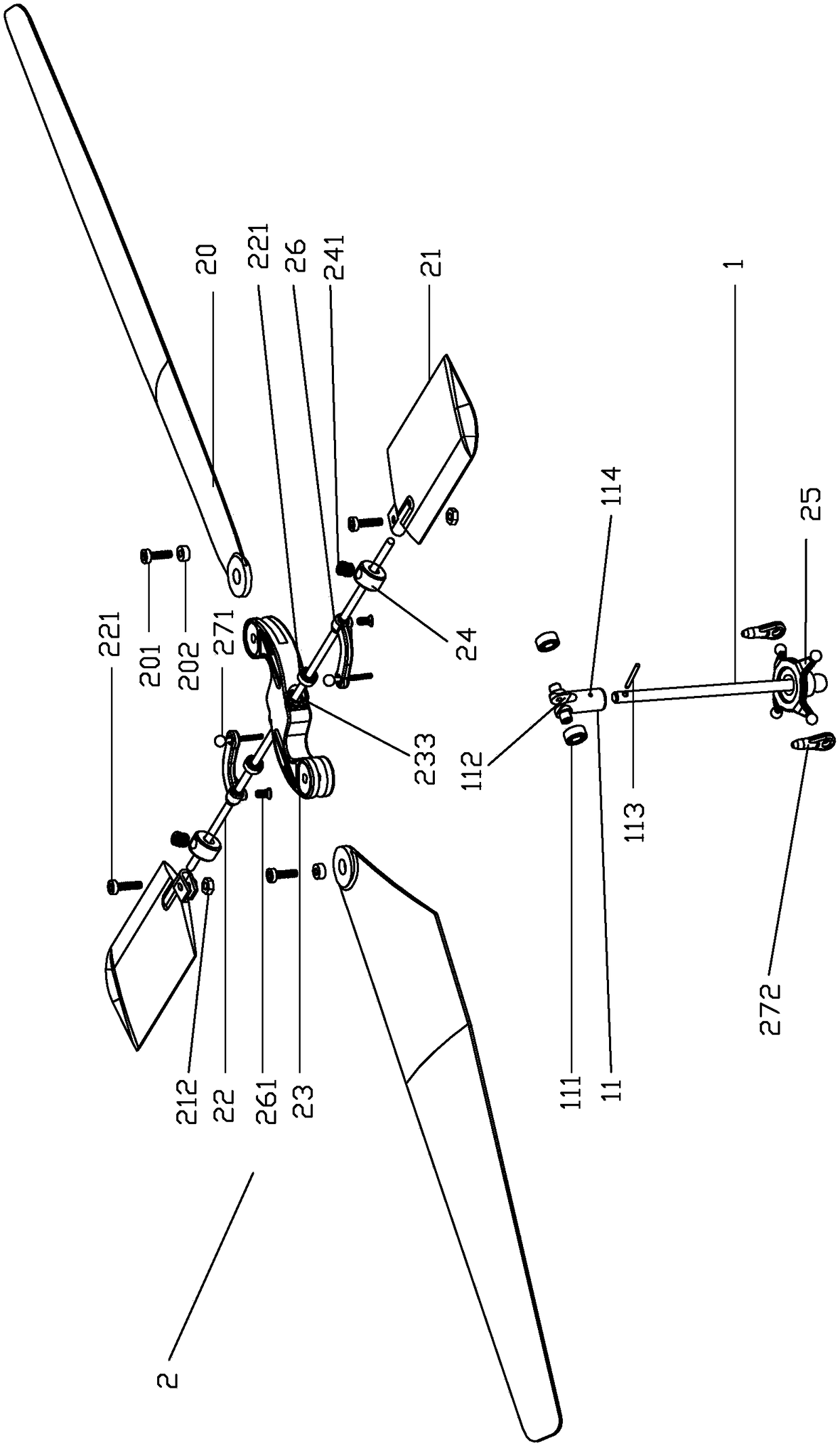

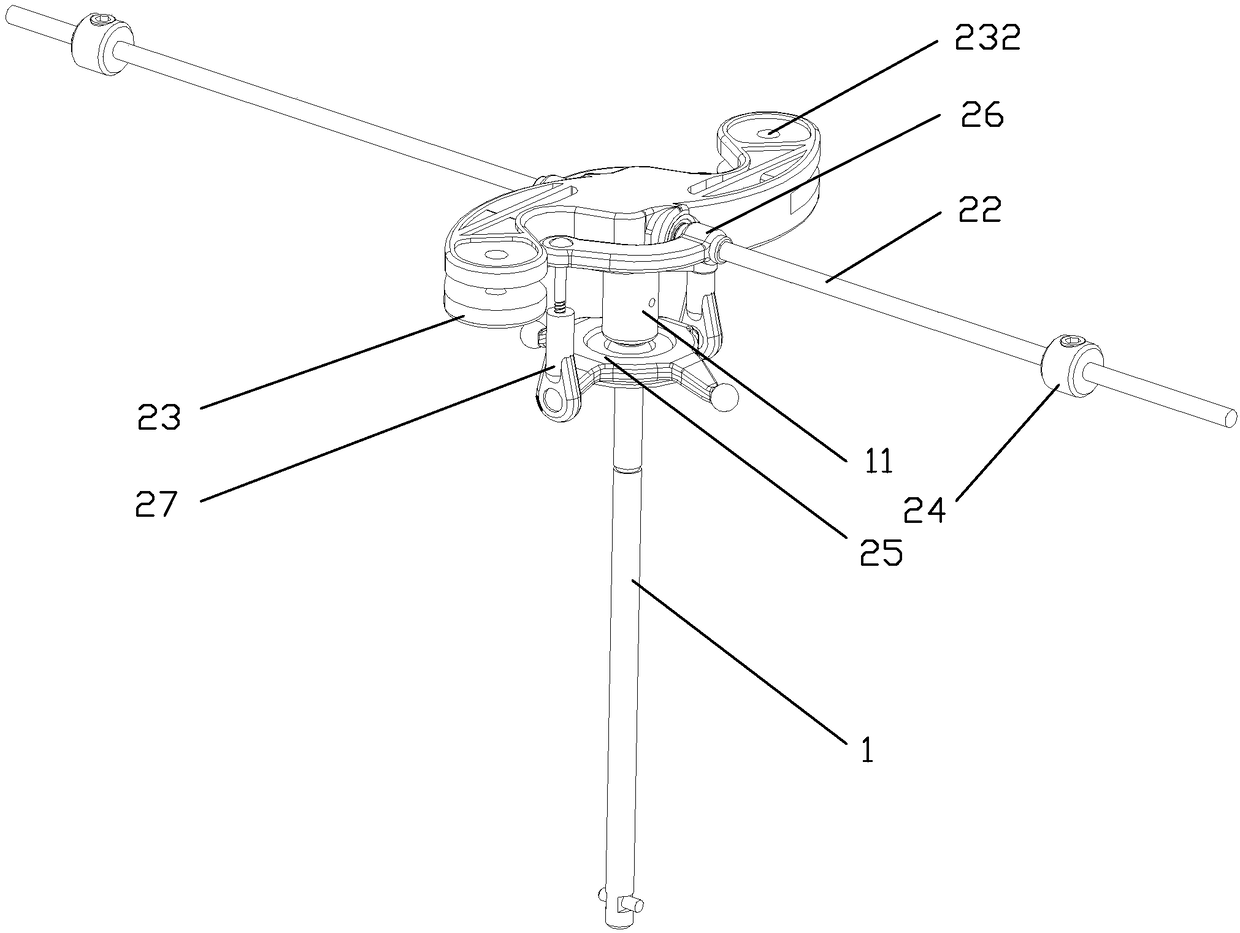

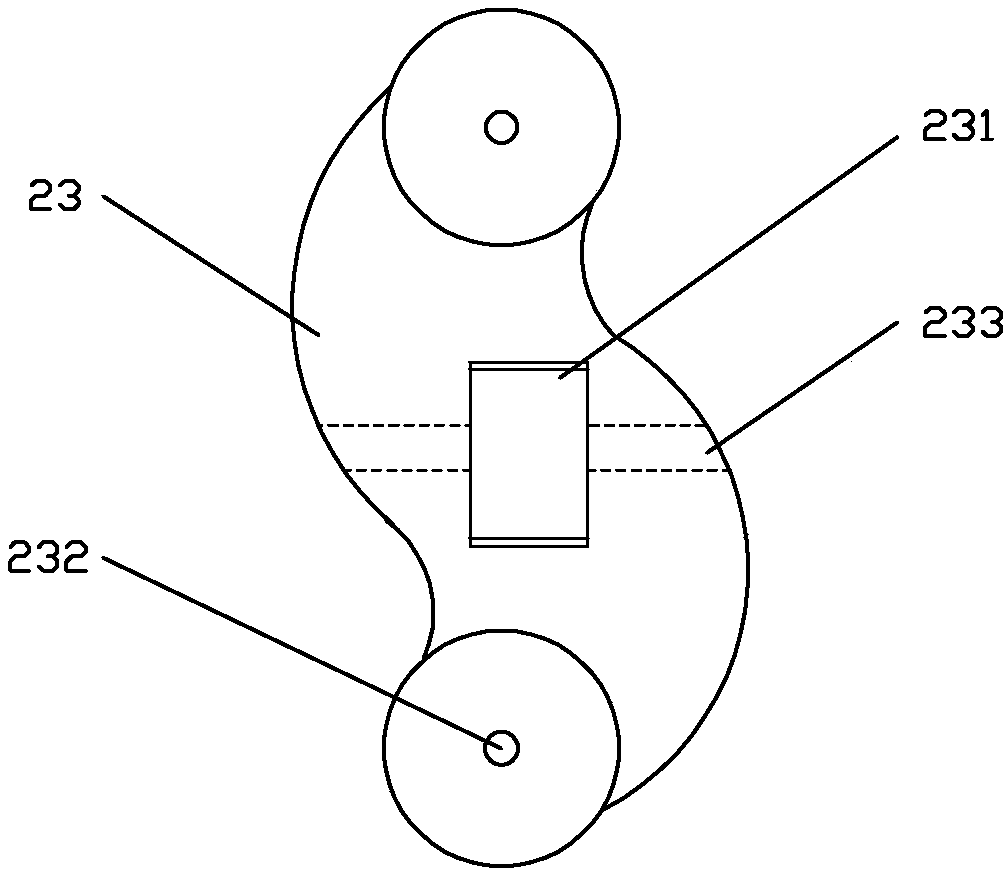

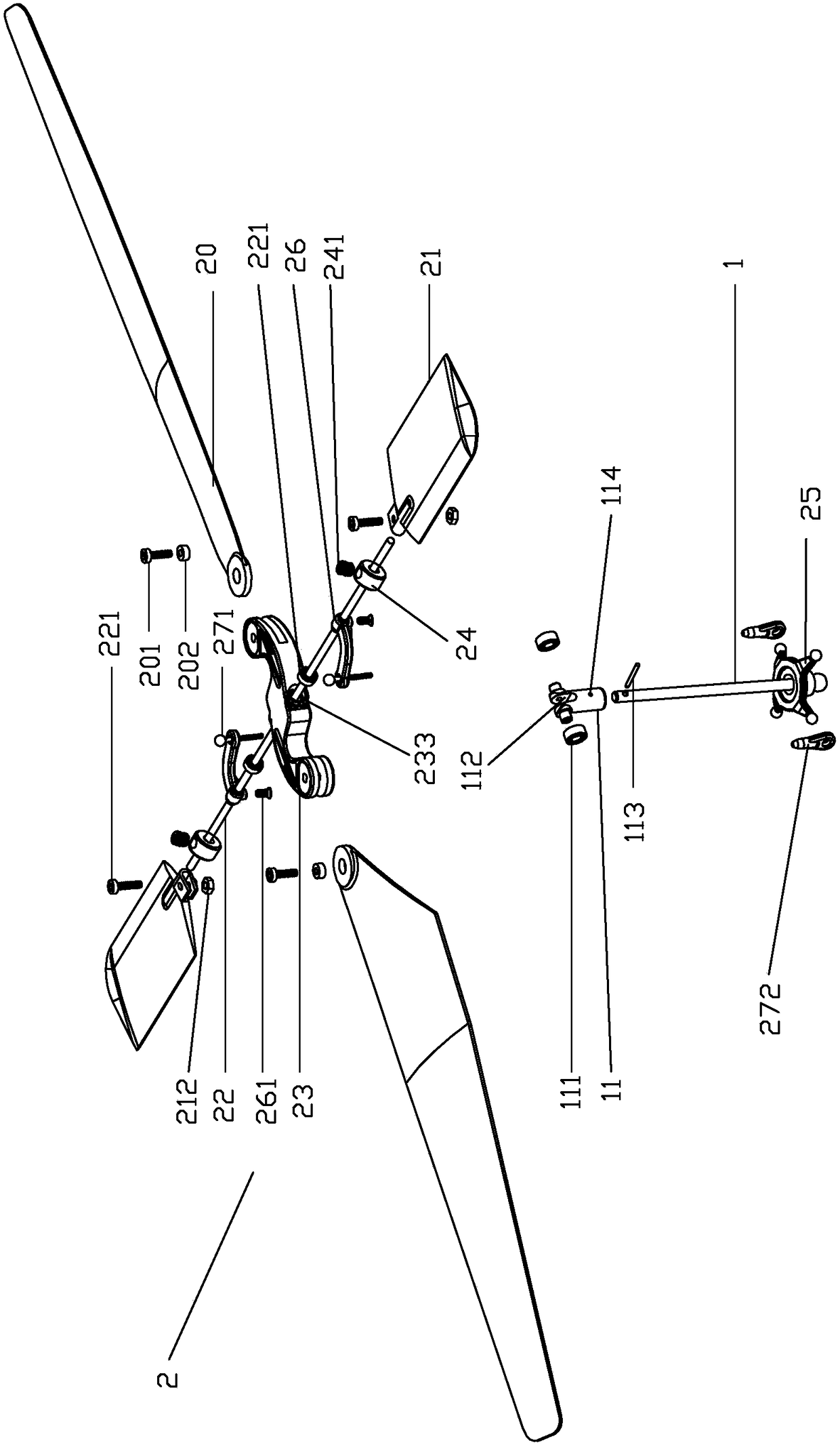

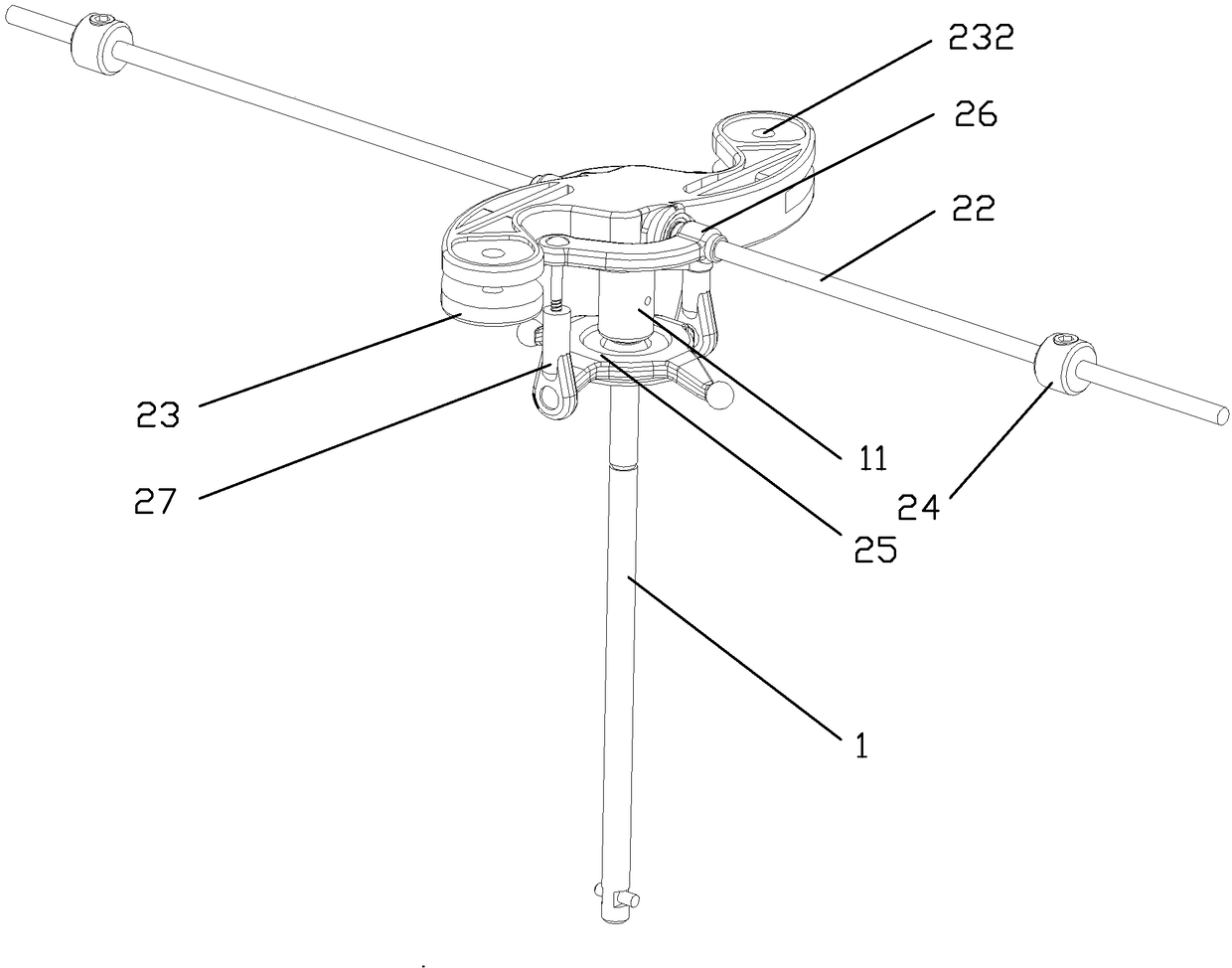

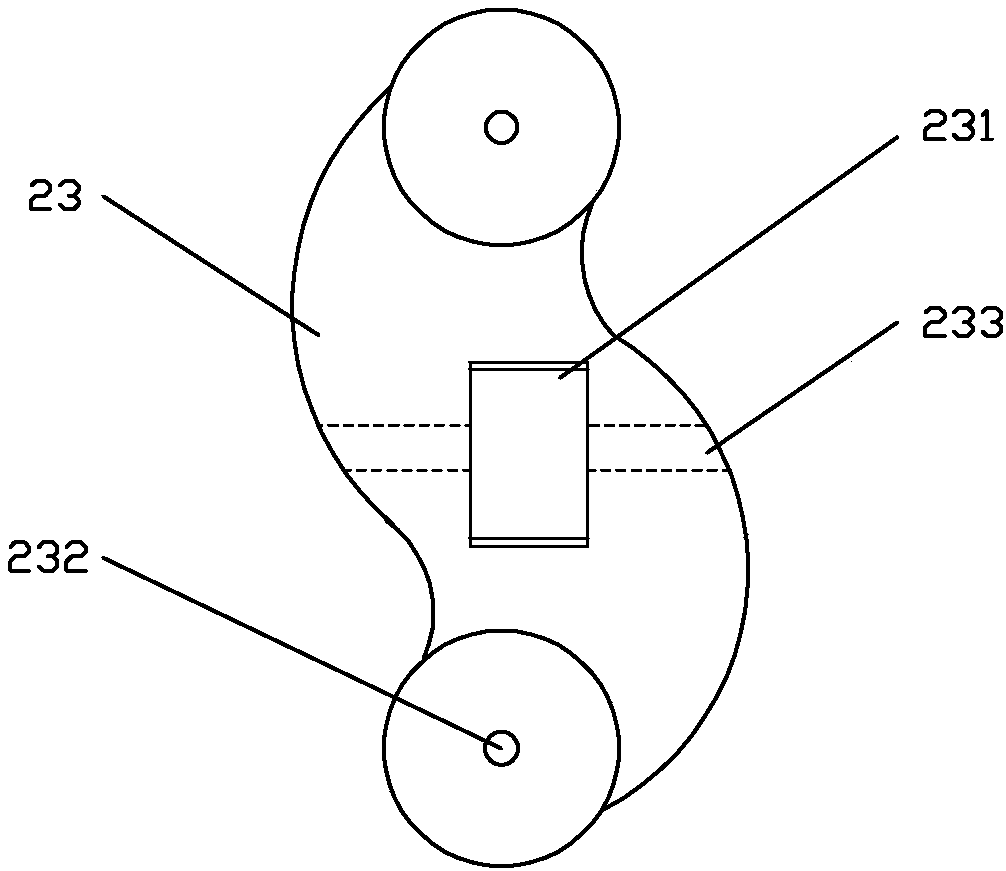

Aerial dynamic balance control device of high-altitude flight toy

InactiveCN105771270ASmooth and smooth flight movementGuarantee the safety of useToy aircraftsAviationDrive shaft

The invention discloses an aerial dynamic balance control device of a high-altitude flight toy. The balance device comprises an aerocraft driving shaft and a rotating device which is fixedly connected to the driving shaft, wherein the rotating device comprises a pair of main blades and a pair of balance blades which are connected by virtue of blade fixing devices. The entire body of the aerial dynamic balance control device of the high-altitude flight toy provided by the invention can be automatically balanced during steering, so that an aerocraft is more smooth and stable in a flight motion, and the aerocraft is prevented from becoming broken apart in the case that centrifugal force is out of control.

Owner:许美兰

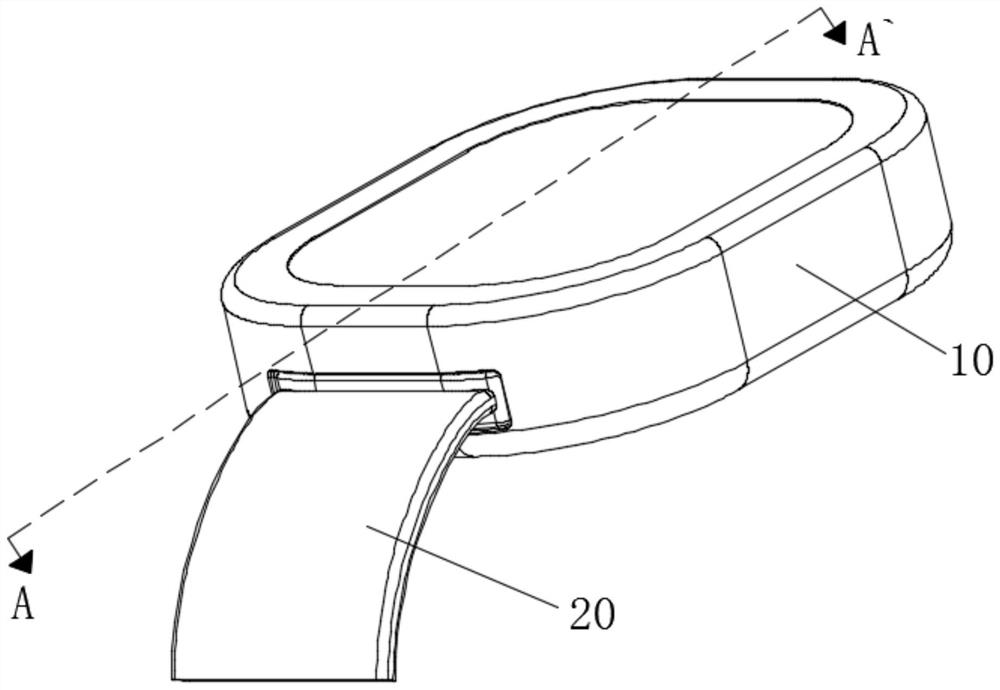

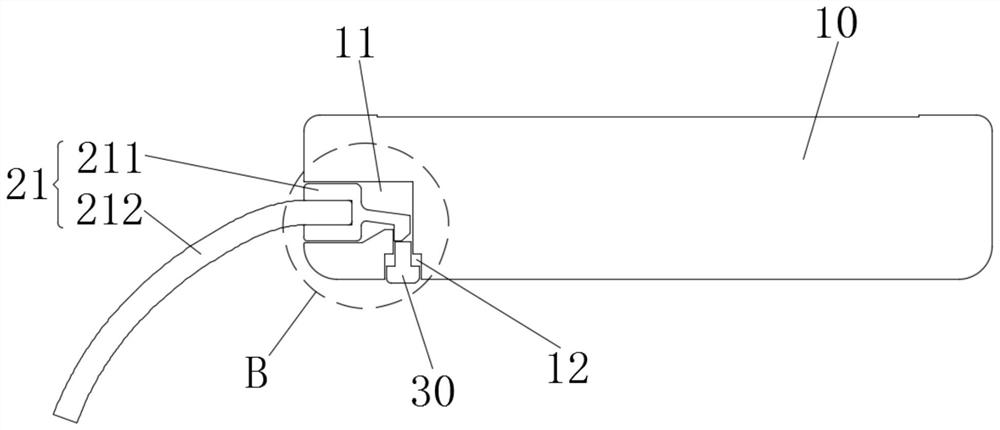

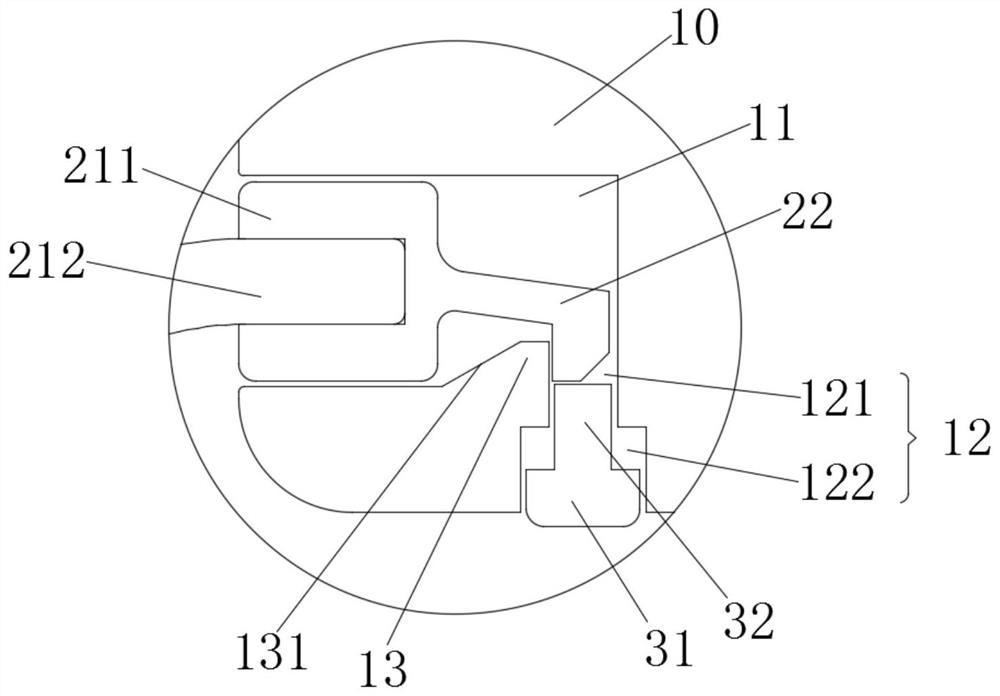

Watch with detachable watchband

Owner:TCL COMM NINGBO

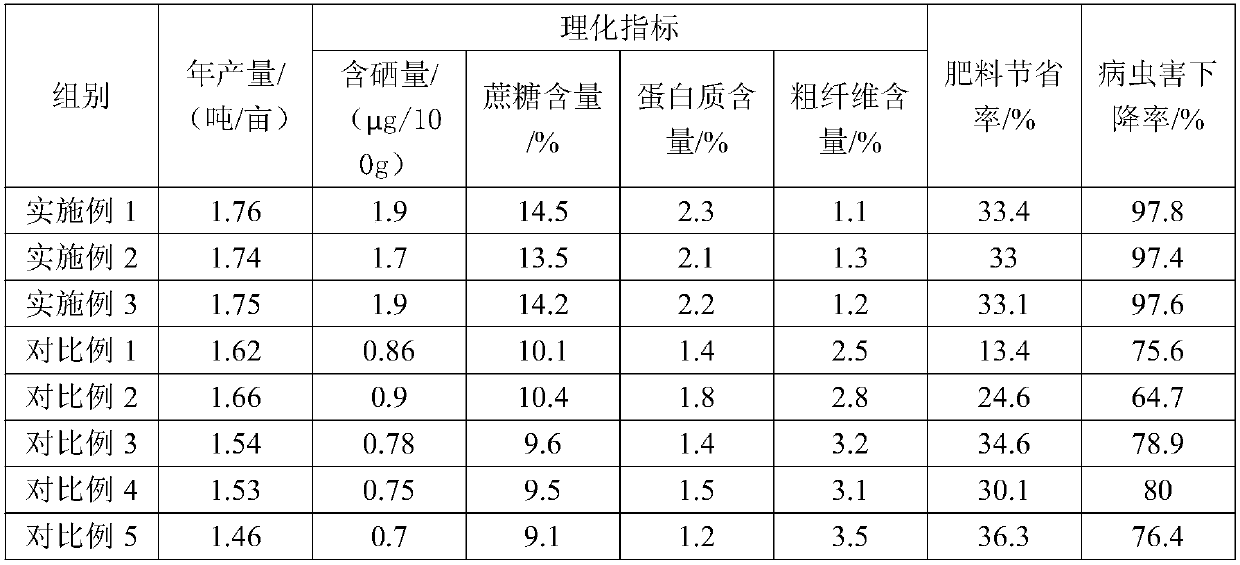

Selenium-enriched Lechang water chestnut planting method

InactiveCN107593305AEasy to controlNo dustPlant cultivationCultivating equipmentsGrowth plantWater Chestnuts

The invention discloses a selenium-enriched Lechang water chestnut planting method. The selenium-enriched Lechang water chestnut planting method adopts the soilless culture technology and comprises preparing a nursery substrate from perlite and vermiculite, arranging seed water chestnut onto a nursery bed, covering the seed water chestnut with a layer of plant ash, then transplanting sprouted water chestnut to a cultivating trough containing base fertilizer and a planting substrate prepared from mushroom residue, corn stalk, vermiculite and coarse sand at a ratio of 3:5:1:1. Through nutrient solution supplementation and foliage fertilization, the selenium-enriched Lechang water chestnut planting method can promote plant growth and well appropriately provide nutrition for plants to produceselenium-enriched Lechang water chestnut.

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

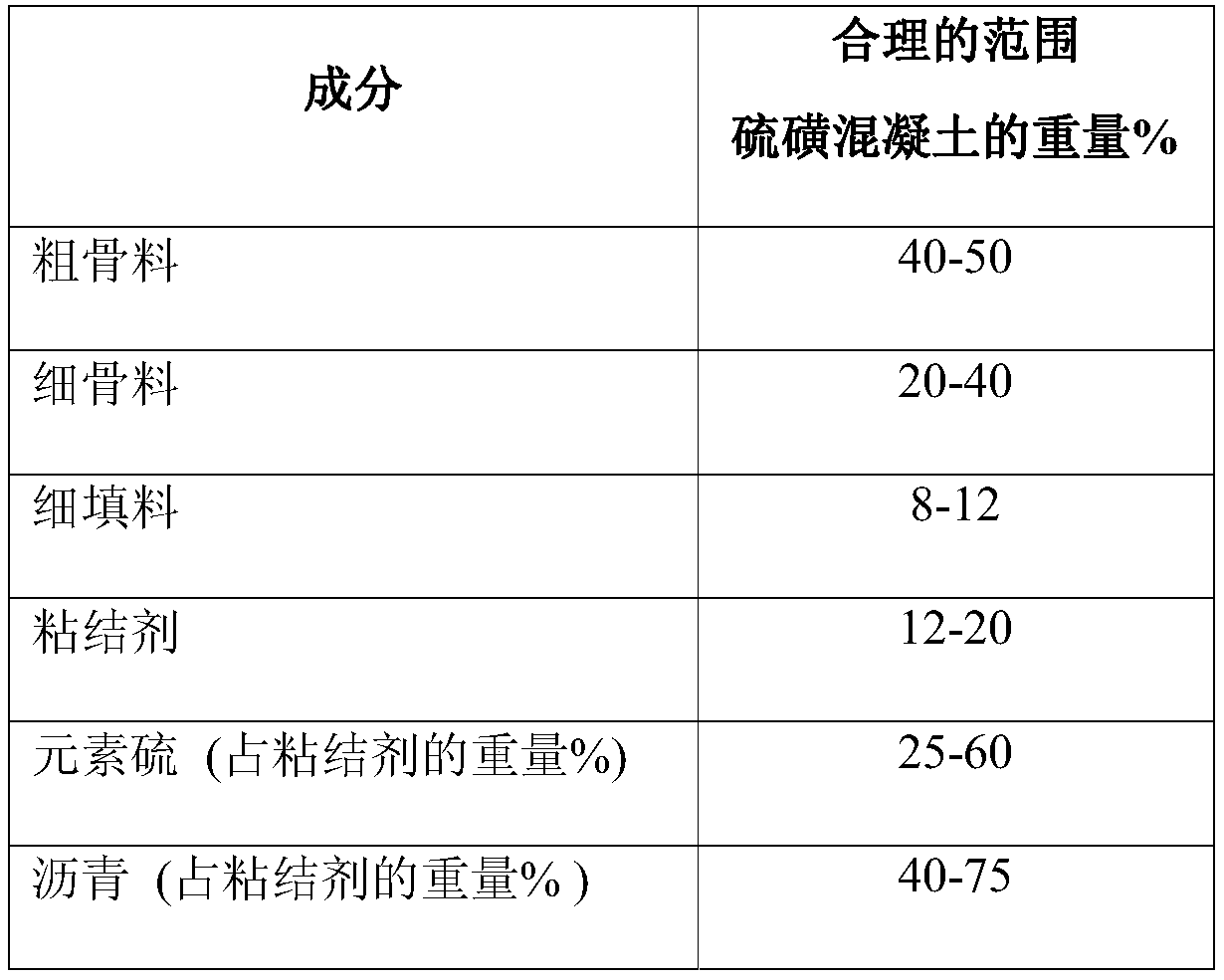

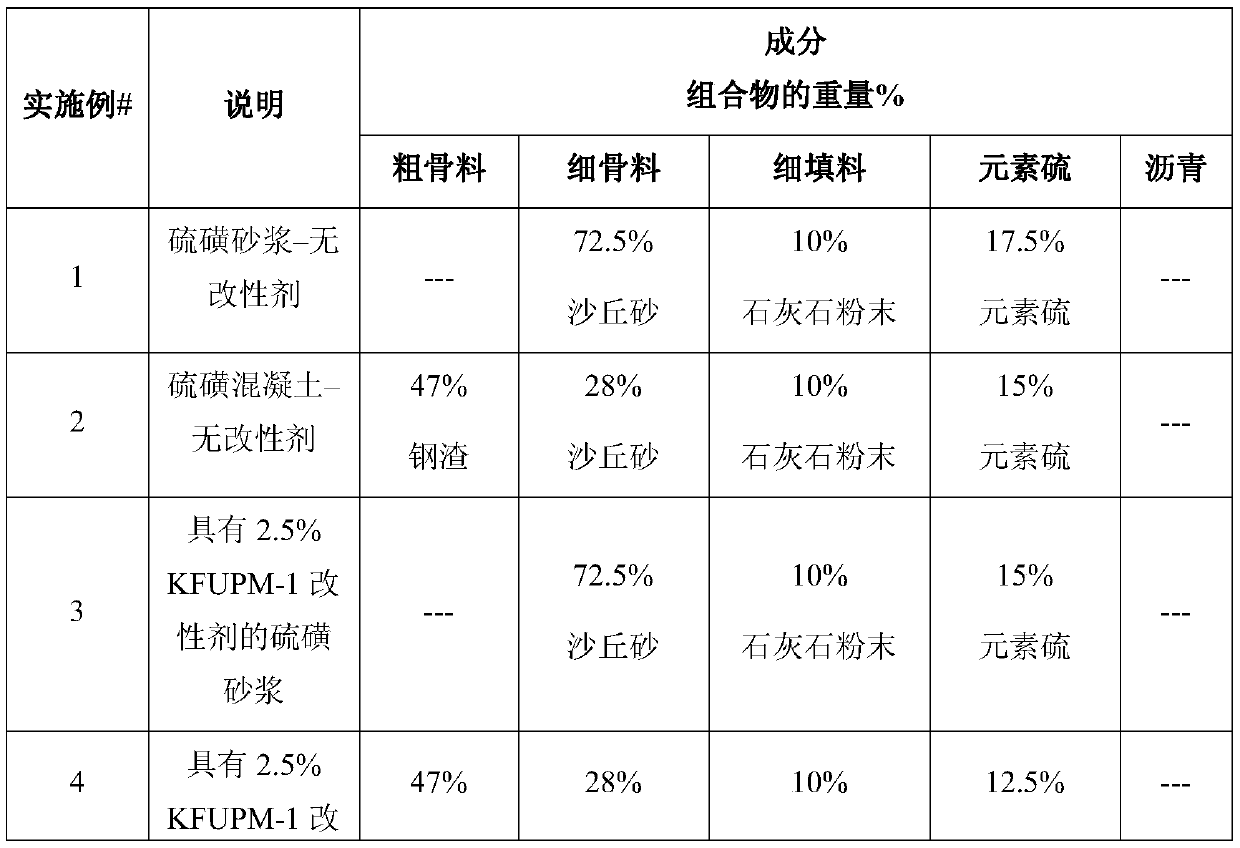

Fire-resistant sulfur concrete

A sulfur concrete has constituents that include a coarse aggregate in an amount in a range of 40-50 wt% of the weight of the sulfur concrete, a fine aggregate in an amount in a range of 20-40 wt% of the weight of the sulfur concrete, a fine filler in an amount in a range of 8-12 wt% of the weight of the sulfur concrete, and a binder in an amount in a range of 12- 20 wt% of the weight of the sulfurconcrete. The binder includes elemental sulfur in an amount in a range of 25-60 wt % of the weight of the binder and asphalt in an amount in a range of 40-75 wt % of the weight of the binder.

Owner:SAUDI ARABIAN OIL CO +1

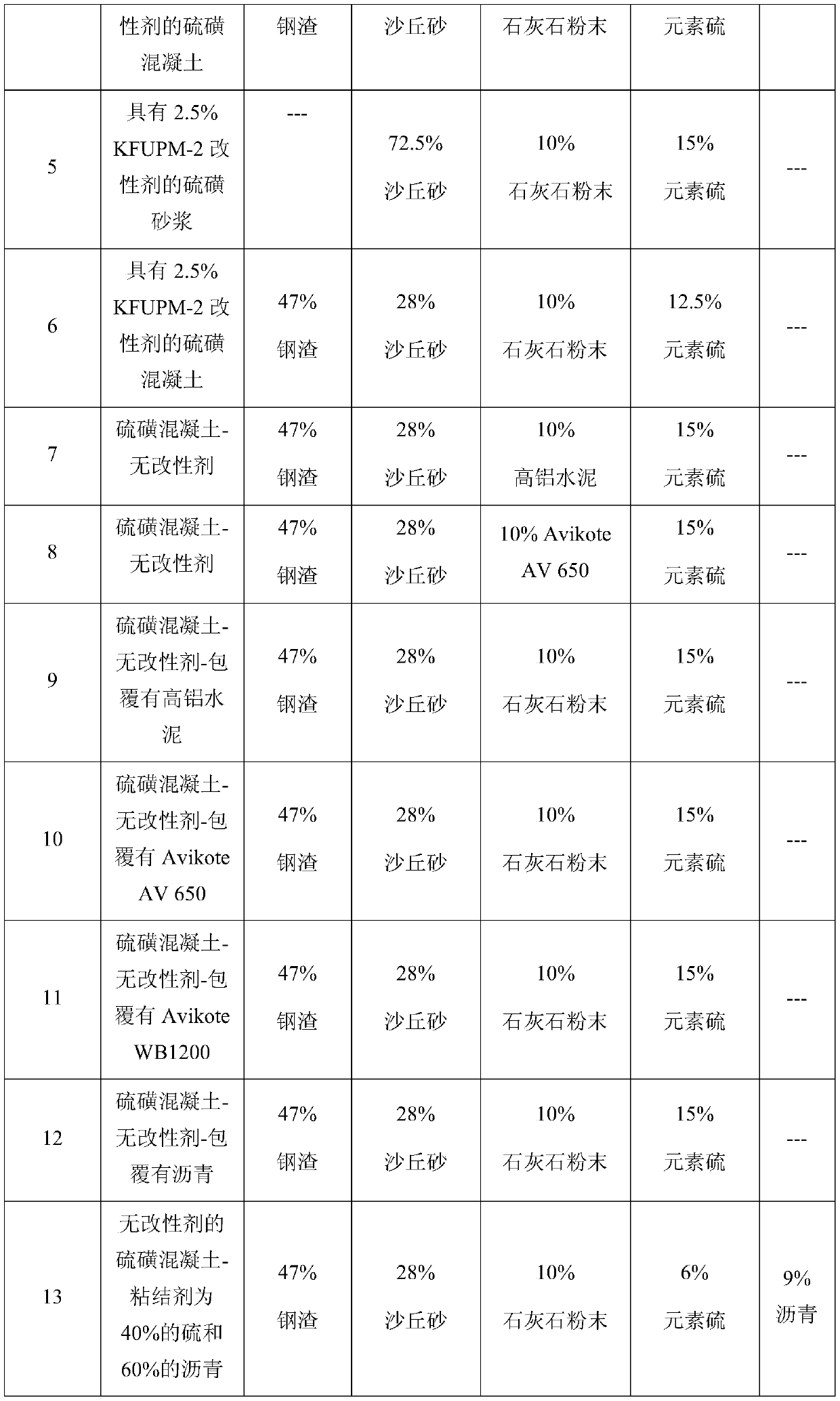

Waterproof dense board

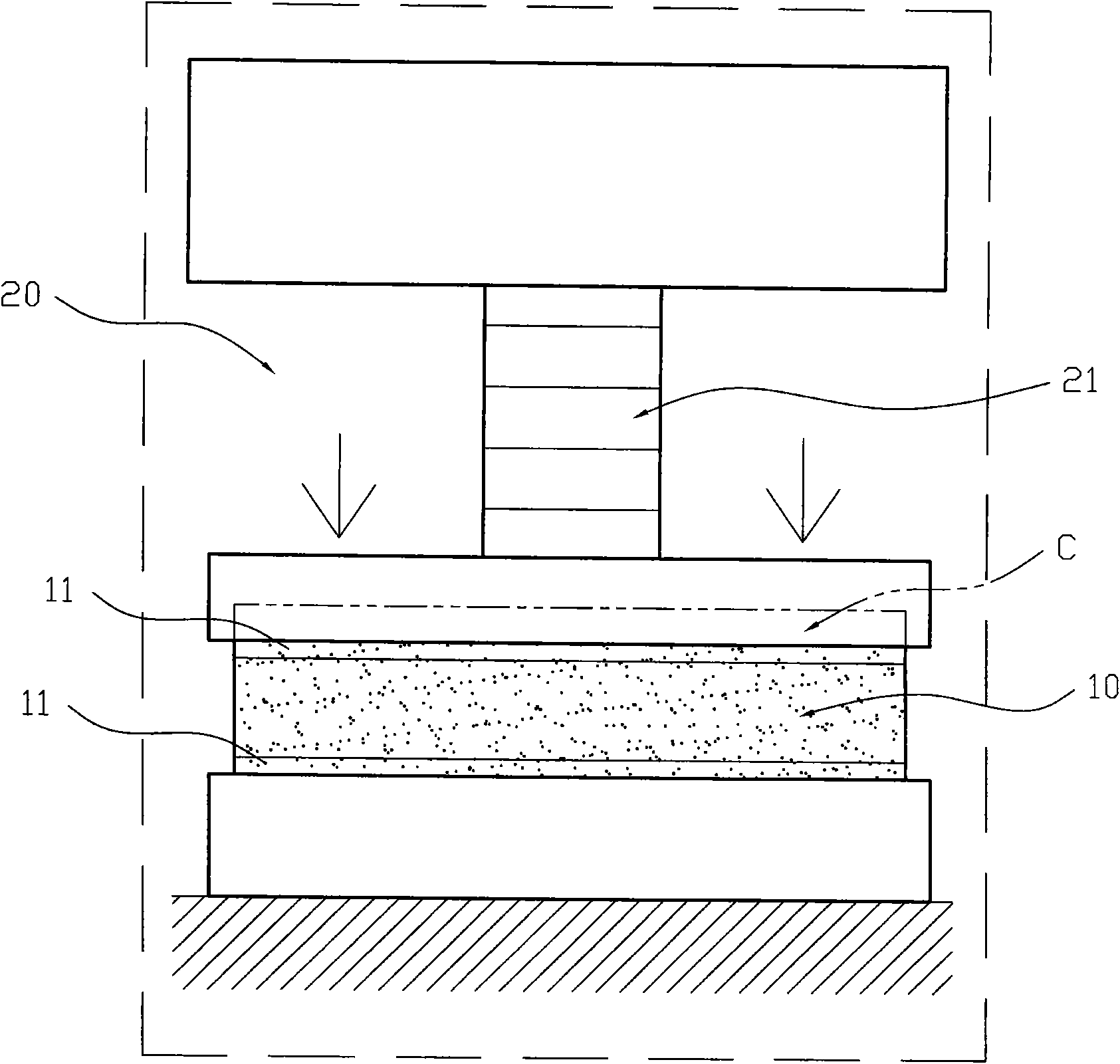

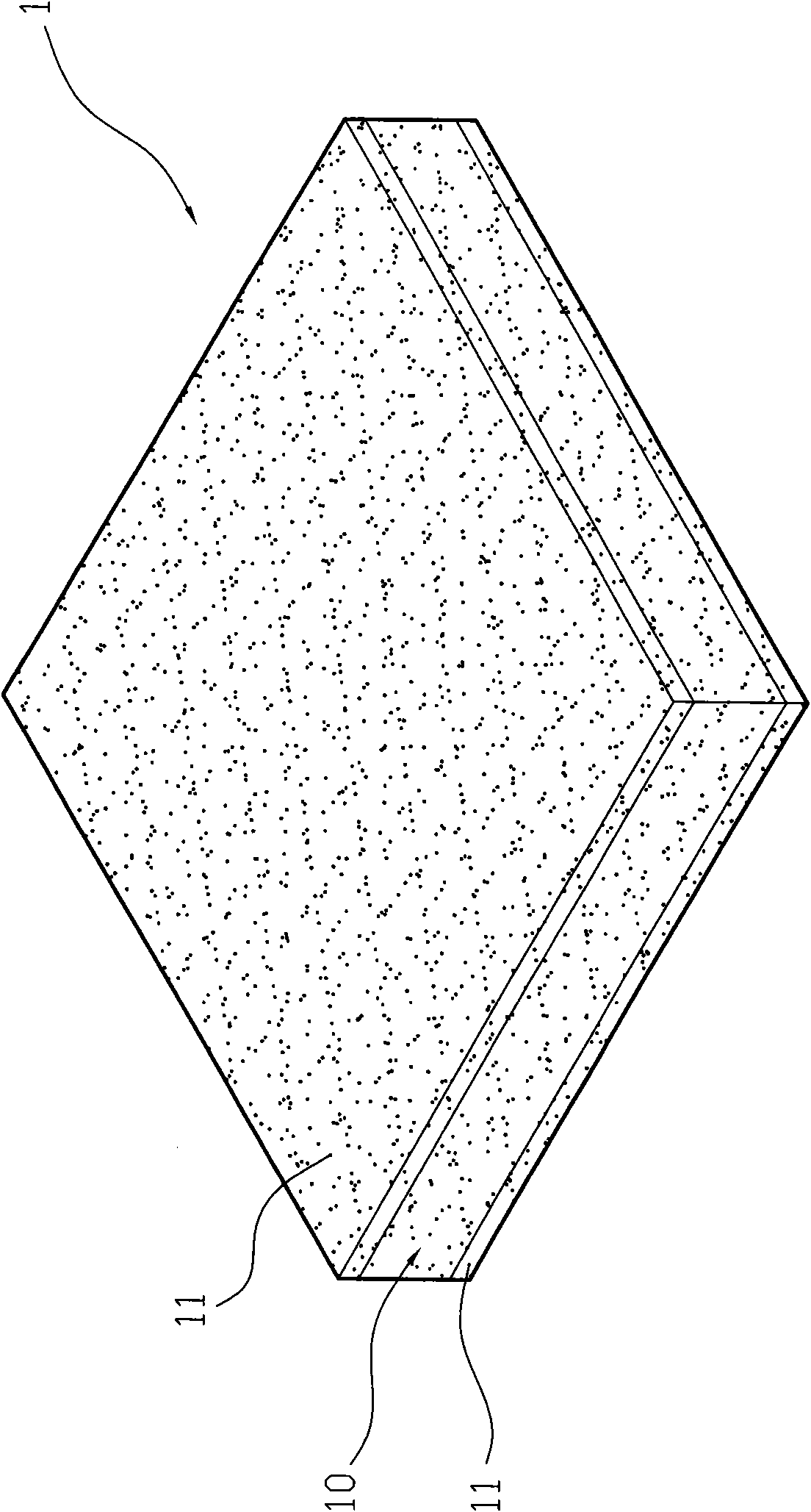

InactiveCN102825643AAvoid deformationPrevent shrinkageWood working apparatusDomestic articlesEngineeringHot press

The invention relates to a waterproof dense board. A manufacturing process of the waterproof dense board comprises the following steps of: rubber mixing molding, wherein bits of wood are formed by an adhesive obtain a dense board; and carbonization processing, wherein the dense board is placed into a hot press which is used for uniformly baking the dense board at a high temperature in a convection manner and drives a packing apparatus to synchronously press and pack the dense board in the high-temperature backing process, and a working temperature of the high-temperature backing process is between 185 DEG C and 250 DEG C, thereby obtaining the waterproof dense board.

Owner:CHENG TAI FENG TIMBER

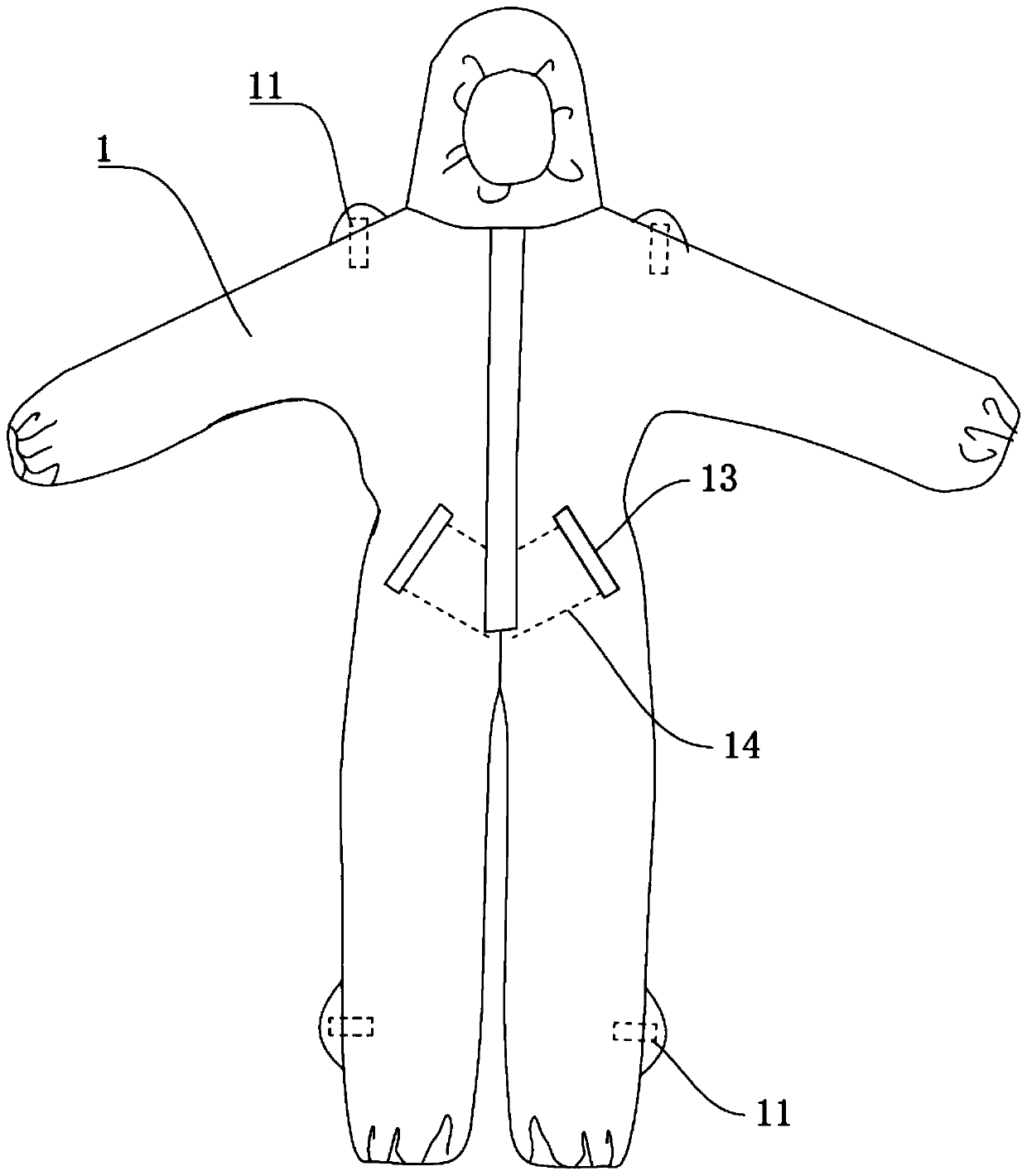

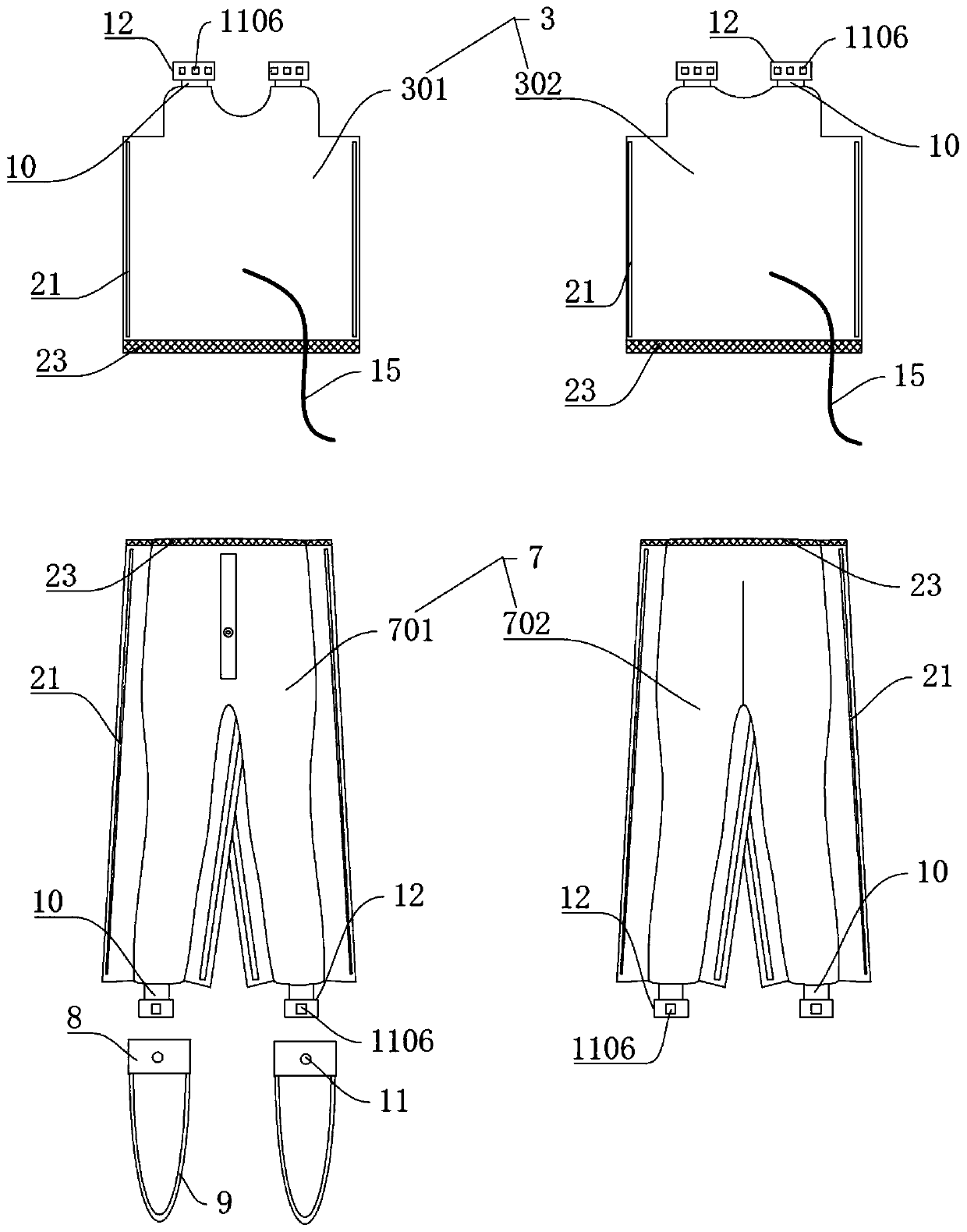

Work clothes supporting use of medical protective clothing and use method thereof

PendingCN111449337AEasy to useLow priceProtective garmentSpecial outerwear garmentsMechanical engineeringNursing

The invention discloses work clothes supporting the use of medical protective clothing and a use method thereof. The work clothes comprise outer-layer clothes and outer-layer trousers, and inner-layerclothes and inner-layer trousers are detachably connected into the outer-layer clothes and the outer-layer trousers; when a wearer of the medical protective clothing needs to take off the innermost layer of clothing, the connection between buckles and clamping holes is removed by pressing a switch, pull belts are pulled through pocket cylinders, the pull belts, the inner-layer clothes and the inner-layer trousers can be disassembled after pulling, the innermost layer of clothing is pulled to the pocket cylinders through the pull belts, and the undressing operation is completed; the innermostlayer of clothing enters the pocket cylinders, two fixing ropes in a fixing group are fastened and knotted to be fixed, the middle positions of the two fixing ropes are cut off, and then the innermostlayer of clothing can be taken out; the invention further provides a method for wearing and taking off the innermost layer of clothing. Through the arrangement, the part, making contact with sweat, of the work clothes can be taken off in the working process of wearing the medical protective clothing, so that the comfort and the working quality of the medical staff are improved, and the health ofthe medical staff is guaranteed.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

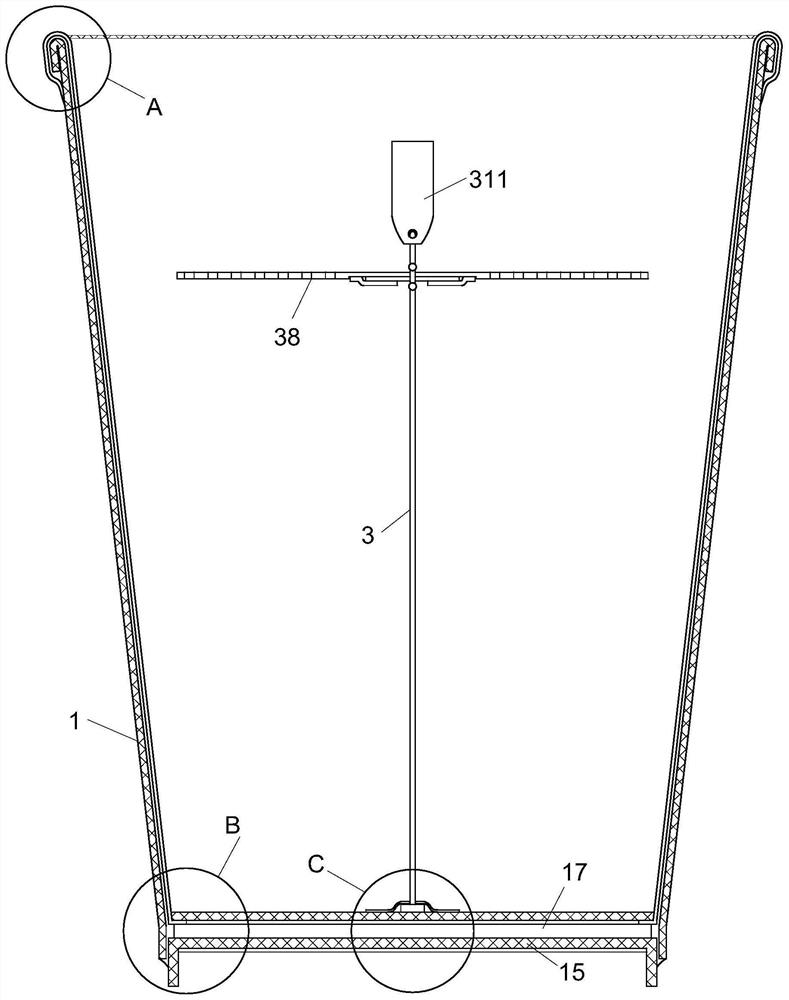

High-rise household garbage classification conveying device

ActiveCN110331841AGuarantee unimpededWon't disintegrateVertical ductsHigh riseMechanical engineering

The invention discloses a high-rise household garbage classifying and conveying device, which comprises a wall body, wherein a lifting cavity is arranged in the wall body, a lifting power device is arranged on the upper side of the lifting cavity, a lifting block is arranged in the lifting cavity in a sliding manner, four garbage storage cavities are uniformly distributed in the lifting block in the front-back direction, a conveying mode similar to a small elevator is adopted, garbage bags are prevented from being disassembled and scattered, the smoothness of a channel is ensured while the cleanness and the sanitation in the channel are kept, the four garbage storage cavities are arranged, garbage can be classified and placed and can be respectively conveyed to different storage cavities,the secondary garbage classification of workers is reduced, the device is civilized and environment-friendly, and meanwhile, a shielding door is opened only when the garbage storage cavities reach thefloor, so that people are prevented from throwing garbage into the channel, and noise and peculiar smell can be reduced.

Owner:苏留俊

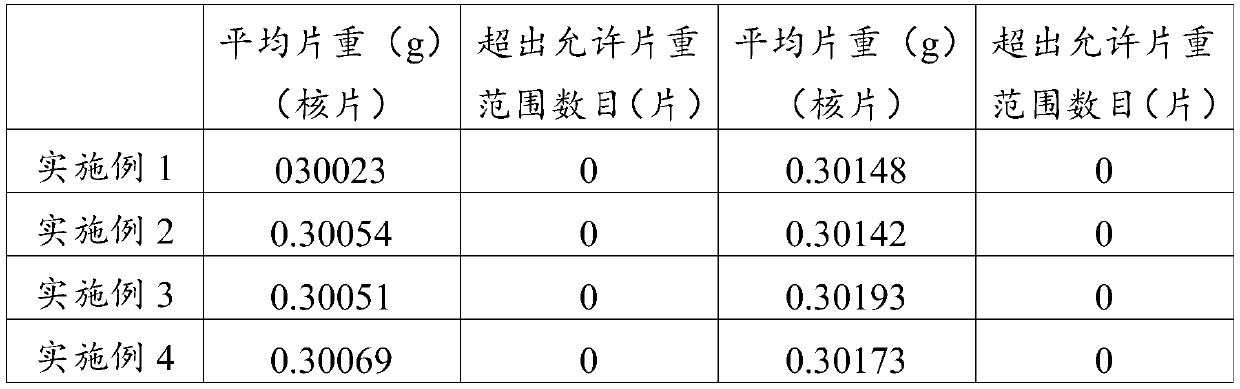

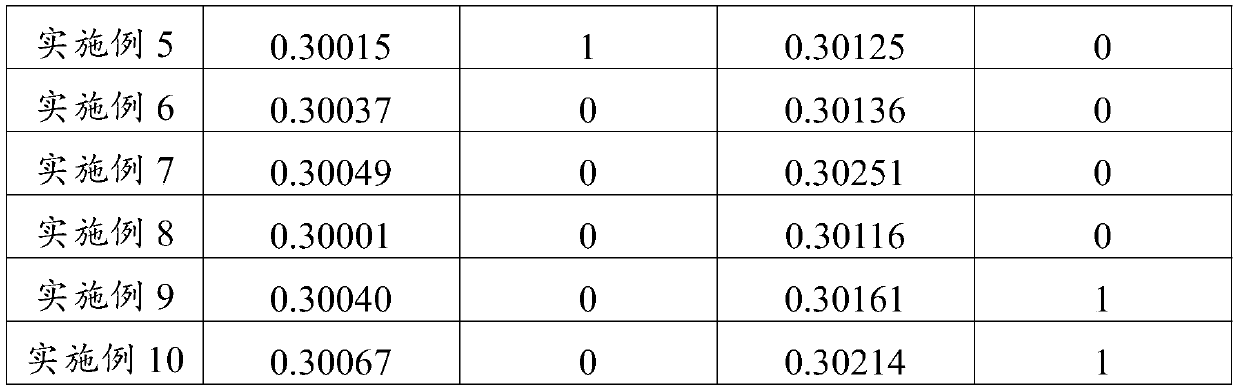

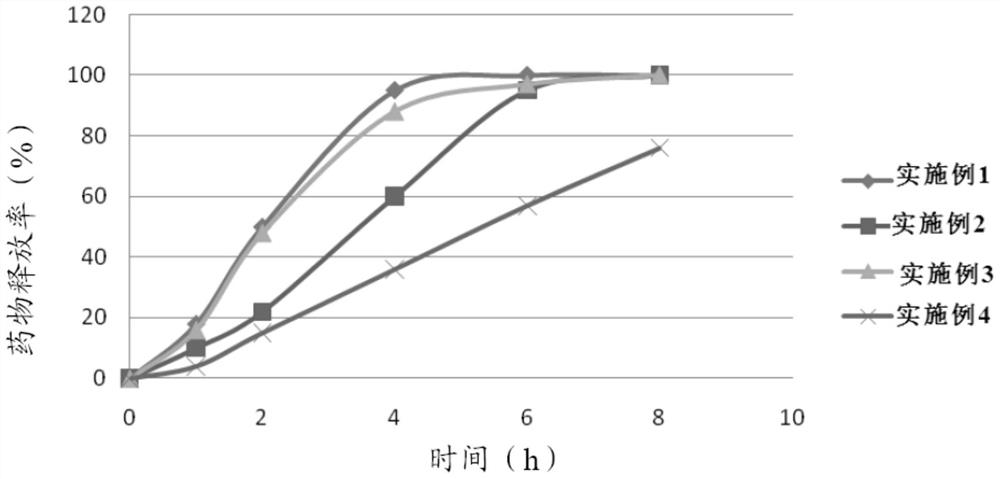

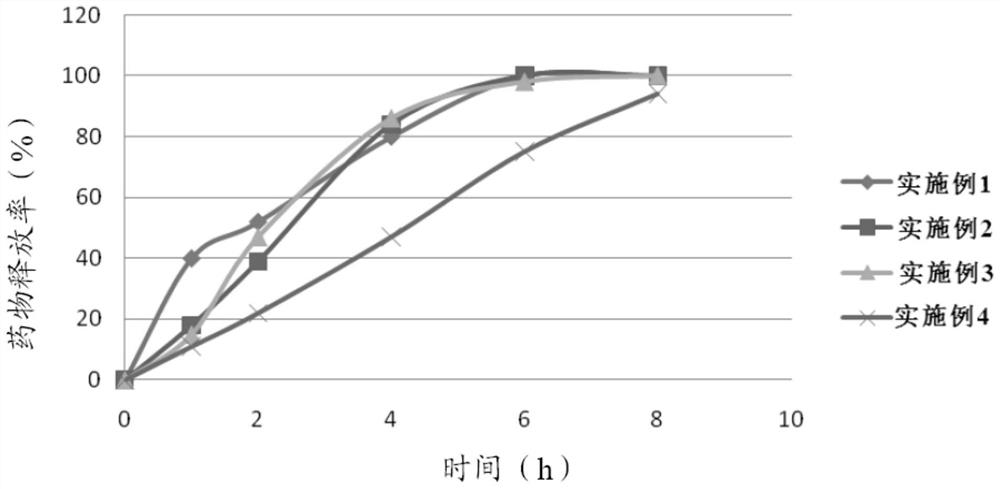

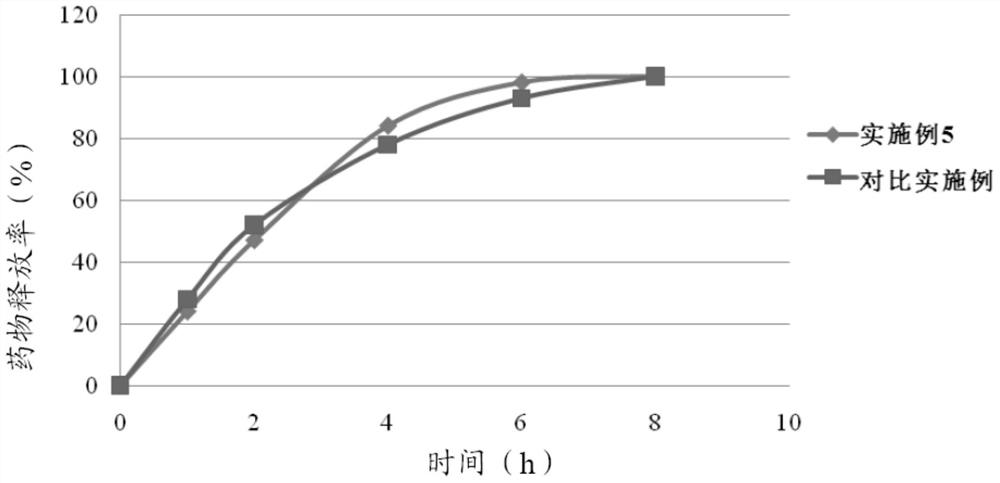

Oral potassium chloride sustained-release tablet and preparation method thereof

ActiveCN106466302BReduce releaseIncrease contentMetabolism disorderPharmaceutical delivery mechanismMethacrylateCellulose

The invention discloses an oral potassium chloride sustained-release tablet and a preparation method thereof. An oral potassium chloride sustained-release tablet of the present invention comprises a tablet core containing an effective dose of potassium chloride and a coating coated on the tablet core, and is characterized in that: the coating is a sustained-release coating, which includes weight A mixture of aminomethacrylate copolymer type A and ethylcellulose in a ratio of (1-9):1. The preparation method includes the following steps: wet granulation of the potassium chloride tablet core material containing an effective dose, and then compressing into the tablet core, coating the tablet core with a coating liquid, and forming the tablet core on the surface of the tablet core. Coating step. In the embodiment of the present invention, the oral potassium chloride sustained-release tablet coating releases potassium chloride by means of membrane diffusion, so as to achieve stable sustained release of potassium chloride, without causing potential safety hazards to patients, and the preparation method is simple in process, and the process conditions It is easy to control, so that the prepared oral potassium chloride sustained-release tablet of the present invention has a high qualification rate and yield.

Owner:BRIGHT FUTURE PHARMA LAB LTD (CN) +1

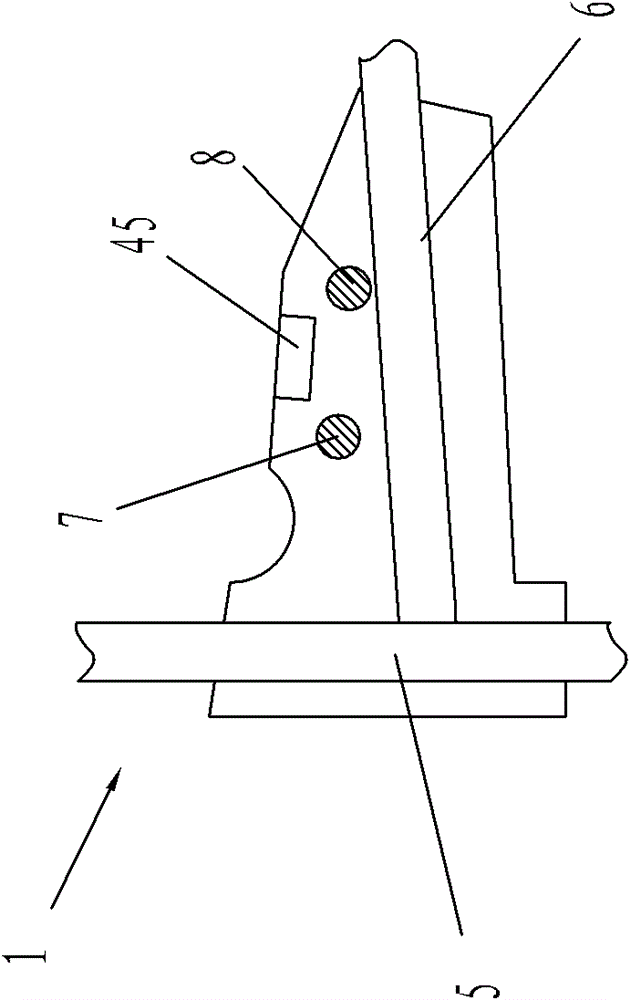

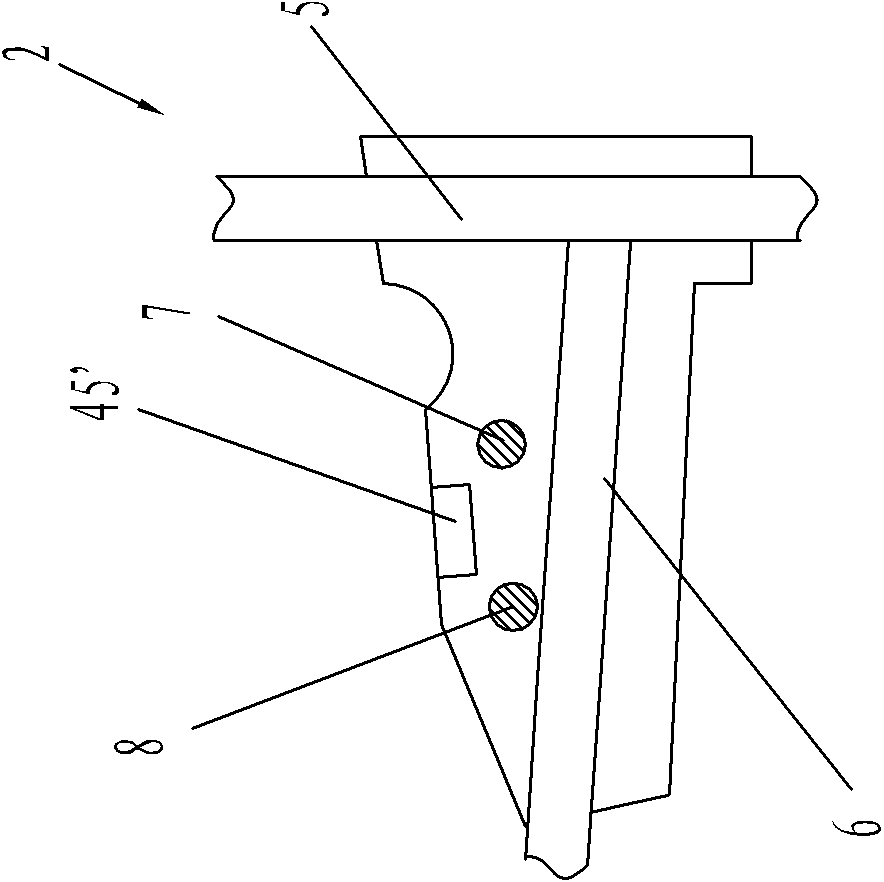

Fasteners for I-beam sheds

The invention relates to a buckling member for an I-steel tent, which comprises a first buckling sheet and a second buckling sheet adaptive to the first buckling sheet. The first buckling sheet and the second buckling sheet are respectively provided with clamping grooves. The clamping groove on the first buckling sheet corresponds with the clamping groove on the second buckling sheet. The first buckling sheet and the second buckling sheet are respectively provided with screw holes. When the buckling member for the I-steel tent disclosed by the invention is used, I-steel as a tent leg and I-steel as a transverse beam are tightly clamped and fixed together through the first buckling sheet and the second buckling sheet; the two I-steels are firmly connected and fixed in the clamping grooves on the buckling sheets respectively; compared with the prior art, the connection through the buckling member is more firm; higher-intensity impact or vibration can be born; in the event of tunnelling and preventing gun, the I-steel tent cannot be collapsed and dismounted; and the buckling member for the I-steel tent disclosed by the invention is simple in structure and applied to large-range popularization.

Owner:王传峰

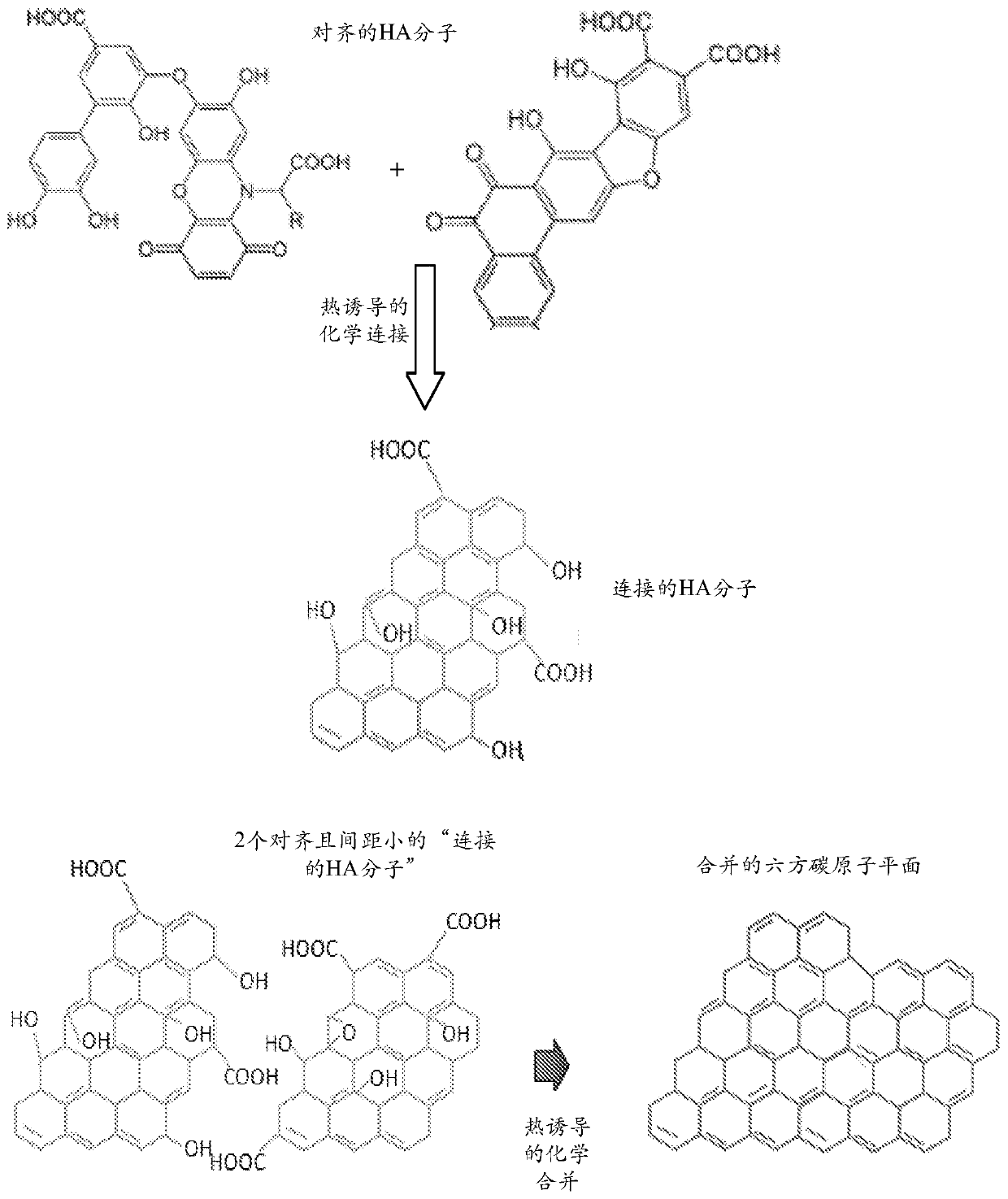

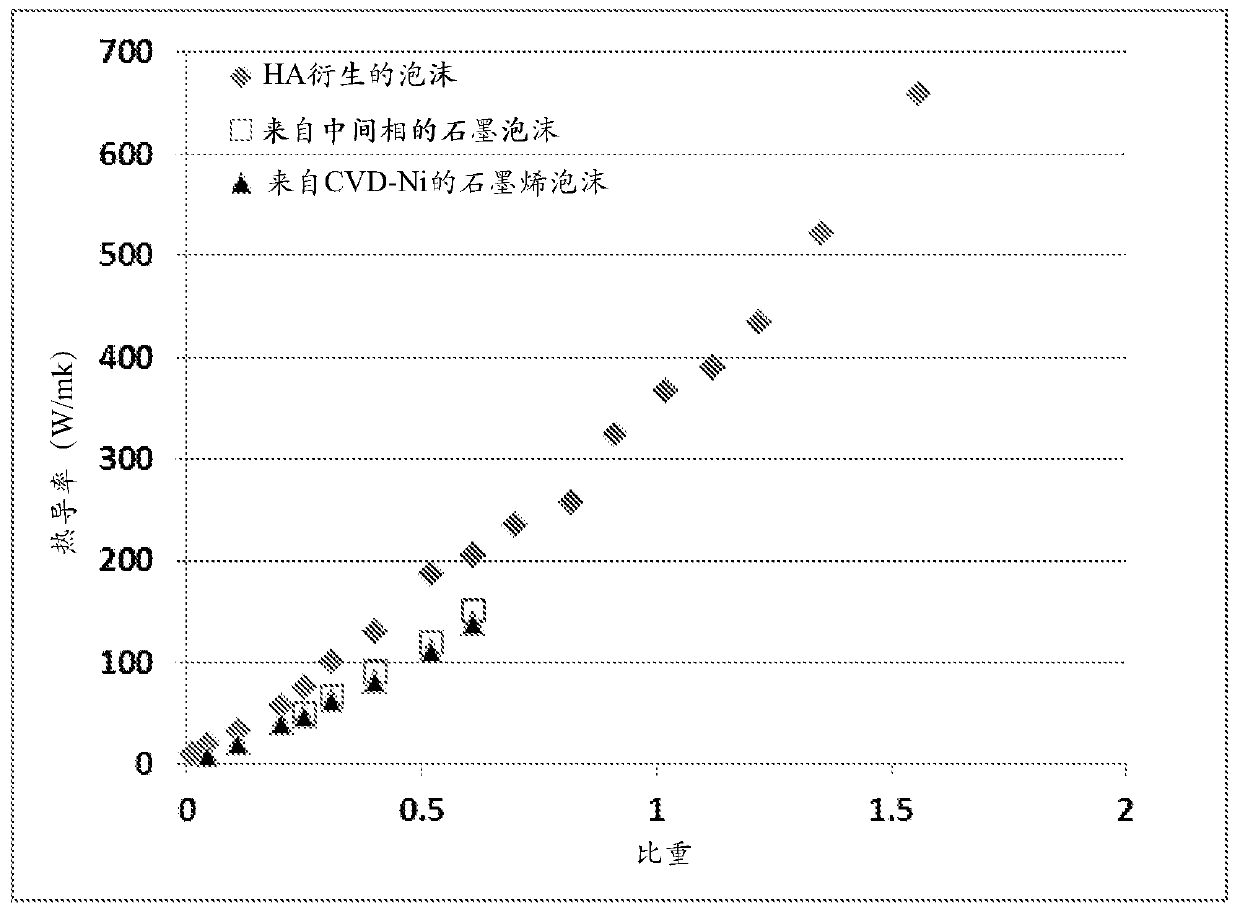

Humic Acid Derived Conductive Foams and Devices

ActiveCN109803820BImproves Structural IntegrityWon't disintegrateMaterial nanotechnologyLiquid surface applicatorsPhysical chemistryMineralogy

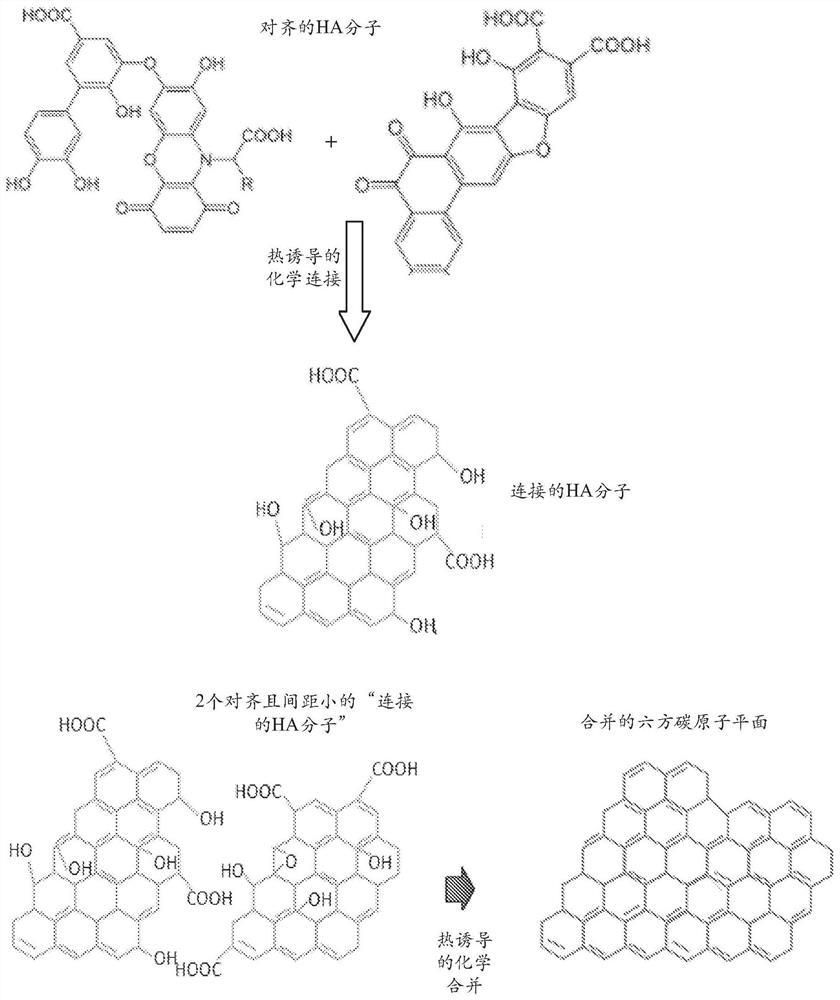

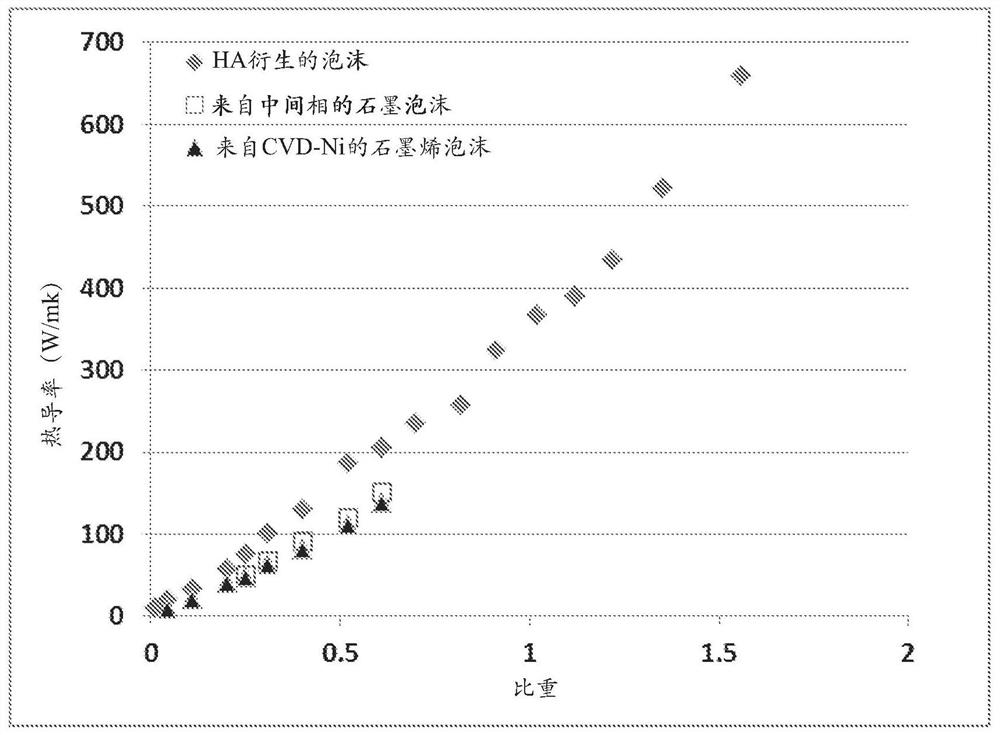

A foam derived from humic acid, which is composed of a plurality of pores and pore walls, wherein the pore walls contain monolayer or few-layer humic acid-derived hexagonal carbon atom planes or sheets, and the few-layer hexagonal carbon atom planes Or the sheet has 2-10 layers of stacked hexagonal carbon atom planes with an interplanar spacing d of from 0.3354 nm to 0.40 nm as measured by X-ray diffraction? 002#191, and the single-layer or few-layer hexagonal carbon atom plane contains 0.01% to 25% by weight of non-carbon elements, and wherein the humic acid is selected from oxidized humic acid, reduced humic acid , fluorinated humic acids, chlorinated humic acids, brominated humic acids, iodized humic acids, hydrogenated humic acids, nitrogenated humic acids, doped humic acids, chemical Functionalized humic acids, or combinations thereof.

cpu cooling fan

ActiveCN105545776BLarge air volumeImprove cooling effectPump componentsDigital data processing detailsAir volumeCooling effect

Owner:安徽刚毅电子科技有限公司

A modified ceramic composite coalescence material for oily wastewater deoiling

InactiveCN103920474BImprove material propertiesWon't disintegrateOther chemical processesWater/sewage treatment by sorptionCeramic compositeActivated Aluminum Oxide

The invention discloses an oily wastewater deoiling and modification ceramic composite coalescence material. The oily wastewater deoiling and modification ceramic composite coalescence material is composed of, by weight, 20 parts to 70 parts of activated aluminum oxide materials r-Al2O3, 20 parts to 70 parts of kaolin, 5 parts of feldspar, 10 parts to 20 parts of pseudo-boehmite, 5 parts to 30 parts of wood charcoal, and 0.1 part to 40 parts of oxidized polypropylene or polythene organic polymer materials. Prescription making, ball-milling and smashing, kneading, vacuum pugging, extrusion forming, drying and sintering are conducted to enable an aluminum oxide cellular material to be obtained, the sintering temperature is controlled between 480 DEG C and 1500 DEGC, a green body is sintered for 10 hours to 24 hours, and then the green body is covered with the oxidized organic polymer materials; the aluminum oxide cellular material is covered with the oxidized polypropylene or the oxidized polythene at the temperature ranging from 100 degrees to 680 degrees, and then the composite modification ceramic coalescence material formed by the oxidized organic polymer materials covered with the aluminum oxide cellular material is obtained. The oily wastewater deoiling and modification ceramic composite coalescence material has the advantages of being high in adsorbability, long in service life, capable of being resistant to acid and alkali, and good in deoiling effect.

Owner:黄鸿安

Transplantation method for nucleus

InactiveCN100357435CSimple and fast operationAccurate removalRecombinant DNA-technologyNeedle penetrationTransfer gene

This invention discloses a simple and effective microoperation nucleolus transplant method. This invention has the following steps: extruding the inject pin that has absorbed biology substance before on the ovum cell to form the transparent strip gauffer between the inject pin and ovum holding pin, then sticking and penetrating into the transparent strip gauffer with the inject pin to enter the opening of the ovum holing pin, then pulling the inject pin out from the surrounding gap of the ovum and adding the negative pressure in the ovum holing pin to absorb the pole body and object karyoplasms into the ovum holing pin, and then adjusting the place of the ovum cell with ovum holing pin to make its center at the same horizontal line with the needle-point of the inject pin, fixing up the ovum cell again, injecting the biology substance in the inject pin into the cell cytoplast or the surrounding gap of the ovum. This invention can complete the micro stoning and nucleus injecting processing at one time rapidly without special device; it has little damage to the ovum and can be used extensively in the cell project such as animal clone and transfer gene and so on.

Owner:SHANDONG UNIV

Composite microbial bacterium stock solution suitable for sewage treatment and active liquid culture method

The invention discloses a compound microorganism bacterium stock solution suitable for sewage treatment and an active liquid culture method, and relates to the technical field of sewage treatment and microorganisms. The compound microorganism bacterium stock solution comprises bacillus subtilis, rhodococcus, pseudoalteromonas, thiobacillus denitrificans, bifidobacterium, saccharomycetes and a solid granular carrier. The carrier is added into the composite microorganism bacterium stock solution, so that microorganisms are attached to the carrier for proliferation and agglomeration growth, the effect of the composite microorganism bacterium stock solution on water body treatment is guaranteed, and the problem that the ammonia nitrogen removal rate is too low due to the fact that the microorganisms are not uniformly dispersed in the water body is solved.

Owner:新疆河润科技股份有限公司

Super cyclone type internal and external gas turbine inlet air conversion device and manufacturing method thereof

InactiveCN104632355AEmission reductionReduce generationInternal combustion piston enginesCombustion-air/fuel-air treatmentCycloneCombustion chamber

The invention discloses a super cyclone type internal and external gas turbine inlet air conversion device and a manufacturing method thereof. The super cyclone type internal and external gas turbine inlet air conversion device is applicable to internal and external gas turbines, effectively enables air entering the internal and external gas turbines to be activated and evenly distributed in a combustion chamber so as to be sufficiently mixed with fuel molecules. The super cyclone type internal and external gas turbine inlet air conversion device comprises a hollow conical barrel body. The hollow conical barrel body comprises a barrel-shaped base and a conical body. The peripheral wall of the barrel-shaped base is arranged in the extending direction of the hollow conical barrel body, and one end of the barrel-shaped base forms an open end. A connecting end is formed on one side of the open end of the barrel-shaped base. The connecting end is connected with the conical body. The conical body is formed by an annular wall face. By the adoption of the super cyclone type internal and external gas turbine inlet air conversion device, multiple functions are integrated on a single air inlet auxiliary device, the cost spent for purchasing and assembling multiple devices is reduced, the better vortex generation, catalytic agent conversion and exhaust emission effects are provided, and the industrial development leaps forwards.

Owner:林益煌

A sorting and conveying device for high-rise domestic waste

ActiveCN110331841BGuarantee unimpededWon't disintegrateVertical ductsAgricultural engineeringStructural engineering

The invention discloses a high-rise household garbage classifying and conveying device, which comprises a wall body, wherein a lifting cavity is arranged in the wall body, a lifting power device is arranged on the upper side of the lifting cavity, a lifting block is arranged in the lifting cavity in a sliding manner, four garbage storage cavities are uniformly distributed in the lifting block in the front-back direction, a conveying mode similar to a small elevator is adopted, garbage bags are prevented from being disassembled and scattered, the smoothness of a channel is ensured while the cleanness and the sanitation in the channel are kept, the four garbage storage cavities are arranged, garbage can be classified and placed and can be respectively conveyed to different storage cavities,the secondary garbage classification of workers is reduced, the device is civilized and environment-friendly, and meanwhile, a shielding door is opened only when the garbage storage cavities reach thefloor, so that people are prevented from throwing garbage into the channel, and noise and peculiar smell can be reduced.

Owner:苏留俊

Humic acid-derived conductive foams and devices

ActiveCN109803820AImproves Structural IntegrityWon't disintegrateMaterial nanotechnologyLiquid surface applicatorsComposite materialHumic acid

A humic acid-derived foam composed of multiple pores and pore walls, wherein the pore walls contain single-layer or few-layer humic acid-derived hexagonal carbon atomic planes or sheets, the few-layerhexagonal carbon atomic planes or sheets have 2-10 layers of stacked hexagonal carbon atomic planes having an inter-planar spacing d002#191 from 0.3354 nm to 0.40 nm as measured by X-ray diffraction,and the single-layer or few-layer hexagonal carbon atomic planes contain 0.01% to 25% by weight of non-carbon elements, and wherein the humic acid is selected from oxidized humic acid, reduced humicacid, fluorinated humic acid, chlorinated humic acid, brominated humic acid, iodized humic acid, hydrogenated humic acid, nitrogenated humic acid, doped humic acid, chemically functionalized humic acid, or a combination thereof.

Owner:NANOTEK INSTR

Method for preparing special crude tipping paper good in sterilizing effect and capable of reducing pressure

The invention relates to the technical field of tipping paper, and discloses a method for preparing special crude tipping paper good in sterilizing effect and capable of reducing pressure. The methodincludes the following steps of putting 2-3 parts of sodium alginate, 1-2 parts of titanium dioxide, 1-2 parts of a wax emulsion, 1-2 parts of a defoaming agent, 1-3 parts of an acrylate emulsion, 10-15 parts of a lubricant into a container with a stirring function, pouring 1-3 parts of an ethyl alcohol solvent with the concentration of 90% into the container, and starting the stirring function after the raw materials are completely put in so that the raw materials in the container can be stirred, wherein the primary stirring time is 10-15 min. By means of the method, through the interaction of the titanium dioxide and the acrylate emulsion, the mixture is firmer and free of decomposition, meanwhile the color fading of the tipping paper can be prevented, the temperature tolerance of the tipping paper is improved through the wax emulsion, bacteria outside and inside the tipping paper can be killed through wintergreen oil, and it is ensured that a user cannot breathe in bacteria during smoking.

Owner:武汉银采天纸业股份有限公司

Aircraft model with auxiliary leveling blade control system

InactiveCN109464812ASmooth and smooth flight movementGuarantee the safety of useToy aircraftsAviationJet aeroplane

The invention discloses an aircraft model with an auxiliary leveling blade control system, which comprises an aircraft driving shaft and a rotating device fixedly connected with the driving shaft, wherein the rotating device comprises an auxiliary main blade and an auxiliary leveling blade which are connected through a blade fixing device. According to the aircraft model with auxiliary leveling blade control system, the whole fuselage can be automatically leveled in the steering process, so that the flying motion of the aviation aircraft can be more stable and smooth, and the model airplane cannot be disintegrated due to the out-of-control of centrifugal force.

Owner:马铿杰

Preparation method of a novel long-acting disinfectant using polyvinyl alcohol as a macromolecule retarding material

InactiveCN103238602BEnhanced interactionWon't disintegrateBiocideDisinfectantsDisinfectantRelease time

The invention designs a preparation method of a novel long-acting sanitizer taking polyvinyl alcohol as a macromolecule retardant material. The preparation method comprises the following steps of: stirring and mixing a complete alcoholysis type polyvinyl alcohol solution with a sanitizer, namely dichloro dimethyl hydantoin, subsequently freezing for 24 hours at low temperature, taking out and thawing so as to obtain piece-shaped polyvinyl alcohol gel; and cutting the gel into small pieces and drying so as to obtain the novel long-acting sanitizer which takes polyvinyl alcohol as the continuous phase and sanitizer grains are dispersed therein. When the long-acting sanitizer is used, the polyvinyl alcohol absorbs water to swell up, however, the framework is not dissolved and disintegrated, the sanitizer is slowly released, the residual chlorine value in a water body is stable, and the slow-release time can be more than 30 days; and when dichloro dimethyl hydantoin is completely released, the piece-shaped polyvinyl alcohol retardant material can be taken out from the water body, so that the water body is not polluted.

Owner:BEIJING UNIV OF CHEM TECH

Simulation running debugging device for steering engine of model airplane

InactiveCN108067002AGuarantee the safety of useSmooth and smooth flight movementToy aircraftsJet aeroplaneAviation

The invention discloses a simulation running debugging device for a steering engine of a model airplane. The device comprises an aviation aircraft drive shaft and a rotation device which is fixedly connected with the drive shaft, the rotation device comprises a pair of main blades and a pair of balance blades, and the main blades are connected with the balance blades through a blade fixing device.According to the simulation running debugging device for the steering engine of the model airplane, a whole aircraft body can be automatically balanced in the steering process, the flying motion of an aviation aircraft can be more stable and smooth accordingly, and the situation can be avoided that the aviation aircraft is broken up due to out-of-control centrifugal force.

Owner:马铿钧

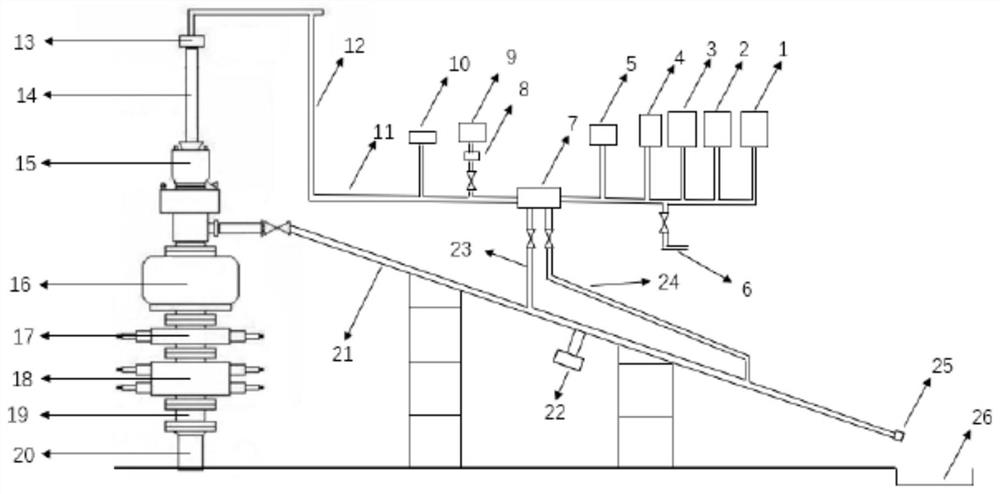

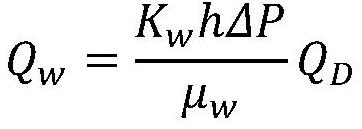

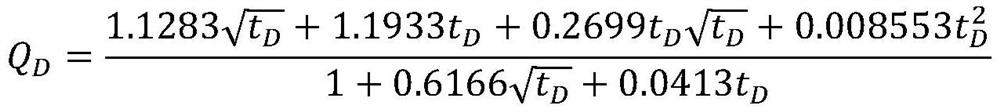

Nitrogen well drilling device and treatment method and application of formation produced water in nitrogen well drilling

PendingCN113833425ALimit ApplicabilityImprove drilling efficiencyConstructionsFlushingNitrogen generatorWell drilling

The invention discloses a nitrogen well drilling device and a treatment method and application of formation produced water in nitrogen well drilling. The nitrogen well drilling device comprises an air compressor, a dryer, a membrane separation nitrogen making machine, a supercharger and wellhead equipment which are sequentially connected through pipelines, wherein a drying agent powder pump is arranged on the pipeline between the supercharger and the wellhead equipment and used for conveying a drying agent to adsorb the formation produced water. By adopting the device and the treatment method for nitrogen well drilling, the nitrogen well drilling working condition with the formation produced water can be treated, so that the applicability of nitrogen well drilling can be improved, and the well drilling efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com