Waterproof dense board

A flat, high-density technology, applied in the field of dense boards, can solve the problems of affecting the bonding effect of wood chips, expensive wood costs, and inconvenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable your examiner to have a further understanding and understanding of the purpose, features and effects of the present invention, please cooperate with [Description of Drawings] to describe in detail as follows:

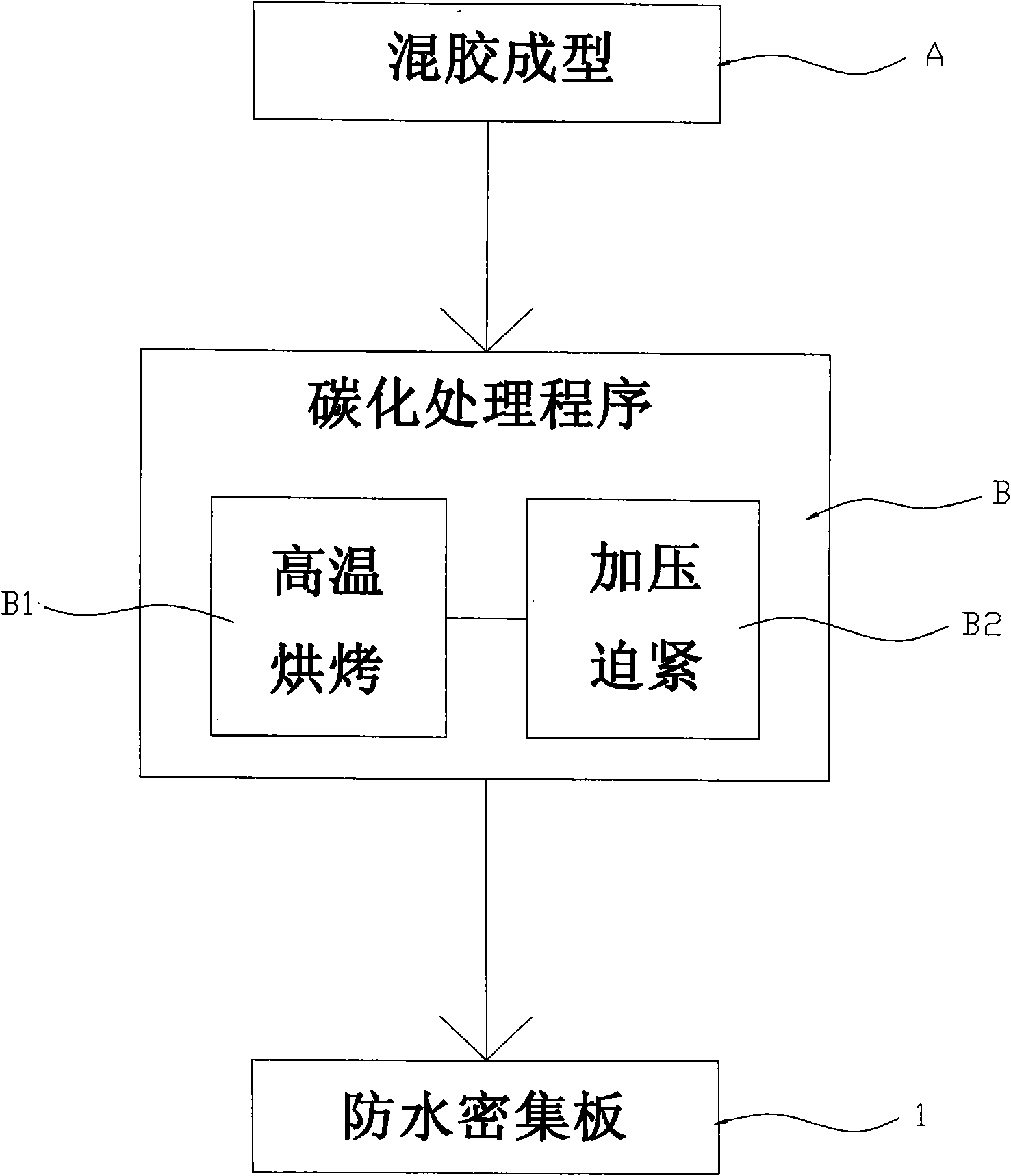

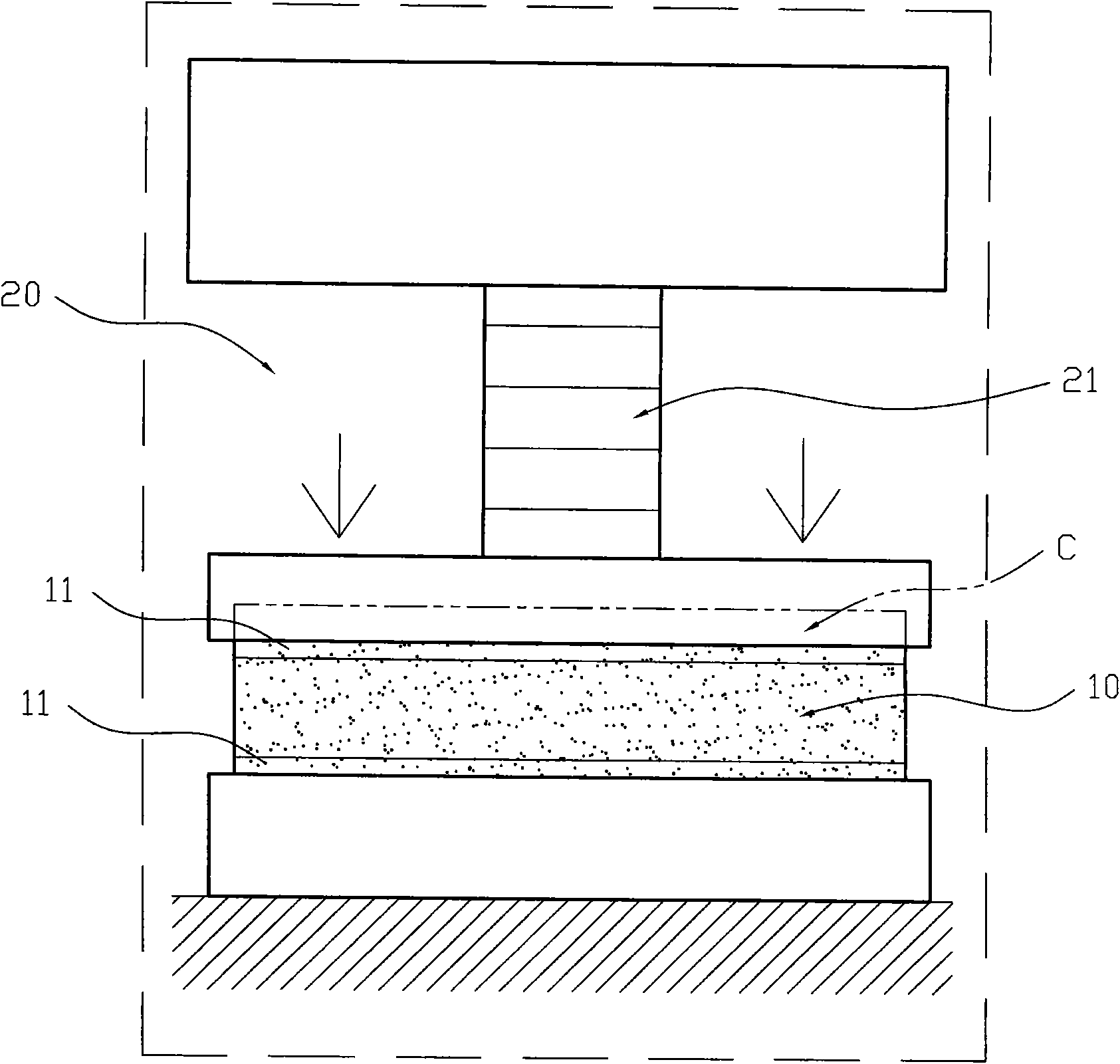

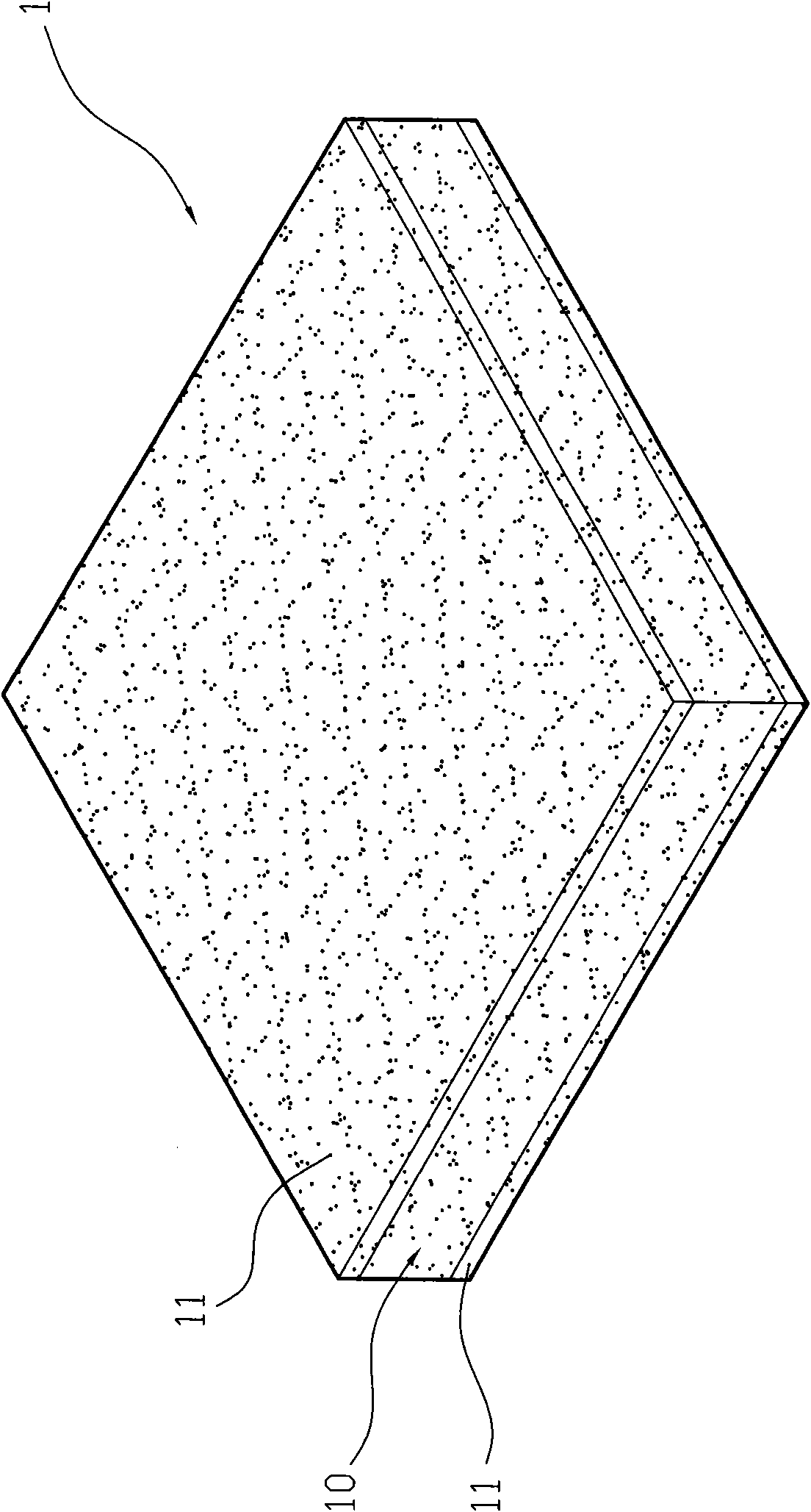

[0027] First, please start by Figure 1 to Figure 3 As shown, a waterproof dense board, the manufacturing process of its waterproof dense board 1 includes the following steps: a rubber mixing molding A and a carbonization treatment process B, wherein the rubber mixing molding A is first penetrated by wood chips The glue is molded to obtain a dense board 10, the wood chips are high-density wood (such as: fir, pine), the dense board 10 is respectively connected with a flat plate 11 on both sides, carbonization treatment procedure B, and then the dense board 10 is placed in a hot pressing device 20, the hot pressing device 20 is an electric furnace, and the heat source can evenly perform a high-temperature baking B1 on the dense plate 10 in a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com