Fasteners for I-beam sheds

A technology of steel sheds and fasteners, applied in mining equipment, earth square drilling, temporary shields, etc., can solve the problems of insufficient connection, easy collapse, disintegration, and inability to withstand high-intensity impact or vibration, etc., to achieve suitable The effect of large-scale promotion, strong connection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

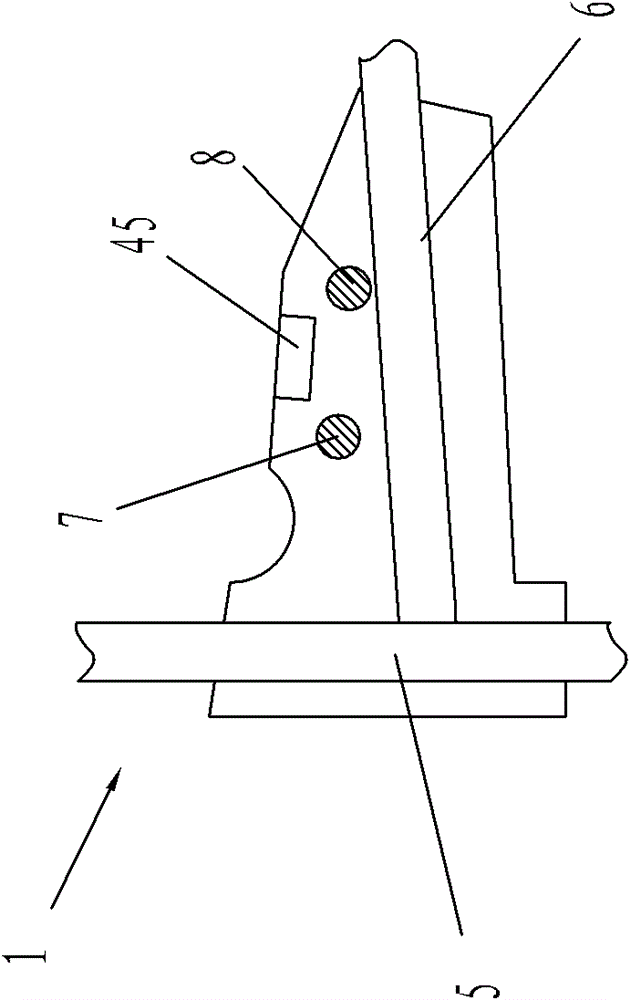

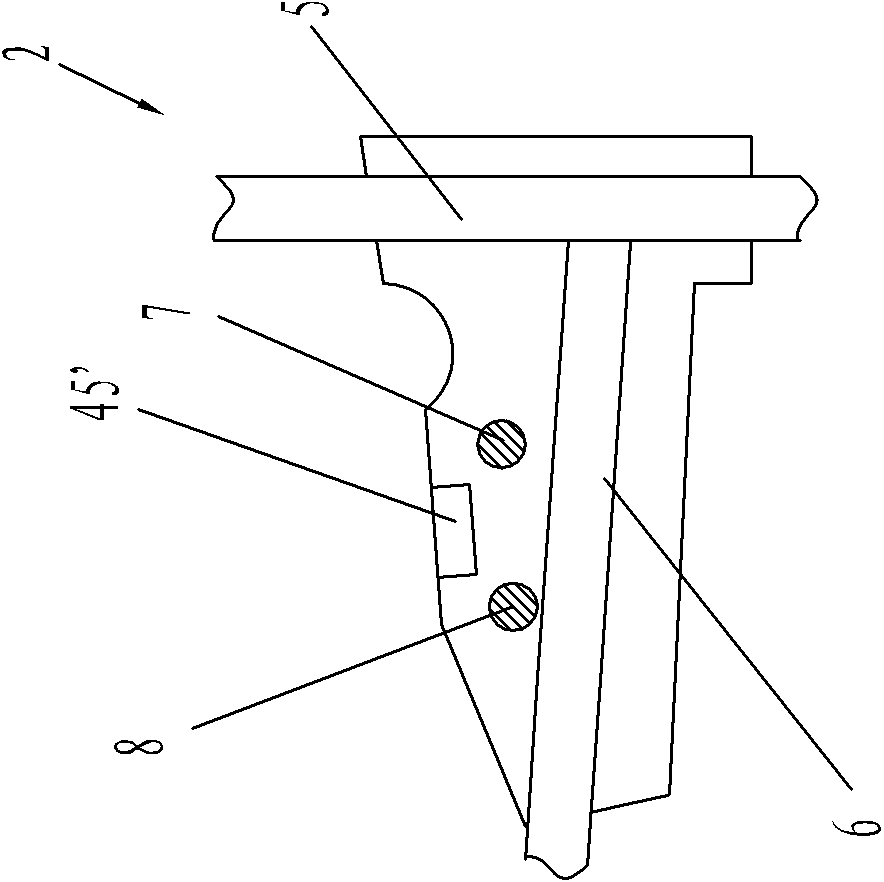

[0017] like figure 1 As shown, the fastener for the I-shaped steel roof of the present invention includes a first buckle 1 and a second buckle 2 that is compatible with the first buckle 1 . The first buckle 1 and the second buckle 2 are left-right symmetrical. Wherein, the first buckle 1 is substantially in a "T" shape, including a first straight side 31 and a first transverse side 41 connected to the middle of the first straight side 31 .

[0018] A first straight groove 32 extending on the first straight edge 31 is formed on the first straight edge 31 , and a first transverse groove 42 extending on the first lateral edge 41 is formed in the middle of the first lateral edge 41 . The left end of the first transverse groove 42 communicates with the first straight groove 32 and forms an included angle of 75 degrees, and the included angle can range from 72 degrees to 77 degrees. Wherein, the right end of the first transverse groove 42 is inclined upward. The first straight gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com