Steel tube binding type steel high strength concrete pole

A high-strength concrete and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of longitudinal reinforcement and steel flange instability, protective layer falling off, low axial compression ratio limit, etc., to reduce secondary disasters, Improve the fire resistance limit, good fire resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

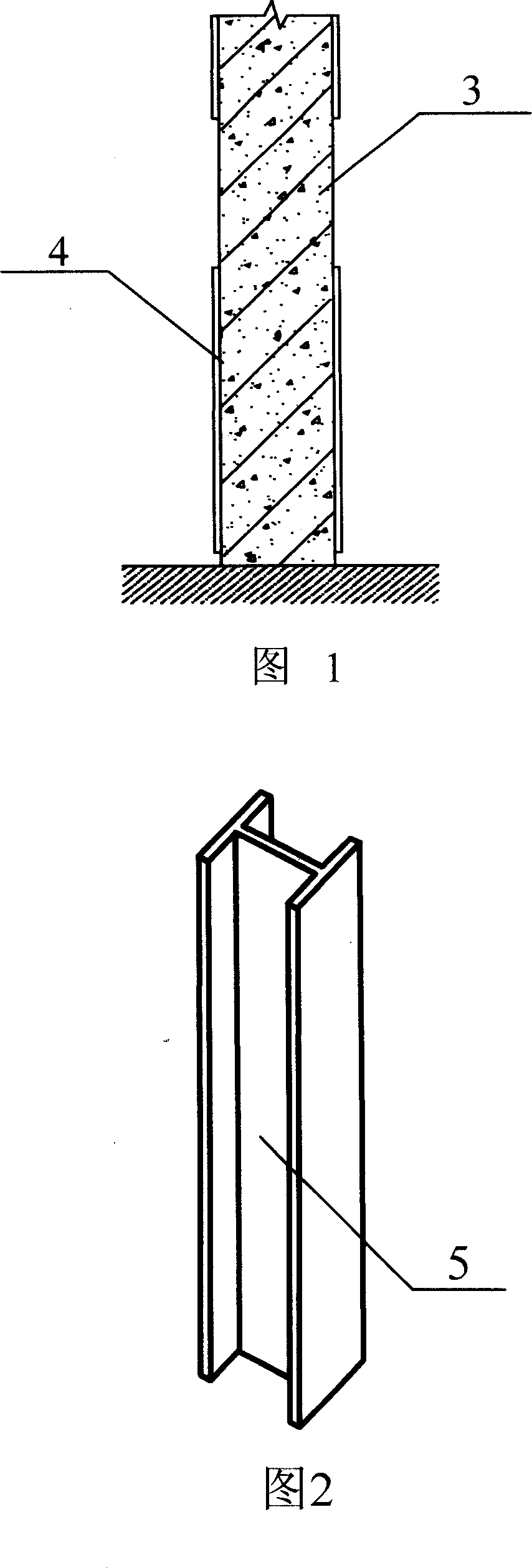

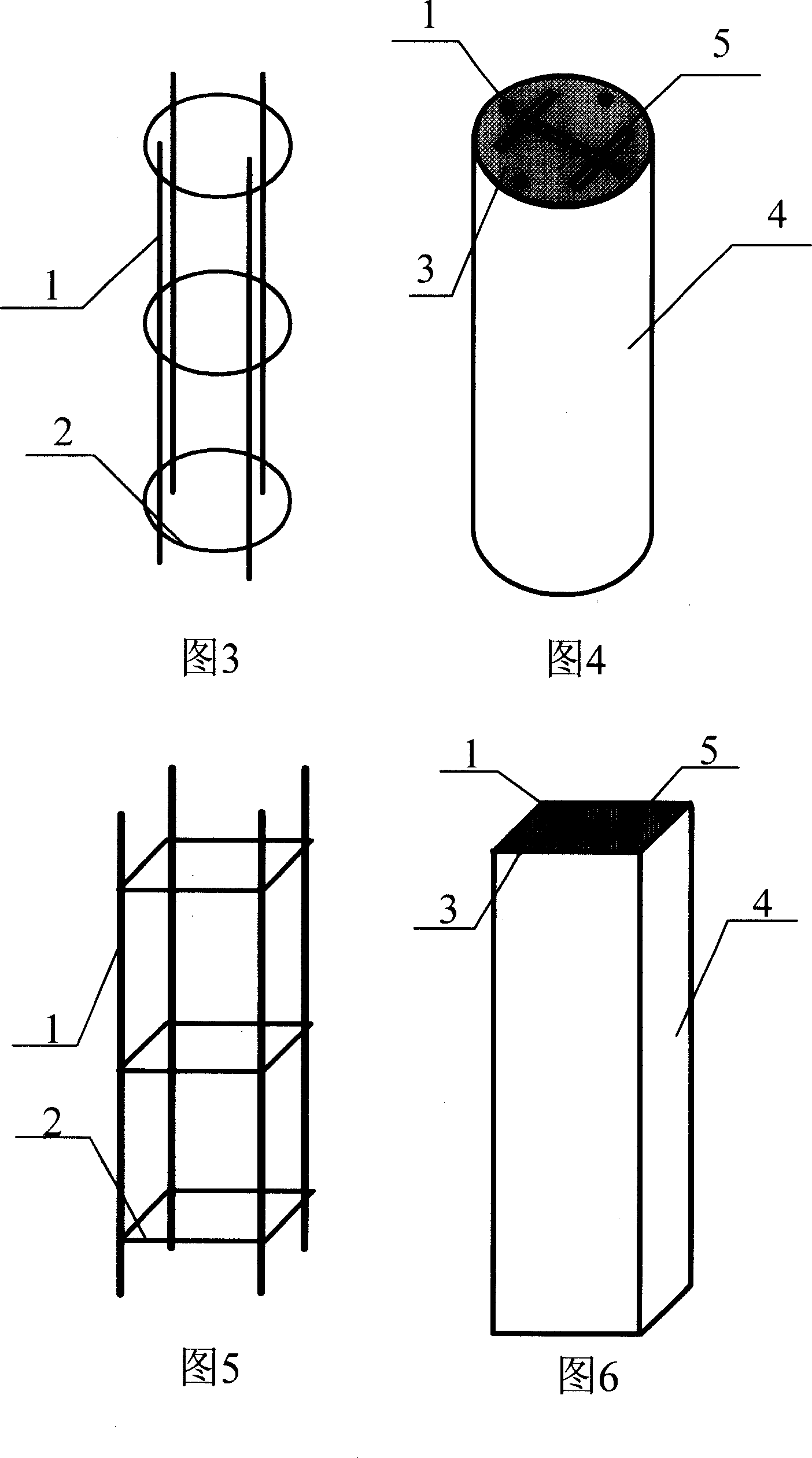

[0024] Specific embodiment 1: The present embodiment will be specifically described below in conjunction with Fig. 1, Fig. 2 and Fig. 3. This embodiment is composed of longitudinal bars 1, stirrups 2, concrete 3, steel pipes 4 and section steel 5, and the longitudinal bars 1 are arranged vertically. In the height direction of the longitudinal bar 1, a stirrup 2 for erecting the vertical bar is set, and a section steel 5 is arranged inside the stirrup 2, and a steel pipe 4 is provided outside the stirrup 2, and concrete 3 is poured in the steel pipe 4, and the steel pipe 4 is broken near the end of both ends.

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment will be described in detail below in conjunction with FIG. 2 . In this embodiment, the steel pipe 4 is a round steel pipe, and other components and connections are the same as in Embodiment 1.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment will be described in detail below in conjunction with FIG. 3 . In this embodiment, the steel pipe 4 is a square steel pipe, and other components and connections are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com