Super cyclone type internal and external gas turbine inlet air conversion device and manufacturing method thereof

A conversion device and cyclone technology, applied in the field of internal and external combustion engine intake air conversion devices, can solve the problems of ineffectiveness, limited effect, cumbersome assembly process, etc., to reduce the cost of purchase and assembly, the generation of optimal eddy current, and the reduction of catalyst conversion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

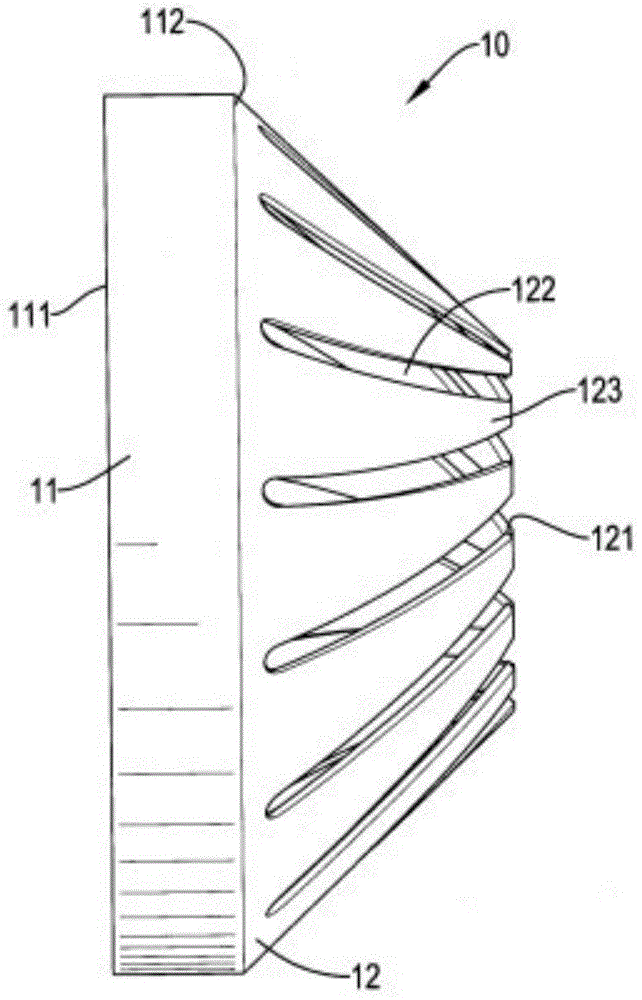

[0043] see figure 1 , a super cyclone-type internal and external combustion engine intake conversion device according to a preferred embodiment of the present invention includes a hollow cone-shaped cylinder 10, and the hollow cone-shaped cylinder 10 includes a cylindrical base 11 and a cone 12;

[0044] The peripheral wall of the cylindrical base 11 is disposed along the extending direction of the hollow cone-shaped cylindrical body 10 , and an open end 111 is formed at one end of the cylindrical base 11 ; one side of the open end 111 of the cylindrical base 11 forms a connecting end 112, the connecting end 112 is connected with the conical body 12;

[0045] The conical body 12 is composed of an annular wall surface, the annular wall surface has an inner diameter and an outer diameter, one end of the conical body 12 is connected with the connecting end 112 , and the inner diameter and the outer diameter thereof move away from the cylindrical base along the connecting end 112 ...

Embodiment 2

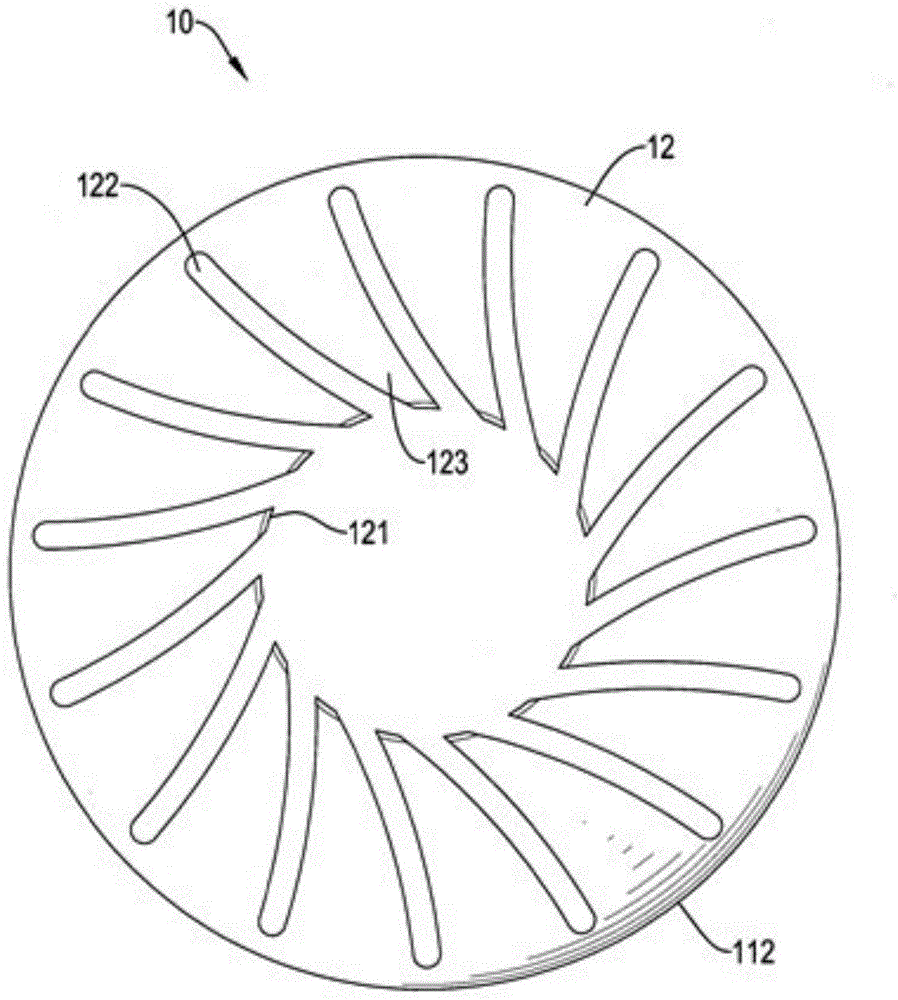

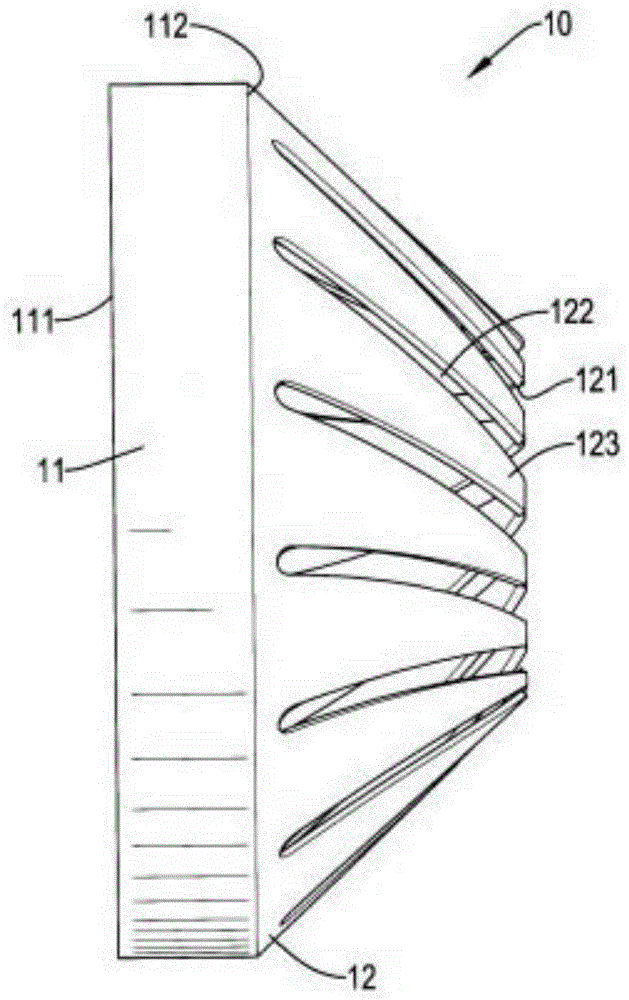

[0049] like image 3 As shown, the difference from Embodiment 1 is that the curved gap 122 extends from the opening 121 toward the cylindrical base 11 and is offset toward the clockwise direction (right rotation).

[0050] further as Figure 4 As shown, the side view of the opening 121 of the cone 12 can clearly see the hollow cone-shaped cylinder 10 of the super cyclone-type internal and external combustion engine intake conversion device, and the curved gap 122 is in the form of a right-hand rotation arrangement.

[0051] The anti-clockwise (left-handed) or clockwise (right-handed) curvature of the above-mentioned curved gaps 122 and the interval and size of the curved gaps 122 can be adjusted according to user requirements, and there is no limitation here.

[0052] In the present invention, the curved gaps 122 of the super cyclone-type internal and external combustion engine intake conversion device are arranged in a counterclockwise direction (left-handed) or clockwise (...

Embodiment 3

[0057] like Figure 7 The shown manufacturing method of the super cyclone type internal and external combustion engine intake reforming device comprises the following steps:

[0058] S1: First, cut aluminum alloy, copper alloy, alloy steel, and plastic-steel substrates into appropriate sizes according to the requirements of the combustion chamber or intake pipe of the internal and external combustion engine;

[0059] S2: Reuse punches, dies and punching methods to form a hollow conical cylindrical body with a cylindrical base and a conical body; wherein a plurality of curved gaps are formed on one side of the conical body relative to the cylindrical base, and are formed by all the The curved gap divides the cone into a plurality of pieces relative to one side of the cylindrical base;

[0060] S3: Next, the hollow cone-shaped cylinder is processed and trimmed to remove burrs or polish;

[0061] S4: Finally, a catalyst is uniformly coated on the inner and outer surfaces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com