A process for preparing high-strength modified sulfur concrete by cold-water bath vibrating molding method

A technology of sulfur concrete and molding method, applied in the field of building materials, can solve the problems of many holes in the matrix, complicated preparation process, toxicity of modifiers, etc., and achieve the effect of high compactness of the matrix, low strength dispersion and stable compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

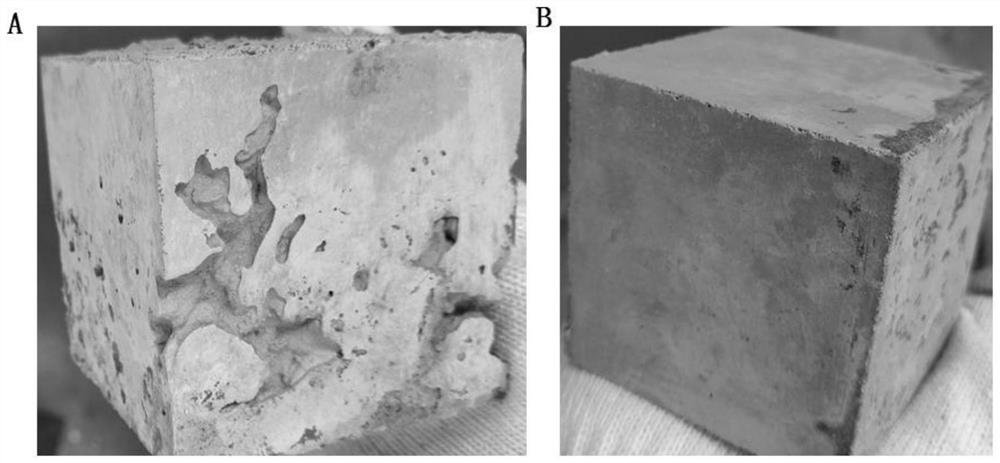

[0046] Example 1 Establishment and optimization of high-strength modified sulfur concrete cold-water bath vibrating molding process

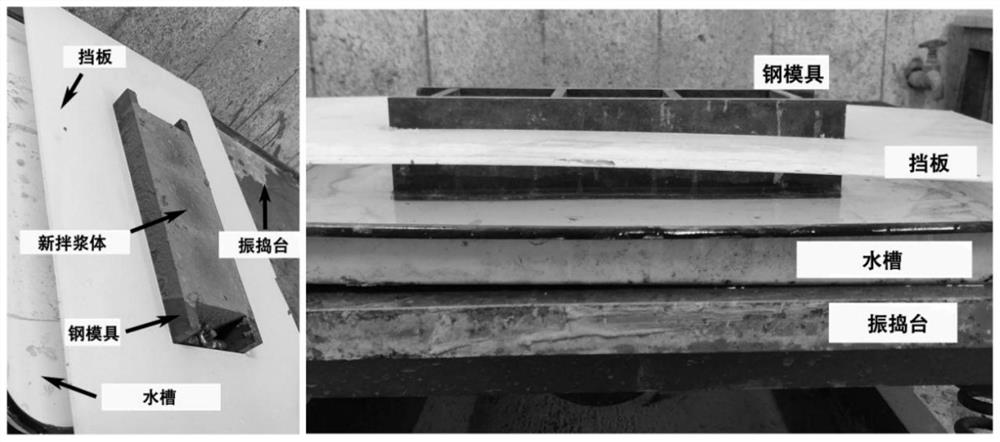

[0047]1. Establishment of cold-water bath vibrating molding process for modified sulfur concrete

[0048] Modified sulfur concrete includes the following components by mass:

[0049] Modified sulfur 11.5%-14.2%, filler (P.O.42.5 cement, slag, fly ash and other mineral fillers) 11.5%-14.2%, ordinary river sand 22%-30%, aggregate mixture [particle size is 5mm-9mm Granite crushed stone and granite crushed stone with a particle size of 10mm-15mm = 3:1 (mass ratio)] 42.6%-51.0%; the modified sulfur includes 97% sulfur and 3% modifier dicyclopentadiene .

[0050] The specific preparation steps are as follows:

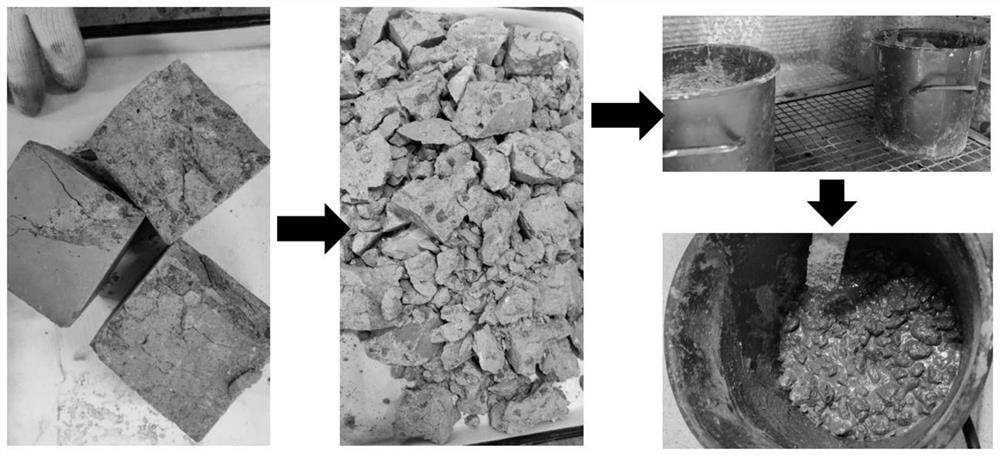

[0051] 1. Pretreatment of materials

[0052] 1.1. Weigh the corresponding amount of filler, river sand, aggregate mixture (granite crushed stone with a particle size of 5mm-9mm and granite crushed stone with a particle size of 10mm-15mm), s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com