Temperature control device

a temperature control device and temperature control technology, applied in the direction of lighting and heating apparatus, machines using electric/magnetic effects, refrigerating machines, etc., can solve the problems of reducing the strength of the seal member, affecting the proper operation of the temperature control device, and damage to the seal member, so as to reduce the space required for providing the seal wall, increase the thickness of the seal wall, and enhance the strength of the seal wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]A temperature control device according to an exemplary embodiment of the invention will be described below with reference to the attached drawings.

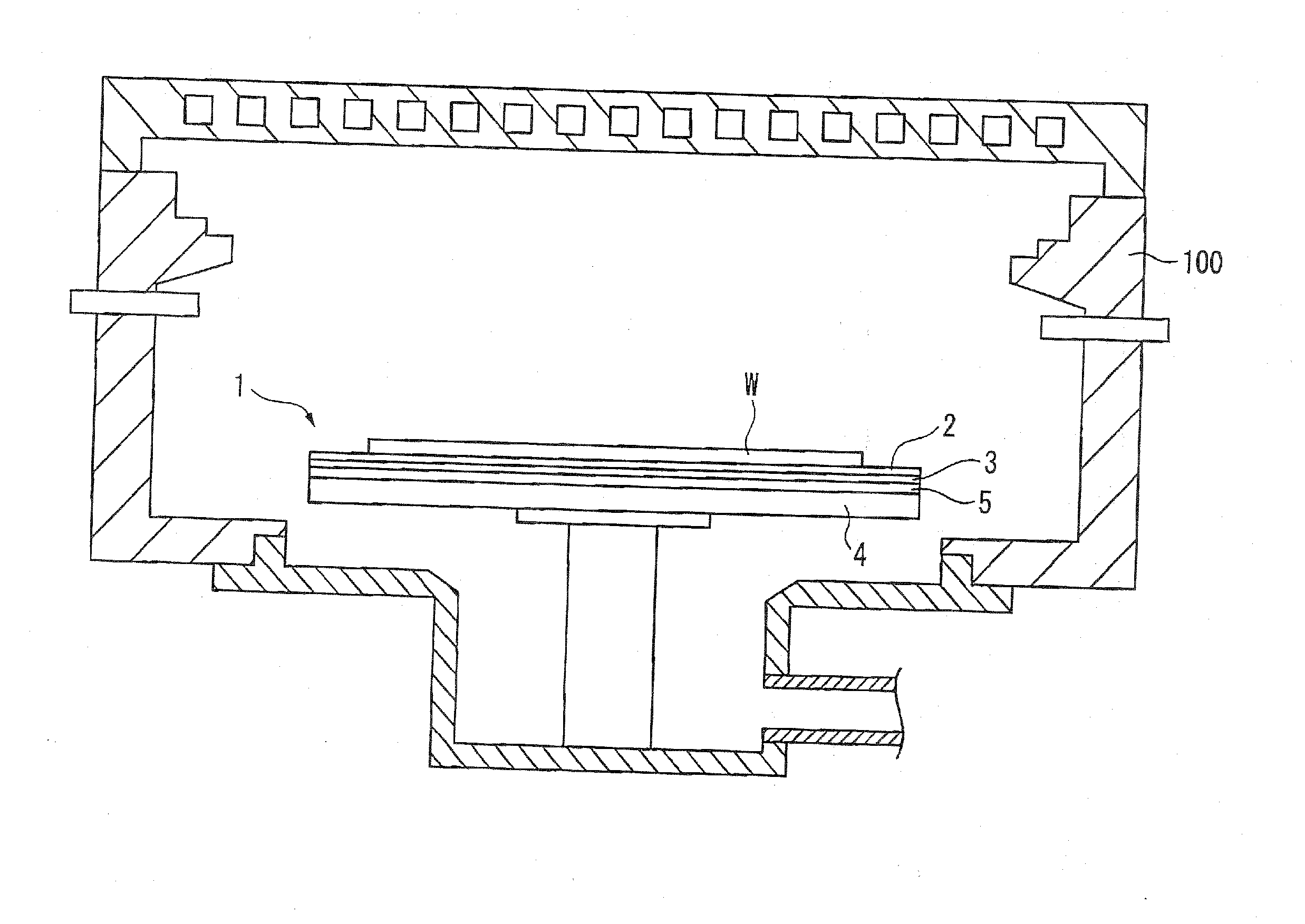

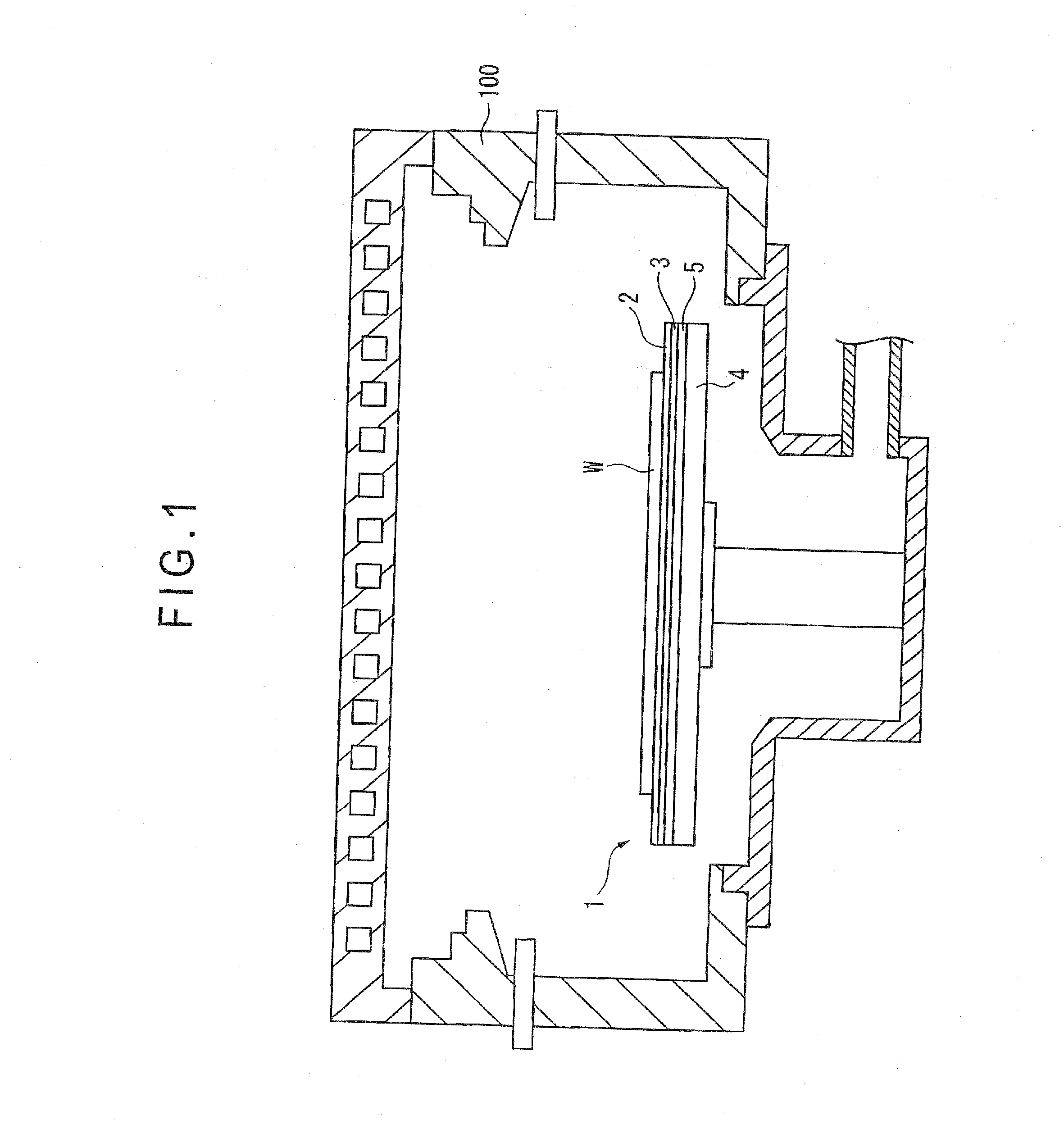

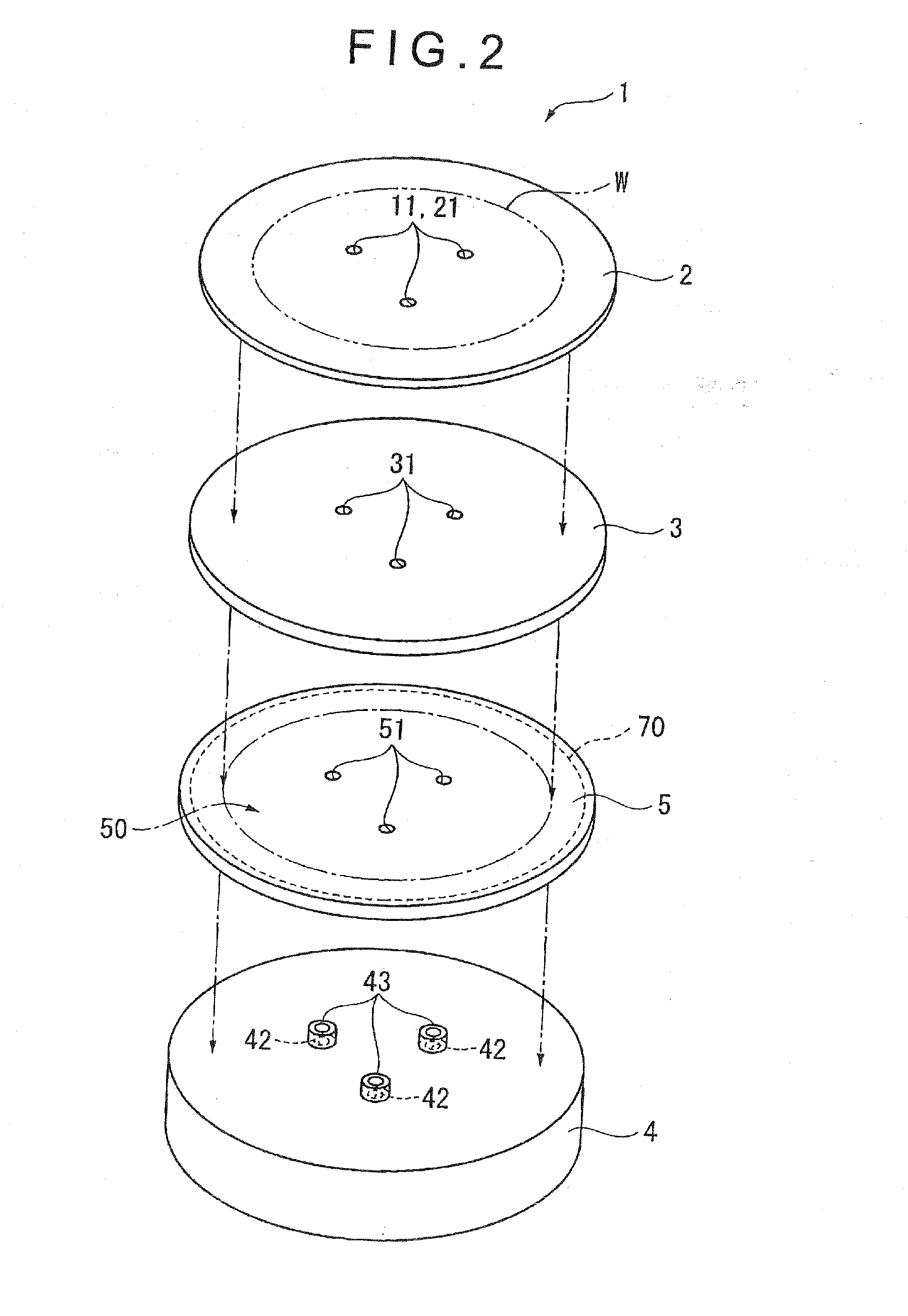

[0033]As shown in FIG. 1, a semiconductor wafer W (an object to be temperature-controlled) is a disc that is sucked and placed on a top plate 2 by an electrostatic chuck in a vacuum chamber 100 so that various semiconductor processing such as dry etching is performed on the semiconductor wafer with a process gas in a plasma atmosphere. When the semiconductor wafer is subjected to a dry etching, the inside of the vacuum chamber 100 is vacuumized and is kept at a predetermined low pressure. In this state, etching gas is introduced into the vacuum chamber 100. The introduced etching gas is turned into plasma for etching the semiconductor wafer W. When such various semiconductor processing is performed, the temperature of the semiconductor wafer W is controlled at a target temperature by the temperature control device 1 and a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com