Salt leaching and in-situ oxidation combined method for refined treatment of industrial waste salt containing organic matters

A technology for refining and treating industrial waste salt, which is applied in the purification of alkali metal chlorides, alkali metal halides, alkali metal sulfite/sulfate, etc. It can solve the problems of poor removal of organic pollutants, low purity of recovered salt, and The problem of small application range can achieve the effect of avoiding high energy consumption and pollution of incineration tail gas, reducing production cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

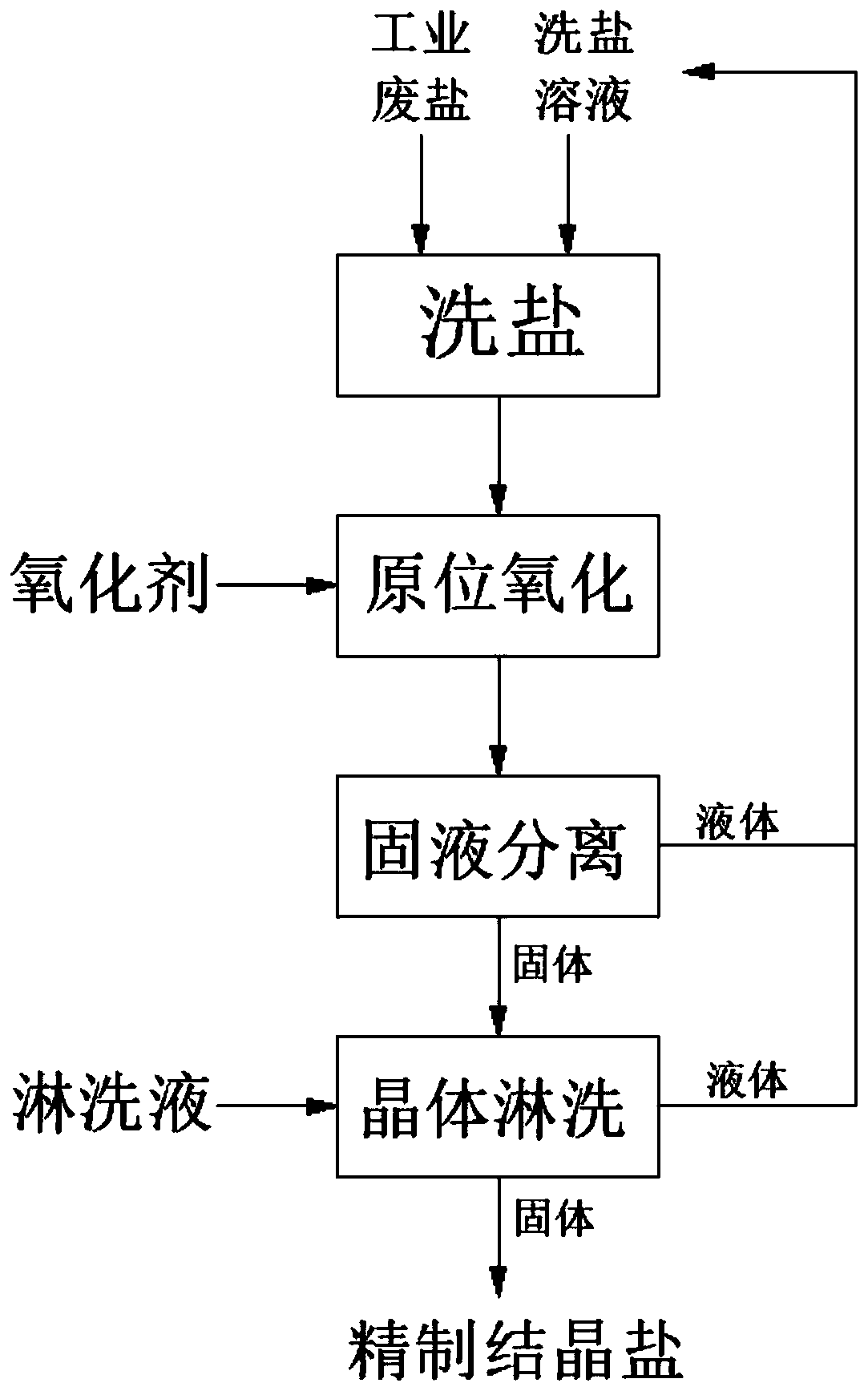

Method used

Image

Examples

Embodiment 1

[0066] This embodiment provides a method for refining and treating industrial waste salt containing organic matter by washing salt combined with in-situ oxidation, which specifically includes the following steps:

[0067] (I) preparation concentration is 30wt% sodium chloride solution (washing salt solution) at 60 ℃, under stirring condition, add the sodium chloride waste salt that COD content is 100000mg / L, the volume of washing salt solution and sodium chloride The mass ratio of waste salt is 10m 3 : 1t, the temperature of the slurry is controlled to be 90°C, and the stirring is continued for 6h;

[0068] (II) In the rinsing slurry that step (I) obtains, add the mixed oxidizing agent of required theoretical amount 10 times, comprise hydrogen peroxide (3 times of theoretical amount), sodium hypochlorite (3 times of theoretical amount) and oxygen (theoretical amount) in the mixed oxidizing agent 4 times of that), add hydrochloric acid to adjust the pH=3, carry out the oxidati...

Embodiment 2

[0073] This embodiment provides a method for refining and treating industrial waste salt containing organic matter by washing salt combined with in-situ oxidation, which specifically includes the following steps:

[0074] (1) preparation concentration is 10wt% sodium sulfate solution (washing salt solution) at 30 DEG C, add COD content under stirring condition and be the sodium sulfate waste salt of 35000mg / L, the volume of washing salt solution is the same as that of sodium sulfate waste salt The mass ratio is 7m 3 : 1t, the temperature of the slurry is controlled to be 50°C, and the stirring is continued for 2h;

[0075] (II) Add 7 times the required theoretical amount of sodium peroxide to the rinsing slurry obtained in step (I) to carry out an oxidation reaction, control the oxidation reaction temperature to 50° C., and continue stirring for 2 hours;

[0076] (Ⅲ) The reaction product obtained in step (II) is subjected to solid-liquid separation, and the liquid obtained is...

Embodiment 3

[0080] This embodiment provides a method for refining and treating industrial waste salt containing organic matter by washing salt combined with in-situ oxidation, which specifically includes the following steps:

[0081] (I) preparation concentration is 0wt% sodium chloride solution (washing salt solution) at 30 DEG C, under stirring condition, add the sodium chloride waste salt that COD content is 100mg / L, the volume of washing salt solution and sodium chloride The mass ratio of waste salt is 3m 3 : 1t, the temperature of the slurry is controlled to be 95°C, and the mixing and suspension operation is 0.5h;

[0082] (II) Add ozone 5 times the required theoretical amount to the rinsing slurry obtained in step (I) to carry out an oxidation reaction, control the oxidation reaction temperature to 95° C., and continue stirring for 8 hours;

[0083] (Ⅲ) solid-liquid separation is carried out to the reaction product obtained in step (II), and the obtained liquid is returned to step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com