Method for producing amino-phenyl-beta-hydroxyethyl sulfone sulfate

A technology of hydroxyethylsulfone and p-aminophenyl, which is applied in the field of production of aminophenyl-β-hydroxyethylsulfone sulfate, can solve the problems of low product yield, consumption of raw materials and three wastes, and reduce production costs , Conducive to popularization and application, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

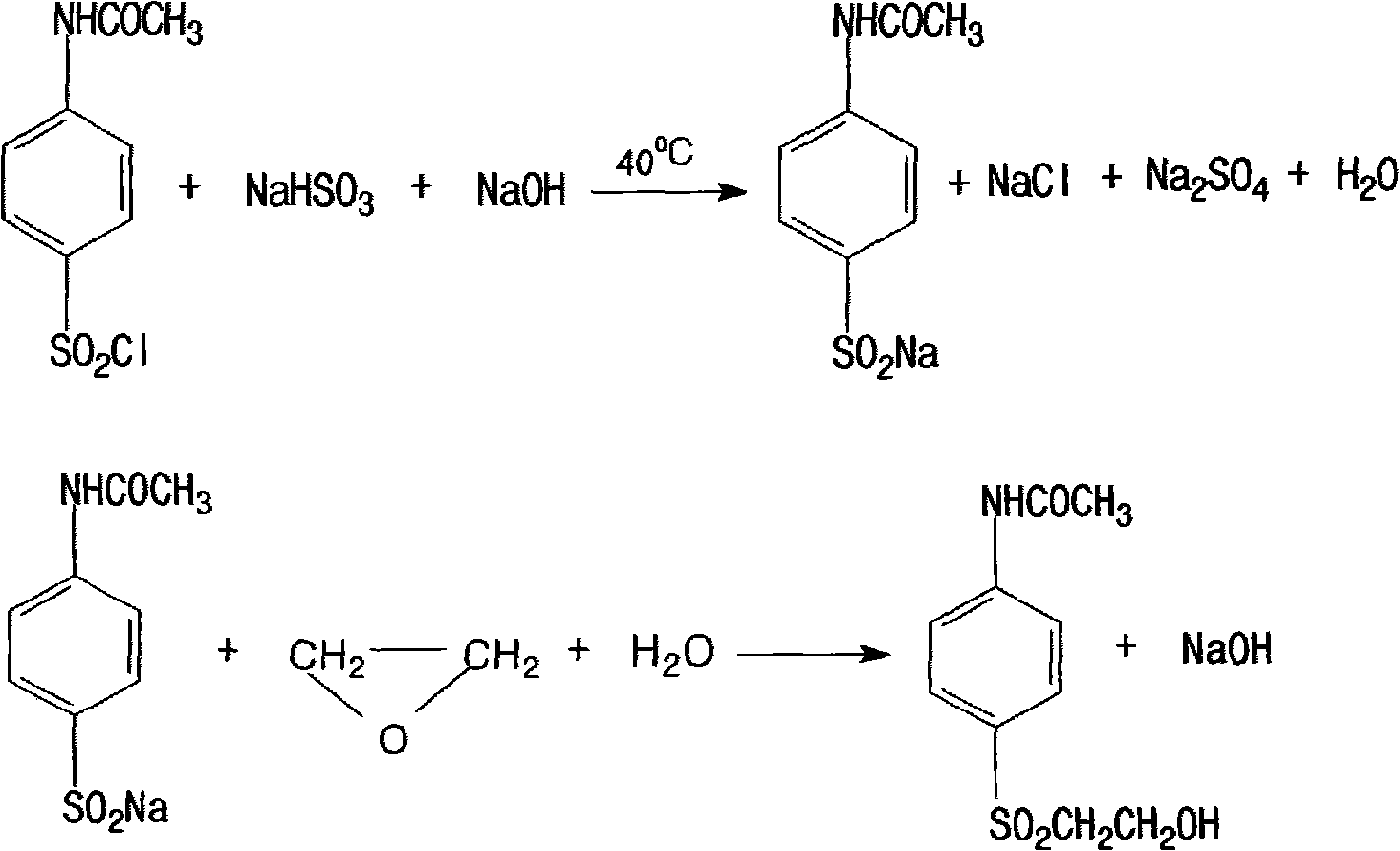

[0033] Embodiment one: see figure 1 , the production technology of p-aminophenyl-beta-hydroxyethyl sulfone sulfate, comprises the steps:

[0034] (1) Add N,N dimethylformamide (DMF) to reactor 1, then add p-nitrochlorobenzene and mercaptoethanol, dissolve and mix well, then slowly add solid sodium hydroxide, p-nitrochlorobenzene , mercaptoethanol, N, N dimethylformamide, and the molar ratio of solid sodium hydroxide are 1:1-1.2:1.5-2:1, and the solid sodium hydroxide is controlled to be added within 3-5h. Then react with sodium for 3-5h to obtain the reaction product, and the reaction temperature is controlled at 50-80°C;

[0035] Filter the reaction product through filter pool 2 at a temperature lower than 40°C to remove solid NaCl to obtain the filtrate; the filtrate enters the vacuum distillation kettle 3, and distills the filtrate under reduced pressure at 60-150mmHg and 120-150°C for 1-2h , the vacuum still 3 is connected with the vacuum tank 5 through the condenser 4, ...

Embodiment 2

[0042] Embodiment two: see figure 1 , same as embodiment 1 step, difference is process parameter, specifically as follows:

[0043] (1) The molar ratio of p-nitrochlorobenzene, mercaptoethanol, DMF and solid sodium hydroxide in the reactor 1 is 1:1:1.5:1, and the solid sodium hydroxide is controlled to be added within 3-4h, and hydrogen is added Sodium oxide is then reacted for 3-4 hours to obtain the reaction product; the reaction temperature is controlled at 50-60°C;

[0044] The reaction product is filtered through the filter pool 2 at a temperature of 38°C, and the filtrate is obtained after removing solid NaCl; the filtrate enters the vacuum still 3, and the filtrate is distilled under reduced pressure at 60-80mmHg and 120-130°C for 1.5h;

[0045] (2) The reaction temperature of oxidation kettle 6 is 80-90° C., and the continuous addition time of hydrogen peroxide is controlled within 2-3 hours. The molar ratio of hydrogen peroxide and p-nitrophenyl-β-hydroxyethyl sulfi...

Embodiment 3

[0050] Embodiment three: see figure 1 , same as embodiment 1 step, difference is process parameter, specifically as follows:

[0051] (1) The molar ratio of p-nitrochlorobenzene, mercaptoethanol, DMF, and solid sodium hydroxide in the reactor 1 is 1: 1.2: 2: 1, and the solid sodium hydroxide is controlled to be added within 3-5h, and hydrogen is added Sodium oxide is then reacted for 3-5 hours to obtain the reaction product; the reaction temperature is controlled at 70-80°C;

[0052] The reaction product is filtered through the filter tank 2 at a temperature of 30° C., and the filtrate is obtained after removing solid NaCl; the filtrate enters the vacuum still 3, and the filtrate is distilled under reduced pressure at 90-120 mmHg and 130-140° C. for 2 hours;

[0053] (2) Add p-nitrophenyl-β-hydroxyethyl sulfide and sodium tungstate to the oxidation kettle 6, then slowly add hydrogen peroxide and stir, the temperature is controlled at 90-100°C, and the continuous addition time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com