Antioxidant applied to acrylonitrile-butadiene rubber latex and carboxylic acrylonitrile butadiene rubber latex and preparation method

A carboxylated nitrile latex and antioxidant technology, applied in the field of antioxidants, can solve the problems of unfavorable latex, increased cost, and reduced antioxidant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-7

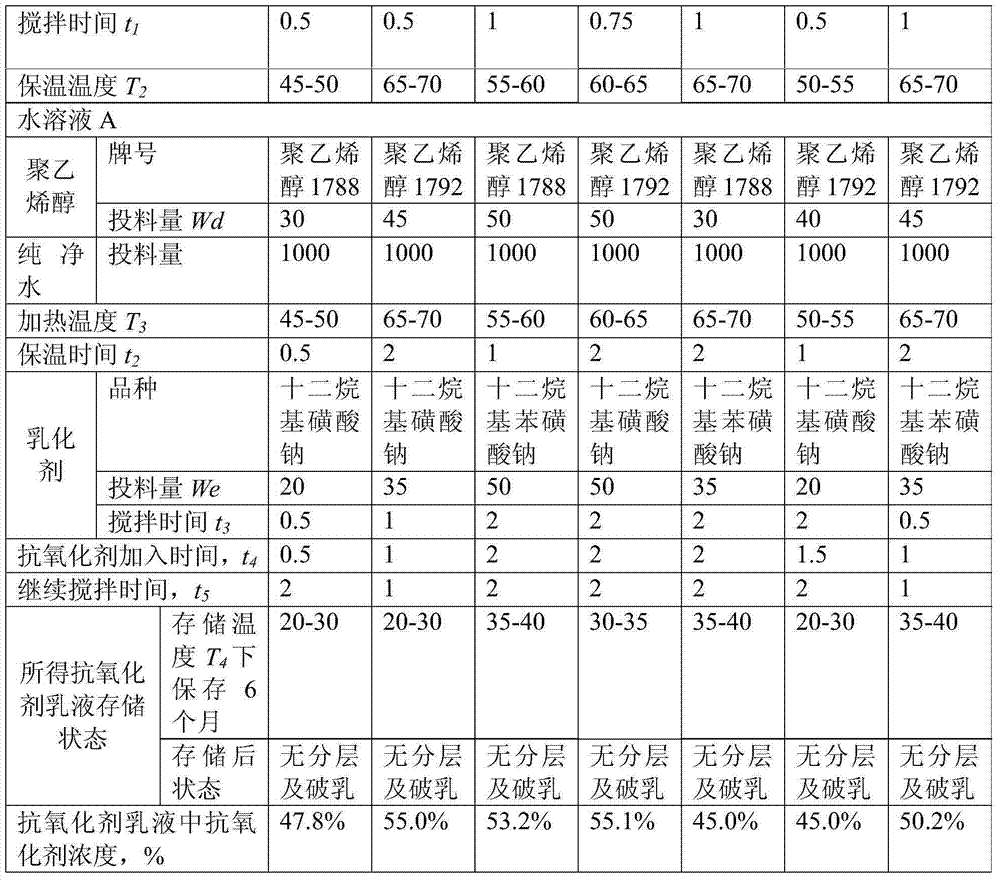

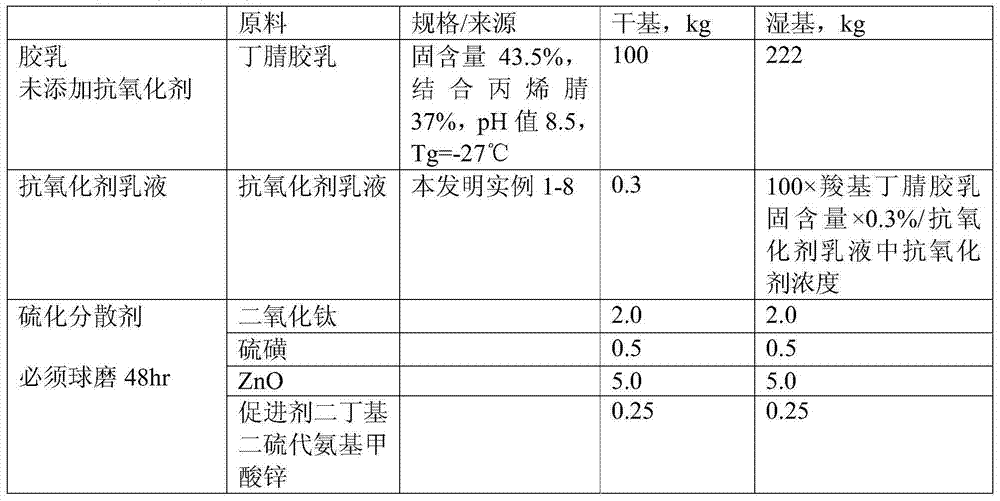

[0033] Compound antioxidant: the mass is the mass of antioxidant a) component (where a1 is the mass of 4,6-bis(octylthiomethyl)o-cresol, a2 is the mass of 4,6-bis(n-dodecylthiomethyl) base) the mass of o-cresol), and the mass is the antioxidant b) component (where b1 is the mass of 3,5-di-tert-butyl-4-hydroxyphenylpropionate isooctyl, b2 is 3,5-di-tert- The mass of butyl-4-hydroxyphenylpropionic acid C7-C9 mixed alcohol ester) and the mass of antioxidant c) component, at temperature T 1 under stirring t 1 hours, then heated to T 2 Keep warm for later use. In this way, the compound antioxidant is obtained, and the total antioxidant quality W is obtained;

[0034] will mass W d Add polyvinyl alcohol to 1000kg of pure water, start stirring, and heat to T under stirring 3 , hold at this temperature t 2 Hour. Maintaining this temperature, add mass W to it e emulsifier, stirring t 3 hours, and keep warm at T 3 Next, the aqueous solution A was obtained.

[0035] Put the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com