Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

206 results about "Emulsion copolymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing fluorine and silicon containing hydrophobic and oil repellent fabric finishing agent

InactiveCN101016697AImprove waterproof performanceGood oil resistanceFibre treatmentEmulsionFunctional monomer

The invention discloses a method for preparing fluorine hydrophobic oil-repellent fabric finishing agent, wherein the finishing agent is lacte emulsion with blue fluorescence. And the preparation comprises that using fluorine monometer, hydrocarbons unsaturated monometer, acid monometer and functional monometer as material, with inducer, adjusting agent, buffer agent and emulsifier, via emulsion polymerization method to be composed to obtain needed finishing agent. The inventive finishing agent has better hydrophobic oil-repellent effect, high stability and high yield, or the like.

Owner:ZHEJIANG UNIV OF TECH

Coating compositions having improved stability

ActiveUS20060047062A1Improve shelf lifeReduce gassing and gellationConductive materialNon-conductive material with dispersed conductive materialChemistryEmulsion

This invention relates to waterborne coating compositions having improved compatability with metal pigments, i.e., improved shelf life and reduced gassing and gellation. The compositions comprise at least one aqueous dispersion of (1) at least one emulsion copolymer polymerized from (a) at least one ethylenically unsaturated anionic monomer and (b) at least one other olefinically unsaturated monomer, said copolymer being made using at least one phosphate surfactant having at least one phosphorus acid group or salt thereof, said copolymer being crosslinked, and (2) at least one non-water soluble metal pigment. The compositions are useful in paints and other coatings.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Acryloxyalkoxysilicane modified acrylic acid ester polymerization emulsion and its preparation method and application

InactiveCN101121771AGood weather resistanceHigh reactivityOrganic detergent compounding agentsOther chemical processesMethacrylatePolymer science

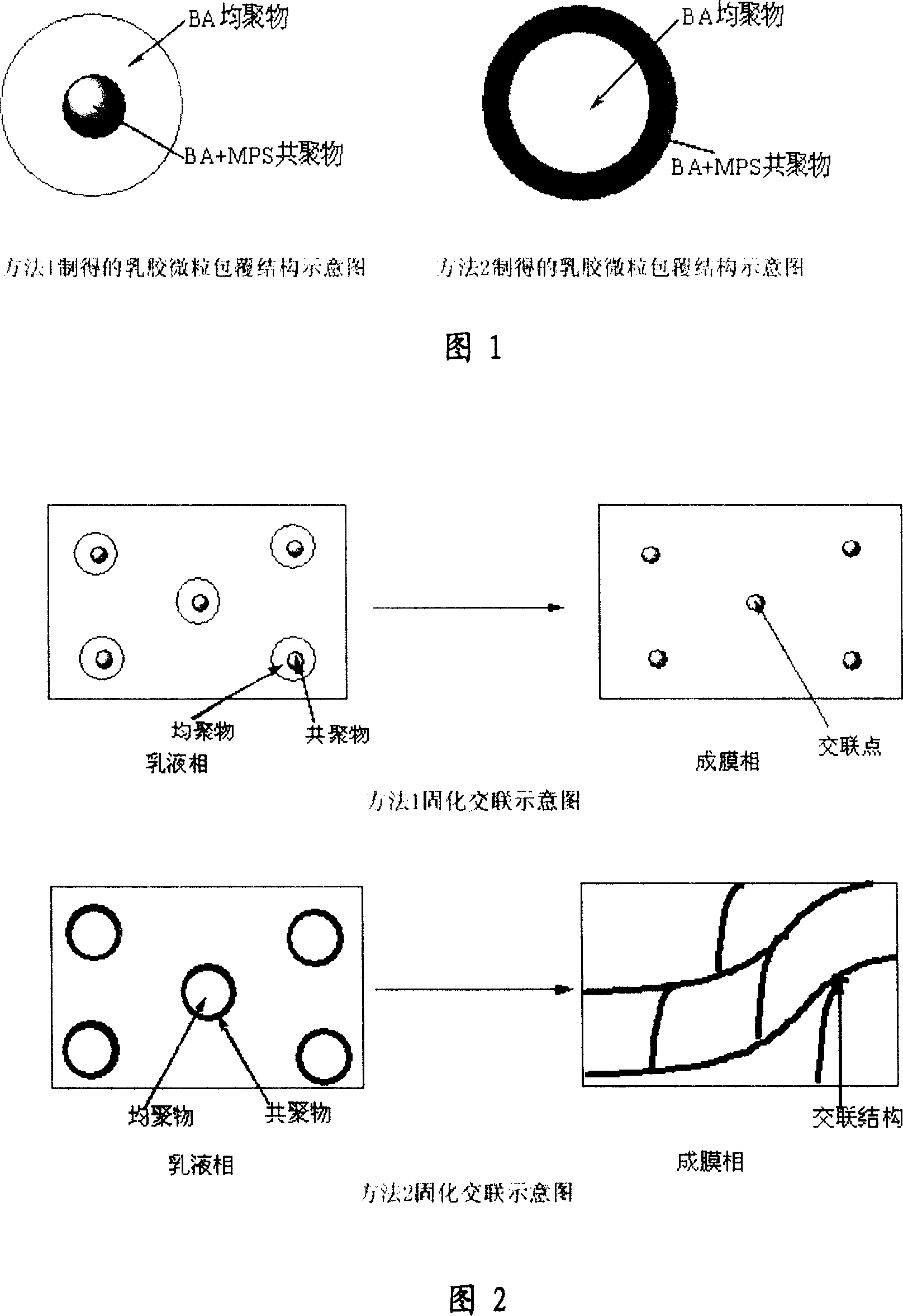

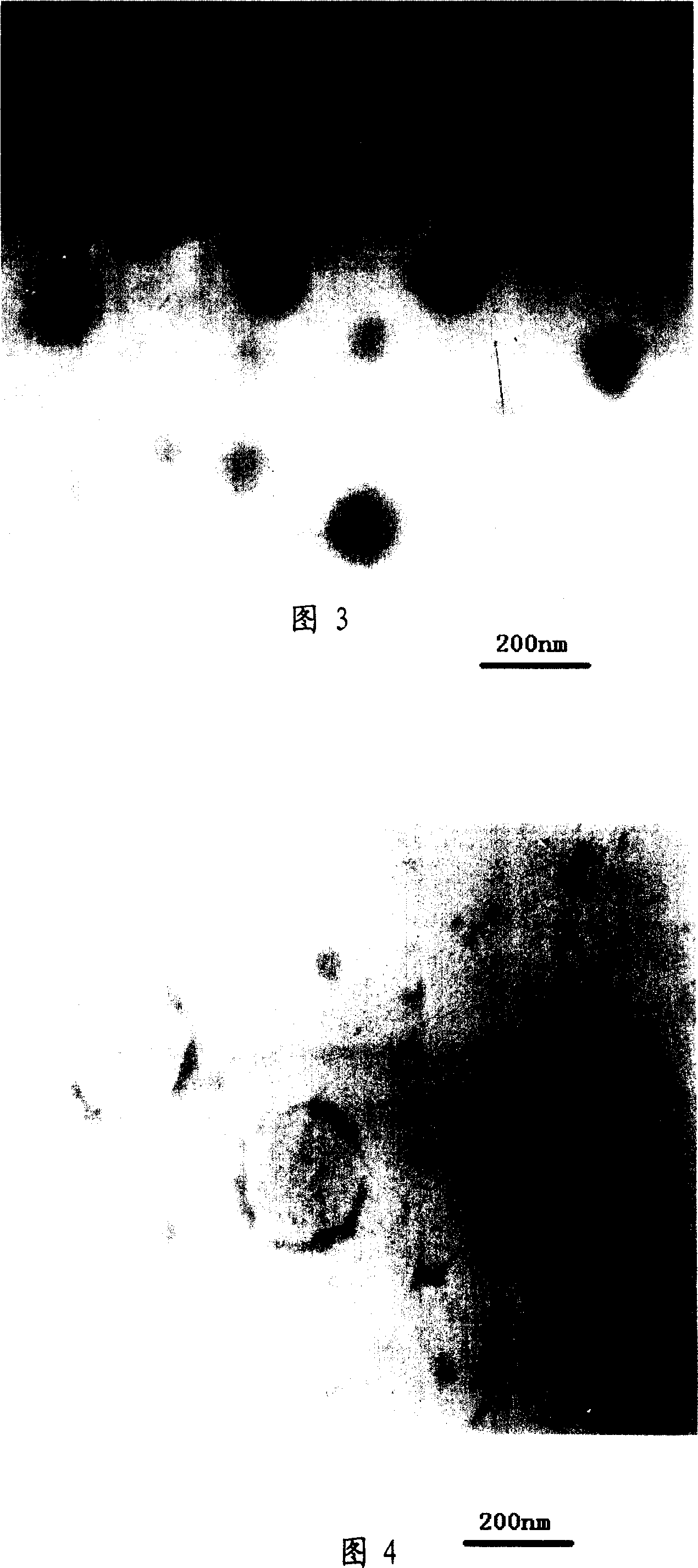

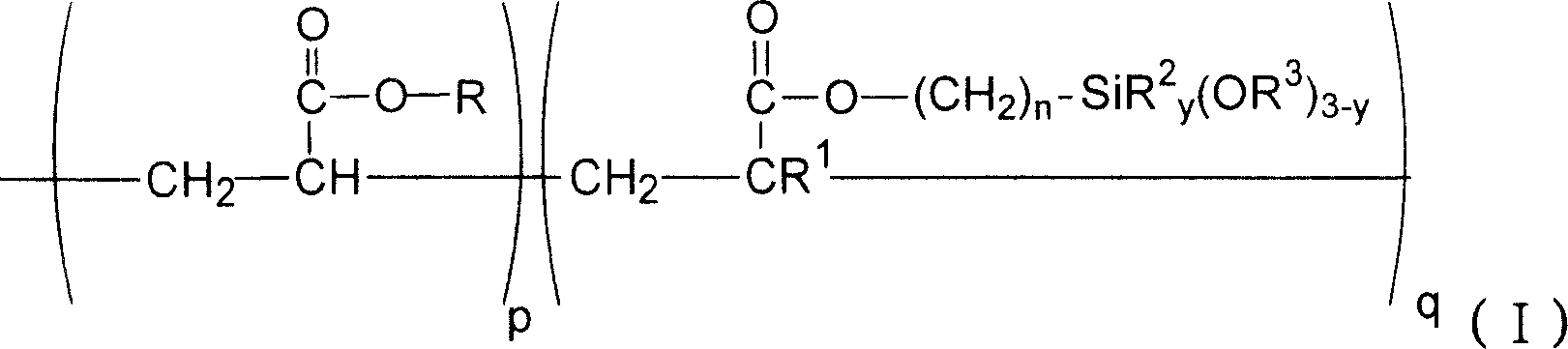

Disclosed are an acrylate emulsion modified by one or more acryloxyalkoxysilanes with a controllable latex particle shape, and a preparation method and application thereof. The emulsion of the present invention is obtained by the emulsion copolymerization of (meth)acryloyloxyalkoxysilane and acrylic acid hydrocarbyl ester, and it is not necessary to use methacrylate monomers with high volatility and toxicity, styrene and unsaturated acids. other types of unsaturated monomers. Using the relationship of the reactivity ratio in the reaction kinetics, by controlling the entry of the reaction raw materials, copolymers with different latex particle morphological structures can be obtained through emulsion polymerization. The copolymerization method is simple in operation, low in cost and environmentally friendly. The polymer product thus obtained has significantly improved certain mechanical properties. The emulsions can be used in buffer coatings, adhesives, sealants, gaskets, inks, and cleaning agents. The sealant made with this emulsion has good stability and can be placed stably for more than one year at room temperature. It can be widely used in sealing, coating and bonding of automobiles, building materials, daily products, etc.

Owner:汉高股份两合公司

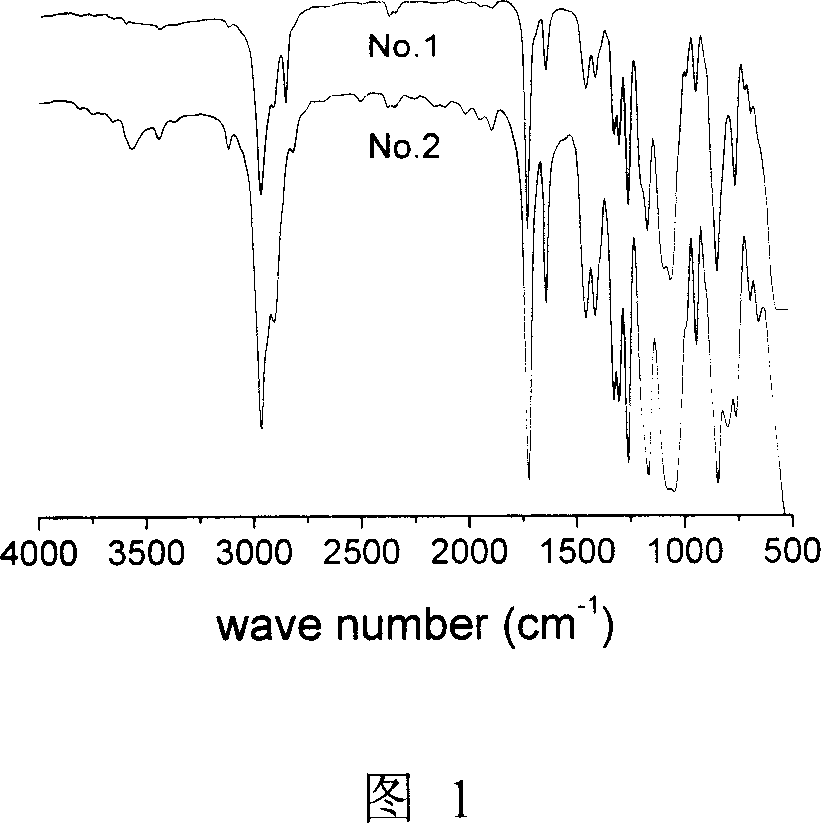

Silicon-containing (methyl) acrylate monomer and its copolymer and their prepn process

InactiveCN1974581AGood adhesionImprove water resistanceGroup 4/14 element organic compoundsSilanesDisilane

The present invention discloses silicon-containing (methyl) acrylate monomer and its copolymer and their preparation process. The silicon-containing (methyl) acrylate monomer as silane or silane oligomer with methyl propenyl acyloxy radical or propenyl acyloxy radical is prepared through the catalytic reaction of silane coupler with (methyl) propenyl acyloxy radical, and hexamethyl disilane or hexamethyl disilane and active organosilicon under the action of catalyst. The present invention also discloses one kind of silicon-containing (methyl) acrylate copolymer and its solution copolymerization, water emulsion copolymerization and ultraviolet curing process. The copolymer has excellent adhering performance, waterproof and antifouling performance and weather resistance.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

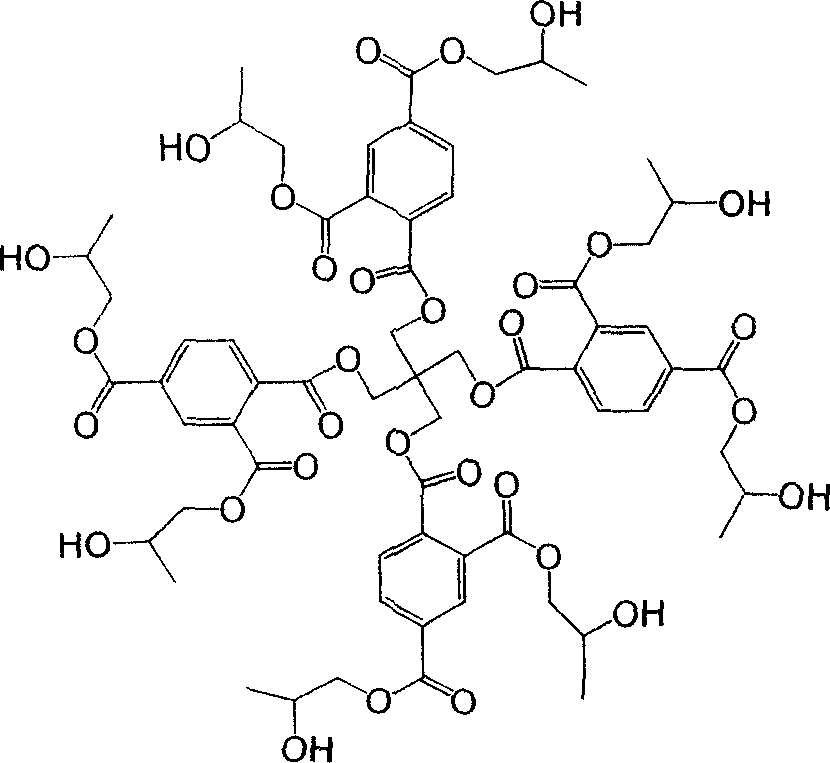

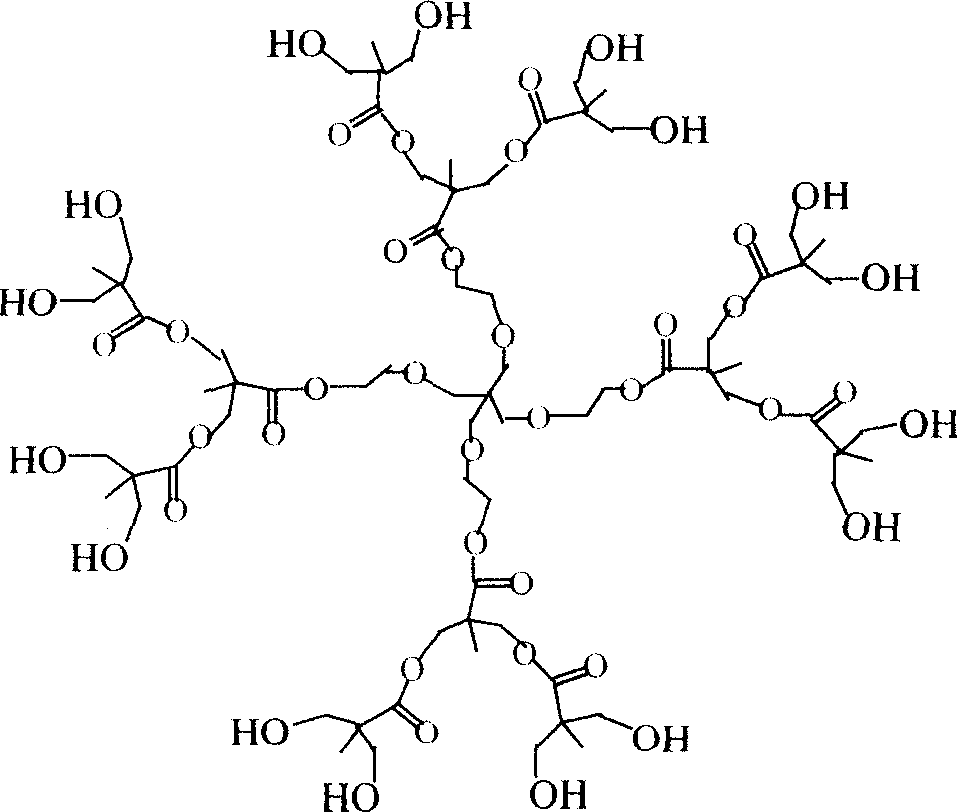

Method for preparing super branched polyacrylate fluorine and application in finishing agent for textile

InactiveCN1687180AWide variety of sourcesNovel preparation methodFibre treatmentPhysical paper treatmentEnd-groupDouble bond

The present invention relates to a fluorine-contained ultrabranched polyacrylate which can be used in water-proofing oil-proofing fabric finishing agent and its preparation method. Said method includes the following steps: using hydroxyterminated ultrabranched polyester as reaction substrate, adopting 'direct method' or 'indirect method' to modifying its hydroxyl end group into polymerizable active double bond, then adding perfluorinated acyl chlroide or esters, and making it and residual hydroxyl end group of said ultrabranched polyester implement esterification reaction; finally making part of its terminal group form into acrylate double bond and making its another part form into perfluoroalkyl so as to obtain the fluorine-contained ultrabranched polyacrylate. Then said fluorine-contanied ultrabranched polyacrylate and hydrocarbon (methyl) acrylate are undergone the process of emulsion copolymerization so as to obtain the water-proofing oil-proofing fluorine-contained fabric finishing agent emulsion.

Owner:上海瀛正科技有限公司

Water-resisting, oil-proof, antifouling agent for fabric and production process thereof

The present invention is waterproof, oilproof and anti-fouling agent for fabric and its production process. The waterproof, oilproof and anti-fouling agent is the mixture of emulsion polymerized fluoric acrylate polymer and pyrolytic closed polyurethane cross-linking agent. Its components include N-ethyl-N-hydroxyethyl perfluoro octyl sulfonamide 80-100 weight portions, isophorone diisocyanate 8-11 weight portions, hydroxyethyl acrylate 4-6 weight portions, acrylic acid 7-10 weight portions, acrylate 650-800 weight portions, and N-hydroxymethyl acrylamide 20-30 weight portions. It is used in the step of high temperature stoving and settling of fabric, and has the advantages of obvious effect, simple production process and lowered production cost.

Owner:LIAONING FIXED STAR FINE CHEM

Styrene-acrylate copolymer composition suitable for surface size

InactiveUS6734232B2Avoid difficult choicesWater-repelling agents additionPaper coatingCelluloseSurfactant free

Owner:ECOLAB USA INC

Self-emulsified aqueous epoxy emulsion and method for preparing same

The present invention provides one kind of self-emulsifying water thinned epoxy emulsion and its production process. The self-emulsifying water thinned epoxy emulsion is produced through emulsion copolymerization with the polymer intermediate, which is obtained through polymerizing the mixed organosilicon monomer comprising alkenyl-containing trimethyl silane and octalkyl cyclotetrasiloxane and acrylic acid monomer, epoxy resin and acrylic acid monomer. The self-emulsifying water thinned epoxy emulsion has homogeneous particle size, high stability, and stable production process. The anticorrosive paint compounded with the self-emulsifying water thinned epoxy emulsion reaches the level of solvent type epoxy resin paint.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

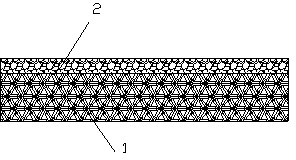

Coating film with large moisture permeability

ActiveCN104029449AGood moisture absorption and moisture conductivityReliable performanceSynthetic resin layered productsGas-tight/water-tight arrangementsCelluloseMoisture absorption

The invention discloses a coating film with the large moisture permeability. The coating film comprises a basic film layer and a coating layer, wherein the basic film layer is an expanded polytetrafluoroethylene film layer; the coating layer coating the expanded polytetrafluoroethylene film layer is a polyurethane emulsion copolymerization coating layer containing superfine micro-powder of hemp stalk cores; a coating agent of the polyurethane emulsion copolymerization coating layer containing the superfine micro-powder of the hemp stalk cores is prepared by uniformly stirring the following raw materials in percentage by weight: 20-25% of polyurethane; 55-60% of a dimethylfomamide solvent; 2-5% of a hydrophilic group solvent and 18-25% of the superfine micro-powder of the hemp stalk cores. Through the manner, the coating film has good moisture absorbing and guide performances; the content of moisture permeable factor fibrin in the superfine micro-powder of the hemp stalk cores is large; micro-grooves and micropores exist in the coasting film, so that the moisture absorption area and the diffusion area are increased; the coating film has excellent performances such as ultraviolet resistance, water proofing, dust proofing, oil proofing, moisture permeability and corrosion resistance on oxide solutions.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

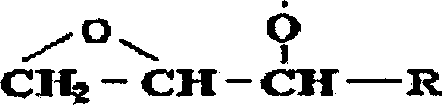

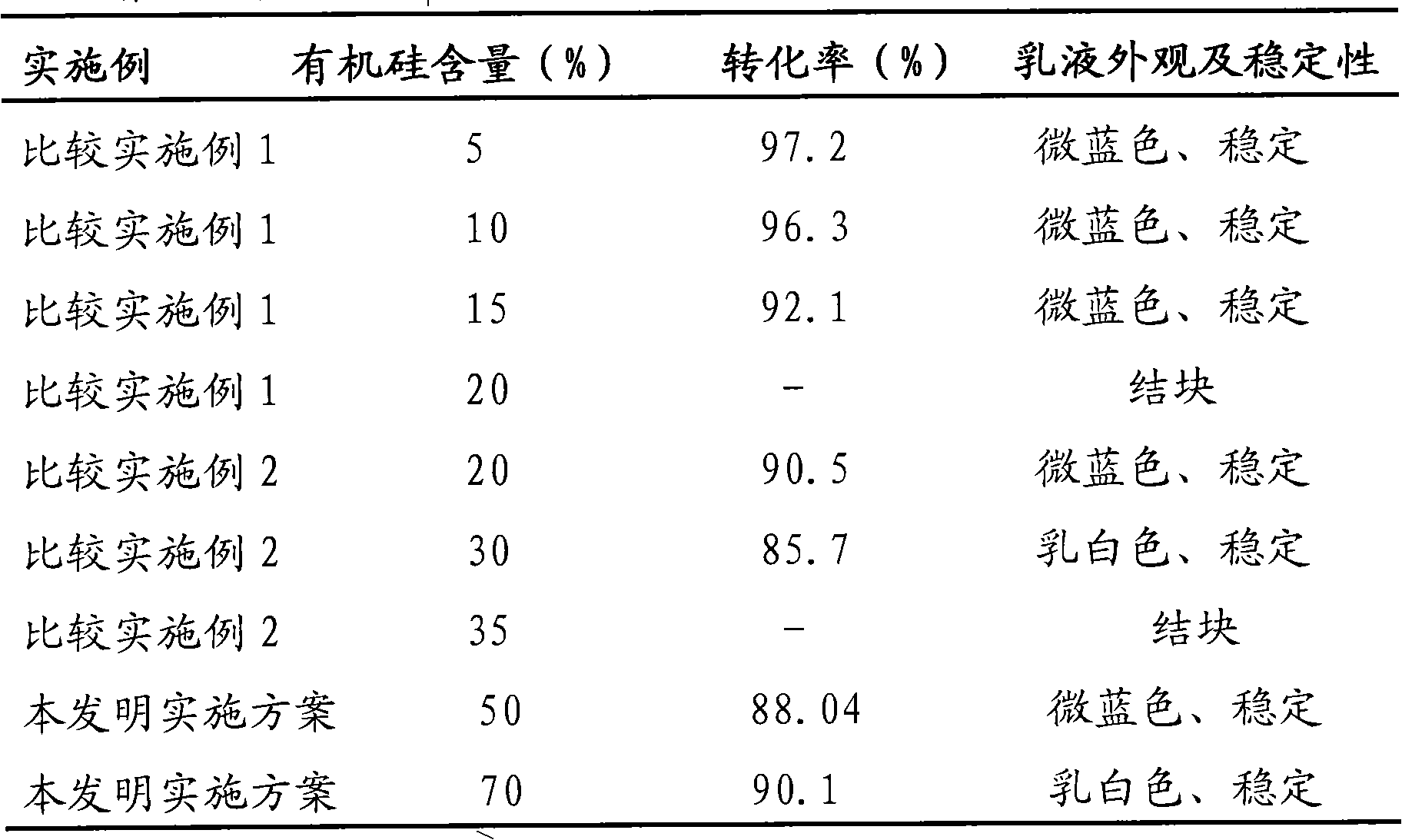

Synthesis method of organic silicon modified acrylate copolymer

The invention discloses a synthesis method of an organic silicon modified acrylate copolymer by using an emulsion copolymerization method. The synthesis method comprises the following steps: (1) synthesizing organic silicon seed emulsion: adding emulsifier and deionized water according to a proportion in a formula into a three-mouth flask provided with a stirrer, a dropping funnel and a reflux condensing tube by using a semicontinuous dropping method, adjusting the bath temperature to 75 DEG C, then, adding catalyst and dropwise adding organic silicon monomers, and after the dropwise adding is finished, introducing nitrogen gas for 30 minutes; reacting for 5 hours, slowly cooling, adjusting the pH value of the system to 7-8 by using 10% sodium carbonate solution and standing the solution for 12 hours; and (2) carrying out graft copolymerization by using acrylic ester monomers: dropwise adding acrylic ester monomers and initiator by also adopting the semicontinuous dropping method after adjusting the reaction temperature to 75 DEG C, and introducing nitrogen gas for 30 minutes; reacting for 5 hours, adjusting the pH value to 7-8 by using ammonia water; and discharging. The synthesis method is simple in process, efficient and environment friendly, the organic silicon content of the prepared emulsion is over 50%, and no agglomeration is generated.

Owner:BEIJING JIASHENG CENTURY TECH

Preparation method of (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion

The invention discloses a preparation method of an epoxy polyether-based (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion, which comprises the following steps of: under the effect of cationic / nonionic or anionic / nonionic surfactants, firstly carrying out seeded emulsion copolymerization on perfluoroalkyl(methyl) acrylate, aliphatic long carbon chain (methyl) acrylate, reactive vinyl monomer and alpha-alkenyl alkoxysilane in an aqueous phase so as to synthesize a silanized long carbon chain fluorinated polyacrylate emulsion; cooling to room temperature; regulating a pH value of the system to be 5.0-6.0; adding an epoxy polyether-based (sesqui) siloxane cross-linking agent and a stiffening agent; continuously stirring for 30 min; and obtaining the (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion after filtering. The modified fluorinated polyacrylate emulsion disclosed by the invention can be used for after-treatment of textiles after dilution, so that the stiff handfeel of textiles can be improved, and an excellent water-repellent and oil-repellent performance is given to the textiles.

Owner:SHAANXI UNIV OF SCI & TECH

Self-flame-resisting type acrylic emulsion and preparation method thereof

The invention relates to a self-flame-resisting type acrylic emulsion. The self-flame-resisting type acrylic emulsion is characterized in that according to a self-flame-resisting type modified styrene-acrylic emulsion, reaction type halogen-containing flame-resisting type vinyl monomer and acrylic esters monomer can be in emulsion copolymerization, a flame-resisting group is fixed on a resin molecular structure in a chemical bond mode and cannot resolve or drop, synthesized acrylic emulsion has self-flame-resisting property, and when coating is prepared, another flame retardant is not required to be added, and long-lasting flame-resisting property can be realized. The invention further provides a preparation method of the self-flame-resisting type acrylic emulsion. The prepared self-flame-resisting type acrylic emulsion has good adhesion, water tolerance and durability, and a prepared film has water tolerance, alkali resistance, scrubbing resistance and long-lasting self-flame-resisting property, and the self-flame-resisting type acrylic emulsion is widely used for flame-resisting coating of indoor and outdoor woodware, steel structures and buildings, not only has a decorating function, but also has a protecting function.

Owner:UNION FOSHAN CHEM +1

Olefin Acrylate Emulsion Copolymerization

ActiveUS20100280198A1Emulsion stabilizationGood film formingEmulsion paintsPolyolefinEmulsion copolymerization

A polymerization process to copolymerize hydrophobic ethylenically unsaturated C4-C30. J olefins with polar monomers such as acrylates is described. The process utilizes an acid source to modify / catalyze the reactivity of the polar monomer and / or radically activated repeat unit from the polar monomer to promote incorporation of the ethylenically unsaturated olefin. The copolymer shows excellent adhesion to a variety of polymeric and / or polar substrates such as polyolefins, acrylatc coatings, wood, etc.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Polymer emulsion and preparation method thereof

The invention discloses polymer emulsion and a preparation method thereof. The polymer emulsion is characterized by using hard monomer, soft monomer and crylic acid as polymer monomers, using crylic acid long-chain alkyl ester as modified monomer, using polymerizable organosilicon emulsifier PMSC as the emulsifier of the system and using thermal decomposition initiator as the initiator to obtain high-performance polymer emulsion by semi-continuous type emulsion copolymerization. The polymer emulsion obtained by the method has favorable waterproofness, water resistance, weather resistance, adhesiveness and film coating effect, and can be widely used as paint, adhesive, fabric waterproof agent, and the like, thereby having bright development potential.

Owner:NANJING UNIV OF TECH

Preparation method of double self cross-linking elastic emulsion

InactiveCN103709316AImprove polymerization stabilityGood storage stabilityCoatingsCross-linkPolymer science

The invention discloses a preparation method of a double self cross-linking elastic emulsion. The method combines two post cross-linking modes: (1) adding multivalent metal ion compounds to carry out cross-linking reactions; (2) adding diacetone acrylamide into emulsion so as to make diacetone acrylamide participate in the emulsion copolymerization reactions during the emulsion polymerization process so as to introduce keto-carbonyl groups into the chains of copolymer, and then adding binary caprylic hydrazide such as adipic dihydrazide into the emulsion so as to obtain the self cross-linking elastic emulsion. A diacetone-acrylamide and binary caprylic hydrazide cross-linking system and a carboxylic acid and multivalent metal salt cross-linking system are both simultaneously induced into an acrylate emulsion polymerization system to replace an elastic emulsion system formed trough a single reactive cross-linking agent; thus the polymerization property and storage stability of emulsion are improved, the waterproof property, contamination resistant property, after-tack property, and elastic elongation rate of the surface of a coating coated by the elastic emulsion are all improved; and the coating product which adopts the two room temperature self cross-linking systems, has a good adhesive force and elasticity, and has a very good surface waterproof property.

Owner:SUZHOU BONA CHEM TECH

Preparation method of fluorine-containing polyacrylate soap-free emulsion

InactiveCN102585086AOvercome the defect of easy migrationImprove polymerization stabilityCoatingsEnd-groupSolvent

The invention relates to a preparation method of a fluorine-containing polyacrylate soap-free emulsion. According to the invention, the fluorine-containing polyacrylate soap-free emulsion is prepared by adopting an amphiphilic segmented copolymer polyacrylic acid-b-polyhexafluorobutyl acrylate (PAA-b-PHFBA) to substitute a routine emulsifier, and carrying out soap-free emulsion copolymerization on acrylate monomers, and can be applied to the leather field, the textile field, the coating field, the papermaking field, the adhesive field and the like. The compatibility of the hydrophobic segment of the used PAA-b-PHFBA and above prepolymerization monomers is good, so a problem of bad compatibility of fluorine-containing monomers is solved, thereby the stability of the emulsion polymerization process is substantially improved. Additionally, the PAA-b-PHFBA is anchored to emulsion particles in the emulsion polymerization, and the hydrophilic segment stretches into a water phase to stabilize the emulsion particles through an electrostatic effect and a steric hindrance effect, so the storage stability and the freeze-thaw resistance stability of the emulsion are improved, disadvantages of bad adhesion, bad water resistance and bad solvent resistance of films of common emulsions are overcome, and the mechanical properties, the adhesion and the abrasive resistance of the film of the emulsion are improved.

Owner:山西佳宇丰化工科技有限公司

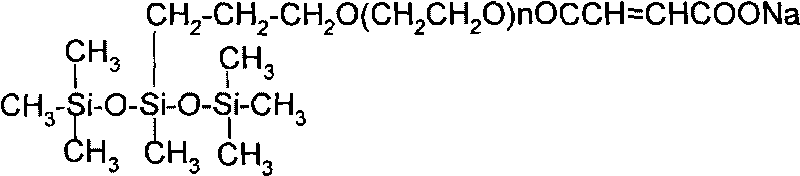

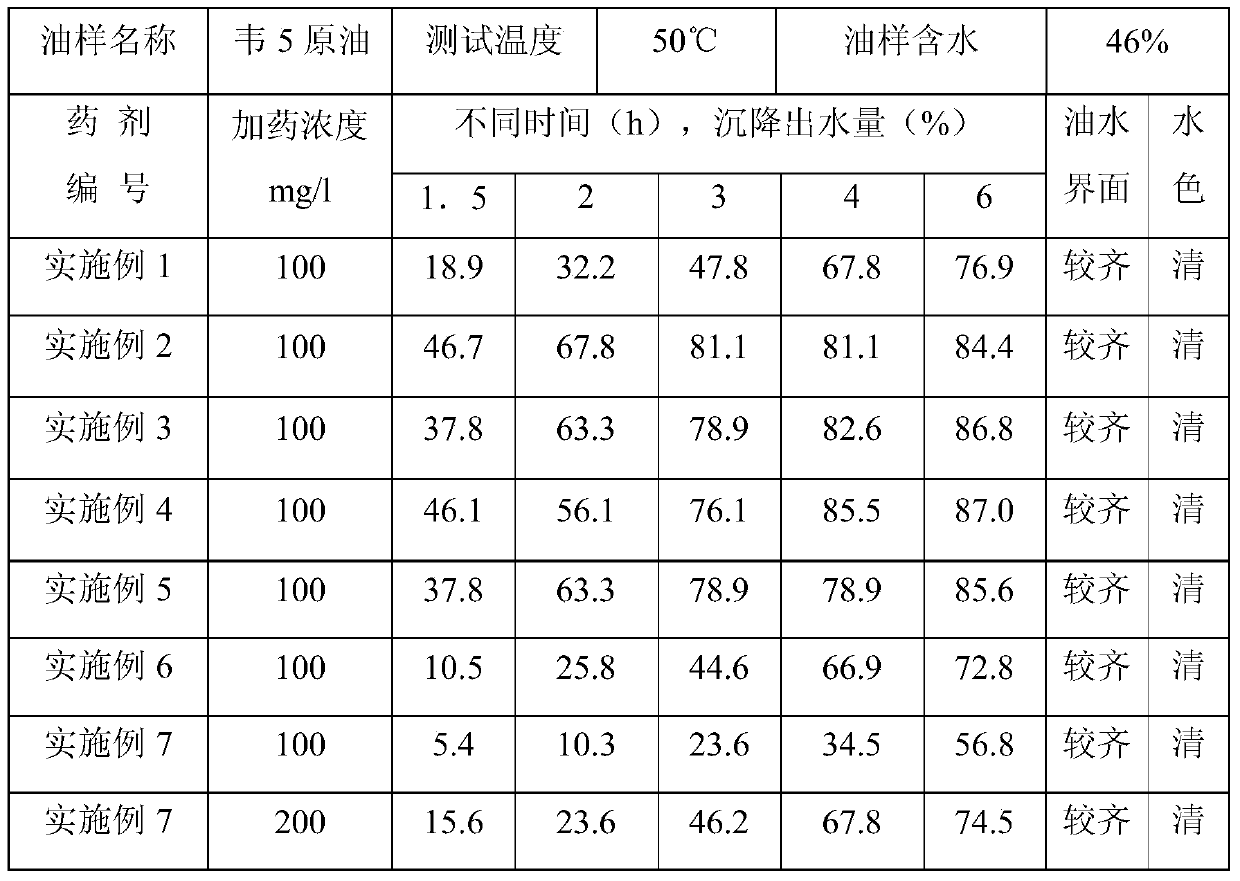

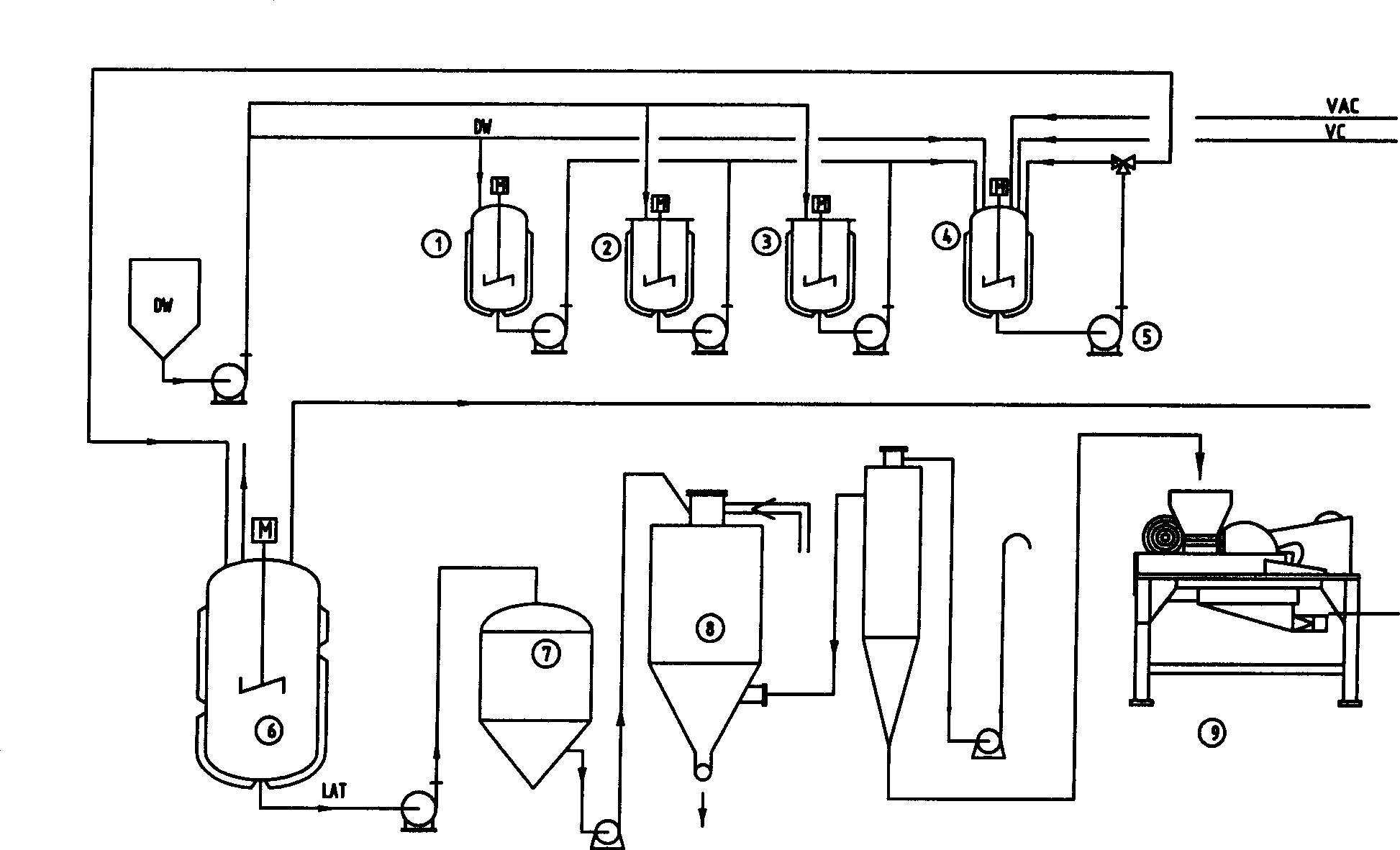

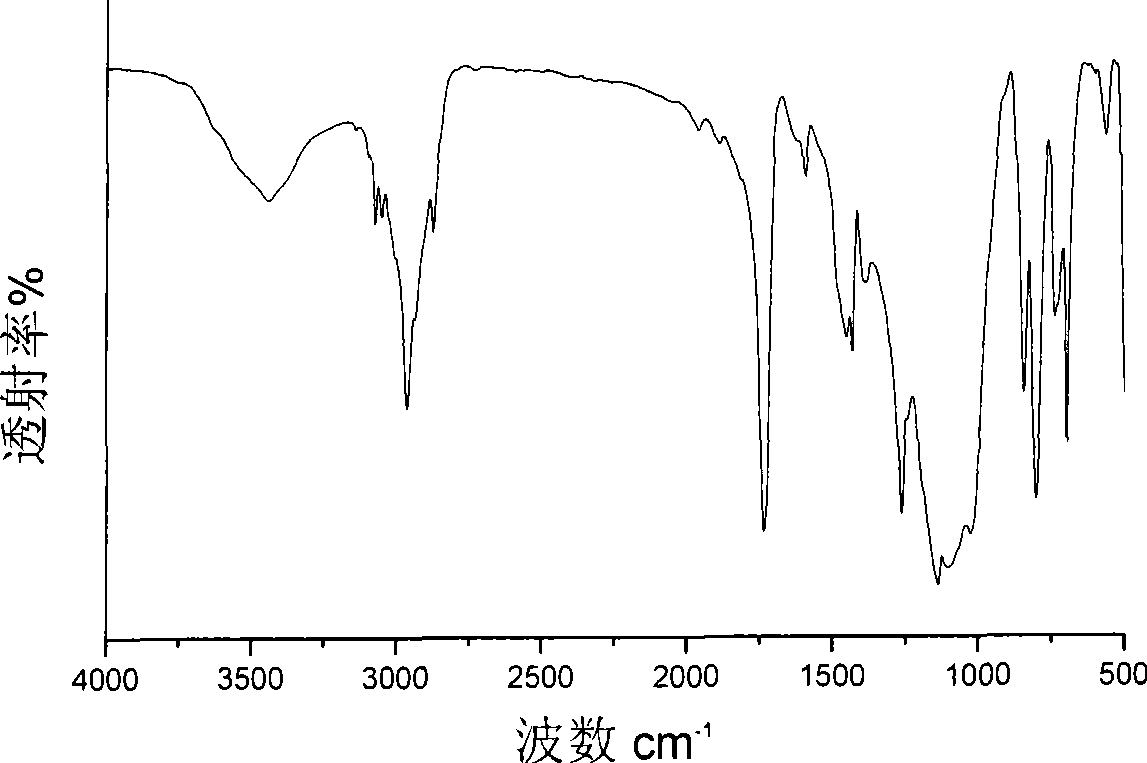

Non-polyether demulsifier and preparation method thereof

ActiveCN105504143AAvoid pollutionMolecular chain lengthDewatering/demulsification with chemical meansHydrophilic monomerCross-link

The invention provides a novel non-polyether demulsifier and its preparation method. The non-polyether demulsifier contains a copolymer prepared by seeded emulsion copolymerization of a hydrophilic monomer, a hydrophobic monomer and an optional cross-linked monomer. The weight ratio of the hydrophilic monomer to the hydrophobic monomer is 3: 97-20: 80. The demulsifier of the invention has advantages as follows: raw materials are easily available; production condition is mild; high temperature and high pressure are not required; operation is convenient; and cost is low. The non-polyether demulsifier of the invention can be used in demulsification of crude oil in an oil field, especially in demulsification of thickened oil. The non-polyether demulsifier has a good demulsification effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stable organosilicon modified copolymer emulsion and its preparation method

InactiveCN1354189AFacilitate the reverse of the hydrolysis reactionAvoid hydrolysis and polycondensation reactionsPolymer scienceLacquer

The present invention relates to a stable organosilicon modified copolymer emulsion and its preparation method. Said copolymer emulsion is made up by uisng monomer containing olefine and siloxane and vinyl monomer containing no siloxane through the emulsion copolymerization initiated by free radical in the presence of hydrolysis inhibitor, protective colloid and pH buffer. In the copolymer, the ratio of siloxane monomer can be up to 35%, and its polymerization process also can be normally implemented, and the obtained emulsion is stable, so that the obtained coating film is superior to that of similar copolymer emulsion with low siloxane content in water-proof property, resistance to contamination, adhesive force and weatherability. It is applicable to preparation of latex paints for cement base material, mosaic and tile, also can be used for preparing lacquer and coating paint, etc.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Interpolymer paste resin and its preparing method

InactiveCN1480473AExcellent pasting performanceReduce low temperature plasticizing performanceWater solubleCarvacryl acetate

A pasty copolymer resin of chloroethylene-vinyl acetate is prepared through under the protection of surfactant dispersing the chloroethylene monomer and vinyl acetate monomer in water by use of high-speed pump or slowly stirring to form fine liquid drips, polymerizing at 40-65 deg.C under the action of trigger system to obtain copolymer latex with 0.1-2.0 microns glanularity, and spray drying. Its advantages are better paste-forming performance and good low-temp plasticity.

Owner:SHENYANG CHEM IND CO LTD

Water-whitening resistant pressure-sensitive adhesive

InactiveUS20050176876A1Improve abilitiesImprove propertiesEster polymer adhesivesEmulsion paintsPolymer scienceMeth-

Pressure-sensitive adhesive compositions that resist water-whitening are provided. The compositions comprise emulsion copolymers formed from a plurality of monomers that includes a plurality of (meth)acrylic monomers, at least one trifluoroalkyl(meth)acrylate monomer, and at least one alkylimidazolidone (meth)acrylate monomer. Preferably, the (meth)acrylic monomers comprise a plurality of soft monomers, at least one hard monomer and at least one acid monomer. The plurality of monomers may further include at least one aliphatic urethane di(meth)acrylate, an oligomer. The pressure-sensitive adhesive composition also comprises a surfactant system including at least one surfactant.

Owner:AVERY DENNISON CORP

Resin emulsion for water-borne wood paint and preparation method thereof

The invention discloses a resin emulsion for a water-borne wood paint and a preparation method thereof. The resin emulsion and the preparation method thereof are characterized in that: firstly, vinyl versatate is introduced to a prescription and is subjected to an emulsion copolymerization reaction together with alkyl methacrylate and other functional monomers; secondly, an emulsion polymerization process for intermittently feeding is adopted; and each polymerized emulsion particle comprises four layer from the inside to the outside, namely an inner core, an outer core, an inner casing and an outer casing respectively; and thirdly, an inner casing reaction material and an outer casing reaction material contain diacetone acrylamide and other cross-linking agents; and in the drying and film-forming process of the water-borne paint, the diacetone acrylamide and other cross-linking agents are subjected to a cross-linking reaction with adipic dihy drazide so as to form a compact body form netlike structure. According to the water-borne wood paint prepared from the resin emulsion, the water resistance, heat resistance and hardness of a paint film can be remarkably improved.

Owner:山东宝达新材料有限公司

Impact-reinforcing agent having multilayered structure, method for preparing the same, and thermoplastic resin comprising the same

ActiveUS20060074148A1Improve impact resistanceUniform colorCoatingsHydrophilic monomerPolyvinyl chloride

The present invention relates to an acrylic impact modifier having a multilayered structure, which offers both superior impact resistance and coloring characteristics to engineering plastics, such as polycarbonate (PC) and a polycarbonate / polybutylene terephthalate alloy resin, or to a polyvinyl chloride resin. The present invention provides an acrylic impact modifier having a multilayered structure comprising: a) a seed prepared by emulsion copolymerization of a vinylic monomer and a hydrophilic monomer; b) a rubbery core surrounding the seed and comprising a C2 to C8 alkyl acrylate polymer, and c) a shell surrounding the rubbery core and comprising a C1, to C4 alkyl methacrylate polymer, a method for preparing the same, and a thermoplastic resin comprising the same.

Owner:LG CHEM LTD

Flame-retardant interfacial modifier and preparation method and flame retardant polycarbonate composition

InactiveCN101456936AImprove flame retardant performanceHigh impact strengthMethacrylatePolymer science

The invention discloses an inflaming retarding interface modifier and a preparation method thereof, and an inflaming retarding polycarbonate composite. The inflaming retarding interface modifier comprises two parts, namely high phenyl polysilsesquioxane and polyacrylate which are combined through a vinyl free radical polymerization reaction. The preparation method comprises: the emulsion copolymerization of high phenyl polysilsesquioxane, acrylic esters, and methacrylate in turn, and the emulsion breaking and drying. The inflaming retarding polycarbonate composite comprises: 97.8 to 99.3 mass portions of polycarbonate, 0.1 to 1.0 mass portion of the inflaming retarding interface modifier, 0.05 to 1.0 mass portion of fluoro-resin, and 0.05 to 1.0 mass portion of organic sulphonate. The total dosage of the three flame retardants is 0.5 portion; and the polycarbonate composite spline with the thickness of 1.6mm can be enabled to reach the UL94V-0 grade. The composite can be used for preparing all kinds of office automation equipment, electronic and electric equipment and so on.

Owner:SOUTH CHINA UNIV OF TECH

Novel water-based ink binder self-crosslinking emulsion for flexographic printing and preparation method thereof

The invention discloses a novel water-based ink binder self-crosslinking emulsion for flexographic printing and a preparation method of the novel water-based ink binder self-crosslinking emulsion. Theself-crosslinking emulsion is a copolymer emulsion prepared from the following components through emulsion copolymerization, by weight, 30-70 parts of deionized water, 5-35 parts of water-based resin, 2-40 parts of alkyl acrylate monomer with the total carbon number being 4-12, 0-25 parts of methacrylate monomer with the total carbon number being 5-10, 0-25 parts of a styrene monomer, 0.2-5 partsof a hydroxyl (meth)acrylate monomer, 0.5-5 parts of a crosslinking monomer, 0.01-0.5 part of a metal ion crosslinking agent, 0.01-0.1 part of an initiator and 0-10 parts of a pH regulator. The water-based ink binder self-crosslinking emulsion can be subjected to a self-crosslinking reaction at room temperature, and has excellent resolubility, water resistance and printing transfer performance.

Owner:BEIJING UNIV OF CHEM TECH +1

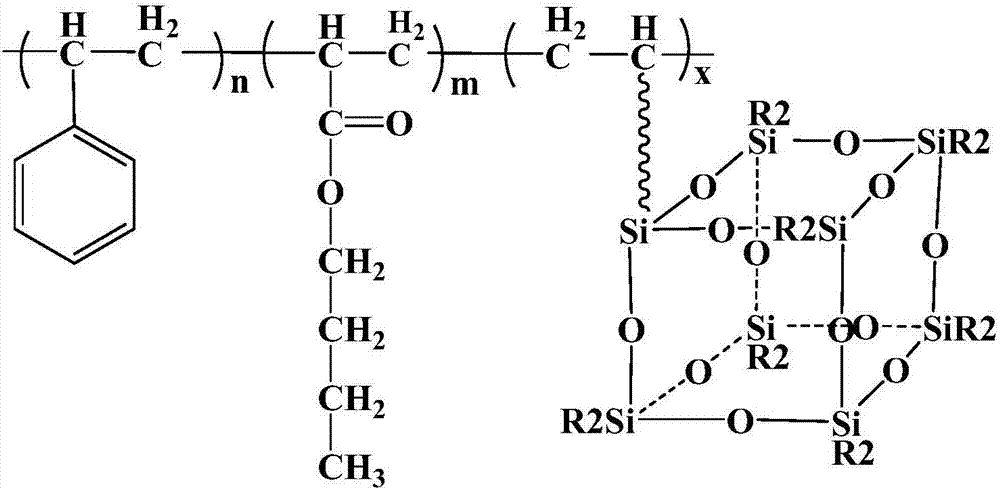

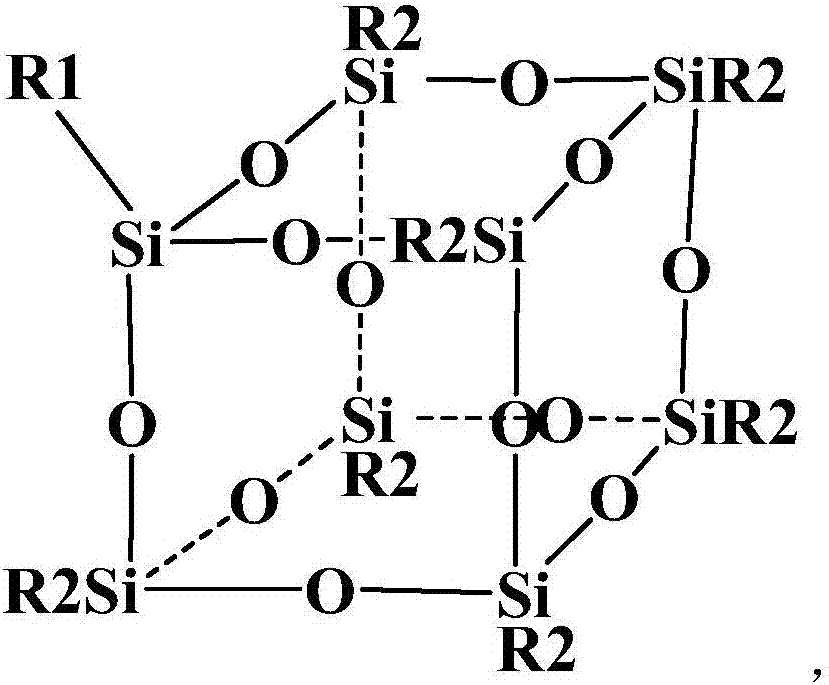

POSS modified styrene-acrylic emulsion copolymer, preparation method and application

The invention discloses a POSS modified styrene-acrylic emulsion copolymer, a preparation method and application. The copolymer comprises the following components in parts by weight: 40 to 60 parts of deionized water, 15 to 20 parts of styrene, 15 to 20 parts of butyl acrylate, 3 to 5 parts of an emulsifying agent, 2 to 7 parts of POSS, 1 to 2 parts of a water-soluble initiator, 0.1 to 0.3 part of a pH value conditioning agent and 3 to 5 parts of other auxiliaries. As an exterior wall coating material, the POSS modified styrene-acrylic emulsion obtained in the invention has the advantages of low surface tension, high pollution resistance and high self-cleaning performance. In the copolymer, an Si-O-Si bond can be formed by POSS and the wall, so that the adhesive force of the styrene-acrylic emulsion as the exterior wall coating is improved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Preparation method of carboxyl silicon modified acrylic resin emulsion

The invention relates to a preparation method of a carboxyl silicon modified acrylic resin emulsion, and the preparation method comprises the following steps of: mixing vinyl carboxyl silicone oil with a reactive alkenyl monomer and a functional monomer to prepare an oil-phase component, and then emulsifying by using an anionic / nonionic surface-active agent water solution to prepare a pre-emulsion; and then carrying out water-phase emulsion copolymerization on the pre-emulsion under the action of the anionic / nonionic surface-active agent water solution and an initiating agent, then depressurizing, eliminating low boiling, deodorizing, and regulating pH to 6.0-7.0 to prepare the carboxyl silicon modified acrylic resin emulsion. The carboxyl silicon modified acrylic resin emulsion prepared through the method disclosed by the invention has good centrifugalization stability and storage stability, is less in possibility of generating the phenomena of emulsion breaking and oil floating, is used for preparing a resin coating and can improve the phenomena of hot sticking and cold shortness of acrylic resin and endue certain hydrophobic and flexible functions to the resin coating.

Owner:深圳市中源鸿福科技有限公司

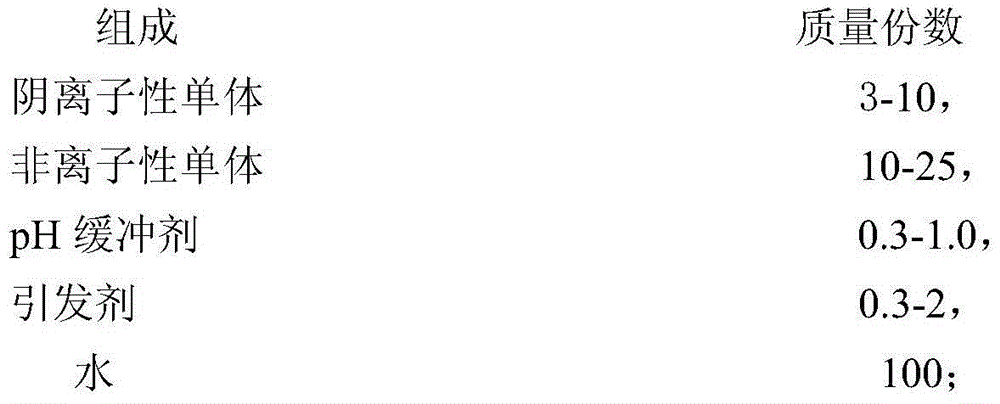

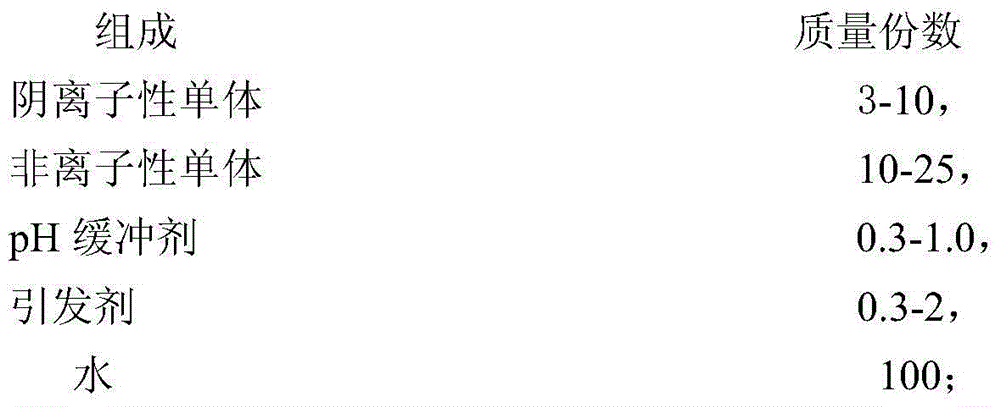

Polymer dispersion and preparation method thereof

InactiveCN104693345AImprove securityPrevent gelationOther chemical processesPh bufferingReaction system

The invention discloses a polymer dispersion and a preparation method thereof. The polymer dispersion is obtained through the soap-free emulsion copolymerization technology. The polymer dispersion comprises a negative ion monomer, a non-ionic monomer, a pH buffering agent, an initiator, an antalkali and water, wherein the negative ion monomer accounts for 3-10 parts of the raw materials, the non-ionic monomer accounts for 10-25 parts of the raw materials, the pH buffering agent accounts for 0.3-1.0 part of the raw materials, the initiator accounts for 0.3-2 parts of the raw materials, and the water accounts for 100 parts of the raw materials. A proper amount of the antalkali is used for adjusting the pH value of a reaction system to range from 6.0 to 9.0. The obtained polymer dispersion is used as a dust depressor, an effective shell can be formed on the surface of dust, and the construction safety and application safety of the polymer dispersion are higher. The polymer dispersion is applied as the chemical dust depressor, can be diluted with water to be sprayed for use, and is good in overall performance, safe and environmentally friendly.

Owner:HEBEI UNIV OF TECH

HASE rheology modifier VAE emulsion copolymer composition

The present invention relates to a composition comprising a vinyl acetate copolymer and a HASE thickener comprising structural units of ethyl acrylate, methacrylic acid, acrylic acid, and a hydrophobic macromonomer. The composition of the present invention shows an improvement in heat aged stability over a vinyl acetate copolymer based paint thickened with a HASE that does not include structural units of acrylic acid.

Owner:ROHM & HAAS CO

Method for preparing polymer retanning fat-liquoring agent and retanning fat-liquoring agent

InactiveCN101831024AMeet the protection requirementsWith retanningTanning treatmentLeather impregnationOrganic solventSodium methacrylate

The invention discloses a method for preparing a polymer retanning fat-liquoring agent and the retanning fat-liquoring agent. The preparation method comprises the following steps of: preparing long-chain fatty alcohol maleic acid monoester by adopting C8-C18 long-chain fatty alcohol and maleic anhydride, preparing the long-chain fatty alcohol maleic acid monoester into long-chain fatty alcohol maleic acid monoester salt, and then dripping methacrylic acid octadecyl ester, aqueous solution of sodium methacrylate and aqueous solution of initiator into the long-chain fatty alcohol maleic acid monoester salt to perform aqueous emulsion copolymerization to form the polymer retanning fat-liquoring agent. The polymer retanning fat-liquoring agent contains terpolymer of the methacrylic acid octadecyl ester, the long-chain fatty alcohol maleic acid monoester and the methacrylic acid. The preparation method saves an organic solvent during synthesizing the retanning fat-liquoring agent so as to reduce environmental pollution, and meanwhile overcomes the defect of insufficient fat-liquoring performance of a long-chain fatty alcohol maleic acid monoester and methacrylic acid copolymer by introducing oleophilic methacrylic acid octadecyl ester monomer into the polymer.

Owner:甘肃宏良皮业股份有限公司

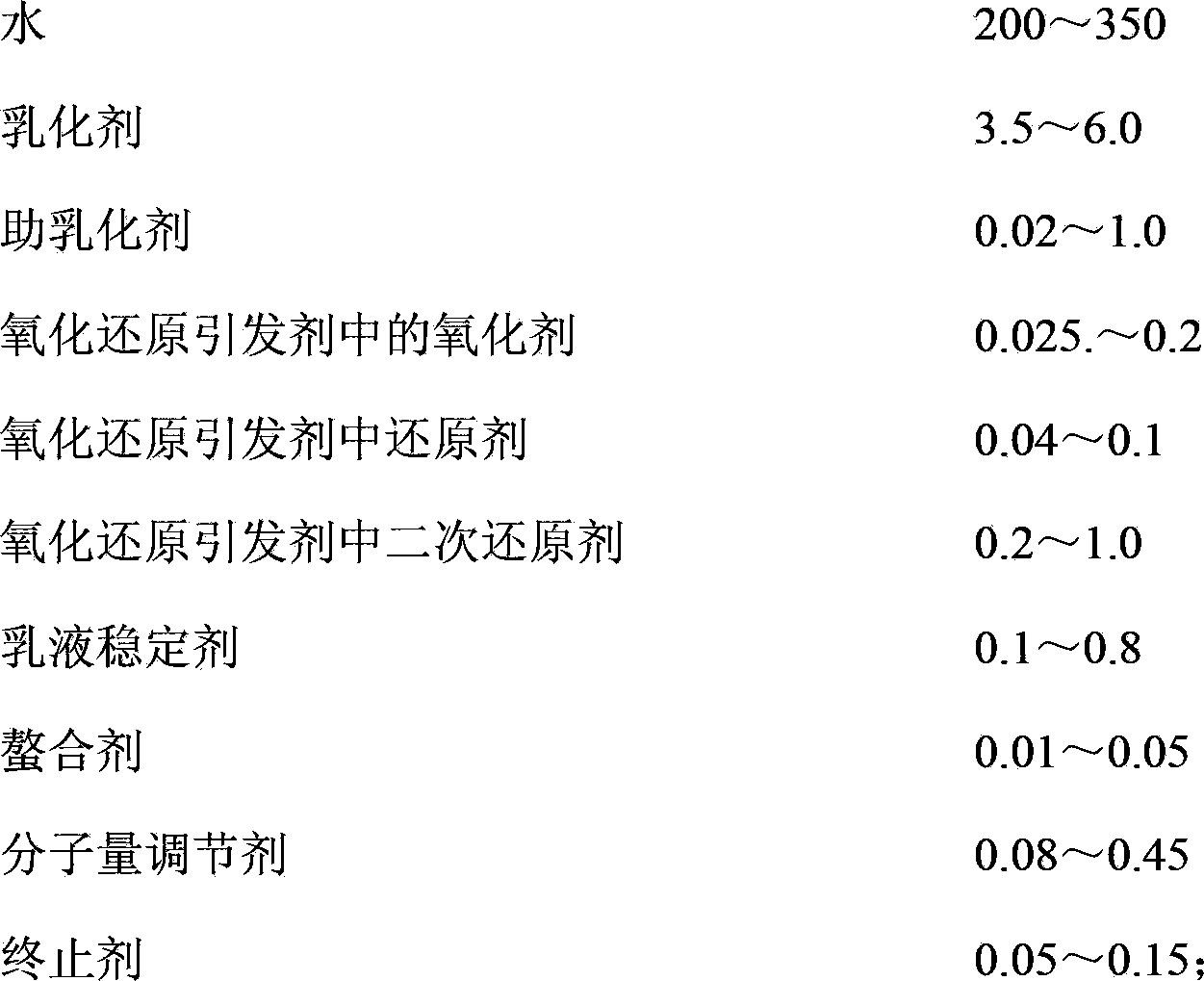

Preparation method of acrylonitrile-butadiene rubber

The invention relates to a preparation method of an acrylonitrile-butadiene rubber, belonging to a manufacturing method of a high-molecular compound by copolymerizing butadiene and acrylonitrile. The acrylonitrile-butadiene rubber is prepared by carrying out cold-process intermitted emulsion polymerization on the raw materials butadiene and acrylonitrile. The method is characterized in that the acrylonitrile-butadiene rubber has the following technical indexes: the Mooney viscosity is 30-95, the acrylonitrile monomer content accounts for 18-46 wt%, the degree of swelling is 20-50%, and the tensile strength is 10-22 Mpa. The invention provides an acrylonitrile-butadiene rubber with different acrylonitrile contents and excellent oil resistance and physical and mechanical properties and a preparation method thereof. The reaction temperature and the butadiene-acrylonitrile monomer ratio are regulated and controlled by using the unique emulsion system, redox system, monomer feeding mode and technological conditions; and the acrylonitrile and butadiene are subjected to emulsion copolymerization to obtain the acrylonitrile-butadiene rubbers with different acrylonitrile contents. The acrylonitrile-butadiene rubber prepared by the method has favorable oil resistance; and the method is suitable for preparing acrylonitrile-butadiene rubber raw materials required by various oil-resistant rubber products.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com