Method for preparing super branched polyacrylate fluorine and application in finishing agent for textile

A polyacrylate and hyperbranched polyester technology, applied in the direction of physical treatment of paper, etc., can solve the problems of uneven distribution of fluorine atoms on the surface of substrates, many self-polymers in copolymerization products, uneven distribution of fluorine atoms, etc. The effect of novel method, light color and broad industrial application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

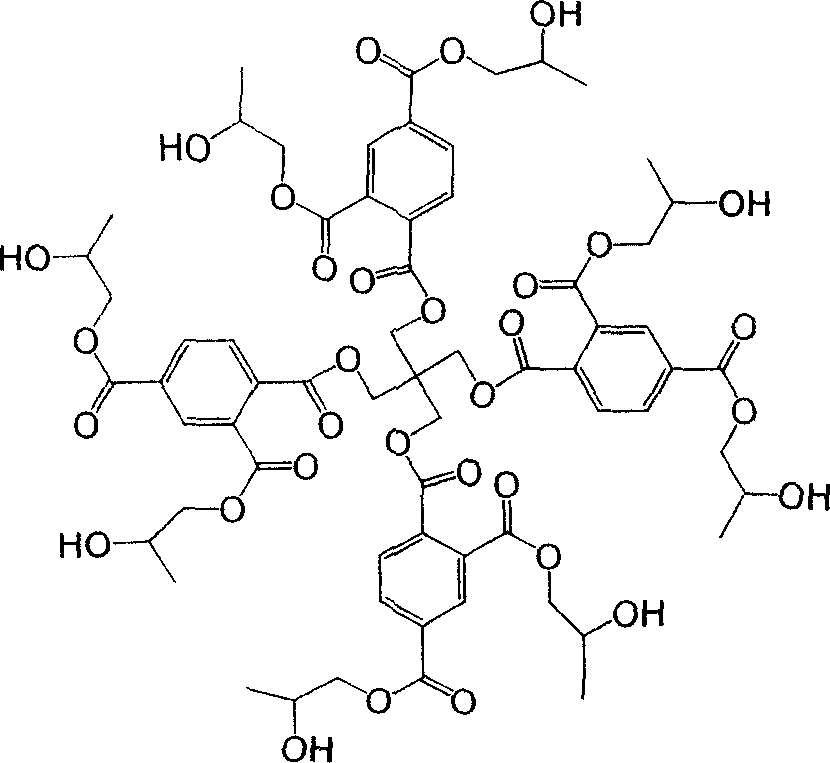

[0037] Embodiment 1. take pentaerythritol as core, prepare polycarboxy polyester by esterification with trimellitic anhydride;

[0038] A 250ml four-necked flask reactor equipped with a magnetic stirrer, a nitrogen inlet and a condenser was used to add 20g (0.147mol) pentaerythritol, 150ml dioxane, 113g (0.588mol) trimellitic anhydride, 0.14g (1000ppm) ) stannous chloride, be warming up to the dioxane reflux state under continuous stirring, react for 8 hours, after the reaction solution is cooled, dioxane is distilled under reduced pressure to obtain a kind of white powder, namely polycarboxy polyester; The yield of the reaction was 96%.

[0039] The obtained product is analyzed by infrared spectrum, and the acid anhydride corresponds to infrared 1810cm -1 The peak disappears. At 1760cm -1 The characteristic peak of ester group appears.

[0040] Using the titration method, the acid value of the product was determined to be 502 mgKOH / g with potassium hydroxide ethanol stand...

Embodiment 2

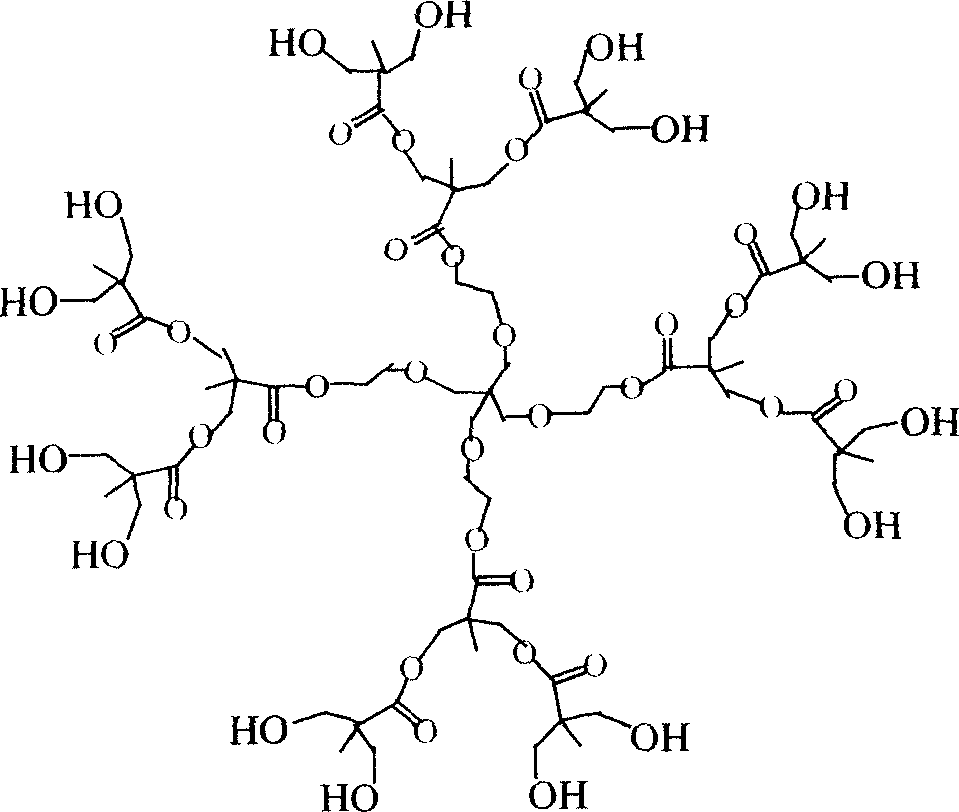

[0044] Embodiment 2. prepare the hyperbranched polyester of terminal hydroxyl with propylene oxide modified polycarboxyl polyester;

[0045] Adopt a 250ml four-necked flask reactor equipped with a magnetic stirrer, an oil bath and a nitrogen inlet, a condenser and a dropping funnel, add 20g (0.022mol) of polycarboxylated polyester synthesized in Example 1, 100ml of tetrahydrofuran, 15.8g (0.264mol) of propylene oxide and 1.1g (3wt%) of N,N-dimethylbenzylamine were reacted at 65°C for 7 hours, and tetrahydrofuran was distilled under reduced pressure to obtain a colorless viscous liquid, namely terminal hydroxyl group The hyperbranched polyester, its molecular structure is:

[0046]

[0047] The obtained product was analyzed by infrared spectroscopy, and the carboxylic acid corresponds to infrared 1680cm -1 The peak disappears. At 1760cm 1 The characteristic peak of ester group becomes stronger.

[0048] Using the titration method, the acid value of the product was determ...

Embodiment 3

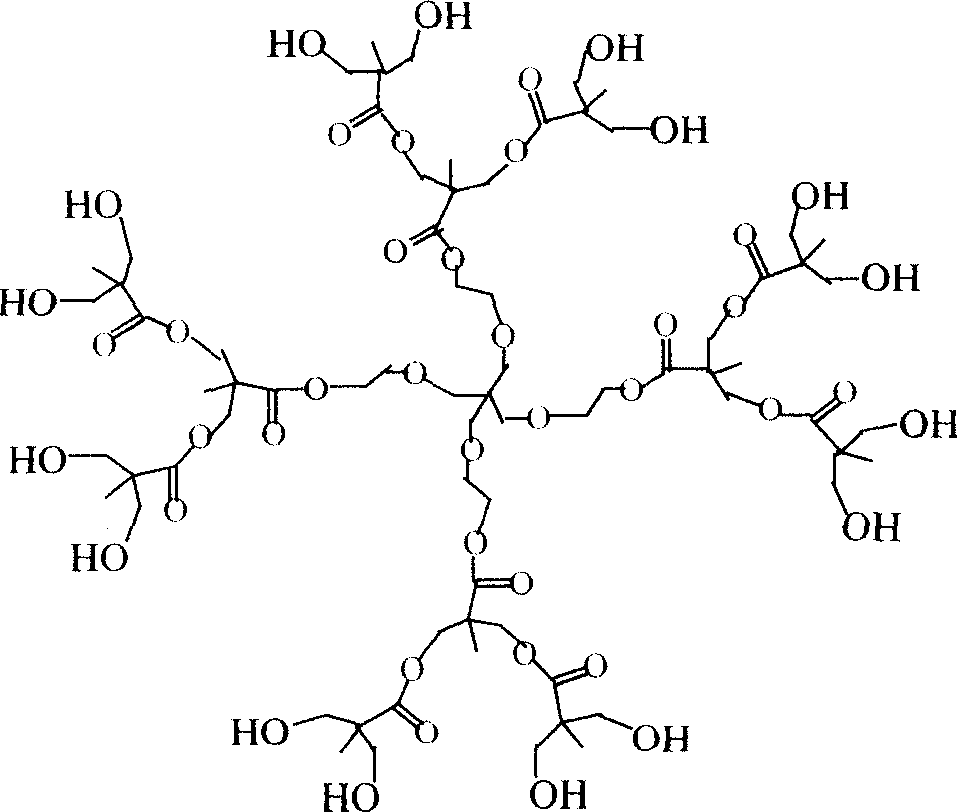

[0052] Example 3. Using the hyperbranched polyester with 8 hydroxyl groups obtained in Example 2 as the core, a "direct method" was used to prepare a hyperbranched polyester with partial acrylated end groups

[0053] Adopt the 250ml three-necked flask reactor equipped with magnetic stirrer, nitrogen inlet and condensing water separator, add 20g (0.015mol) hyperbranched polyester of 8 hydroxyl groups obtained in Example 2, 5.7g (0.078mol) acrylic acid , 100ml toluene and 0.04g (500ppm) p-hydroxyanisole, stir and heat up to 100 ° C, form a transparent solution under nitrogen and continue stirring, add 1g (5wt%) p-toluenesulfonic acid, stir and heat up to toluene reflux state, the reaction is 4-5 hours, and the water output is almost the same as the theoretical value. Cool down, and after the reaction solution is cooled, use saturated NaHCO 3 The aqueous solution washes away residual acrylic monomer and p-toluenesulfonic acid. Separate liquid and use anhydrous Na 2 SO 4 The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com