Polymer dispersion and preparation method thereof

A technology for dispersions and polymers, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as reducing the effective action period, and achieve the effects of preventing stability decline, ensuring stable composition, and appropriate copolymerization temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

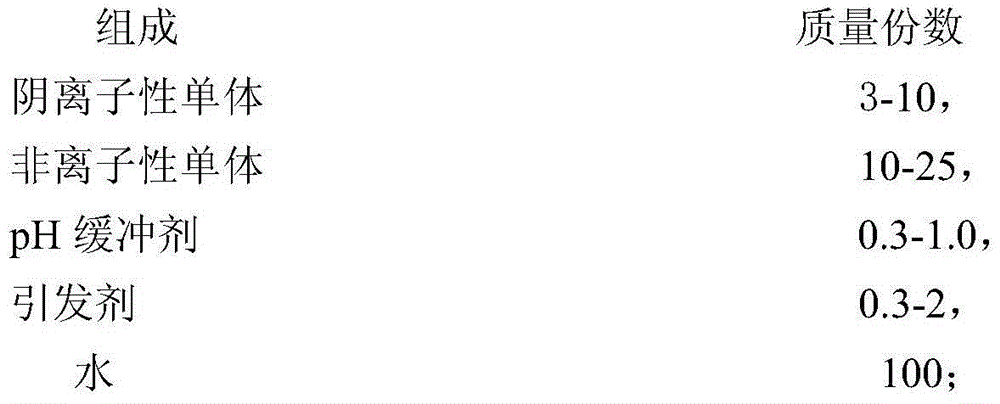

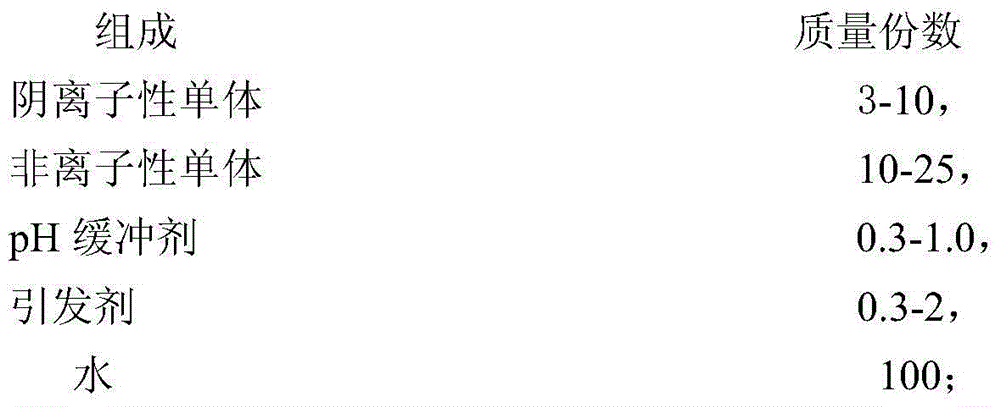

Method used

Image

Examples

Embodiment 1

[0040] The parts by mass are in grams, 3g of acrylic acid is used as anionic monomer, 18g of butyl acrylate, 5g of methyl methacrylate and 2g of hydroxyethyl methacrylate are used as nonionic monomers, and they are uniformly mixed and used as a raw material solution for later use. Add 0.4 g of sodium bicarbonate and 100 g of distilled water to a reactor equipped with a stirrer, a thermometer, a dropping funnel, and a nitrogen conduit, start stirring, and replace with argon for 15 minutes. When the water bath was heated to 80° C., 8 g of potassium persulfate aqueous solution with a mass concentration of 5% and 4 g of sodium vinyl sulfonate were added. After the temperature stabilized, the above-mentioned raw material solution was continuously added dropwise through the dropping funnel, and the dropping speed was controlled, and the dropwise addition was completed within 3 hours. The temperature of the system was raised to 85° C., kept for 1.5 hours, and the system was lowered t...

Embodiment 2

[0046] The implementation steps are the same as in Example 1, the difference is: as a nonionic monomer, 2g hydroxyethyl methacrylate is replaced by 2g methoxy polyoxyethylene ether methacrylate (polyether molecular weight 500); polymerization temperature is 85°C.

[0047] The performance evaluation method is the same as in Example 1.

Embodiment 3

[0049] The number of parts by mass is in grams, and 3g of acrylic acid, 16g of butyl acrylate and 4g of styrene are mixed in proportion to form a raw material solution for later use. Add 0.3 g of sodium carbonate and 100 g of distilled water to a reactor equipped with a stirrer, a thermometer, a dropping funnel, and a nitrogen conduit, start stirring, and replace with nitrogen for 20 minutes. When the water bath was heated to 80° C., 10 g of 5% potassium persulfate aqueous solution, 2 g of allyl sodium sulfonate and 2 g of 2-acrylamide-2-methylpropanesulfonic acid were added. After the temperature stabilized, the raw material solution was continuously added dropwise through the dropping funnel, and the dropping speed was controlled, and the dropwise addition was completed within 3 hours. The temperature of the system was raised to 85° C., kept for 1.5 hours, and the system was lowered to room temperature under stirring. The pH value of the system was adjusted with 2-hydroxyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com