Self-emulsified aqueous epoxy emulsion and method for preparing same

A technology of water-based epoxy emulsion and production method, used in epoxy resin coatings, coatings and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

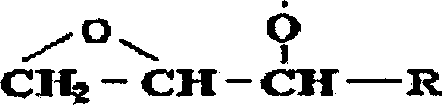

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1, the synthesis of organosilicon polymerization intermediate

[0066] Silicone monomer 480Kg (among them: vinyltrimethylsilane 300Kg, octamethylcyclotetrasiloxane 180Kg), reactive emulsifier 48Kg (among them: α-allyl alkylphenol polyoxyethylene ether 6Kg, α-allyl alkylphenol polyoxyethylene ether ammonium sulfate 42Kg), crosslinking agent (allyl methacrylate) 1Kg, acrylic acid monomer 469Kg (of which: methyl methacrylate 140Kg, butyl acrylate 280Kg, acrylic acid Isooctyl ester 49Kg), initiator (dibenzoyl peroxide) 2Kg, add to the reaction pot, heat up to 55-60°C under stirring conditions, stop heating, exothermic reaction occurs in the reaction system, and the temperature rises to 65-60°C 70°C, keep the temperature at 68-70°C, and react at a constant temperature for 3 hours to obtain an organosilicon polymerization intermediate with a viscosity of 450 mPa·s and a molecular weight of 2500.

Embodiment 2

[0067] Embodiment 2, the synthesis of organosilicon polymerization intermediate

[0068] Silicone monomer 360Kg (among them: 3-propenylpropyltrimethylsilane 220Kg, octamethylcyclotetrasiloxane 140Kg), reactive emulsifier 96Kg (among them: allyl alcohol polyoxyethylene ether 16Kg, α - Allyl alkylphenol polyoxyethylene ether ammonium sulfate 80Kg), crosslinking agent (N, N-methylene 2-acrylamide) 1Kg, acrylic acid monomer 542Kg (wherein: methyl methacrylate 160Kg, butyl acrylate Ester 360Kg, isooctyl acrylate 22Kg), initiator (dicumyl peroxide) 1Kg, put into the reaction pot, heat up to 67-70°C under stirring conditions, stop heating, exothermic reaction occurs in the reaction system, the temperature Raise to 75-80°C, keep the temperature at 78-80°C, and react at constant temperature for 90 minutes to obtain an organosilicon polymerization intermediate with a viscosity of 700 mPa·s and a molecular weight of 4000.

Embodiment 3

[0069] Embodiment 3, the polymerization of aqueous epoxy emulsion

[0070] 75Kg of the organosilicon polymerization intermediate prepared in Example 1, 440Kg of epoxy resin, and 354Kg of deionized water were added to the reaction pot, and the temperature was maintained at 85-87°C. While stirring, 80Kg of acrylic acid monomer (wherein: methacrylic acid Methyl ester 16Kg, butyl acrylate 34Kg, acrylamide 5Kg and acrylic acid 25Kg), add 2Kg ammonium persulfate at the same time, keep warm and react for 30 minutes. Then add 9Kg potassium hydroxide. Promptly obtain the aqueous epoxy emulsion of the present invention. The emulsion is a milky white viscous liquid with a solid content of 51.5%, a viscosity of 8.9 Pa·s, and a molecular weight of 6.7×10 4 , the pH value is 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com