A kind of alkaline low phosphorus reverse osmosis membrane scale inhibitor and preparation method

A technology of reverse osmosis membrane and scale inhibitor, which is applied in the field of water treatment, can solve the problems of biological contamination of bacteria in membrane system, environmental water source pollution, and high production cost, and achieve the effects of reducing biological pollution, simple production process and less dosage of dosing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

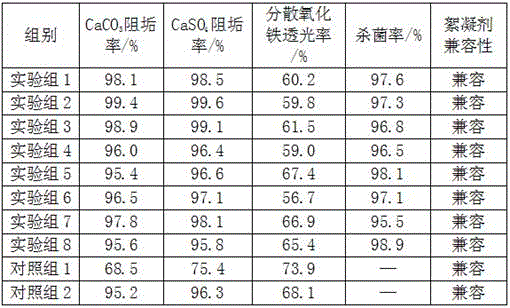

Examples

Embodiment 1

[0036] The alkaline low-phosphorus reverse osmosis membrane antiscalant of this embodiment includes the following components in mass percent:

[0037] EDTMPS 20%,

[0038]PAA 30%,

[0039] Dimethyl Fumarate 10%,

[0040] Graphene oxide aqueous dispersion 4.0%,

[0041] 10% (by mass) borax in water 36%.

[0042] The preparation method of the alkaline low-phosphorus reverse osmosis membrane antiscalant in this embodiment is as follows: the mass percentage of this embodiment takes each raw material, and EDTMPS, PAA, dimethyl fumarate and graphene oxide aqueous dispersion are sequentially Add it into the container, stir at room temperature for 2.0 hours, mix well, add a pH regulator, control the pH value of the material system to 9-11, and ultrasonically treat it for 15 minutes, then heat the material to 80°C, filter while it is hot, and cool the filtrate, that is Obtain the present embodiment alkaline low phosphorus reverse osmosis membrane antiscalant.

Embodiment 2

[0044] The alkaline low-phosphorus reverse osmosis membrane antiscalant of this embodiment includes the following components in mass percent:

[0045] EDTMPS 35%,

[0046] PAA 25%,

[0047] Dimethyl Fumarate 8.5%,

[0048] Graphene oxide aqueous dispersion 4.6%,

[0049] 15% (by mass) borax in water 26.9%.

[0050] The preparation method is the same as in Example 1.

Embodiment 3

[0052] The alkaline low-phosphorus reverse osmosis membrane antiscalant of this embodiment includes the following components in mass percent:

[0053] EDTMPS 25%,

[0054] PAA 25%,

[0055] Dimethyl Fumarate 8%,

[0056] Graphene oxide aqueous dispersion 3.5%,

[0057] 10% (by mass) borax in water 38.5%.

[0058] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com