Neutral deoiling derusting cleaning agent

A rust-removing cleaning agent, neutral technology, applied in the field of cleaning agents, can solve the problems of long-term storage of unfavorable products, easy decomposition and failure, unstable corrosion inhibitor, etc., to achieve stable cleaning agent, uniform rust removal, and thorough rust removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of cleaning agent solutions of different formulations

[0032] recipe one

[0033] Prepare 500kg product of the present invention, each component contained in it and batching amount (kg) thereof are as follows:

[0034] Component Ingredients (Kg)

[0035] HPMA 100

[0036] HEDP 25

[0038] Surfactant AS 10

[0039] Thiourea 0.5

[0040] h 2 O margin

[0041] The prepared product has a pH value of about 7, a light yellow homogeneous liquid, and no suspended matter.

[0042] recipe two

[0043] Prepare 500kg product of the present invention, each component contained in it and batching amount (kg) thereof are as follows:

[0044] Component Ingredients (Kg)

[0045] HPMA 50

[0046] PAAS 100

[0047] ATMP 25

[0048] EDTMP 15

[0049] NaHCO 3 40

[0050] NaOH 10

[0051] Surfactant AS 5

[0052] Thiourea 4

[0053] h 2 O margin

[0054] The prepared product has a pH value of about 7.5,...

Embodiment 2

[0066] Embodiment 2 The example of cleaning pipelines in a circular manner

[0067] A factory newly built a circulating water device, and the pipes of the device were cleaned before being put into production. The dirt in the pipes was anti-rust oil, floating rust, etc.

[0068] Pipe volume 3m3 Material carbon steel, stainless steel, aluminum

[0069] Cleaning agent dosage

[0070] Adopt the cleaning agent 300kg of formula one preparation among the embodiment one

[0071] Passivator 60kg

[0072] cleaning process

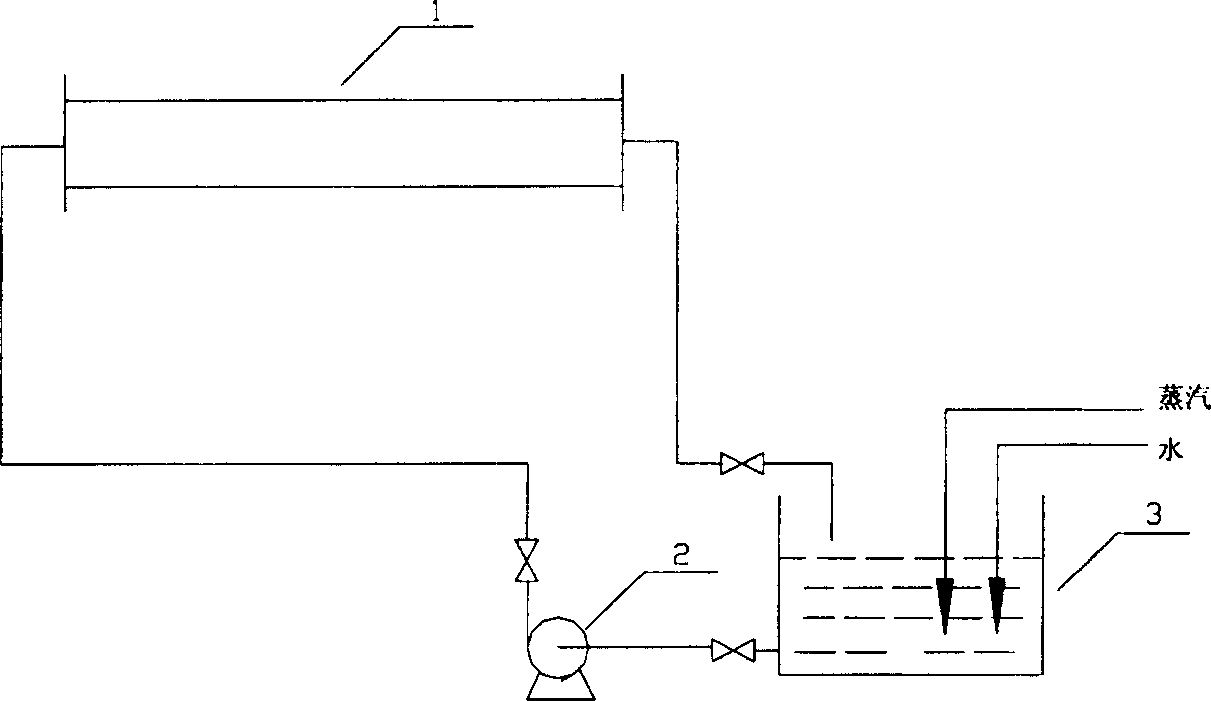

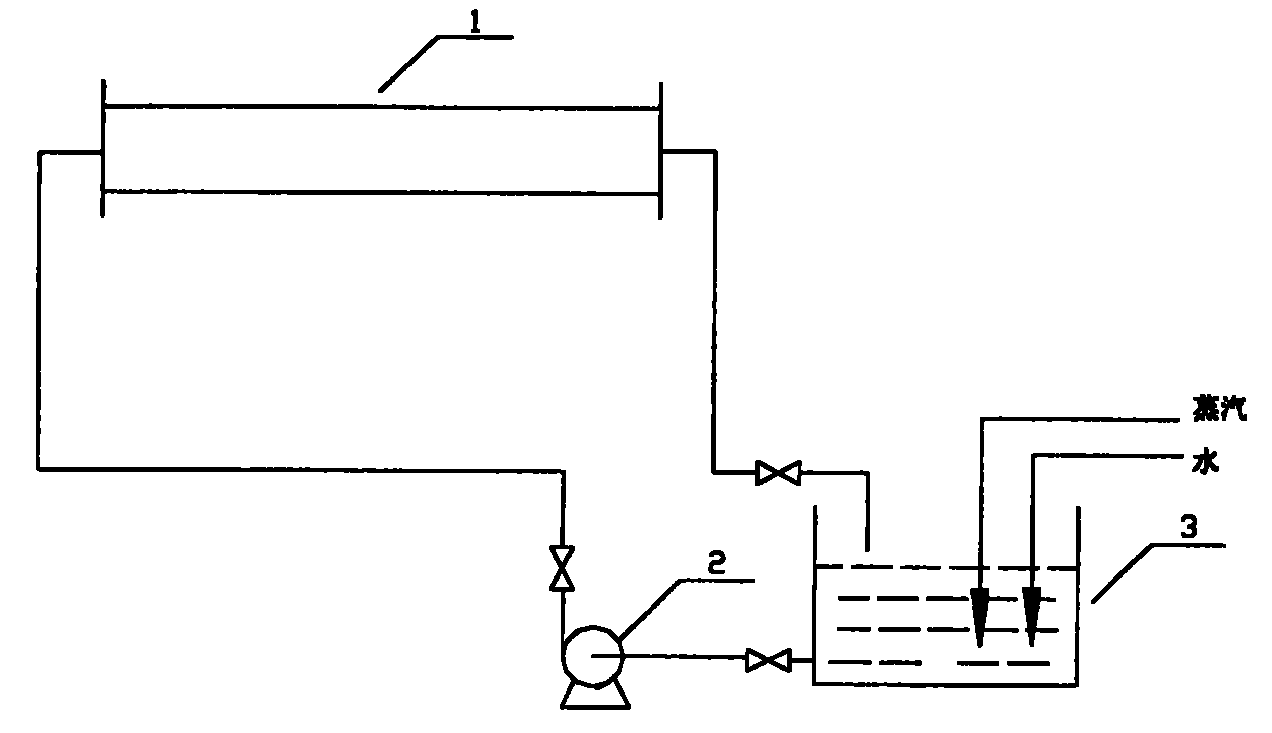

[0073] according to figure 1 The process flow shown is cyclic cleaning.

[0074] In the drawings: 1 represents the pipeline system to be cleaned, 2 represents the circulation pump, and 3 represents the liquid distribution tank.

[0075] First, add 2.7m of water to the liquid distribution tank 3 3 , The trial operation of the circulating pump 2 will not cause evacuation, and there will be liquid return. Then add 300kg of neutral degreasing and derusting cle...

Embodiment 3

[0082] Embodiment 3 The example of cleaning galvanized sheet parts by soaking

[0083] In a VCD manufacturing enterprise, the galvanized sheet components in the VCD were rusted due to the damage of the local galvanized layer during storage, and they were treated with the cleaning agent of the present invention before use.

[0084] Prepare neutral degreasing and derusting cleaning agent according to formula two of embodiment one, and preparation contains this neutral degreasing and derusting cleaning agent weight percent and is 100 kilograms of cleaning liquids of 20%, in treatment tank, cleaning liquid is heated to 50 ℃, then immerse the parts to be cleaned in the tank, and treat them for 10-30 minutes according to the number of rust spots on the parts to be cleaned, then take them out, and then passivate them in the passivation solution for 30 minutes.

[0085] Cleaning effect: the rust spots are cleaned, no rust phenomenon occurs, and the galvanized layer is not damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com