Filler-free halogen-free flame-retardant epoxy resin composition

A technology of epoxy resin and composition, which is applied in the field of flame-retardant composite materials, can solve the problems that filler-type flame retardants cannot meet RTM vacuum diversion, etc., and achieve the effects of improving flame-retardant effect, good wettability, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, in conjunction with specific embodiment, the present invention will be further described:

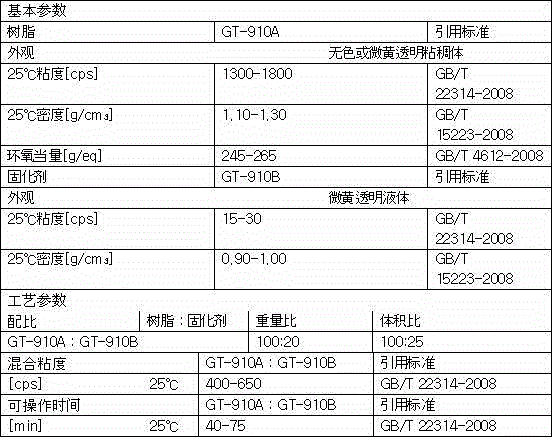

[0035] A kind of filler-free halogen-free flame-retardant epoxy resin composition, it comprises two components A and B, and described A component comprises:

[0036] Low halogen bisphenol A type epoxy resin 128 55-75%

[0037] Bisphenol F epoxy resin 170 5-15%

[0038] Phosphorus nitrogen series flame retardant 10-30%

[0039] Phosphate flame retardant 10-20%

[0040] The B component includes:

[0041] Polyetheramine curing agent D230 10-20%

[0042] Isophoronediamine IPDA 50-70%

[0043] N-Aminoethylpiperazine N-AEP 20-30%;

[0044] The percentages of each component are percentages by weight; the code name is GT-910B.

[0045] The composition is obtained after mixing the components A and B according to the weight ratio of 100:19-21.

[0046] In the above-mentioned one kind of filler-free halogen-free flame-retardant epoxy resin group, the appearance of the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com