Copper oxide doped silver tin oxide composite and preparation method thereof

A composite material, silver tin oxide technology, used in metal processing equipment, transportation and packaging, etc., can solve the problems of uneven distribution, poor uniformity, uneven microstructure, etc., to improve workability and conductivity, increase mixing. Effect of powder efficiency and uniformity, good microstructure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

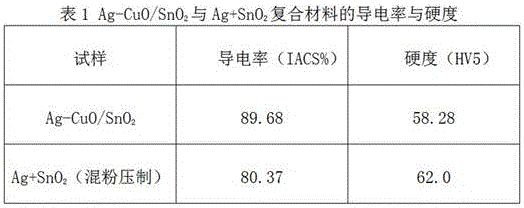

[0027] The invention provides a copper oxide-doped silver-tin oxide composite material and a preparation method thereof. Specifically, salts such as copper nitrate or copper sulfate are prepared into an aqueous solution of a certain concentration, and surfactants such as thioglycolic acid are added during the stirring process. The molar ratio of ions is 10:1; after reacting for 24h, wash and dry, 250 o C heat treatment to form a silver-copper complex, see figure 1 ; Then use the mature powder metallurgy method to sinter and form, that is, mix it with tin dioxide powder to form a composite powder with the same weight ratio of 75-95% silver, 4.9-18.5% tin oxide, and 0.1-1.5% copper oxide. Molding under 200MPa pressure, at 750-850 o C calcined for 2h. Subsequent repressurization at 800MPa and at 600 o C heat treatment, cold working can also be carried out, and electrical contact materials with good performance can be obtained.

[0028] Copper oxide-doped silver-tin oxide comp...

Embodiment 1

[0030] The copper oxide-doped silver-tin oxide composite material is a silver-based composite material containing 5wt% tin oxide and 0.1wt% copper oxide.

[0031] According to the distribution ratio of the ingredients, 1mM thioglycolic acid was formulated into an aqueous solution, and silver powder (200 mesh) was added under magnetic stirring conditions, and complexed with 0.1mM copper nitrate solution for 24 hours. 60 after cleaning o C dry at 250 o C Vacuum annealing, the obtained silver-copper composite powder is mixed with nano-tin oxide powder and pressed at 200MPa, at 750 o C was sintered for 2 hours to obtain the copper oxide-doped silver-tin oxide composite material of this example.

[0032] In each embodiment of the present invention, mM is mmol / L, millimole per liter.

Embodiment 2

[0034] The copper oxide-doped silver-tin oxide composite material is a silver-based composite material containing 15wt% tin oxide and 0.5wt% copper oxide.

[0035] According to the distribution ratio of the ingredients, 1mM thioglycolic acid was formulated into an aqueous solution, and silver powder (200 mesh) was added under magnetic stirring conditions, and complexed with 0.2mM copper sulfate solution for 24 hours. 60 after cleaning o C dry at 250 o C Vacuum annealing, the obtained silver-copper composite powder is mixed with nano-tin oxide powder and pressed at 200MPa, at 750 o C was sintered for 2 hours to obtain the copper oxide-doped silver-tin oxide composite material of this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com