Copper-based active solder for brazing diamond grinding tools

A technology of active solder and grinding tools, which is applied in the direction of manufacturing tools, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of poor wear resistance diamond matching, high solder temperature, etc., and achieve wettability Good, high holding force, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

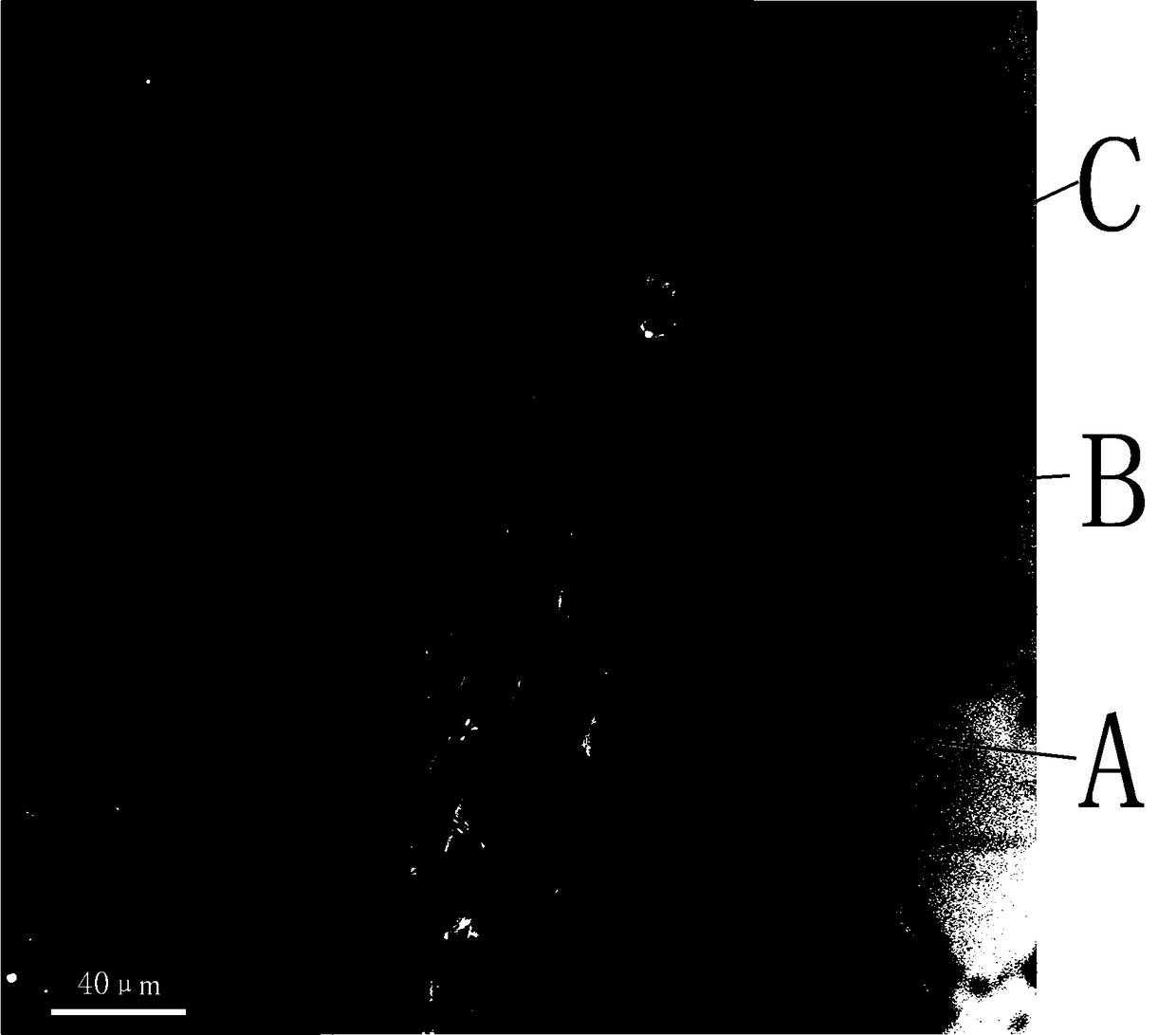

Image

Examples

Embodiment 1

[0028] The copper-based active solder of the present embodiment is composed of the following percentages: the copper accounts for 52%, the tin accounts for 22%, the titanium accounts for 11%, and the nickel accounts for 8.5%. Said chromium accounts for 5%, and said phosphorus accounts for 1.5%.

[0029] The specific preparation method of copper-based active solder is as follows: put the raw materials prepared in proportion into the furnace, heat up to the melting of the alloy, add a covering agent, then add a refining degasser, and refine for 5 minutes to obtain an alloy melt. The poured model was roasted for 30 minutes at a temperature of 1000°C, cooled to 750°C for later use, and the resulting alloy melt was cooled to 800°C and then poured into the model, fully stirred, slag removed, cast into shape, demolded to obtain an ingot, and extruded Die-casting ingot: The preheating temperature is 520°C, the holding time is 20min, the die piece preheating time is 20min, the extrusio...

Embodiment 2

[0033] The copper-based active solder of the present embodiment is composed of the following percentages: the copper accounts for 52%, the tin accounts for 22%, the titanium accounts for 11%, and the nickel accounts for 8.5%. Said chromium accounts for 5%, and said phosphorus accounts for 1.5%.

[0034] The specific preparation method of copper-based active solder is as follows: put the proportioned raw materials into the furnace, raise the temperature until the alloy melts, add the covering agent, then add the refining degasser, and refine for 10 minutes to obtain the alloy melt, which will be The poured model was roasted for 40 minutes at a temperature of 1100°C, cooled to 800°C for later use, and the resulting alloy melt was cooled to 900°C and then poured into the model, fully stirred, slag removed, cast into shape, demolded to obtain an ingot, and extruded Die-casting ingot: preheating temperature is 550°C, holding time is 30min, die preheating time is 30min, extrusion sp...

Embodiment 3

[0037] The copper-based active solder of the present embodiment is composed of the following percentages: the copper accounts for 60%, the tin accounts for 20%, the titanium accounts for 8%, and the nickel accounts for 7%. The said chromium accounts for 4%, and the said phosphorus accounts for 1%.

[0038] The specific preparation method of copper-based active solder is as follows: put the raw materials prepared in proportion into the furnace, heat up to the melting of the alloy, add a covering agent, then add a refining degasser, and refine for 5 minutes to obtain an alloy melt. The poured model was roasted for 30 minutes at a temperature of 1100°C, cooled to 750°C for later use, and the resulting alloy melt was cooled to 800°C and then poured into the model, fully stirred, slag removed, cast into shape, demolded to obtain an ingot, and extruded Die-casting ingot: The preheating temperature is 550°C, the holding time is 30min, the die piece preheating time is 30min, the extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Joint shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com