Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about "Biochemical treatment with wool-protecting/anti-moth agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial fabric/fiber finishing liquid for expelling and killing insect pollination and application method and fabric product/fiber product/paper product thereof

InactiveCN107761374AFix compatibility issuesSimple compositionBiochemical treatment with wool-protecting/anti-moth agentsPaper/cardboardFiberPollination

The invention relates to a fabric / fiber finishing solution for antibacterial and insecticide repelling, its use method and fabric / fiber product / paper product. The mass percentage formula of the fabric / fiber finishing solution is: 0.05-40% of insecticide / repellent; 0.05-20% of antibacterial agent; 5.00-35% of binder; and 0.025-5% of crosslinking agent. The method for using the fabric / fiber finishing liquid of the present invention can be selected according to the difference of the finishing fabric / fiber material, one of the padding method, the spraying method or the dipping method. The fabric / fiber product / paper product is obtained by finishing the fabric / fiber finishing liquid or / and the method of using the fabric / fiber finishing liquid of the present invention. The fabric / fiber finishing liquid and its products of the present invention have the advantages of high efficacy, strong adhesion, water washing resistance, can reach the WHO standard, low cost, good applicability, convenient use and popularization, and the like.

Owner:牛绍英

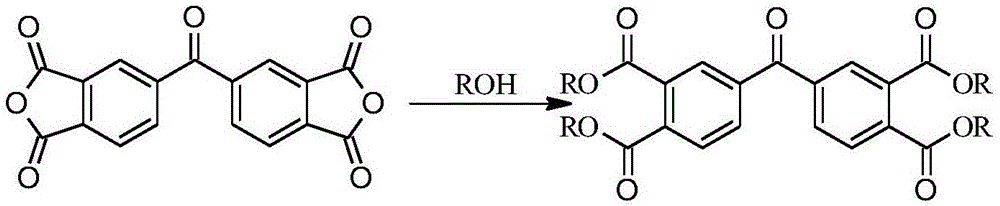

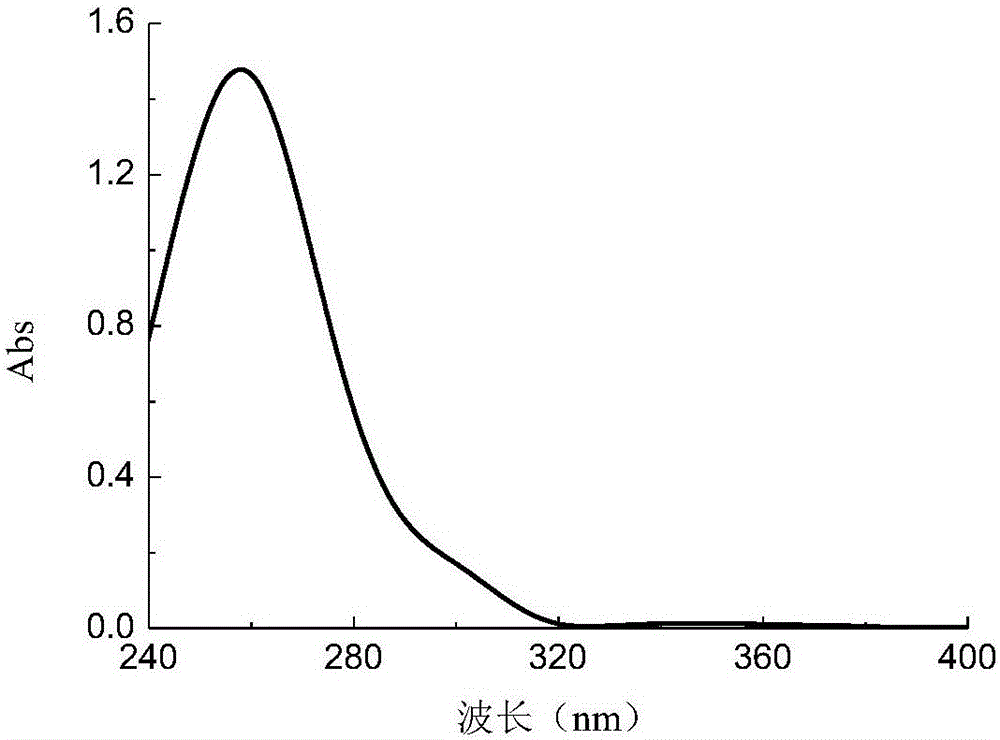

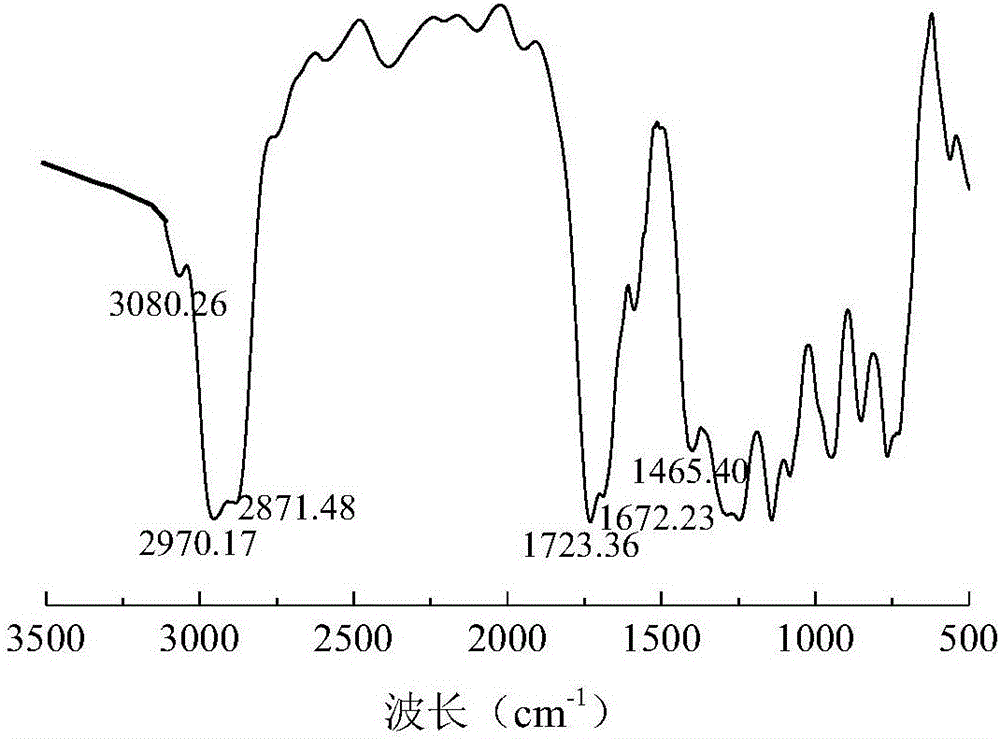

Preparation method for diphenylketone tetraformate serving as light-induced antibacterial finishing agent

ActiveCN107522621ASimple methodEasy to operateBiocideOrganic compound preparationEscherichia coliPolyester

The invention relates to a preparation method for diphenylketone tetraformate serving as a light-induced antibacterial finishing agent. The preparation method comprises the following steps: adding 3,3',4,4'-benzophenonetetracarboxylic dianhydride and alcohol into a reaction kettle which is provided with a water distributor; stirring, slowly adding concentrated sulphuric acid dropwise for reacting, cooling to room temperature, washing, drying, filtering and separating to obtain the diphenylketone tetraformate serving as the light-induced antibacterial finishing agent. The method disclosed by the invention is simple and easy to operate; reaction conditions are mild, and the cost is low; the prepared diphenylketone tetraformate has high-efficiency, lasting and broad-spectrum anti-bacterial performance, has strong affinity with polyester fibres, and is used for finishing a polyester fabric; the finished fabric has high-efficiency and lasting anti-bacterial performance on staphylococcus aureus and Escherichia coli.

Owner:DONGHUA UNIV

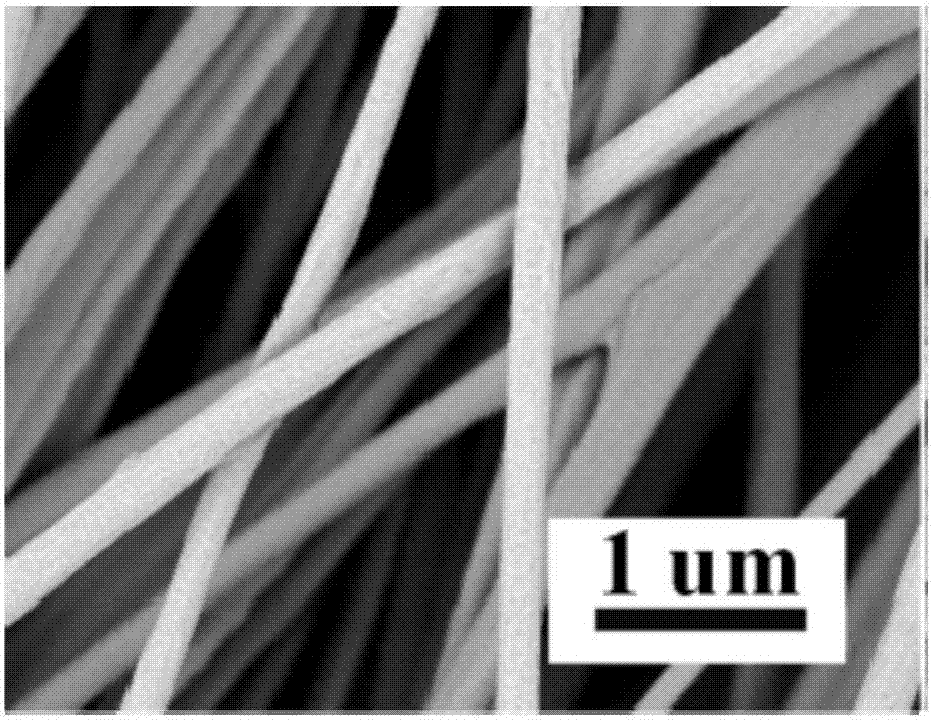

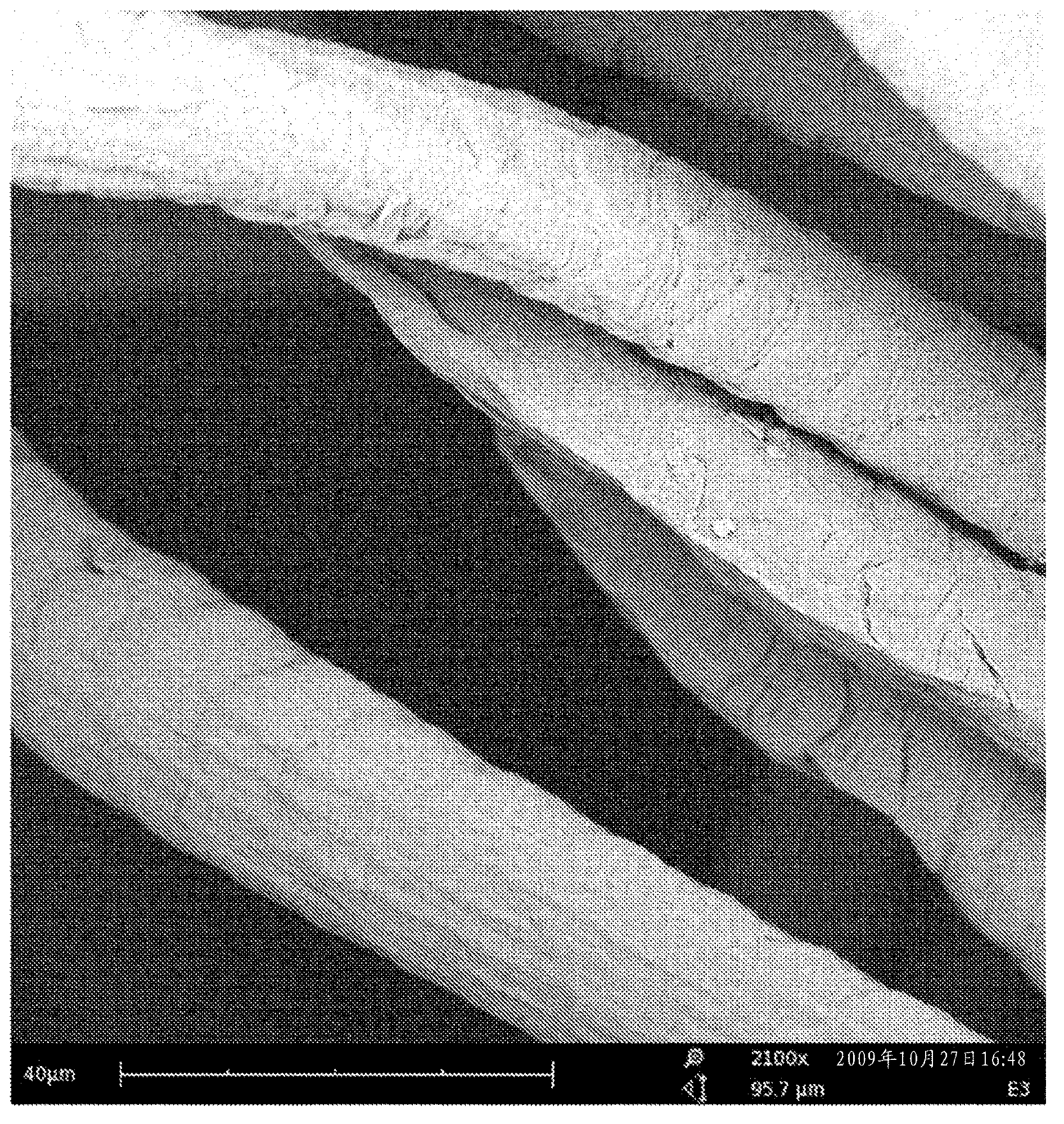

Alginic acid/nano-silver composite nanofiber and preparation method thereof

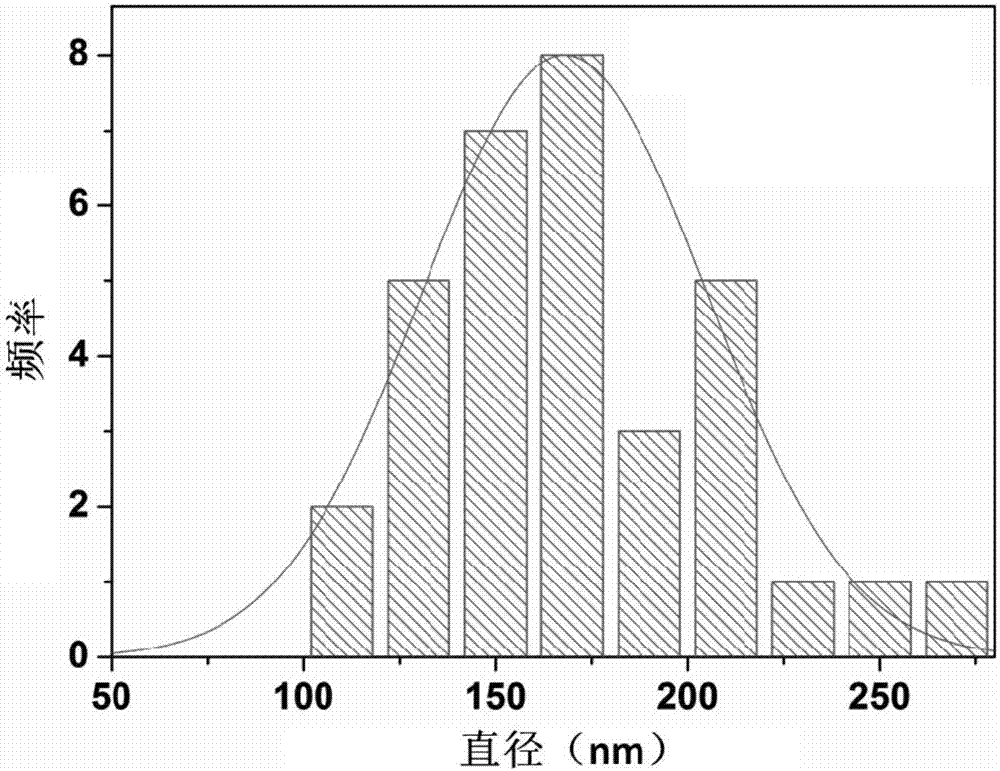

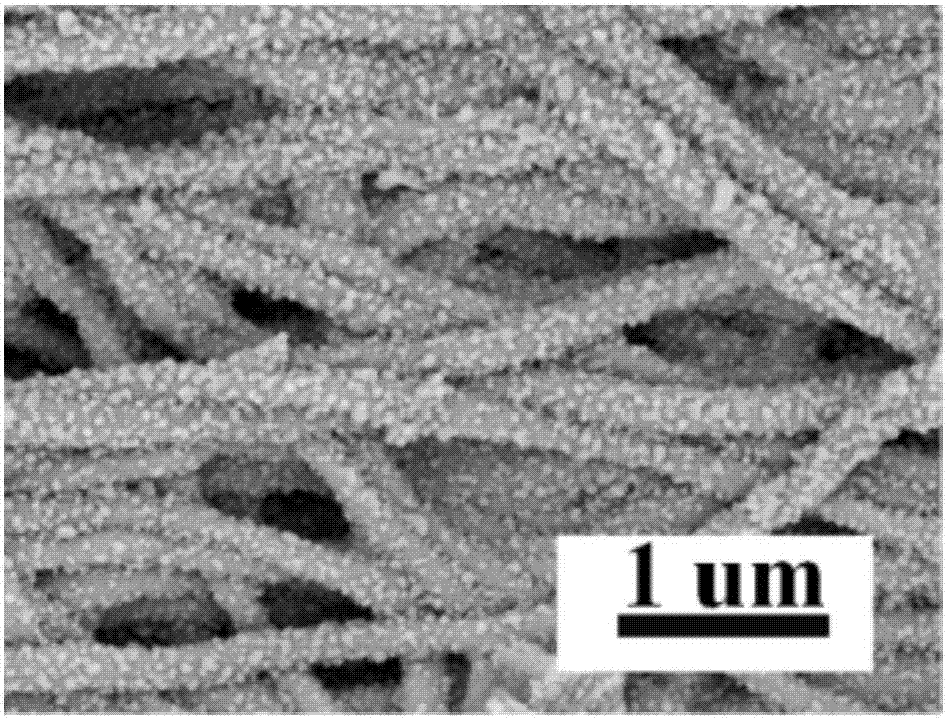

InactiveCN107385562AHigh content of silver nanoparticlesAvoid reunionBiochemical treatment with wool-protecting/anti-moth agentsFilament/thread formingComposite nanofibersIon exchange

The invention discloses an alginic acid / nano-silver composite nanofiber. The alginic acid / nano-silver composite nanofiber is acquired in the manner of preparing a silver alginate nanofiber after the ion exchange of a sodium alginate nanofiber acquired through an electrostatic spinning process and then reducing silver ions. Nano-silver grains are uniformly distributed on the inner and outer surfaces of the alginic acid / nano-silver composite nanofiber. A method for preparing the material successfully overcomes the limitation of the spinning property to the doping content of nano-silver grains and solves the problem of nano-silver grain conglobation in the electrostatic spinning process. The method can realize the large-scale production of the nano-silver containing composite fiber; the composite nanofiber is high in nano-silver grain content; the nano-silver grains are uniformly distributed on the material surface; and the fiber diameter is small, the specific surface area is large, the performance is excellent, the fiber is easy to be recycled and the cost is effectively saved.

Owner:QINGDAO UNIV

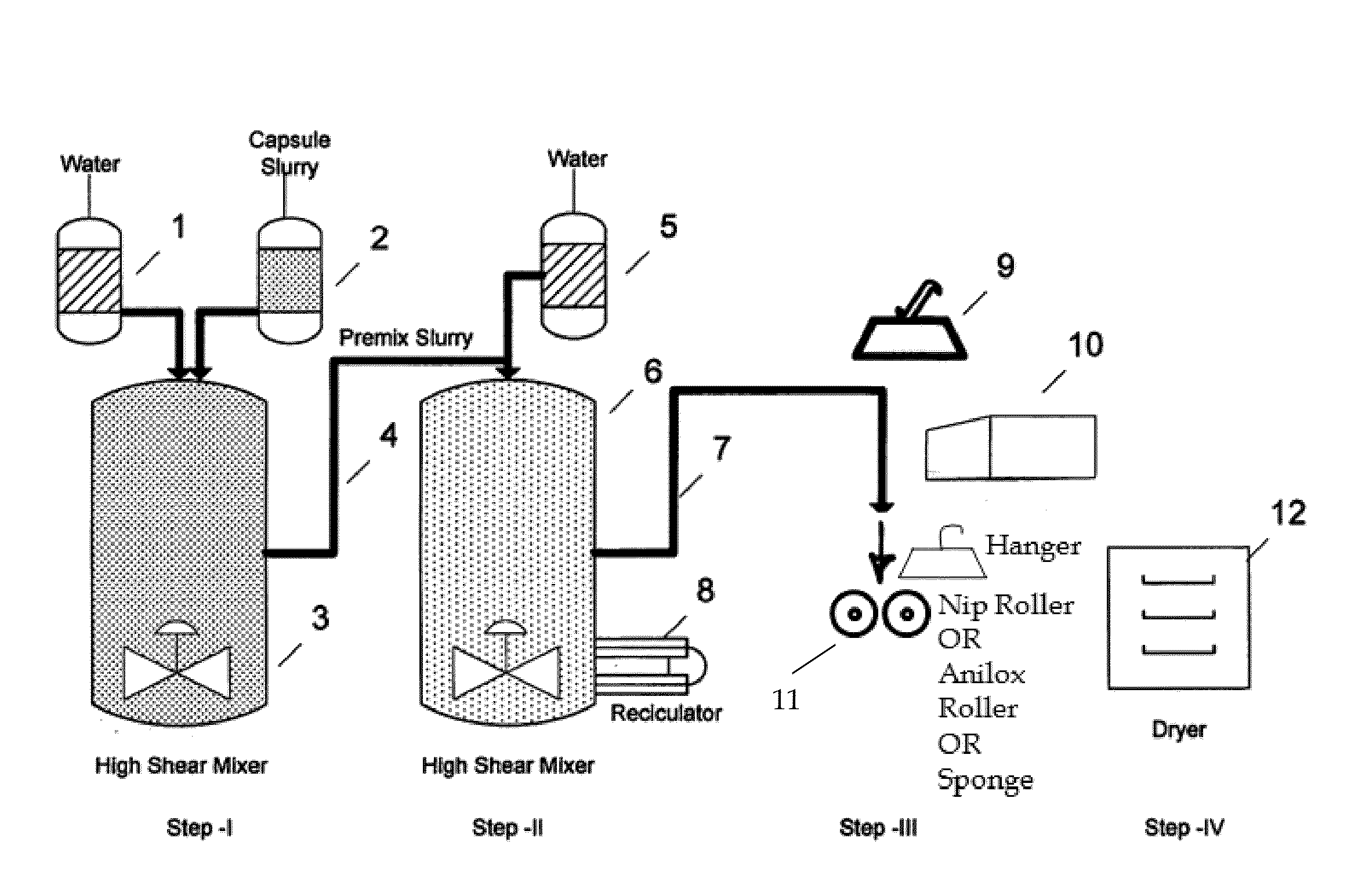

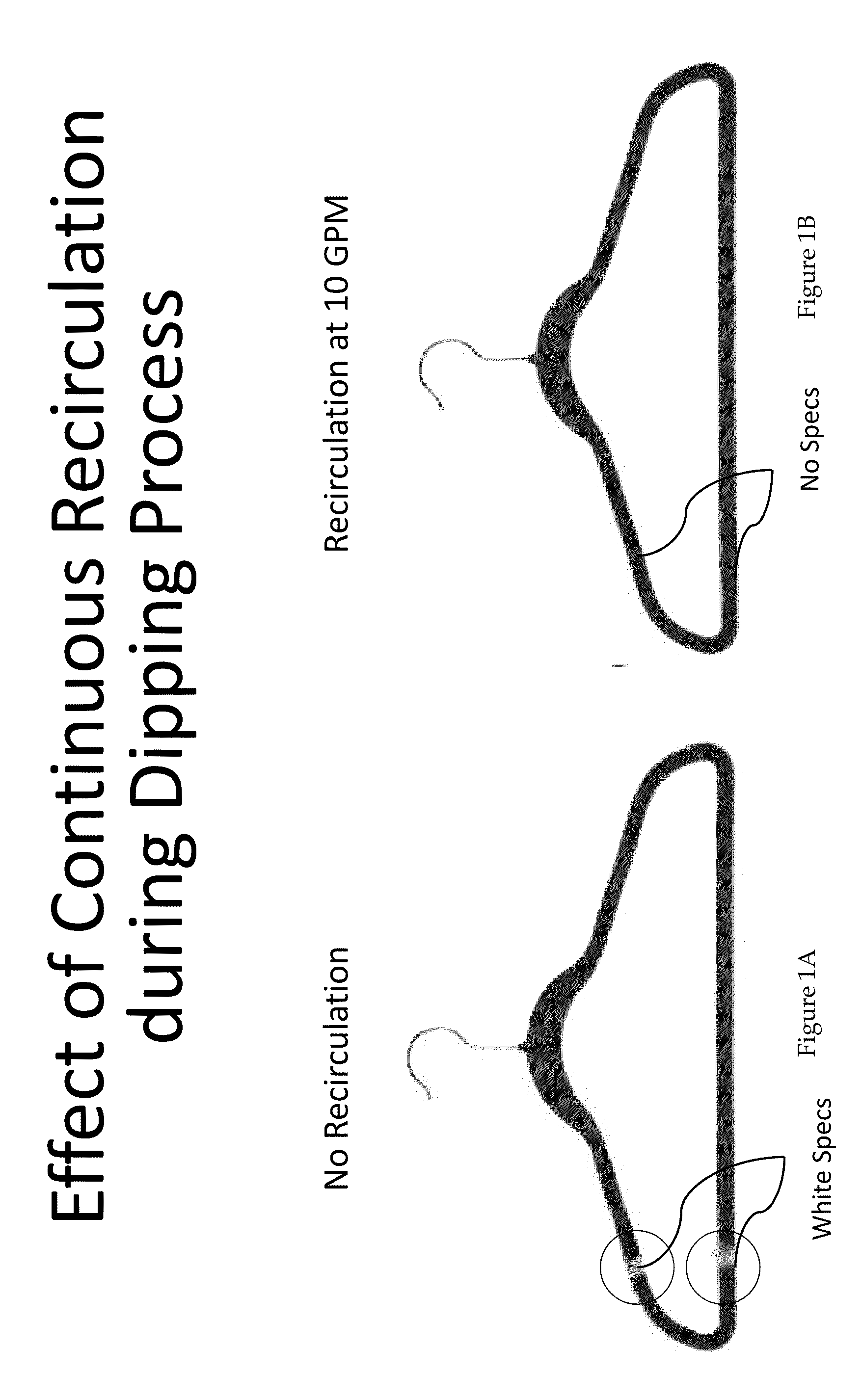

Method for imparting enduring beneficial features to flocked surfaces

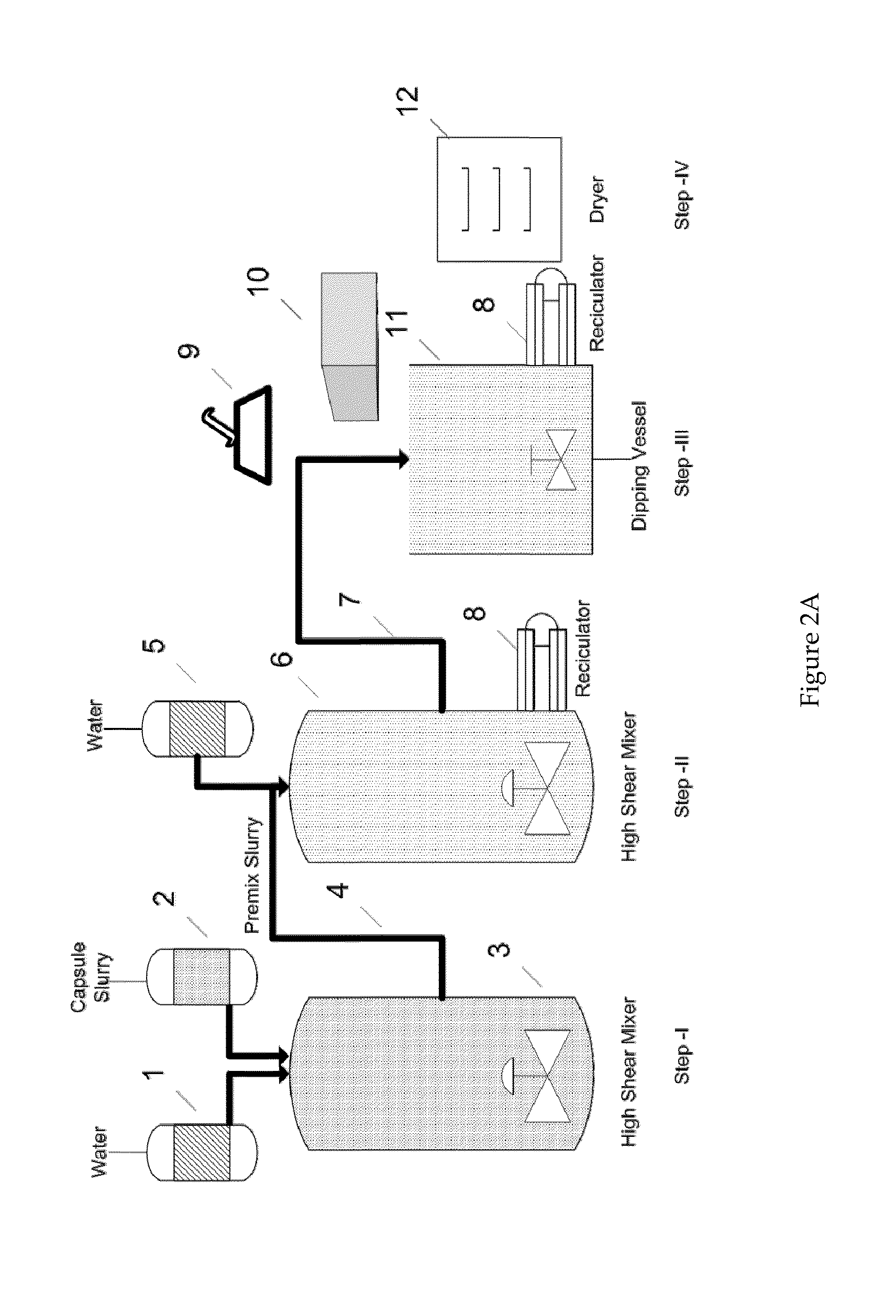

InactiveUS20150098979A1Stably retain a beneficial agentIncrease productionPretreated surfacesSurface layering apparatusAdhesiveEngineering

A method of imparting enduring beneficial features to a hard flocked surface of an article is provided. The method includes encapsulating a desired beneficial agent as a core material in a polymeric microcapsule, and transferring polymeric microcapsule to the surface by a dipping, spraying, or padding application. The beneficial agent, after getting transferred to the surface of a hard flocked article, imparts long lasting performance, provides fragrance and may protect an article from odor, insect, pest, fungi, bacteria, viruses, and the like. The polymeric microcapsules deliver long lasting benefits to surfaces with flocking, such as clothes hangers. Also described is a process for manufacture of flocked items with benefit delivering polymer microcapsules, without the need for binders or adhesives. Benefit agents are released with shear force on the flocked surface, so they are released when used and provide long-lasting performance.

Owner:R&B TECH NA

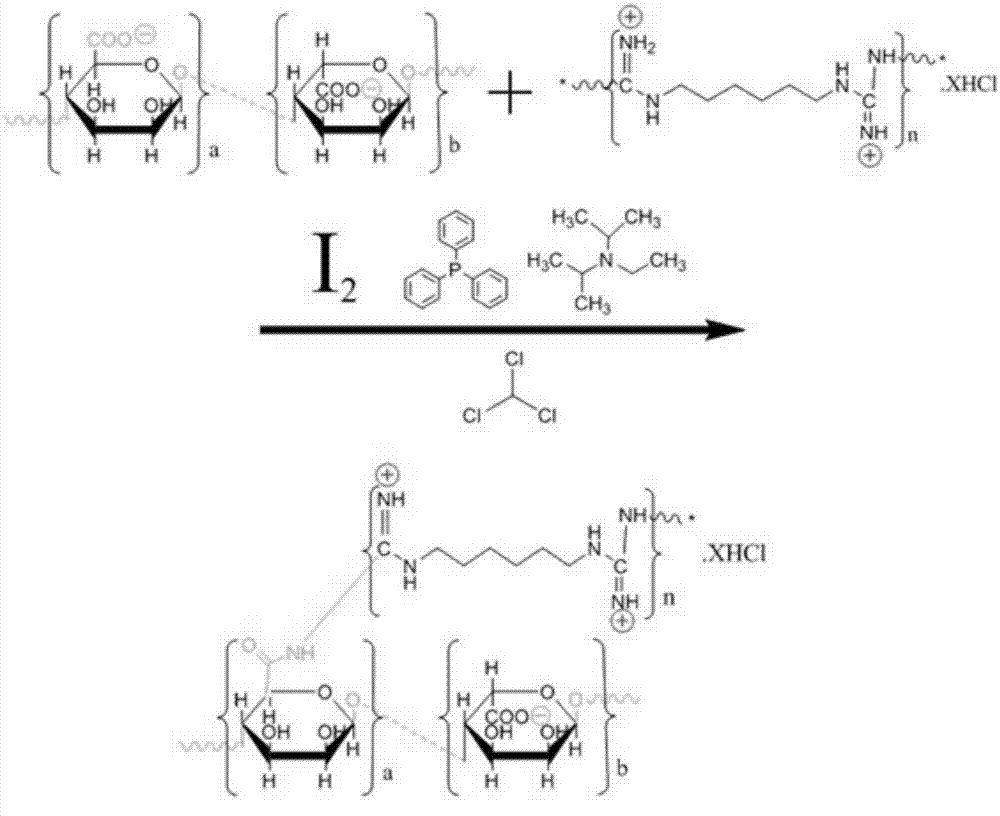

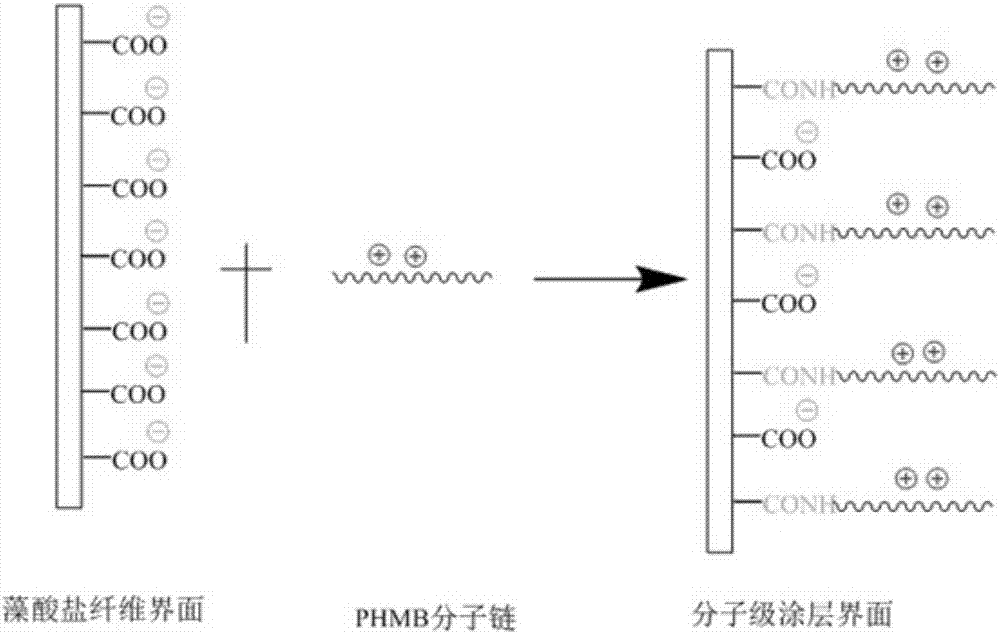

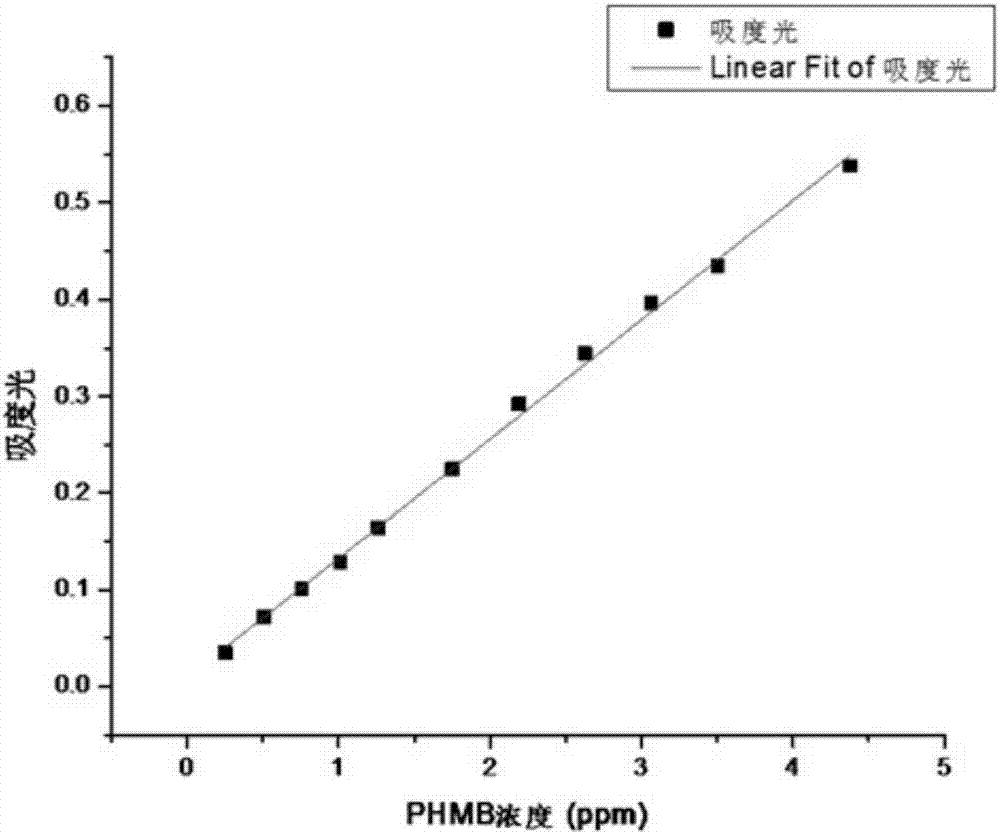

Antimicrobial alginate fiber as well as preparation method and application of antibacterial alginate fiber dressing

ActiveCN107385917AReduce potential security risksSolve the binding puzzleBiochemical treatment with wool-protecting/anti-moth agentsAbsorbent padsFiberPolyhexamethylene guanidine

The invention provides an antimicrobial alginate fiber as well as a preparation method and application of an antimicrobial alginate fiber dressing. According to the invention, the technical difficult problem that the antimicrobial activity of guanidine salt is quickly passivated after polyhexamethyleneguanidine salt as a cationic polymer is mixed with alginate as an anionic polymer is solved, and good and long-term antimicrobial activity of a polyhexamethyleneguanidine alginate fiber with relatively-low content and a medical product are realized. The polyhexamethyleneguanidine salt is low in dissolution rate and provides good safety, so that potential risks of carcinogenesis, mutagenesis and reproductive toxicity are remarkably reduced.

Owner:HUIZHOU HUAYANG MEDICAL EQUIP

Method for preparing antibacterial deodorant high-filling-power down feathers

InactiveCN107385932AImprove bulkLow stalk contentBiochemical treatment with wool-protecting/anti-moth agentsDyeing processAerosol sprayDeodorant

The invention provides a method for preparing antibacterial deodorant high-filling-power down feathers. The method comprises the following steps: (1) performing color separation, screening and impurity removal on goose or duck feathers; (2) performing aerosol spray cleaning on the pretreated feathers, and drying in vacuum; (3) grinding the cleaned feathers by a grinder, adding composite alkali liquor at the temperature of 60-80 DEG C for treating for 2-4 hours, regulating the pH to be 7, filtering while hot to obtain grey feathers, washing with water and drying; (4) adding the grey feathers and a bleaching and dyeing liquid into a bleaching and dyeing cell for bleaching and dyeing, and soaking in a silver-loaded nano antibacterial agent aqueous solution. According to the method disclosed by the invention, the goose or duck feathers serve as a raw material for producing the down feathers, the raw material source is wide, the production cost is reduced, and the prepared down feathers are low in wing stem content and high in filling power and meet the high-quality requirement of consumers.

Owner:陈林梭

Natural antibacterial and deodorizing finishing agent for non-woven fabrics and preparation method of finishing agent

InactiveCN106436323AInhibitionAvoid breedingBiochemical treatment with wool-protecting/anti-moth agentsPolyethylene glycolPOLYOXYETHYLENE ETHER

The invention relates to a natural antibacterial and deodorizing finishing agent for non-woven fabrics. The formula of the natural antibacterial and deodorizing finishing agent comprises the following components in percentage by weight: 5%-20% of polyoxyethylene sorbitan tristearate, 1%-10% of ester-base quaternary ammonium salt, 5%-20% of a natural antibacterial composition, 5%-9% of polyethylene glycol glyceryl ether, 3%-8% of a fragrant slow-released system and the balance of deionized water, wherein the natural antibacterial composition comprises chitosan, aloe oil, chitin, catechinic acid, tea polyphenol, tea-seed oil, tea saponin, a grape seed extract, citric acid, amino acid chelate, an amino acid derivative and an emulsifying agent. The natural antibacterial and deodorizing finishing agent has no stimulation to the skin of the human body, is capable of inhibiting the invasion and breeding of bacteria and high in ammonia absorptivity and further has outstanding antibacterial and deodorization effects. The natural antibacterial and deodorizing finishing agent has the characteristics that fragrance is uniformly released, the fragrance preservation time is long, and the added value of the product is high.

Owner:漳州市鼎鑫电子科技有限公司

Wool Care Composition

ActiveUS20110305644A1Protection from damageEffective protectionBiocideAerosol deliveryClothes mothInsect pest

The present invention relates to a wool care composition comprising pyrethroid insecticide, a copolymer and a solvent wherein the said copolymer binds with the solvent and pyrethroid insecticide. This composition can be an improved aerosol spray formulation for treating of pure or blended woollen clothing and textile, fur and feather lined garments and other keratinous items for protection or insect proofing from various types of insect pests both clothes moths and carpet beetles during their storage, transport and use. Wool care aerosol solution can be sprayed with pressurized container having either a propellant as ready-to-use aerosol or manually operated sprayers. The aerosol spray composition may also contain fragrance and solvent. The other components in the composition are at least one copolymer / emulsifier and / or dispersant.

Owner:DIRECTOR GENERAL DEFENCE RES & DEV ORG

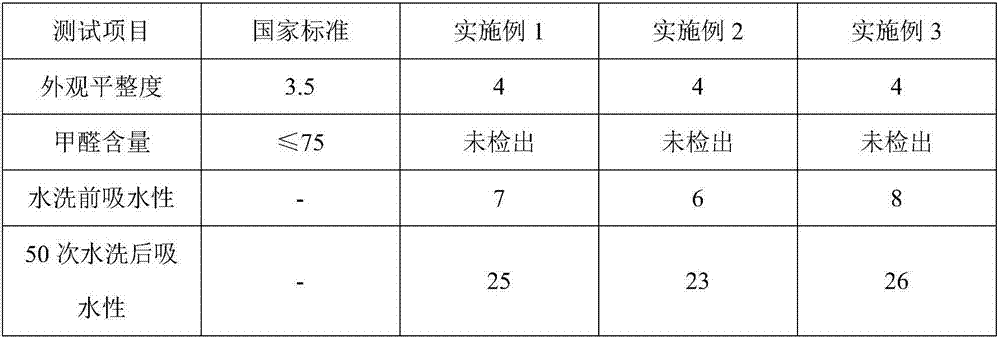

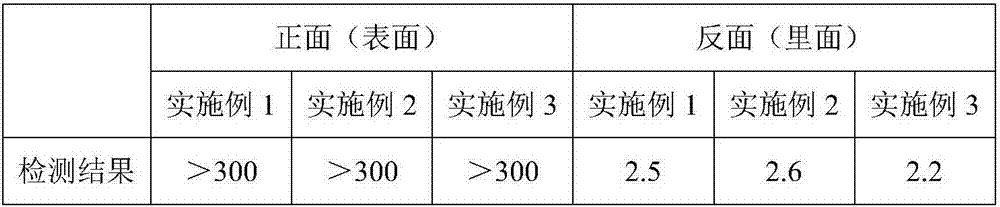

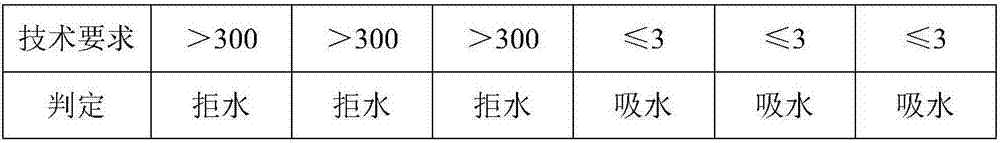

Lasting, antibacterial and sweat-proof non-ironing finishing liquid of cotton fabric, and finishing technology thereof

InactiveCN107354715AImprove wrinkle resistanceImproves easy-care performanceBiochemical treatment with wool-protecting/anti-moth agentsVegetal fibresBiocompatibility TestingZinc

The invention belongs to the technical field of antibacterial finishing of textiles, and especially relates to a lasting, antibacterial and sweat-proof finishing liquid of a cotton fabric, and a finishing technology thereof. The finishing liquid is obtained through compounding chitosan with Chinese herbal medicine extract, nanometer zinc oxide, silver nano-powder and other additives, the chitosan is natural, nontoxic and biodegradable, and has good biocompatibility and excellent antibacterial property, and the surface of the chitosan contains a large number of active groups, so the shrinkage prevention and crease prevention effects are facilitated; honeysuckle flower extract, Houttuynia cordata extract, pomegranate peel extract and the nanometer zinc oxide and silver nano-powder antibacterial agents are wrapped with a film formed by Arabic gum in order to reach slow release and lasting bacterium prevention effects, and the chitosan is compounded to make the cotton fabric have excellent crease resistance, non-ironing property and antibacterial property and improve the hand feeling, the strength and the wash resistance of the cotton fabric; the finished fabric has the advantages of good antibacterial, crease-resistant and non-ironing properties, instant absorption and volatilization of sweat, good breathability, and comfortableness in wearing; and oscillating drying avoids the influences of a pressurized roll device on the breathability of the fabric.

Owner:太仓红桥服饰有限公司

Wool top protease mercerizing finish process

InactiveCN106811979AHigh whitenessHigh glossBiochemical treatment with wool-protecting/anti-moth agentsBiochemical treatment with enzymes/microorganismsThioureaPyrophosphate

The invention discloses a wool top protease mercerizing finish process which includes the steps: 1) pretreatment; 2) hydrogen peroxide bleaching pretreatment: dipping wool tops treated in the step 1) in hydrogen peroxide treating fluid for 30-40 minutes and then drying the wool tops; 3) protease mercerizing treatment: dipping the wool tops treated in the step 2) in 3-4% median protease solution and performing dipping twice and rolling twice; 4) washing and drying. Hydrogen peroxide treating fluid comprises, in weight percentage, 15%-25% of hydrogen peroxide, 10%-15% of citric acid, 2%-7% of sodium pyrophosphate, 5%-8% of thiourea dioxide and 50%-65% of water, and liquor detention rate is 60-80%. By the mode, hydrogen peroxide bleaching pretreatment is combined with protease mercerizing treatment, the whiteness, the glossiness and the felt resistance of the wool tops can be effectively improved, and harmful gas cannot be generated in the treatment procedure, so that the wool top protease mercerizing finish process is safe and environmentally friendly.

Owner:CHANGSHU XINGUANG WOOL TOP SPECIALIST PROCESSOR

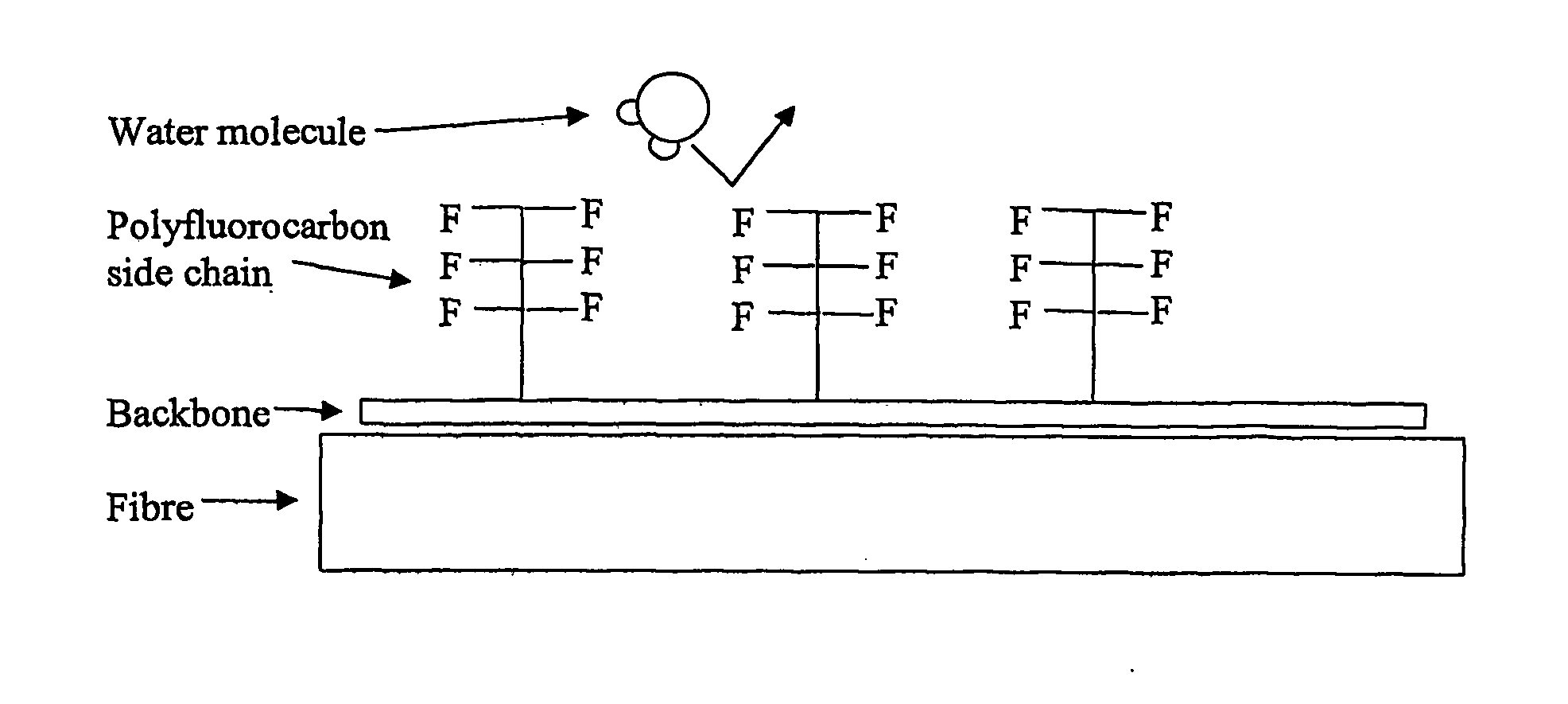

Process for insecticidal impregnation of a fabric or netting or other kind of non-living material

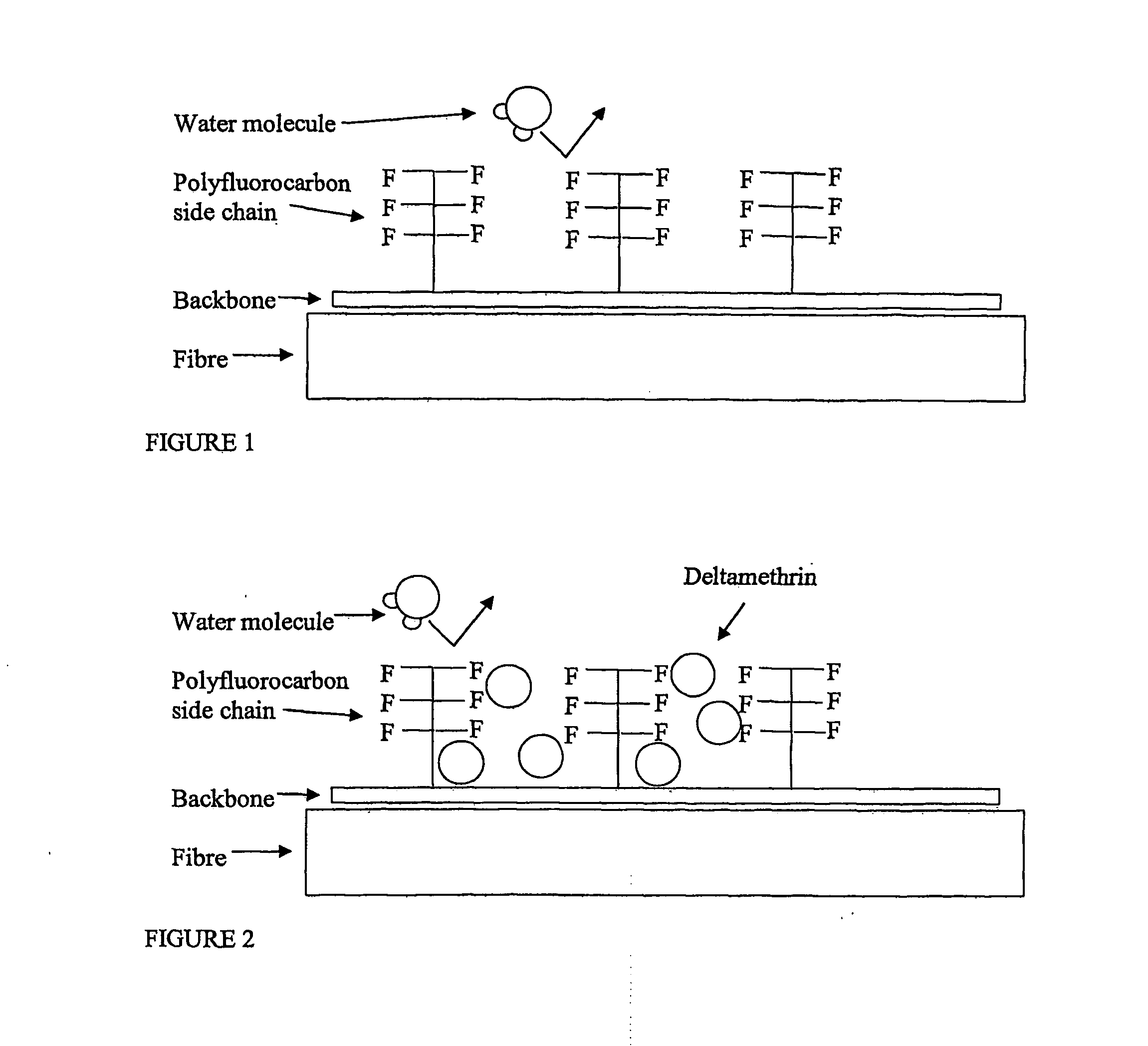

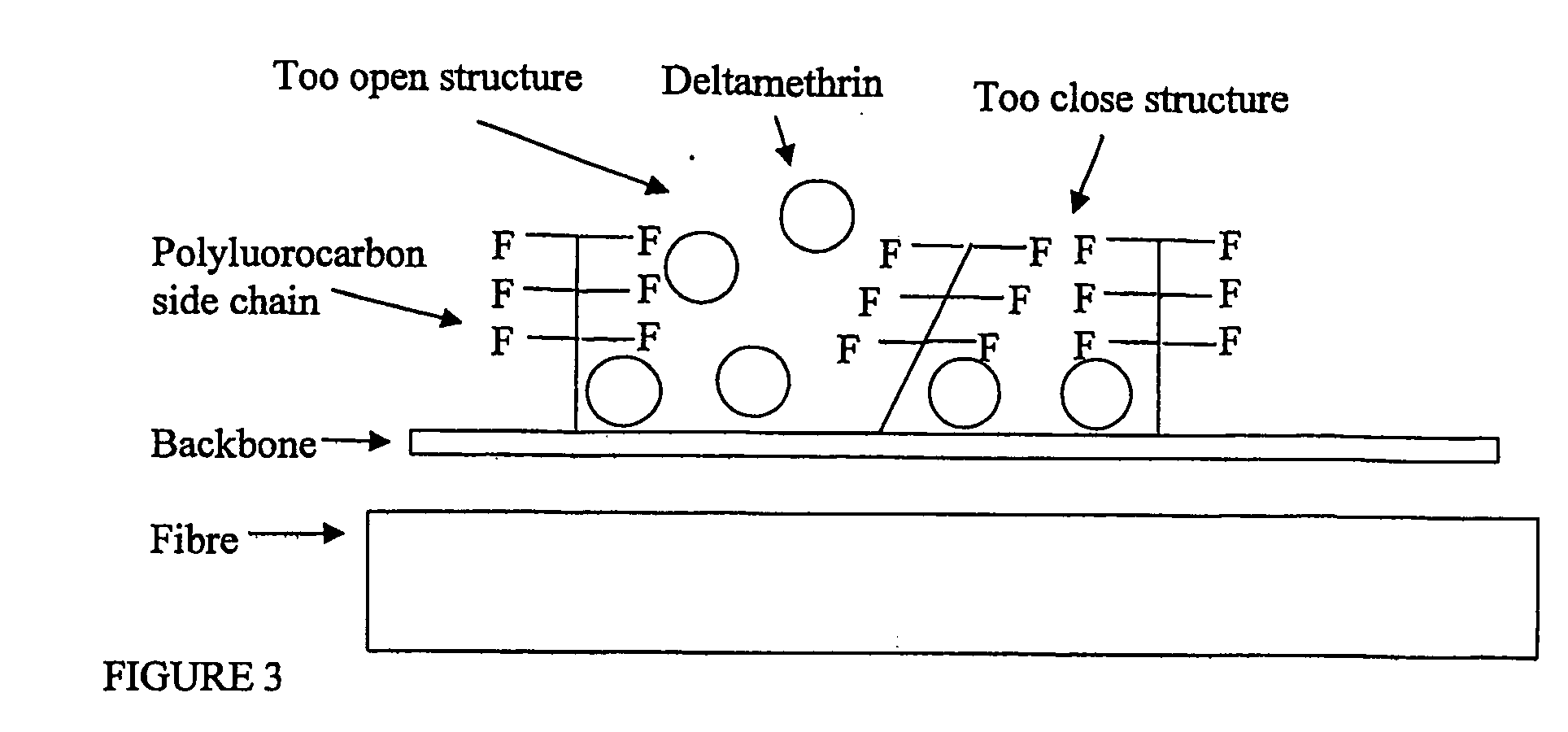

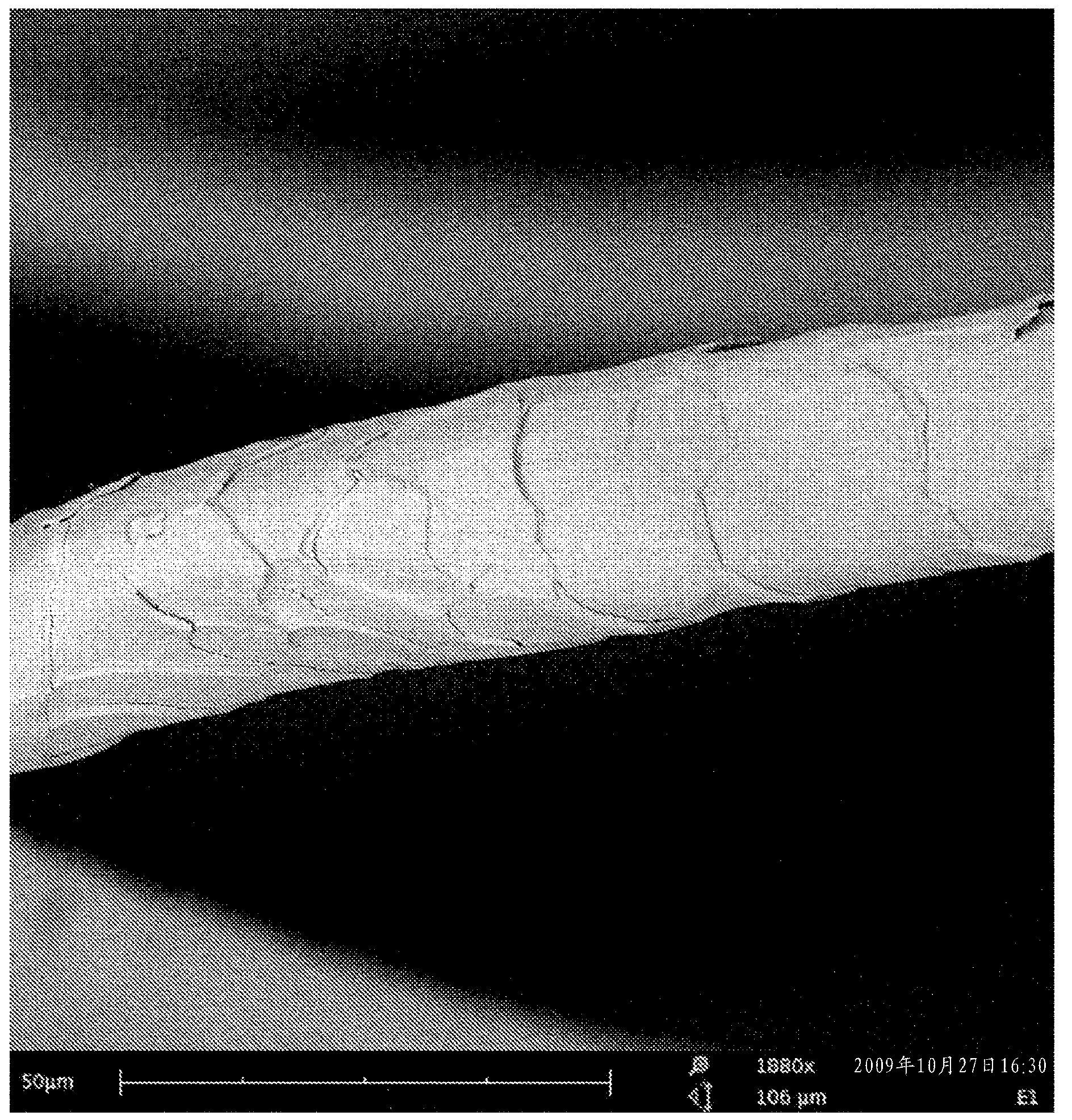

The present invention relates to a process—as disclosed in WO 01 / 37662 for the impregnation of a non living material, for example a fabric or a netting, so as to impart insect killing and / or repellence properties. The process involves the preparation of a solution of an insecticide and a film forming component reducing wash off and degradation of the insecticide, wherein said film forming component comprises a polymeric backbone fixative polymerizing into a film with polyflourocarbon side chains on the polymeric backbone in a drying and curing process of the non-living material. It has been found that the risk for precipitation of the insecticide in the solution of the insecticide is reduced if the insecticide is dissolved in a solvent combined with alcohol or glycol having a water content of less than 5%, and / or the insecticide is dissolved in a solvent and mixed with a water phase emulsion or solution having a temperature of less that 30° C.

Owner:VESTERGAARD FRANDSEN AS

Plush fabric dyeing and finishing technology

InactiveCN105401403AImprove mildew resistanceExcellent mothproofBiochemical treatment with wool-protecting/anti-moth agentsHeat resistant fibresSodium stearateAluminium hydroxide

The invention discloses a plush fabric dyeing and finishing technology, which comprises the following steps: 1) pretreatment; 2) dyeing; and 3) finishing: pouring 1-2 parts by weight of tetramethyl ammonium bromide, 1.3 parts by weight of sodium pyrophosphate, 2.6 parts by weight of glacial acetic acid and 1.3 parts by weight of sodium alginate into 19.5 parts by weight of deionized water, and uniformly stirring; simultaneously pouring 1.1 parts by weight of isothiocyanate, 0.9 part by weight of dodecyl dimethyl benzyl ammonium chloride, 1.2 parts by weight of sodium stearate and 0.4 part by weight of aluminium hydroxide, continuously stirring until the materials are fully and uniformly mixed so as to prepare a finishing liquid; and carrying out dip padding treatment on the fabric in the finishing liquid, taking out the fabric and drying the fabric at constant temperature. By the plush fabric dyeing and finishing technology, the dyed and finished fabric has excellent mildew-proof, anti-moth, anti-microbial, flame retardant and antistatic functions, has strong washing fastness and has soft hand feel.

Owner:常熟市格林染整有限公司

Dyeing and finishing process of wool fabric

InactiveCN105463844AExcellent flame retardantExcellent mothproofBiochemical treatment with wool-protecting/anti-moth agentsHeat resistant fibresSodium CaseinateStearate

The invention discloses a dyeing and finishing process of wool fabric. The dyeing and finishing process comprises the following steps of 1) pretreatment; 2) dye; 3) finishing: putting 1 to 2 parts by weight of polyoxyethylene stearate, 2.2 parts by weight of chitosan, 0.9 part by weight of glycerol monolaurate, 1.3 parts by weight of ammonium sulfate into 15 parts by mass of deionized water in sequence, and uniformly stirring; simultaneously putting 0.5 part by weight of alpha-bromocinnamaldehyde, 0.9 part by weight of benzofuranone, 1.6 parts by weight of diethyl sulfate, and 0.9 part by weight of sodium caseinate in, and continuously stirring until uniformly mixied, so as to obtain finishing liquid; then performing padding treatment on the fabric in the finishing liquid, and drying at constant temperature after taking out. According to the dyeing and finishing process of the wool fabric, the dyed and finished fabric has the excellent properties of flame resistance, moth resistance, mildew resistance, antibiosis, antistativity, strong washability and soft hand feel.

Owner:常熟市大唐王子服饰厂

Nanometer anti-mite mothproof after-finishing reagent for woolen sweater as well as manufacturing process thereof

InactiveCN108060579AFine and uniform particlesImprove permeabilityBiochemical treatment with wool-protecting/anti-moth agentsAnimal fibresEpoxyFiltration

The invention relates to a nanometer anti-mite mothproof after-finishing reagent for woolen sweater as well as a manufacturing process thereof. The manufacturing process comprises the following steps:taking a mixed type high-adhesion material as a wall material of a microcapsule, wherein the volume ratio of cyclodextrin to epoxy resin is (5-20):(5-10); dissolving an oily emulsifier and a mixed high-adhesion material into a toluene solution and stirring to form a solution A; taking a mixture of a broad-spectrum anti-mite agent and a natural insect-removing reagent as a core material of the microcapsule, and mixing and stirring a curing agent and a core material solution to form a solution B, wherein the volume ratio of the anti-mite agent to the insect-removing agent is 6:1 to 3:1, and thevolume ratio of the curing agent to the core material solution is 1:6; and performing processes of stirring, secondary curing, separation and filtration and the like to generate a microcapsule solution, namely the anti-mite mothproof after-finishing reagent for the woolen sweater. The anti-mite mothproof after-finishing reagent for the woolen sweater has the advantages of high viscosity, high dispersibility, washing resistance, no toxicity, environmental friendliness, low cost and simple manufacturing process.

Owner:GUANGDONG PENGYUN IND

Treatment of keratinous fibers with an enzyme having perhydrolase activity

Described are compositions and methods relating to the treatment of keratinous fibers and textiles comprising such fibers with enzymatically-generated peracids in aqueous media. The treatment has beneficial effects, including reducing felting, increasing dye uptake, and reducing prickling tendency.

Owner:DANISCO US INC

Preparation method of household antibacterial carpet

InactiveCN108252089AImprove antibacterial propertiesStable structureOrganic chemistryBiochemical treatment with wool-protecting/anti-moth agentsEscherichia coliStaphylococcus aureus

The invention provides a preparation method of a household antibacterial carpet and an antibacterial agent, which comprises the following steps: soaking carpet cloth into a triazinyl quaternized N-halamine solution for treating for 5-15 minutes at 50-70 DEG C; and heating to 80-90 DEG C, adding sodium hydroxide for reacting for 1-3 hours, cleaning and drying to obtain the household antibacterial carpet. Compared with the prior art, the invention has the advantage that triazinyl quaternized N-halamine is used as the antibacterial agent, quaternary ammonium salt and N-halamine can adsorb pathogenic microorganism with negative charge, destroy the cell wall structure of the microorganism so that dissoluble matter leaks out, and inhibit pathogen oxidase and dehydrogenase. Because the quaternaryammonium salt and the N-halamine coexist, the prepared antibacterial carpet performs excellent organism-killing activity on staphylococcus aureus and escherichia coli. An experiment result shows thatthe household antibacterial carpet prepared by the invention has good antibacterial effect.

Owner:天台圣安伦地毯股份有限公司

Preparation method of aging resistant silk fibers

ActiveCN106319929AGuaranteed flexibilityHigh tensile strengthBiochemical treatment with wool-protecting/anti-moth agentsAnimal fibresEnvironmental resistanceCellulose

The invention relates to field of textile materials, and discloses a preparation method of aging resistant silk fibers. The preparation method comprises the following steps: 1, preparing gamma-cyclodextrin monoaldehyde; 2, preparing silver-loaded gamma-cyclodextrin monoaldehyde; 3, preparing cellulose-fibroin-titanium dioxide xerogel particles; 4, grafting the silk fibers; 5, carrying out impregnated finishing on the silk fibers. The silk fibers prepared by the invention can effectively delay the aging of the silk fibers and avoid borer plaque and bacterial plaque, and further has long aging. In addition, the preparation method of the aging resistant silk fibers can keep the original flexibility of silk and enhance the tensile strength of the silk, and is environment-friendly and harmless, and further does not affect human bodies.

Owner:华美时尚集团有限公司

Bamboo charcoal fiber capable of repelling mosquitoes and flies

InactiveCN109418333AGood killing effectPrevention and treatment of rhinitis and nasal congestionBiocideCarbon fibresAnti virusRhizome

The invention discloses a bamboo charcoal fiber capable of repelling mosquitoes and flies. Bamboo charcoal fiber are soaked in a traditional Chinese medicine liquid capable of repelling mosquitoes andflies, drying is carried out, and then weaving is carried out, wherein the traditional Chinese medicine capable of repelling mosquitoes and flies is prepared by decocting nine raw materials with water with a weight of 2-3 times of the weight of the total weight of the raw materials, and the nine raw materials comprise the following components: 5-15 parts of melia azedarach, 10-20 parts of foliumartemisiae argyi, 10-20 parts of purple perilla, 15-25 parts of grassleaf sweetflag rhizome, 10-20 parts of agastache rugosus, 20-30 parts of black nightshade leaves, 20-30 parts of polygonum hydropiper leaves, 20-30 parts of peach leaves and 3-5 parts of realgar. The traditional Chinese medicine liquid has a synergistic effect, the traditional Chinese medicines mutually promote each other, a goodmosquito killing effect is achieved, and the traditional Chinese medicine liquid is safe, pollution-free and environmentally friendly, and also has certain sterilization, anti-virus and anti-influenza effects. When clothes made of the bamboo charcoal fibers provided by the invention are worn, mosquitoes and flies can be effectively repelled, a protecting effect is achieved for human bodies, and along-acting and active insect repelling effect and mosquito and fly repelling effect are realized.

Owner:桂林市愚人服装有限公司

Long-acting mosquito-repellent thermal-moisture comfortable hemp fabric and preparation method thereof

InactiveCN105926114AGood moisture absorptionExcellent moisture dissipationBiochemical treatment with wool-protecting/anti-moth agentsOpen work fabricsYarnFiltration

The invention provides a method for preparing a long-acting mosquito-repellent thermal-moisture comfortable hemp fabric. The method comprises the steps of washing fresh eucalyptus leaves produced in Yunnan Pu er county, mint and chamomile, placing the fresh eucalyptus leaves produced in Yunnan Pu er county, mint and chamomile at a shade place, airing the raw materials to be half-dry, cutting up and placing the half-dry eucalyptus leaves, mint and chamomile into a solution and boiling the solution, performing filtration and concentration, adding clove oil to obtain mosquito-repellent plant extract; steeping the China-hemp regenerated fiber in the mosquito-repellent plant extract, and performing two-steeping two-rolling processing to obtain regenerated cellulose fiber; taking blended yarn formed by China-hemp and long-staple cotton fiber composite spinning as warp, taking the regenerated cellulose fiber as weft, adopting through hole weave for a woven fabric structure, and forming the long-acting mosquito-repellent thermal-moisture comfortable hemp fabric by weaving through a circular machine. The prepared hemp fabric is green, environmentally friendly, comfortable, breathable, safe, repellent to mosquitoes, effective for a long time, and particularly suitable for making summer clothes.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Process for manufacturing silk quilt with effects of dispelling pathogenic wind and killing worms

InactiveCN109567506AReduce mothExtended service lifeBlanketBed linenEngineeringBULK ACTIVE INGREDIENT

The invention relates to the technical field of textile processing, and particularly relates to a process for manufacturing a silk quilt with effects of dispelling pathogenic wind and killing worms. The silk quilt contains active ingredients of buddleja lindleyana, so that the manufactured silk quilt not only has advantages of fluffiness and softness, but also has effects of dispelling pathogenicwind and killing worms, wherein the active ingredients can reduce a probability that the silk is damaged by worms so as to effectively prolong the service life of the silk quilt; in addition, the silkquilt prepared in the invention also has effects of eliminating pathogenic wind and dampness, activating qi and eliminating phlegm, so that the silk quilt prepared in the invention can be used for along term to benefit health of a user; and sericin contained on fabrics can be removed to the greatest extent by adjusting pH to 9.5-10, adjusting a temperature to 90-100 DEG C, degumming the silk with a hydrogen peroxide solution, sodium silicate and other substances, and matching with physical and mechanical actions of a multifunctional fine cotton fluffer, so that the prepared silk quilt has advantages of bright gloss, soft handfeel, pure whiteness, clear texture and high permeability.

Owner:ANXI COUNTY FENGCHENG JIANJIN PROD APPEARANCE DESIGN SERVICES CENT

Finishing method for silk fiber cotton cloth

InactiveCN108425240AMoth-proof goodImprove mildew resistanceBiochemical treatment with wool-protecting/anti-moth agentsLiquid/gas/vapor removalCooking & bakingBetel

The invention provides a finishing method for silk fiber cotton cloth, and solves the technical problems of too simple structure, easy damage by worms, short use time and the like in existing silk fiber cotton cloth. The finishing method for silk fiber cotton cloth includes the steps of: a. by weight, putting 5-8 parts of sodium aluminum fluosilicate, 6-12 parts of glycerin, 14-20 parts of water absorption silica gel, 8-14 parts of betel nut, 1.5-3.5 parts of an anti-aging agent, 10-20 parts of resmethrin, 4-9 parts of camphor powder, 1-3 parts of a mildew-proof agent and 60-90 parts of waterinto a mixer, and stirring the substances evenly to obtain a finishing liquid; b. subjecting silk fiber cotton cloth to dip padding in the finishing liquid by a dip padding machine, one dipping and one padding; c. putting the silk fiber cotton cloth subjected to dip padding into an oven for drying; d. putting the dried silk fiber cotton cloth into an baking machine for baking; and f. inspecting the baked silk fiber cotton cloth, and carrying out packaging and warehousing. The finishing method provided by the invention has the advantage of good finishing effect.

Owner:海宁迪万沃浦建材科技有限公司

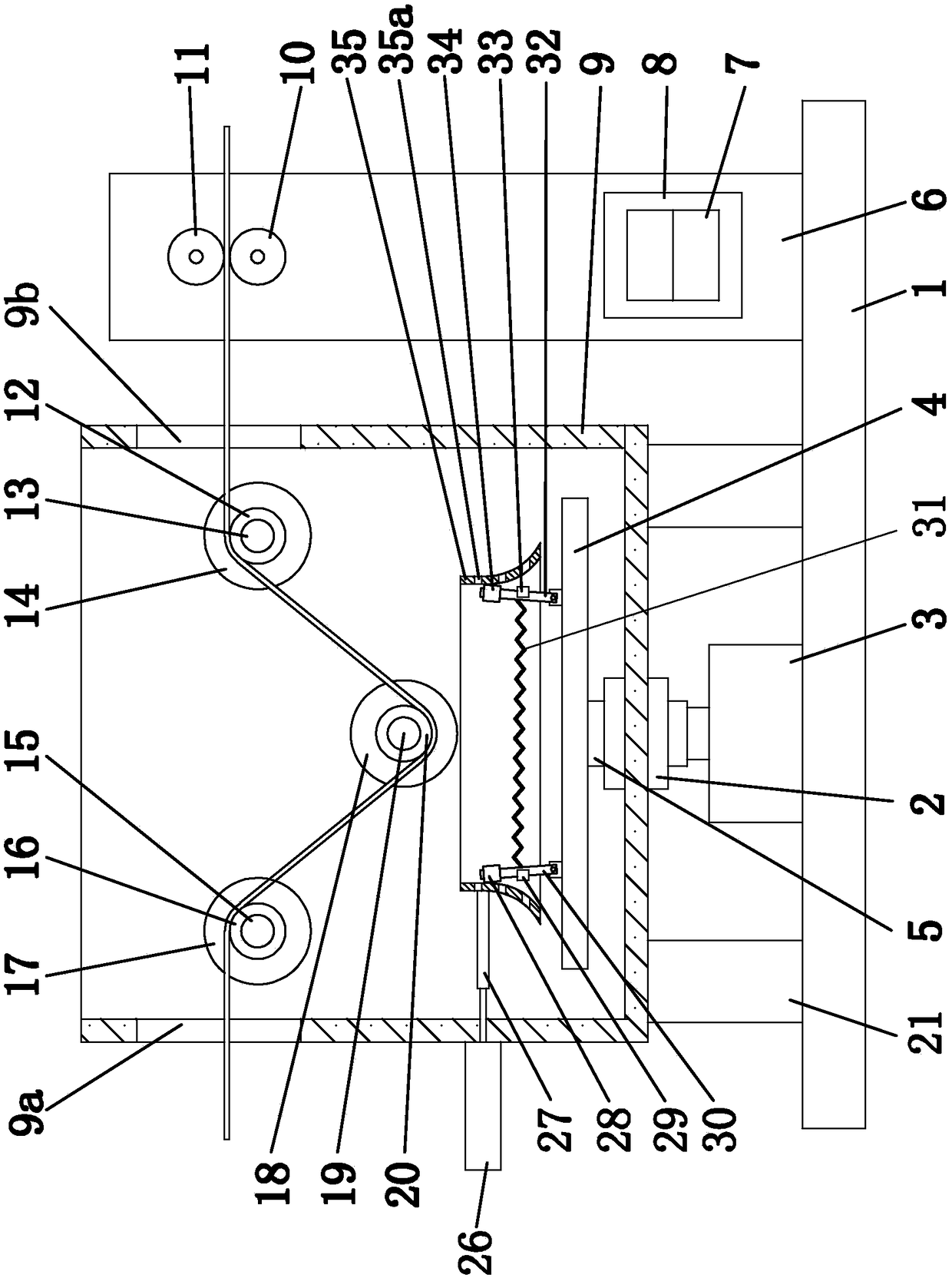

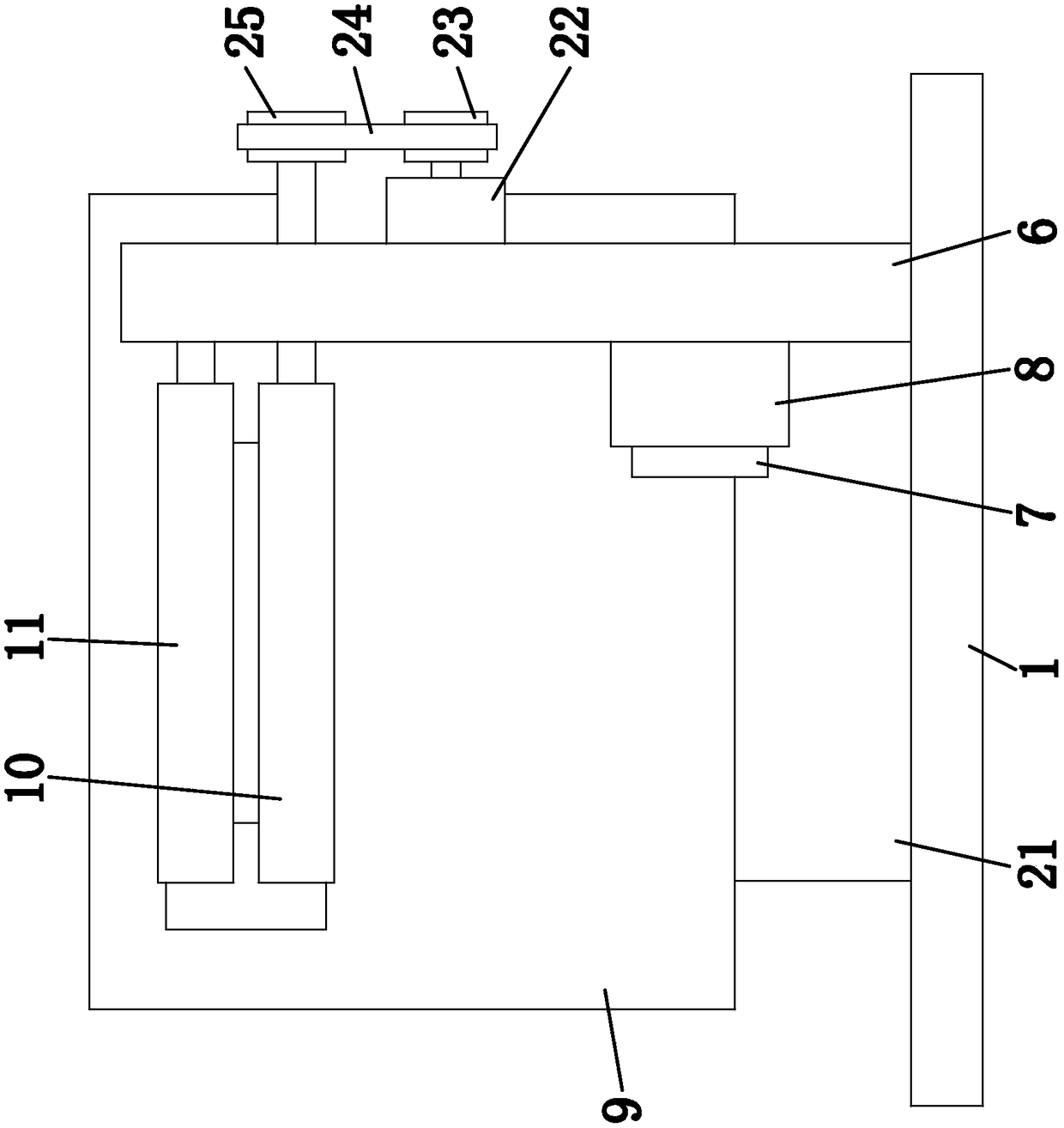

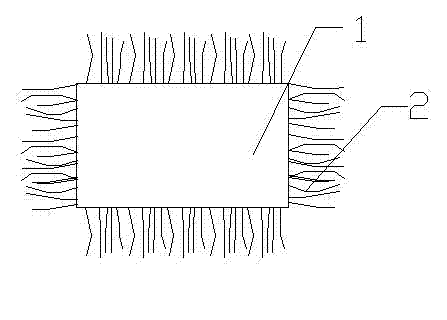

Textile having silk drawing process and preventing dust mites and allergic asthma

ActiveCN102535210AStrong three-dimensional sensePersistent deterrenceBiochemical treatment with wool-protecting/anti-moth agentsTextile decorationCross-linkBenzoyl peroxide

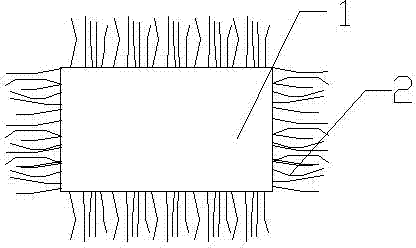

The invention relates to a textile having a silk drawing process and preventing dust mites and allergic asthma, which comprises a textile, wherein bristles are sewn on the periphery of the textile, the bristles are in single sewing or superposed sewing, then the silk drawing of warp yarns or weft yarns in the bristles is carried out, and the spraying treatment of a finished product is carried out by using a mite preventing solution. According to the textile having the silk drawing process and preventing the dust mites and the allergic asthma, the mite preventing solution comprises the following components according to the mixture ratio (weight percent): 2 to 10 percent of mite preventing agent, 5 to 28 percent of adhesive, 1 to 11 percent of cross-linking agent, 1 to 12 percent of emulsifying liquid, 1 to 8 percent of detergent and the balance water. The mite preventing agent can be one of questin, isothiazole quinoline ketone and sulfamide independently or the mixture of the questin, the isothiazole quinoline ketone and the sulfamide. The adhesive is a butyl-rubber solvent type adhesive. The further improvement of the invention is that the cross-linking agent is benzoyl peroxide which is not soluble in the water. The bristles with stronger stereoscopic impression can be made on the textile, and the quality of the product is enhanced; and moreover, the textile having the silk drawing process and preventing the dust mites and the allergic asthma has a permanent action of preventing the dust mites, is used for preventing the relapse of the allergic disease of the dust mites and is beneficial to the physical health of human beings.

Owner:江苏全球康功能纺织品有限公司

Functionalized molded cellulose body and method for producing the same

InactiveUS20180023216A1Reduction tendencySuitable for useArtificial filaments from cellulose solutionsArtificial filament physical treatmentCelluloseFiber

The invention relates to a molded cellulose body which includes a functional substance having low impregnation efficiency, to the use thereof and to a method for introducing functional substances of low impregnation efficiency into a molded cellulose body during its production and after the molding step.

Owner:LENZING AG

Long-acting insect-repelling textile fabric

InactiveCN107700221AAvoid harmWide range of usesBiochemical treatment with wool-protecting/anti-moth agentsResistCombustion

The invention discloses long-acting insect-repelling textile fabric, which is characterized by being prepared by processes of humidification, fixing, dyeing and coating. The invention has the following advantages: by selection of an insect-resist agent for coating the fabric, the insecticidal efficacy is good, and death rate of mosquitoes reaches 95% and above; the insect-resist agent is differentfrom general spraying or combustion type insecticides, is more convenient and cleaner and environmentally-friendly when being used, is harmless to human body, and is safe to use; and the textile fabric of the invention has a wide range of application, can be used as a conventional textile fabric and also can be used for insect-resist camping, cargo transportation, article storage and the like.

Owner:NANTONG GUANZHOU INT TRADE CO LTD

Anti-moth textile fabric and preparation method thereof

InactiveCN106978714AGood moth resistanceImprove breathabilityBiochemical treatment with wool-protecting/anti-moth agentsLiquid repellent fibresFiberChlorinated polyvinyl chloride

The invention provides a piece of anti-moth textile fabric and a preparation method thereof. The textile fabric comprises the following components: tencel, chlorinated polyvinyl chloride fiber, jute fiber, nanometer copper oxide, spandex fiber, a reinforcing agent, and water. The components are mixed, after processing, the textile fabric has the advantages of excellent anti-moth performance, water proofing and oil proofing functions, high temperature resistance, and wear resistance; after multitimes of washing, the trend of performance reduction is not generated; the textile fabric has the advantages of good permeability, excellent strength and toughness, and good anti-moth effects; furtherly, the preparation technology is simple, material cost is low, producing process is green and environmentally friendly without pollution, and the method is suitable for industrialized large scale production.

Owner:合肥云都棉花有限公司

Dyeing and finishing process for garment materials

InactiveCN105350290AGood antibacterialImprove mildew resistanceBiochemical treatment with wool-protecting/anti-moth agentsHeat resistant fibresEthylenediamineCoconut diethanolamide

The invention discloses a dyeing and finishing process for garment materials. The process comprises the following steps: 1) preprocessing; 2) dyeing; 3) finishing: sequentially putting 1 to 2 parts by weight of polyvinylpyrrolidone, 1.4 parts by weight of sodium pyrophosphate, 1.1 parts by weight of cinnamon oil and 0.9 parts by weight of schisantherin into 25 parts by mass of deionized water, and uniformly stirring; simultaneously putting 1.3 parts by weight of sandalwood powder, 0.7 parts by weight of piperazine phosphate, 1.3 parts by weight of coconut diethanolamide and 0.7 parts by weight of hydroxyethyl ethylenediamine into the mixture, continuously stirring, till being fully uniformly mixed, so that finishing liquor is prepared; then enabling the garment materials to be subjected to padding treatment in the finishing liquor, taking the garment materials out, and drying at a constant temperature. By adopting the dyeing and finishing process for the garment materials, the dyed and finished garment materials have the excellent performances of being antibacterial, mildew-proof, mothproof, flame retardant and antistatic, are strong in washability and soft in hand feel.

Owner:常熟市庄丹奴服饰有限公司

Wool and cashmere large biological fiber containing active ingredients of pericarpium citri reticulatae, orange and pomelo and preparation method of wool and cashmere large biological fiber

PendingCN112813680AImprove wrinkle resistanceImprove antistatic performancePhysical treatmentBiochemical treatment with wool-protecting/anti-moth agentsBiotechnologyFiber

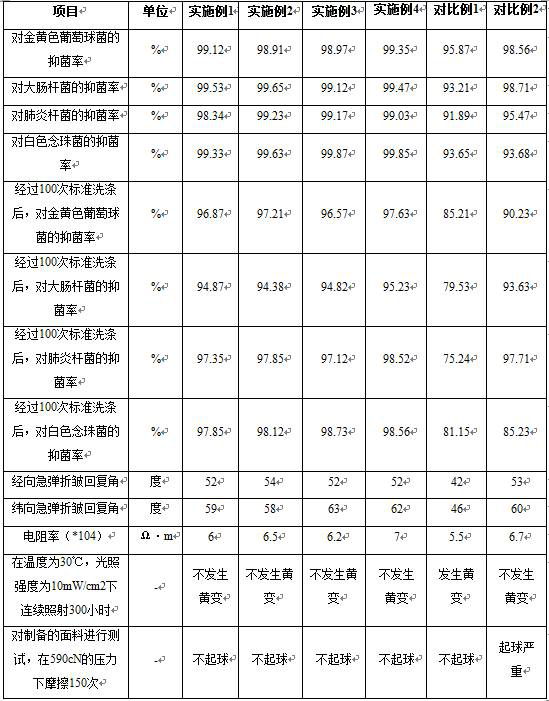

The invention relates to a preparation method of wool and cashmere large biological fiber containing active ingredients of pericarpium citri reticulatae, orange and pomelo. The preparation method comprises the steps of soaking swelling, low-temperature treatment, biological modification, anti-pilling treatment and moth-proof treatment. The wool and cashmere large biological fiber containing the active ingredients of the pericarpium citri reticulatae, the orange and the pomelo is good in wrinkle resistance; the resistivity can be reduced to 6 * 10 <4> omega.m; the biological fiber is good in durability, not prone to yellowing in the using process and free of yellowing after being continuously irradiated for 300 hours at the temperature of 30 DEG C and the illumination intensity of 10 mW / cm <2>; after being rubbed for 150 times under the pressure of 590cN, the biological fiber still does not pill; and the antibacterial rate to staphylococcus aureus can reach 98.91%, the antibacterial rate to escherichia coli can reach 99.12%, the antibacterial rate to pneumobacillus can reach 98.34%, the antibacterial rate to candida albicans can reach 99.33%, and the like.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD +2

Functionalized molded cellulose body and method for producing the same

InactiveUS20120318169A1Reduce fibrillation tendencySuitable for useNatural resin coatingsOil/fat/wax adhesivesCelluloseFiber

The invention relates to a molded cellulose body which includes a functional substance having low impregnation efficiency, to the use thereof and to a method for introducing functional substances of low impregnation efficiency into a molded cellulose body during its production and after the molding step.

Owner:LENZING AG

Nano silver durable antibacterial cloth permeated by semiconductor and preparing method thereof

InactiveCN106319938AHigh antibacterial activityImprove antibacterial propertiesBiochemical treatment with wool-protecting/anti-moth agentsHigh pressureAtmospheric pressure

The invention discloses nano silver durable antibacterial cloth permeated by semiconductor and preparing method thereof. The invention applies the semiconductor permeation in the preparing of nano silver antibacterial solution and obtains nano silver antibacterial cloth from cloth through high pressure airless spray, squeezing and drying. The antibacterial cloth is obtained by semiconductor permeation. The invention comprises the steps of spraying the nano silver antibacterial solution with high pressure airless spray system, spraying with high pressure airless sprayer, evening up with pressure roller and drying. The invention can efficiently kill more than 650 kinds of bacterial, with sterilization rate reaching 99.9%. The invention also has good killing effect for white candida that is hard to be killed by general nano silver. As the invention improves the permeation and adhesive force and the washing resistance of nano silver antibacterial cloth enhances, the antibacterial effect is durable.

Owner:厦门博正科技有限公司

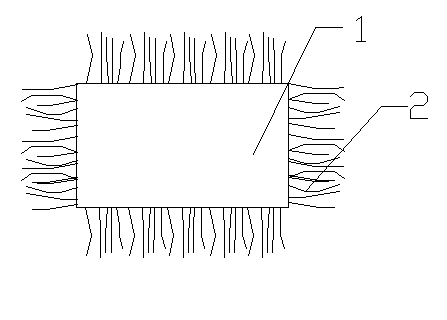

Textile having silk drawing process and preventing dust mites and allergic asthma

ActiveCN102535210BStrong three-dimensional sensePersistent deterrenceBiochemical treatment with wool-protecting/anti-moth agentsTextile decorationPolymer scienceBenzoyl peroxide

Disclosed is an anti-mites and allergic asthma preventing textile treated with silk drawing process; the textile comprises a textile (1).Wherein fringes (2) are sewn on four sides of the textile by single sewing or overlapped sewing. Then the warps or wefts in the fringes (2) are treated with silk drawing process, and the finished product is treated with spraying anti-mites solution. The anti-mites solution comprises following components according to the mixture ratio (weight percent): anti-mites agent 2-10%, adhesive 5-28%, cross-linking agent 1-11%, emulsifying liquid 1-12%, detergent 1-8% and balance water. The anti-mites agent is selected from monomethyl ether, isothiazolinone, sulfamide or mixtures thereof. The adhesive is butyl-rubber solvent type adhesive. The cross-linking agent is benzoyl peroxide which is not soluble in water. More stereoscopic fringes can be manufactured on the textile. The textile has durable anti-mites effect, which can prevent relapse of mites allergic disease, and is beneficial to the health of human beings.

Owner:江苏全球康功能纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com