Treatment of keratinous fibers with an enzyme having perhydrolase activity

A technology of perhydrolase and keratin fiber, which is applied in the direction of hydrolase, enzyme/microbe biochemical treatment, shrink-proof fiber, etc., and can solve the problems of harmfulness to textile workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

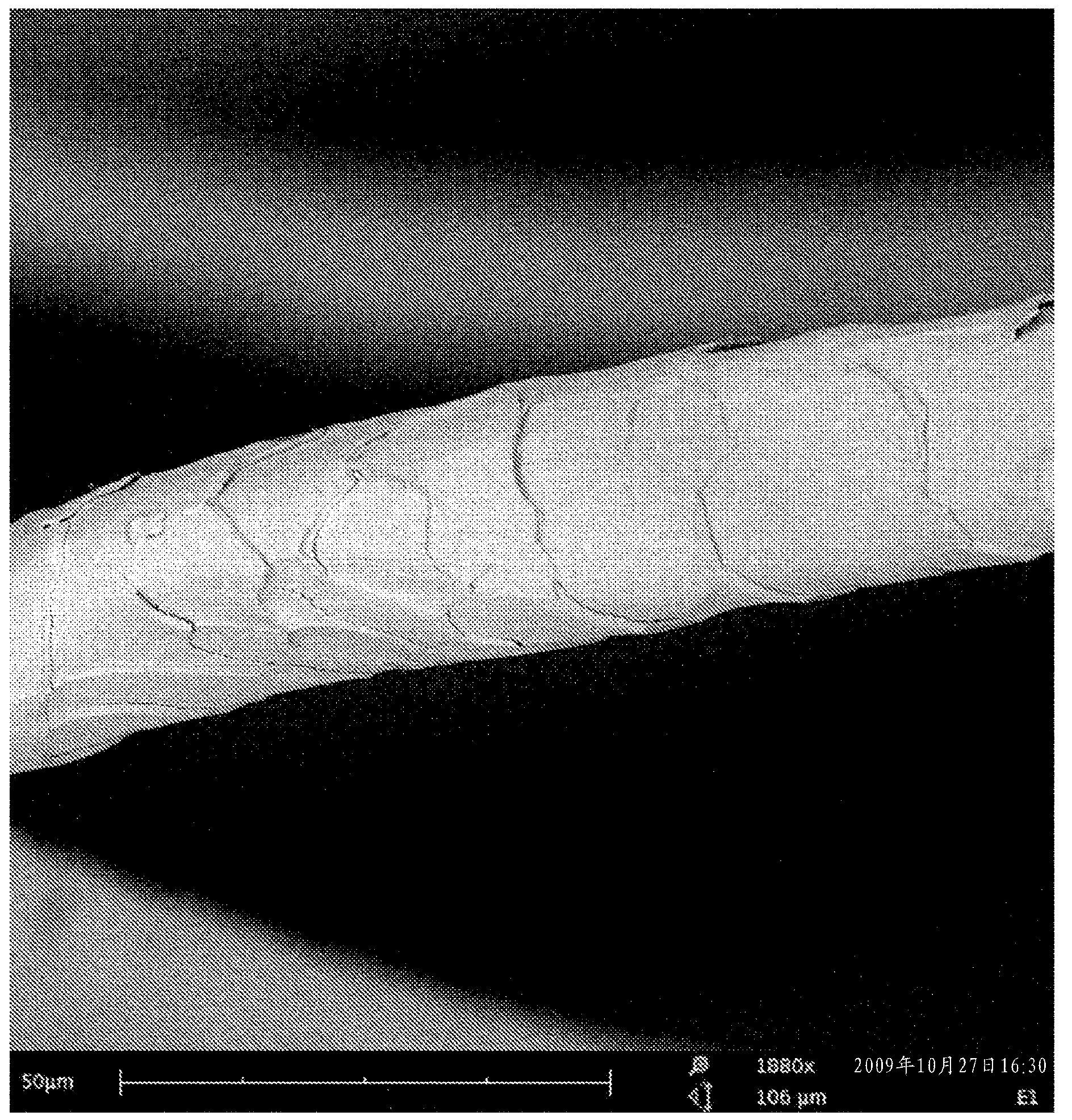

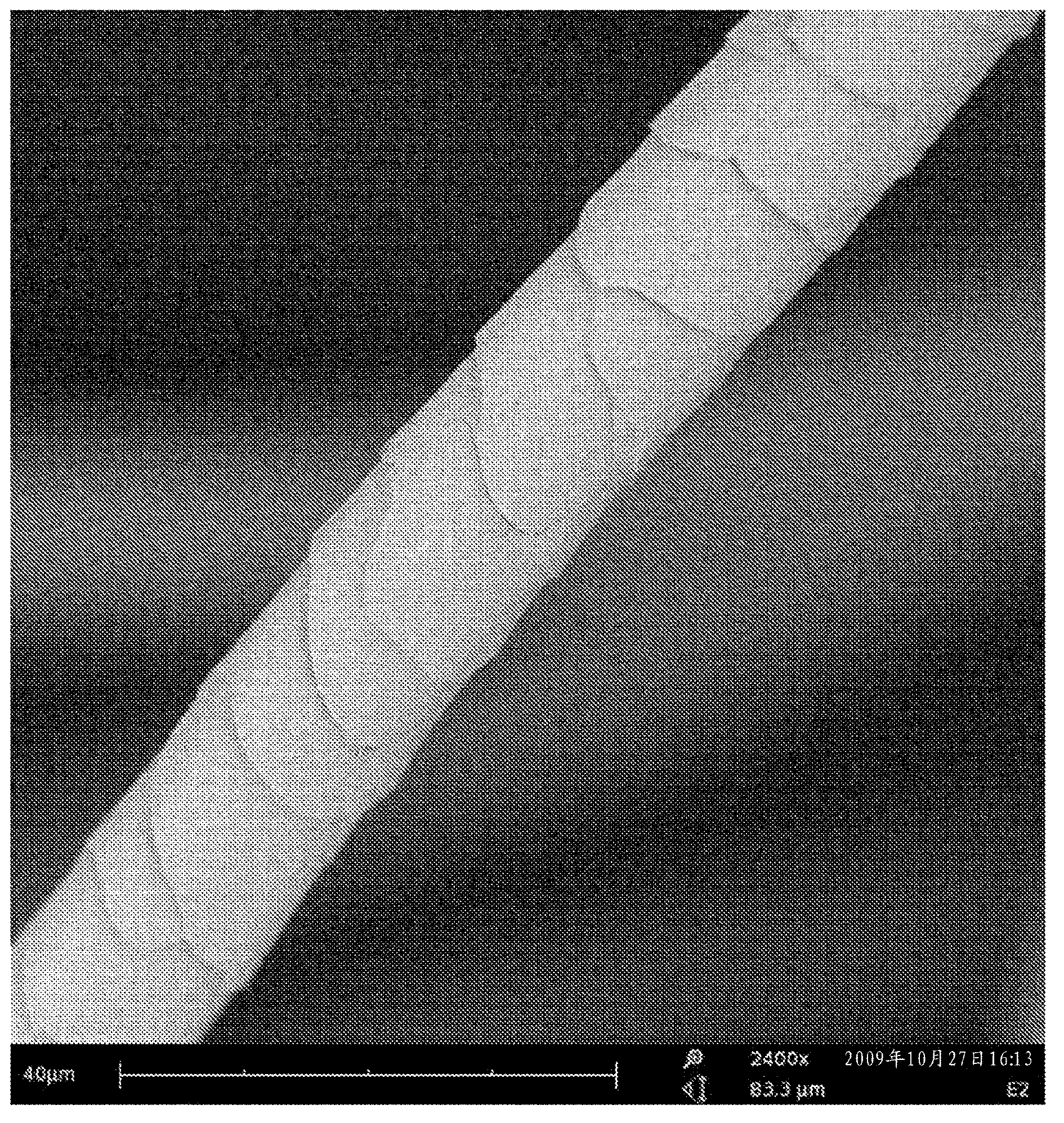

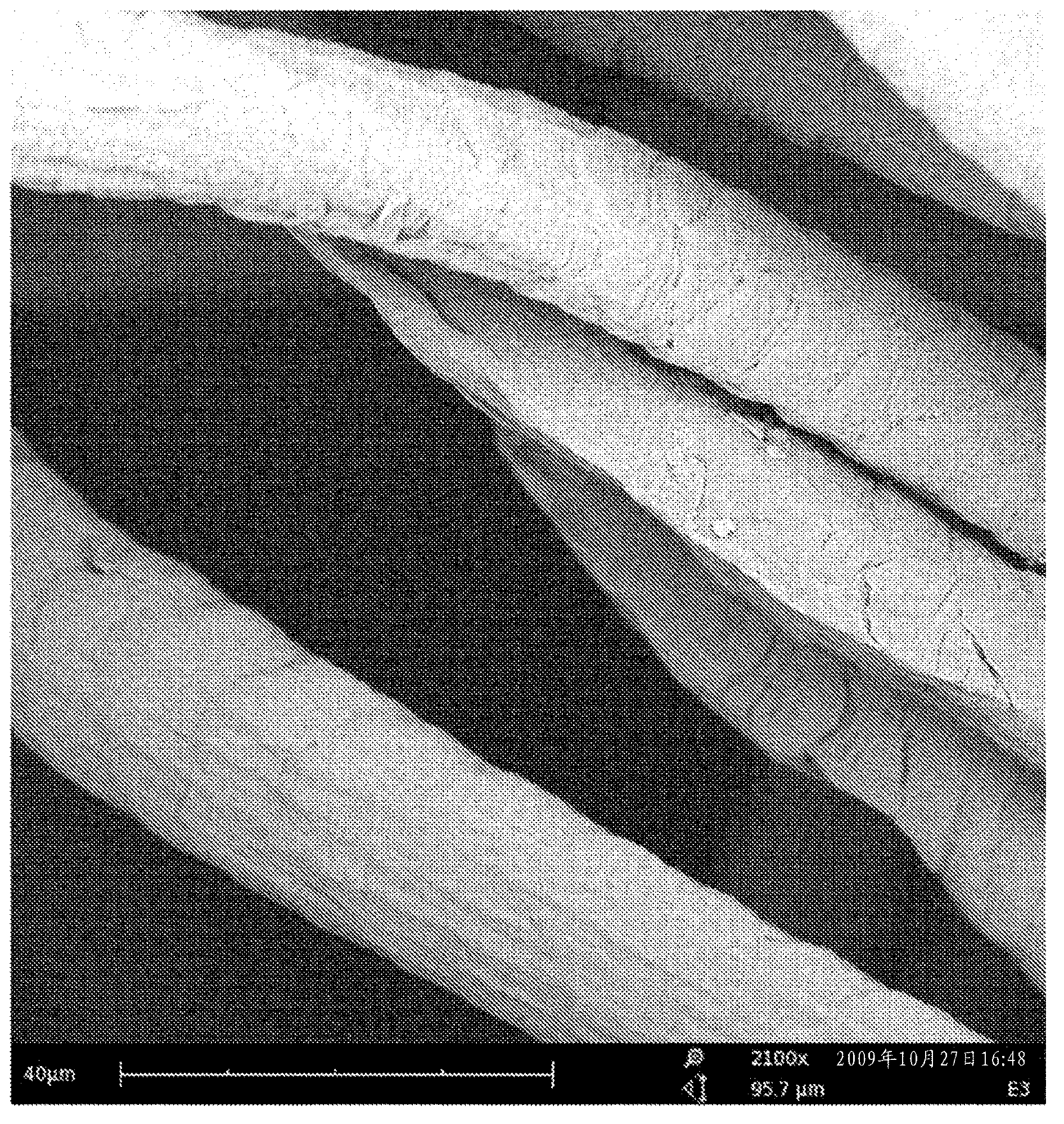

[0127] Example 1: Morphological changes of wool fibers treated with enzymes

[0128] 50 mg of 100% wool fiber (ie, "top wool fiber") was incubated in a glass tube in a reaction volume of 2 ml at 65°C with slow agitation for one hour. The incubation conditions were as follows:

[0129] 1) buffer (100mM sodium phosphate buffer, pH 7),

[0130] 2) Buffer+5μl / ml PGDA+5μl / ml H 2 o 2 (50% w / w), or

[0131] 3) Buffer+5μl / ml PGDA+5μl / ml H 2 o 2 (50% w / w) + 0.8 ppm perhydrolase.

[0132] The particular perhydrolase used was the S54V variant of M. smegmatis perhydrolase (also known as "arylesterase"). After treatment, the wool fibers were rinsed three times with DI water and then air dried. The morphology of the treated wool fibers was evaluated using FEI's Phenom Scanning Electron Microscopy.

[0133] Use buffer+PGDA+H 2 o 2 processing wool fibers ( figure 2 ) compared to buffer-only treatment ( figure 1 ), did not significantly change the morphology of wool scales. Ho...

example 2

[0136] Example 2: Changes in dyeing affinity of enzymatically treated wool fibers

[0137] 50 mg of treated wool fibers (see Example 1) were dyed with Differential Textile Fiber Stain A (a combination of picric acid, G150 chlorazole blue and 3BS crocus scarlet) for 5 minutes at room temperature. A significant increase in dyeing affinity with Discriminative Fabric Fiber Stain A was observed in hydrolytic enzyme-treated wool fibers ( Figure 5 ). In use buffer or buffer+PGDA+H 2 o 2 While the treated wool fiber is dyed medium orange, with buffer or buffer + PGDA + H 2 o 2 + Perhydrolase-treated wool fibers are dyed deep red. These results demonstrate that treatment of wool fibers with perhydrolase increases dye uptake.

example 3

[0138] Example 3: Treated Wool Knit in Launder-O-meter reduced shrinkage

[0139] Three samples of 100% wool jersey (measured at 5" x 5"; test fabric type 532) were each placed in a washfastness tester at 65°C and one of the following conditions (n=3) Incubate for 1 hour with a reaction volume of 300ml (bath ratio = 32:1):

[0140] 1) buffer (100mM sodium phosphate buffer, pH 7),

[0141] 2) Buffer+5μl / ml PGDA+5μl / ml H 2 o 2 (50% w / w), or

[0142] 3) Buffer+5μl / ml PGDA+5μl / ml H 2 o 2 (50% w / w) + 0.8 ppm perhydrolase.

[0143] Representative results are in Image 6 shown in . Samples treated with perhydrolase showed greater 2 o 2 Treated samples showed significantly less shrinkage. These results demonstrate that treatment of wool fibers with perhydrolase reduces shrinkage under laundering conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com