Preparation process of reflective fabric with heavy industry washing fastness

A preparation process and reflective cloth technology, which is applied in the direction of lamination, layered products, glass/slag layered products, etc., can solve the problems of not being able to reach industrial washing, and achieve the effect of improving water washing resistance and high reflective intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

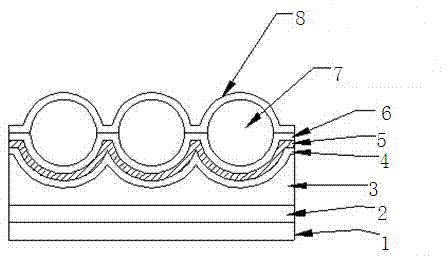

[0039] A preparation process of heavy-industrial washing-resistant reflective cloth, the preparation process steps are as follows:

[0040] (1) Put the PE / PET composite film in the plant heating roller, the heating roller rotation speed is 1-30m / min, the temperature is controlled between 130-210℃, as the PE film melts, the glass beads settle on the PE On the film, after the PE film is cooled, the glass beads are fixed on the PE film, thereby realizing the implantation of glass beads to obtain a glass bead layer, thereby obtaining a semi-finished product with a PE / PET composite film and a glass bead layer;

[0041] (2) The glue prepared by solvent, resin, curing agent and auxiliary agent is evenly coated on the surface of the glass beads described in step (1) to form a spherical focusing layer concentric with the glass beads, and then baked through a drying tunnel Dry solvent film formation, thereby obtaining a semi-finished product with PE / PET composite film, glass bead layer and p...

Embodiment 1

[0048] The raw material ratio of the protective composite rubber in step (5) is: 60 parts of main resin, 1 part of curing agent, 1 part of auxiliary agent, and 30 parts of diluent; the ratio of raw materials of composite rubber in step (6) is: 60 parts of main resin , 10 parts of flame retardant, 1 part of curing agent, 1 part of auxiliary agent, 30 parts of diluent, 2 parts of pigments and fillers. The main resin is solvent-based acrylic resin, the curing agent is isocyanate curing agent, the auxiliary is lubricant, diluting The agent is ethyl acetate, the flame retardant is a phosphorus flame retardant, and the pigment and filler are aluminum powder or aluminum paste.

[0049] The base fabric is chemical fiber cloth; the thickness of the composite adhesive layer is 25um; the thickness of the composite adhesive protective layer is 250um; the inert material layer is a silicon dioxide layer with a thickness of 10nm; the metal plating layer is a metal aluminum plating layer with a t...

Embodiment 2

[0052] The raw material ratio of the protective composite rubber in step (5) is: 60 parts of main resin, 7 parts of curing agent, 1 part of auxiliary agent, and 20 parts of diluent; the ratio of raw materials of composite rubber in step (6) is: 60 parts of main resin , 5 parts of flame retardant, 8 parts of curing agent, 1 part of auxiliary agent, 10 parts of diluent, 3 parts of pigments and fillers. The main resin is solvent acrylic resin, the curing agent is aziridine curing agent, and the auxiliary is dispersing agent. , The diluent is toluene, the flame retardant is nitrogen-based flame retardant, and the filler is toner or color paste.

[0053] The base fabric is TC cloth; the thickness of the composite adhesive layer is 50um; the thickness of the composite adhesive protective layer is 500um; the inert material layer is a silicon dioxide layer with a thickness of 100nm; the metal coating is a metal aluminum coating with a thickness of 0.1nm; focusing layer The thickness is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com