Folding-type display and portable terminal device

A display and folding technology, applied in chemical instruments and methods, instruments, electrical digital data processing, etc., can solve the problems of pencil hardness reduction, image distortion, film deformation, etc., and achieve the effect of excellent convenience and resistance to scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

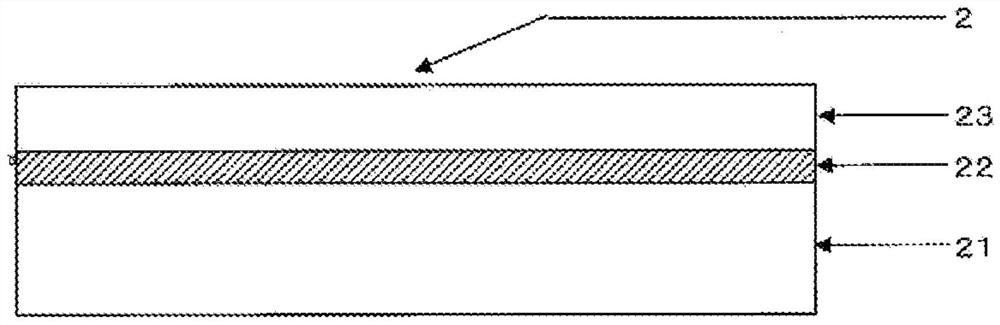

[0119] Coat polyimide-based resin coating solution 1 on one side of polyethylene terephthalate film No. 3 with a Meyer rod so that the film thickness after drying becomes 2.0 μm, and dry at 120°C For 1 minute, a cured layer of polyimide resin was obtained. Next, on the cured layer of the polyimide resin, apply the hard coat coating liquid 2 with a Meyer rod so that the film thickness after drying becomes 10 μm, dry at 80° C. for 30 seconds, and then irradiate ultraviolet rays (cumulative light intensity 200mJ / cm 2 ) to obtain a hard coating film.

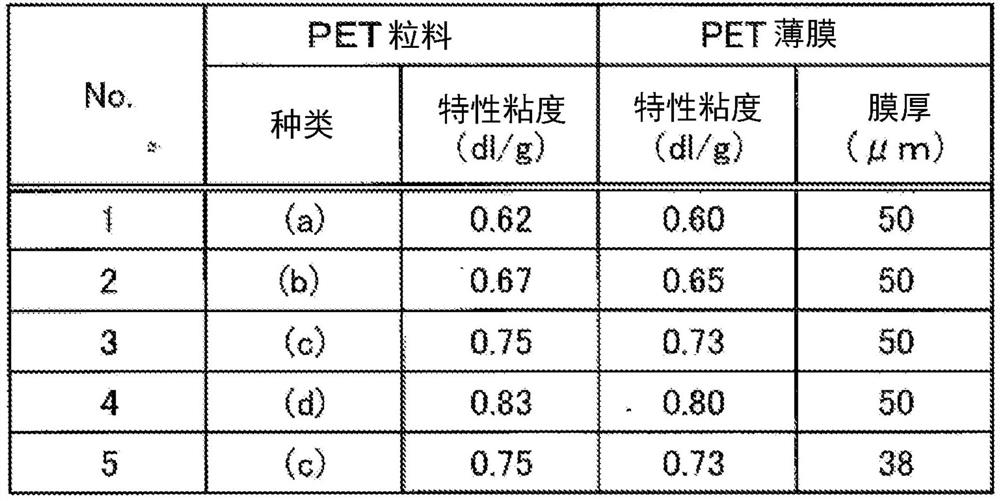

Embodiment 2~5、 comparative example 1~3

[0121] By the same method as in Example 1, a hard coat film was produced under the conditions shown in Table 2.

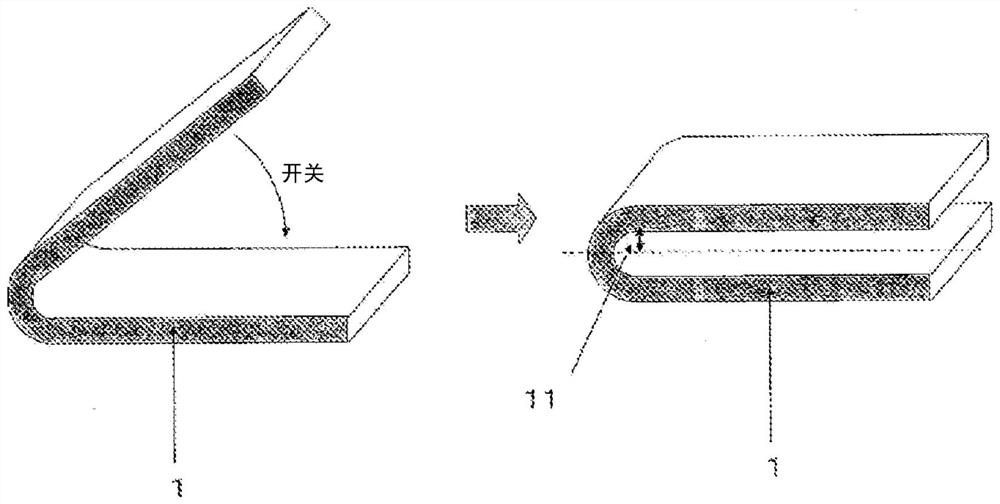

[0122] The produced film is bonded to an organic EL device with a 25 μm thick adhesive layer to form a figure 1 It is a smart phone-type folding display that can be folded in two at the center of the whole with a radius of 3 mm, which is equivalent to the bending radius. The hard coat film is arranged on the surface of one continuous display with the folded portion interposed so that the hard coat layer is located on the surface of the display. When the hard coat film of each Example is used, the operation and visibility as a smartphone that can be folded and moved by folding in two at the central part are satisfied. On the other hand, the foldable displays using the hard coat films of Comparative Examples 2 and 3 are not preferable because image distortion gradually occurs at the folded portion of the display as the frequency of use increases. In addition, Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com