Energy ray-curable resin composition, cured product and laminate

An energy ray curing and resin composition technology, which is applied in the field of cured products and laminates, and energy ray curable resin compositions, and can solve the problems of foreign matter, crack fragments, and lack of flexibility of the coating film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

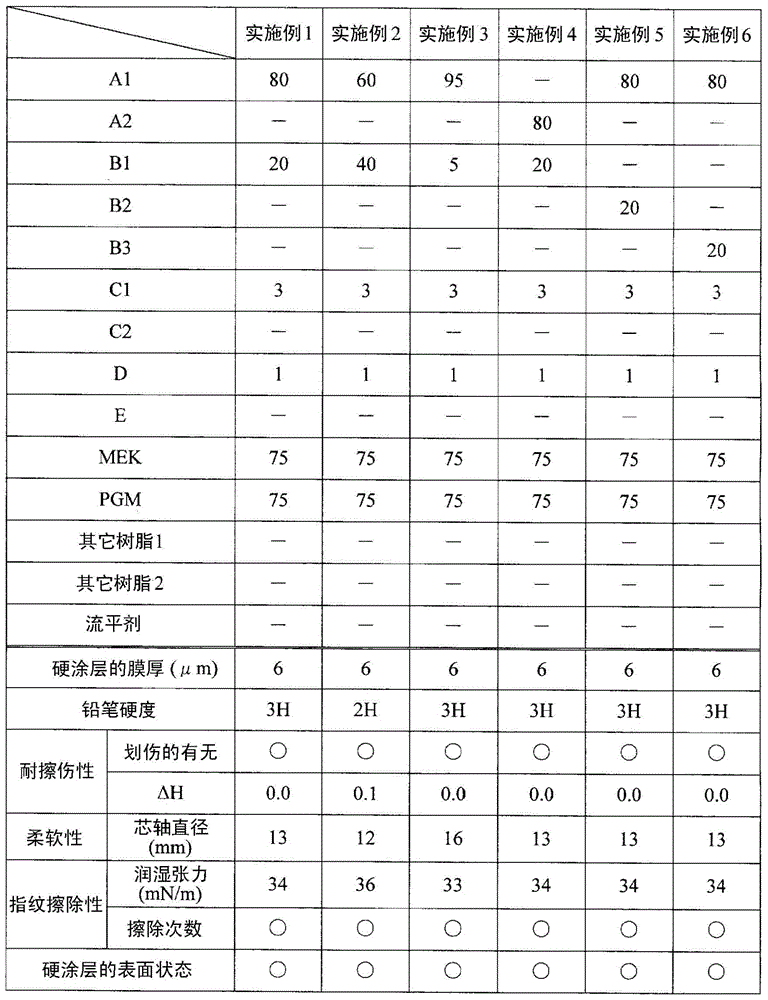

[0111] Add 75 parts by mass of methyl ethyl ketone (MEK) and 75 parts by mass of propylene glycol monomethyl ether (PGM) to (A1) 80 parts by mass, (B1) 20 parts by mass, (C1) 3 parts by mass, and (D) 1 part by mass, and stir was added to prepare the energy ray curable resin composition of Example 1 having a solid content of 41%.

[0112] Next, this energy ray-curable resin composition was applied to a polyethylene terephthalate film (trade name: COSMOSHINE A4300, manufactured by Toyobo Co., Ltd.) with a thickness of 188 μm as a base material using a Baker type film applicator. surface, dry at 140°C for 2 minutes at 300mJ / cm 2 It cured by irradiating ultraviolet rays to form a hard coat layer with a film thickness of 6 μm, thereby obtaining the laminate of Example 1. Table 1 shows the composition of the energy ray curable resin composition and the evaluation results of the laminate.

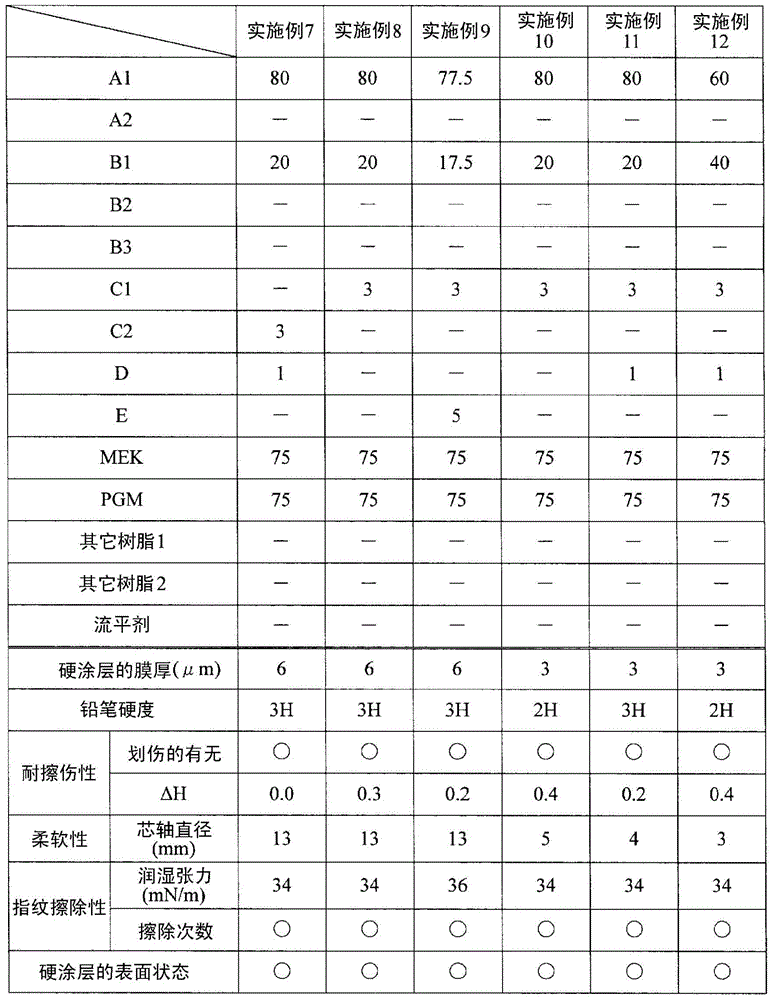

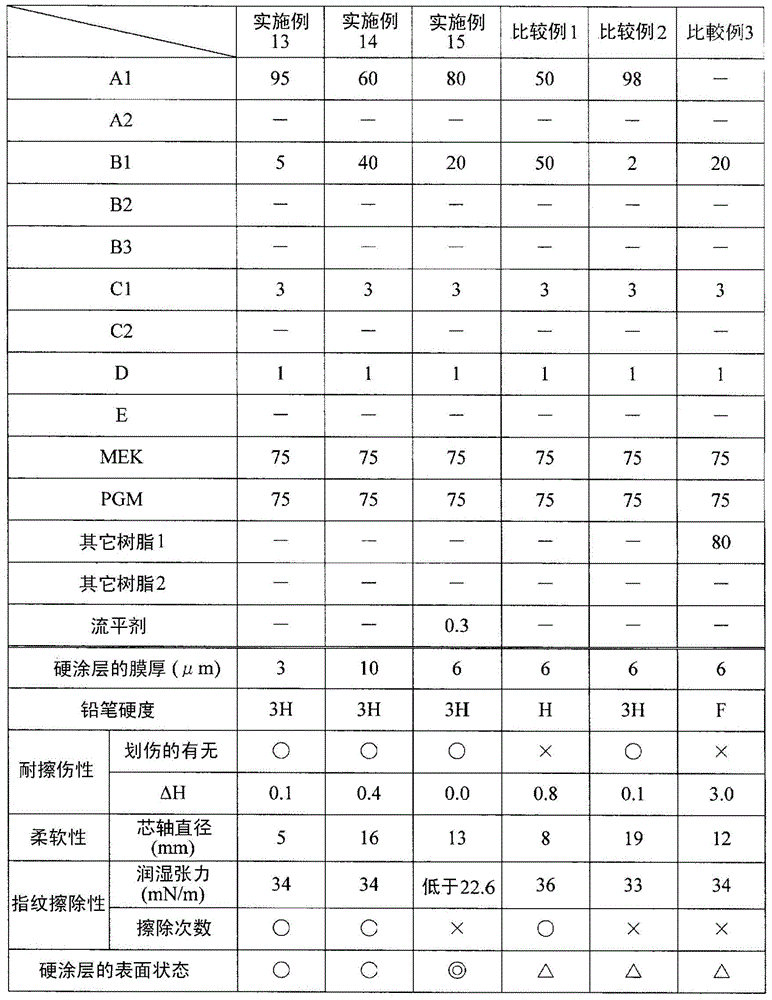

Embodiment 2~15

[0114] Using the energy ray-curable resin compositions of the compositions shown in Tables 1 to 3, respectively, it carried out similarly to Example 1, and produced the laminated body. In addition, about Examples 11-13, the film thickness of a hard-coat layer was made into 3 micrometers. In addition, regarding the laminated body of Example 14, the base material was made into a polyethylene terephthalate film (trade name: COSMOSHINE A4300, manufactured by Toyobo Co., Ltd.) with a thickness of 100 μm, and the film thickness of the hard coat layer was set to 100 μm. is 10 μm. The evaluation results of these laminates are collectively shown in the same table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wetting tension | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com