Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Full paint film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment friendly antibacterial waterborne paint and preparation thereof

InactiveCN101486861AImprove adhesionFull paint filmAntifouling/underwater paintsPaints with biocidesChemistryEmulsion

The invention provides an environment-friendly antibacterial water paint and a preparation method thereof. The components include deionized water, germicide, assistant for film forming, defoaming agent, wetting agent, dispersant, nanometer TiO2, emulsion or water dispersoid resin, filler, anti-settling agent, flatting agent, thickener, pH regulator, scratch resistance agent or slipping agent, pigment or coloring agent, additive with special function and the like. The preparation method includes the steps of: A. preparing the water dispersoid; B. adding the water dispersoid obtained in the step A into the stirred emulsion, then adding the assistant for film forming, the flatting agent, the thickener, the anti-settling agent, and the pH regulator and uniformly stirring and dispersing the components; C. adding the pigment or the coloring agent; and D. charging water and adjusting the Stormer viscosity at the temperature of 25 DEG C to be 65-90KU, thus obtaining the water paint. The water paint provided in the invention has good adhesion to wood materials, full paint films with certain hardness, low VOC, no heavy metal, and the antibacterial and mildewproof functions, and belongs to the environment-friendly and safe children woodwork water paint.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Self-drying type water-solubility alkyd resin and preparation method thereof

InactiveCN101148497AImprove film hardness and water resistanceFull paint filmPolyester coatingsMaleic anhydrideSolubility

The present invention discloses one kind of self dried water soluble alkyd resin containing flax seed oil fatty acid, trimethylol propane, neopentylene glycol, m-phthalic acid, maleic anhydride, trimellitic anhydride, triethylamine, cosolvent, drying agent and leveling agent. It is prepared through the following steps: 1. mixing flax seed oil fatty acid, trimethylol propane, neopentylene glycol and m-phthalic acid, heating to 230-235 deg.c to react while introducing inert gas, and distilling off esterification produced water; 2. cooling to 170 deg.c after the acid value of the resin is lowered to below 10 mgKOH / g, adding maleic anhydride and trimellitic anhydride, and reaction at 170 deg.c until reaching acid value of 40-60 mgKOH / g; 3. cooling and adding assistants gradually, regulating pH value to 7.5-8.5, adding pure water, etc. to obtain the transparent homogeneous resin. The preparation process has less organic solvent discharging, and the resin can form film with excellent performance.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Antibacterial water color ink and method for preparing same

The invention relates to an antibacterial water color ink for printed matters for packaging children products and a method for preparing the same. The method comprises the following steps: firstly, according to the stated weight percentage, evenly mixing and stirring part of a water soluble resin dispersoid, an amine stabilizer, a latent solvent, a bactericidal agent, deionized water and an antifoaming agent, then adding a pigment into the mixture, and dispersing the pigment at a rotating speed of between 500 and 1,200 rpm to prepare an even water soluble dispersed slurry; and secondly, pumping the water soluble dispersed slurry obtained in the step A into a sand mill by a pump, grinding the slurry until the fineness is less than or equal to 10 microns, then adding the remaining water soluble resin dispersoid, a wetting agent and a rheology modifier to the slurry, stirring the mixture until the materials are dispersed and mixed evenly, and adjusting the viscosity to prepare the antibacterial water color ink. The antibacterial water color ink prepared by the method has good adhesive force to various base materials or textiles, and the varnish thereof is full and has certain flexibility; besides, the antibacterial water color ink has low smell and ultra-low VOC without PAE and heavy metals, and has good antibacterial and antifungus functions.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Self-cleaned high-weather resistance aqueous acrylic polyurethane top coating and preparation method

InactiveCN107163807AFull paint filmHigh hardnessFireproof paintsAntifouling/underwater paintsChemistryWeather resistance

The invention discloses a self-cleaned high-weather resistance aqueous acrylic polyurethane top coating and a preparation method. The top coating is a double-component aqueous acrylic polyurethane coating which comprises a component A and a component B, wherein the component A comprises the following components in parts by weight: 40-60 parts of an aqueous hydroxyl acrylic dispersion, 10-20 parts of a pigment filler, 5-20 parts of graphite-phase carbon nitride, 10-20 parts of an aqueous polyaniline emulsion, 1-3 parts of an organic silicon leveling agent, 1-2 parts of a defoaming agent, 4-8 parts of filming aids, 1-2 parts of a neutralizer, 1-3 parts of a dispersing agent, 3-6 parts of an alkali dissolution type thickening agent and 5-13 parts of deionized water; the component B comprises 10-30 parts of aliphatic isocyanate and 4-10 parts of propylene carbonate. The self-cleaned high-weather resistance aqueous acrylic polyurethane top coating disclosed by the invention can be dried by self, can be also dried with heat at 80 DEG C and is rich in coating film, high in hardness and good in chemical resistance; due to introduction of the graphite-phase carbon nitride into the aqueous coating, the self cleaning property of the coating film can be improved, a great amount of labor and materials are saved, and meanwhile the wearing resistance and the thermal stability of the self-cleaned high-weather resistance aqueous acrylic polyurethane top coating are improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Formaldehyde-resistance odor-removing total-effect environmental-friendly water-borne wood white paint and preparation technology thereof

InactiveCN102146257ATake care of your healthFull paint filmPolyurea/polyurethane coatingsPolyether coatingsTotal effectsDefoamer

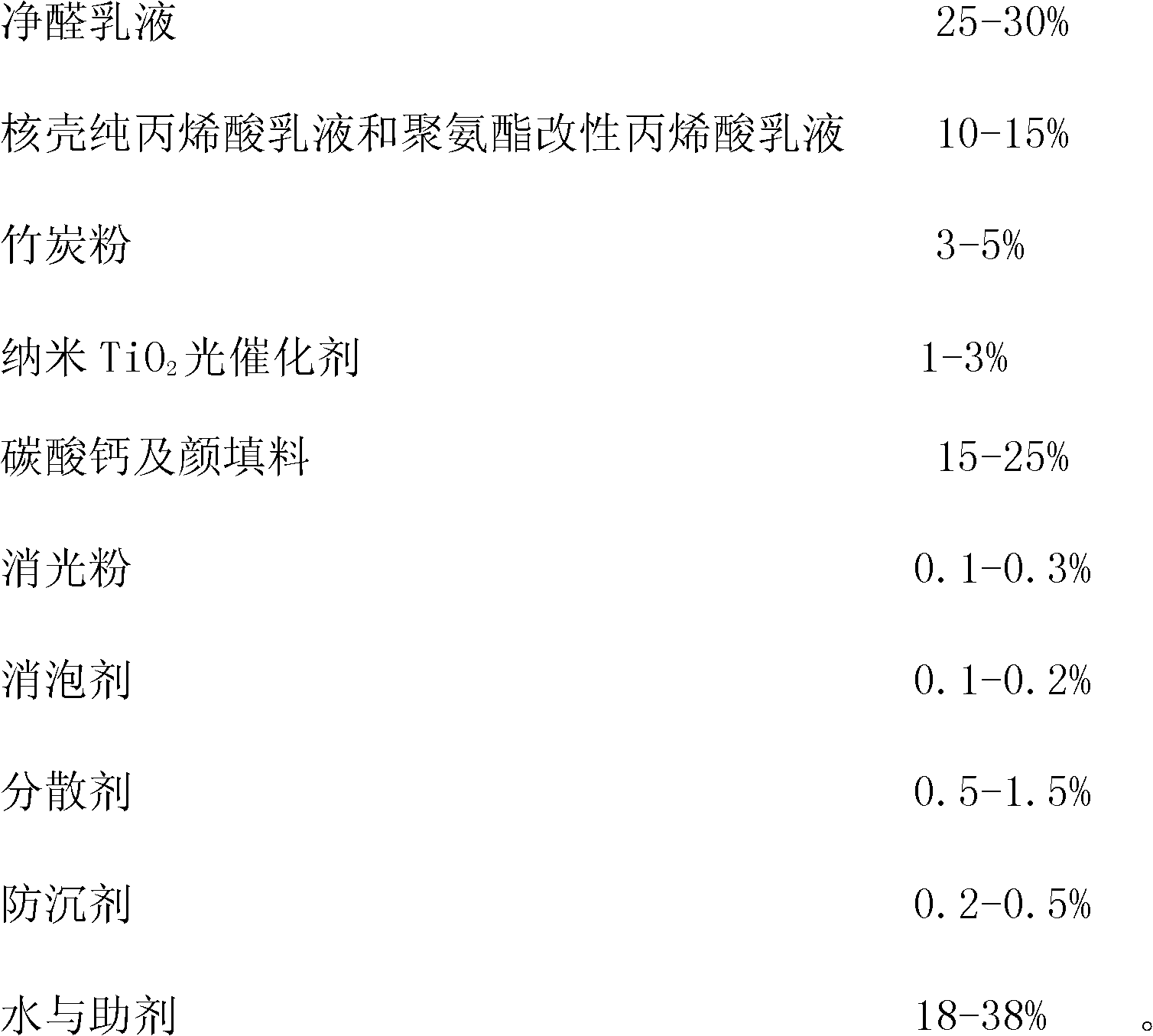

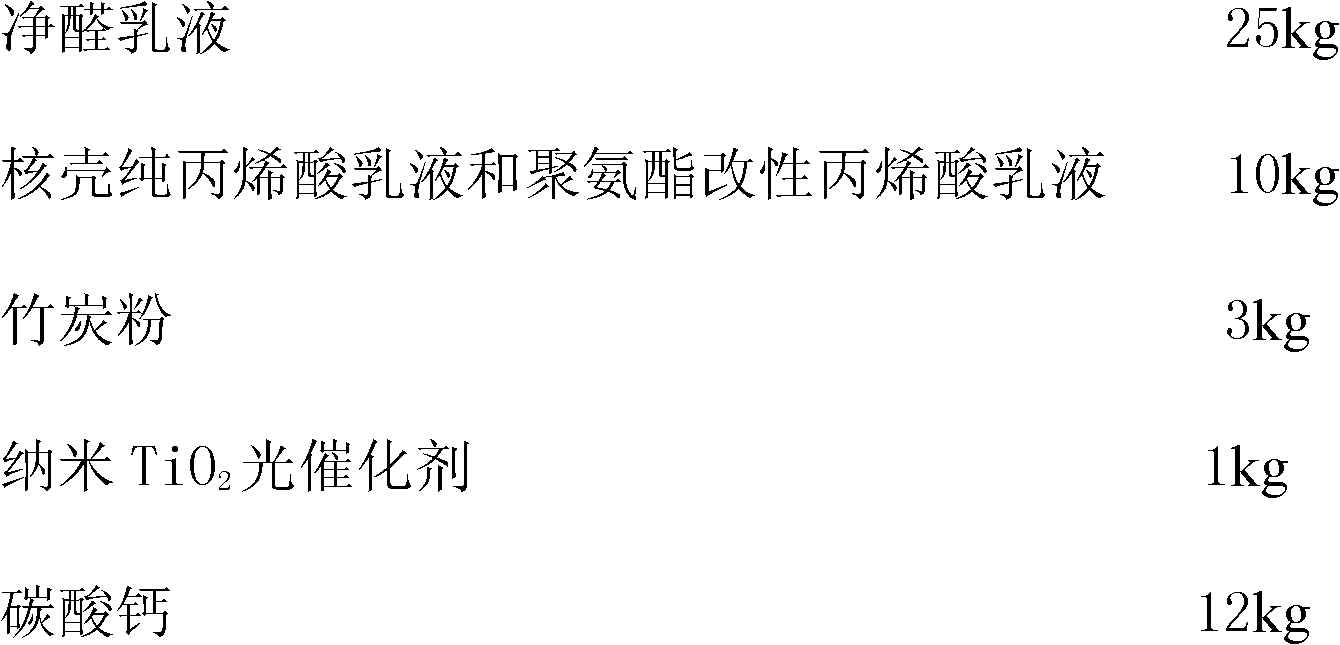

The invention discloses a formaldehyde-resistance odor-removing total-effect environmental-friendly waterborne wood white paint and a preparation technology thereof. The wood white paint comprises the following components in percentage: 25 to 30 percent of formaldehyde removing emulsion, 10 to 15 percent of core-shell pure acrylic acid emulsion and polyurethane modified acrylic acid emulsion, 3 to 5 percent of bamboo carbon powder, 1 to 3 percent of nano TiO2 photocatalyst, 15 to 25 percent of calcium carbonate and pigment and filler, 0.1 to 0.3 percent of delustering powder, 0.1 to 0.2 percent of antifoaming agent, 0.5 to 1.5 percent of dispersing agent, 0.2 to 0.5 percent of anti-sedimentation agent and 18 to 38 percent of water and auxiliaries. The preparation technology comprises the following steps of: firstly adding the core-shell pure acrylic acid emulsion and the polyurethane modified acrylic acid emulsion into a dispersing cylinder and dispersing at an intermediate speed; then uniformly adding micron active bamboo carbon powder; after dispersing for 15 to 30 minutes at a high speed, adding the formaldehyde removing emulsion, scratch resistance wax additive, the water, thedispersing agent, the delustering agent, the antifoaming agent, the anti-sedimentation agent and other components; after dispersing for 40 minutes at an intermediate speed, sampling and detecting thefineness and the viscosity of a finished product; and carrying out filtering, canning and packaging on the finished product.

Owner:中山蓝海洋水性涂料有限公司

Green and environment-friendly anti-ageing coating

InactiveCN106995642AEffectively control the degree of open loopEasy to processAnti-corrosive paintsEpoxy resin coatingsFiberEnvironmental resistance

The invention discloses green and environment-friendly anti-ageing coating. The green and environment-friendly anti-ageing coating is prepared from the following raw materials in parts by weight: 90 to 110 parts of waterborne resin, 3 to 7 parts of melamine, 15 to 25 parts of a starch compound, 12 to 18 parts of talcum powder, 8 to 16 parts of jute fibers, 4 to 8 parts of sepiolite powder, 5 to 9 parts of microencapsulated red phosphorus, 6 to 10 parts of pigment, 5 to 9 parts of zinc oxide, 12 to 14 parts of magnesium hydroxide, 6 to 8 parts of chlorinated paraffin, 8 to 14 parts of absolute ethyl alcohol, 25 to 35 parts of polyethylene wax, 4 to 8 parts of sodium dodecyl sulfate, 1 to 2 parts of an antibacterial agent, 1 to 2 parts of a mildew preventive, 1 to 2 parts of a de-foaming agent, 1 to 2 parts of a wetting agent and 40 to 80 parts of water. The green and environment-friendly anti-ageing coating has the advantages of strong adhesive force, uneasiness of becoming yellow and brittle, plump paint film, capability of inhibiting volatilization of toxic gas, extremely good anticorrosion performance, excellent comprehensive performance and long service life and can be widely used for producing and continuously replacing an existing material.

Owner:安徽三义和能源科技有限公司

Formaldehyde-resistance odor-removing total-effect environmental-friendly water-borne wood white paint and preparation technology thereof

InactiveCN102146257BTake care of your healthFull paint filmPolyurea/polyurethane coatingsPolyether coatingsEnvironmental resistanceLacquer

The invention discloses a formaldehyde-resistance odor-removing total-effect environmental-friendly waterborne wood white paint and a preparation technology thereof. The wood white paint comprises the following components in percentage: 25 to 30 percent of formaldehyde removing emulsion, 10 to 15 percent of core-shell pure acrylic acid emulsion and polyurethane modified acrylic acid emulsion, 3 to 5 percent of bamboo carbon powder, 1 to 3 percent of nano TiO2 photocatalyst, 15 to 25 percent of calcium carbonate and pigment and filler, 0.1 to 0.3 percent of delustering powder, 0.1 to 0.2 percent of antifoaming agent, 0.5 to 1.5 percent of dispersing agent, 0.2 to 0.5 percent of anti-sedimentation agent and 18 to 38 percent of water and auxiliaries. The preparation technology comprises the following steps of: firstly adding the core-shell pure acrylic acid emulsion and the polyurethane modified acrylic acid emulsion into a dispersing cylinder and dispersing at an intermediate speed; then uniformly adding micron active bamboo carbon powder; after dispersing for 15 to 30 minutes at a high speed, adding the formaldehyde removing emulsion, scratch resistance wax additive, the water, thedispersing agent, the delustering agent, the antifoaming agent, the anti-sedimentation agent and other components; after dispersing for 40 minutes at an intermediate speed, sampling and detecting thefineness and the viscosity of a finished product; and carrying out filtering, canning and packaging on the finished product.

Owner:中山蓝海洋水性涂料有限公司

Water-based environment-friendly paint for furniture

InactiveCN106957596AEffectively control the degree of open loopEasy to processAntifouling/underwater paintsPaints with biocidesWater basedSodium bicarbonate

The invention discloses a water-based environment-friendly paint for furniture. The paint comprises the following raw materials in parts by weight: 38-46 parts of water-based alkyd resin, 60-80 parts of water-based polyurethane, 4-8 parts of iron oxide red, 7-9 parts of lithopone, 85-95 parts of filler, 5-10 parts of phenolic resin, 3-6 parts of zinc borate, 8-10 parts of sodium bicarbonate, 55-60 parts of an emulsifying agent, 14-18 parts of absolute ethyl alcohol, 2-4 parts of an antibacterial agent, 2-4 parts of a mildew preventive, 2-3 parts of a defoaming agent, 3-4 parts of a wetting agent, and 60-100 parts of water. The paint is high in attaching performance, free from yellowing and embrittlement, full in a paint film, free from toxic gas, extremely high in corrosion resistance, outstanding in comprehensive performance, and long in service life, and can be widely used for producing and continuously replacing conventional materials.

Owner:安徽三义和能源科技有限公司

A high-weather-resistant comprehensive exterior wall special paint and its preparation method

InactiveCN106810978AHas erosionImproves UV resistanceAnti-corrosive paintsRadiation-absorbing paintsPolymer scienceCalcium carbonate

The invention relates to a high-weather-resistance comprehensive exterior wall special paint and its preparation method, which belong to the technical field of building decoration materials. Polymer 13%~15%, Acrylate emulsion 20%~30%, Ethylene-vinyl acetate copolymer emulsion 5%~15%, Silicon acrylic emulsion 30%~40%, Propylene glycol methyl ether acetate 5%~9%, 4%-7% of light ethyl cellulose, 5%-8% of barite powder and 50%-60% of auxiliary materials; the invention has high weather resistance, good stain resistance, friction resistance, powder resistance, The advantages of aging, waterproof performance, etc., long service life.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

Novel furniture paint

The invention discloses a novel furniture paint which is formed by mixing the following ingredients: polydivinyl acetylene, triethanolamine, sodium tetraborate, castor oil, bisphenol A-type modified phenolic resin, rosin water, turpentine, a styrene-acrylic emulsion, a pearlescent paint and an additive. The invention has the following beneficial effects: the paint is not yellowing or crispy; a paint film is thick; and poisonous gas can be inhibited from being volatized.

Owner:SHIFANG MIDEE WOOD IND

Wooden furniture paint

The invention discloses a wooden furniture paint, which is mainly prepared by stirring the following raw materials according to a weight ratio: 100-110 parts of methyl methacrylate, 52-56 parts of vinyl chloride acetate resin, 14-16 parts of phenylethyl acetate, 50-54 parts of ethanol, 7 parts of flatting agent, 4 parts of antifoaming agent, 6 parts of sodium bicarbonate and 4 parts of sodium persulfate. As proved by industrial tests, the paint has the advantages of strong coating adhesion, no yellowing or brittleness, rich paint film and capability of suppressing volatilization of toxic gas.

Owner:WUJIANG TIANYUAN PLASTIC

Environment-friendly water-based crackle coating and preparation method thereof

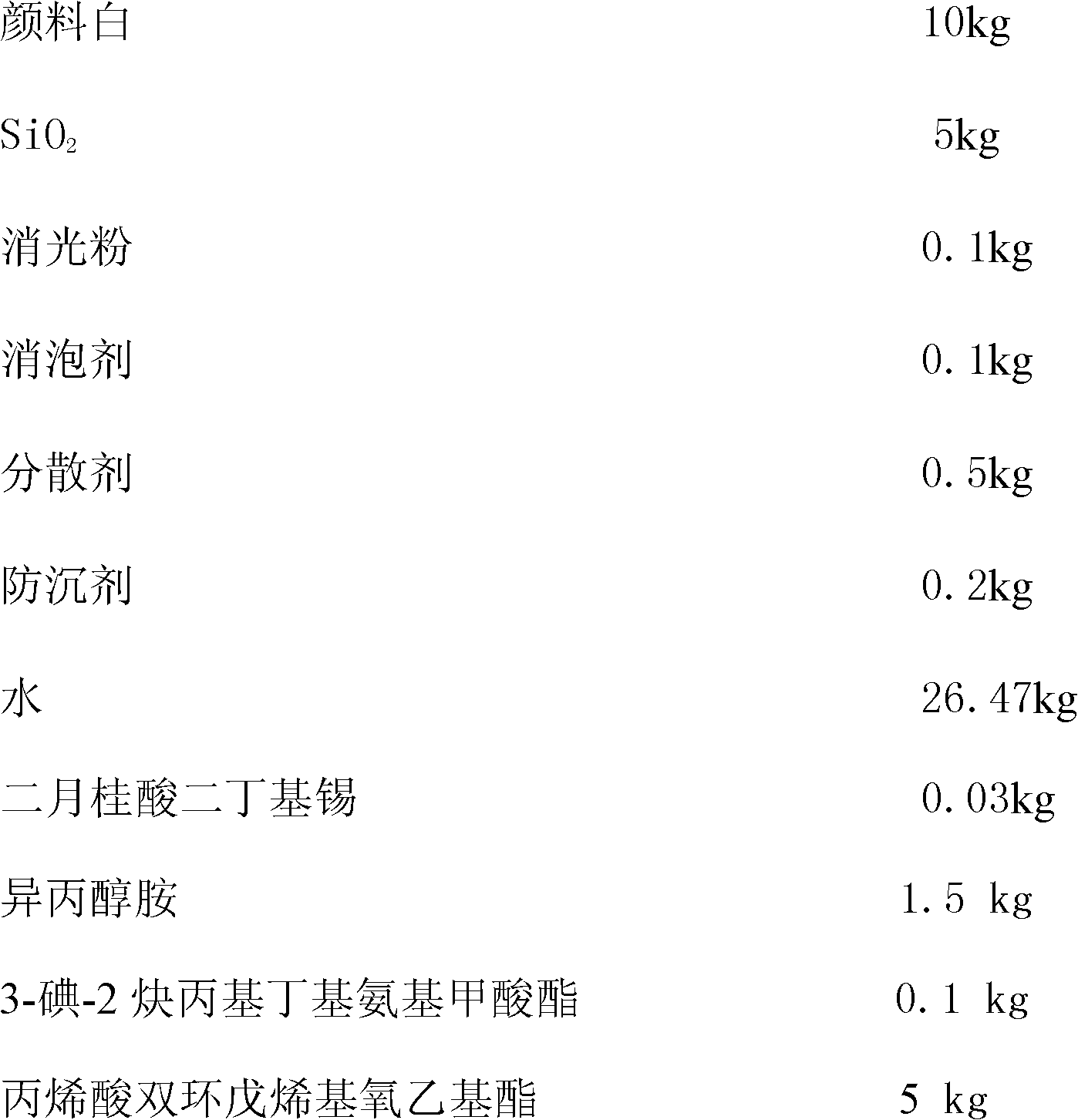

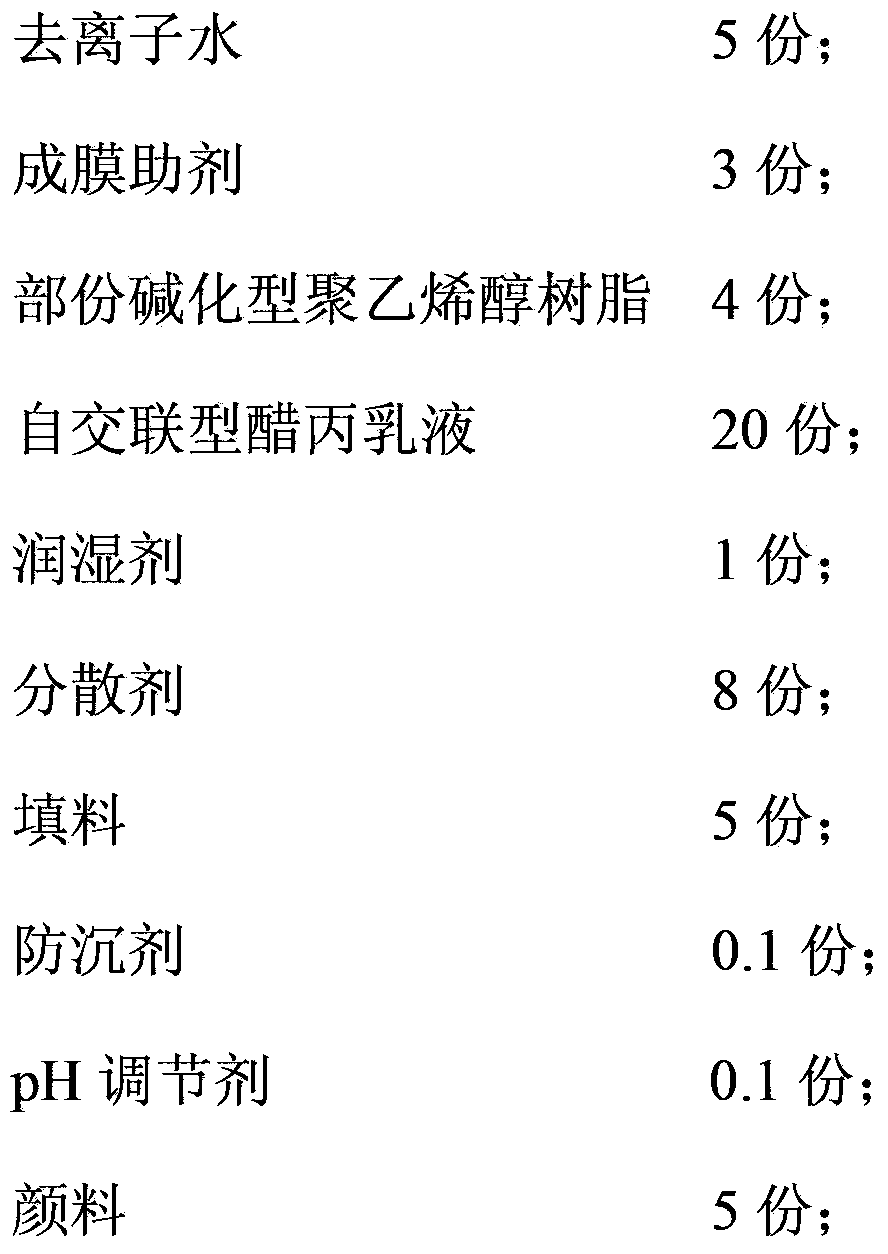

The invention relates to an environment-friendly water-based crackle coating, containing the following components in parts by weight: 5-40 parts of deionized water, 3-15 parts of a film forming auxiliary agent, 4-25 parts of partially alkalized polyvinyl alcohol resin, 4-20 parts of a self-crosslinking vinyl acetate-acrylic emulsion, 0.1-1 part of a wetting agent, 2-8 parts of a dispersant, 5-30 parts of a filler, 0.1-1 part of an anti-settling agent and 0.1-1 part of a pH regulator. The environment-friendly water-based crackle coating has good adhesive force to wood materials, ceramic products and the like, can form a full paint film, has certain hardness and low VOC (volatile organic compounds), does not contain heavy metals, belongs to environment-friendly safe wooden article water-based coatings, and can generate a special crack effect at the same time.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Coating for metal surface of security door

ActiveCN103421413AStrong adhesionNot easy to peel offEpoxy resin coatingsPolyester coatingsCellulosePolymer science

Coating for a metal surface of a security door is composed of the following components, by mass, 60-70 parts of epoxy resin E-12, 40-45 parts of polyester resin, 20-25 parts of cellulose acetate butyrate, 50-55 parts of PU curing agents, 20-30 parts of trioctyl trimellitate, 10-15 parts of titanium dioxide, 25-30 parts of hexamethoxy methyl melamine, 0.05-1 part of fluorine-based alkyl polyether modified polysiloxane, 30-40 parts of p-toluene sulfonic acid n-butanol and 5-10 parts of ultraviolet absorbent UV-329. The coating is smooth in surface, the paint surface is smooth, a coating is high in adhesive force and not prone to stripping, the coating is long in service life and resists wear and acid-base corrosion, the loss is 0.01g after the coating is worn 10000 times, a paint film of the product is full, good in weather resistance and free of harming personal health of users, and the coating can be widely produced and can continuously replace existing materials.

Owner:江苏悠谷未来科技有限公司

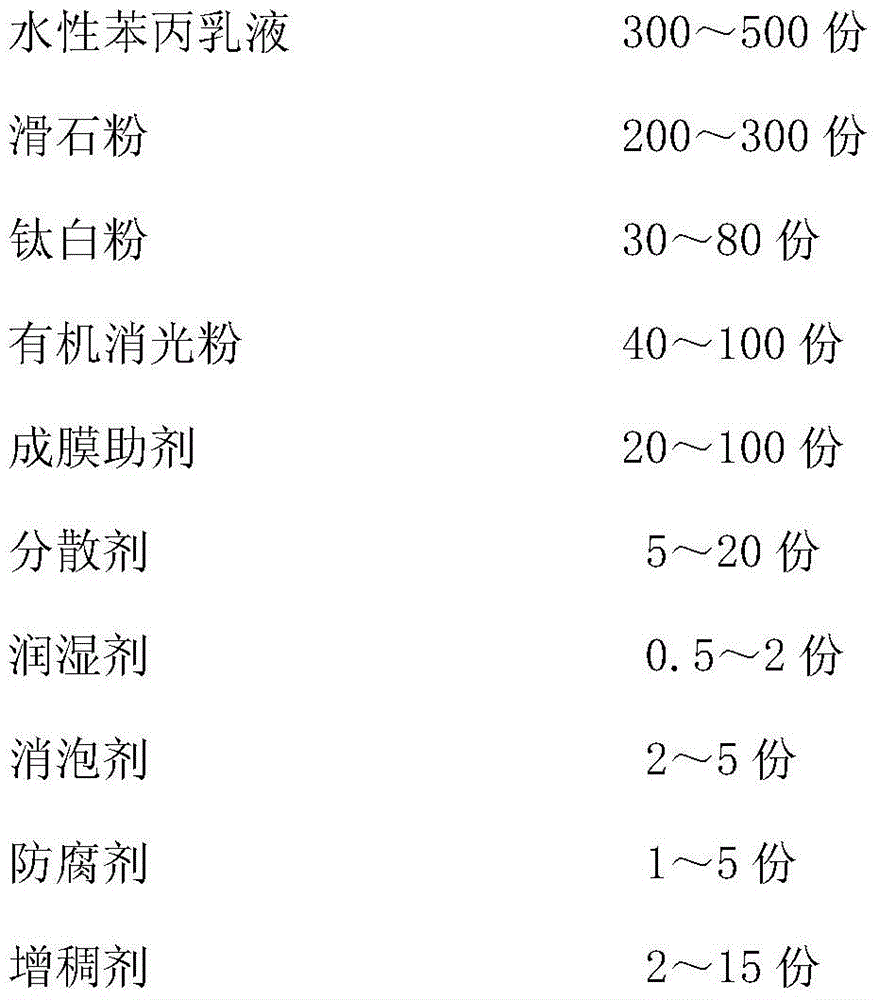

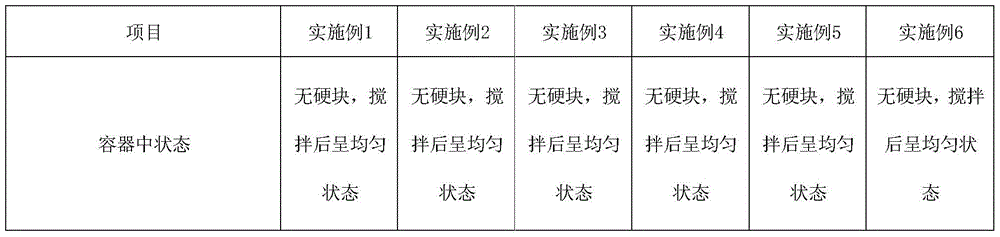

Novel associative water-based interior wall latex paint and production method thereof

The invention discloses novel associative water-based interior wall latex paint and a production method thereof. The novel associative water-based interior wall latex paint is prepared from the following raw materials of pure water, a dry film preservative, carboxymethylcellulose, a water glass disperser, a wetting agent, glycerol, a defoaming agent, a PH adjusting agent, anatase titanium dioxide, superfine kaolin, heavy calcium carbonate of 1,000 meshes, a film forming auxiliary, an acrylate type leveling agent, water-based associative pure acrylate emulsion, an in-can preservative, an alkali-swelled thickening agent, an associative alkali-swelled thickening agent and an associative thickening agent which are premixed, dispersed, blended, toned, filtered and packaged to obtain packed latex paint.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

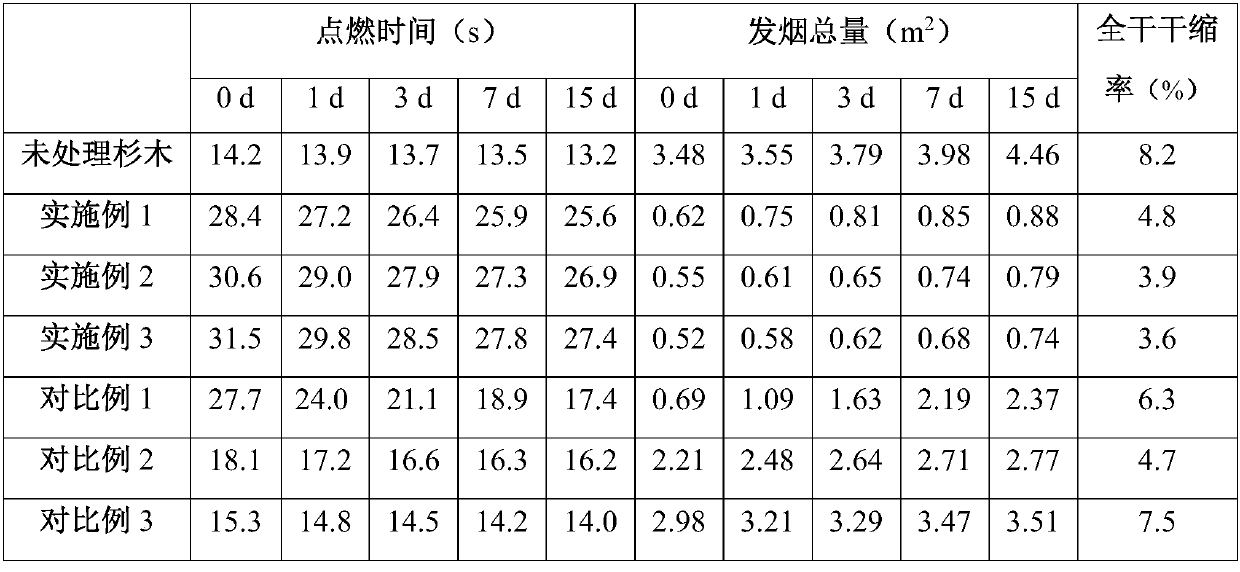

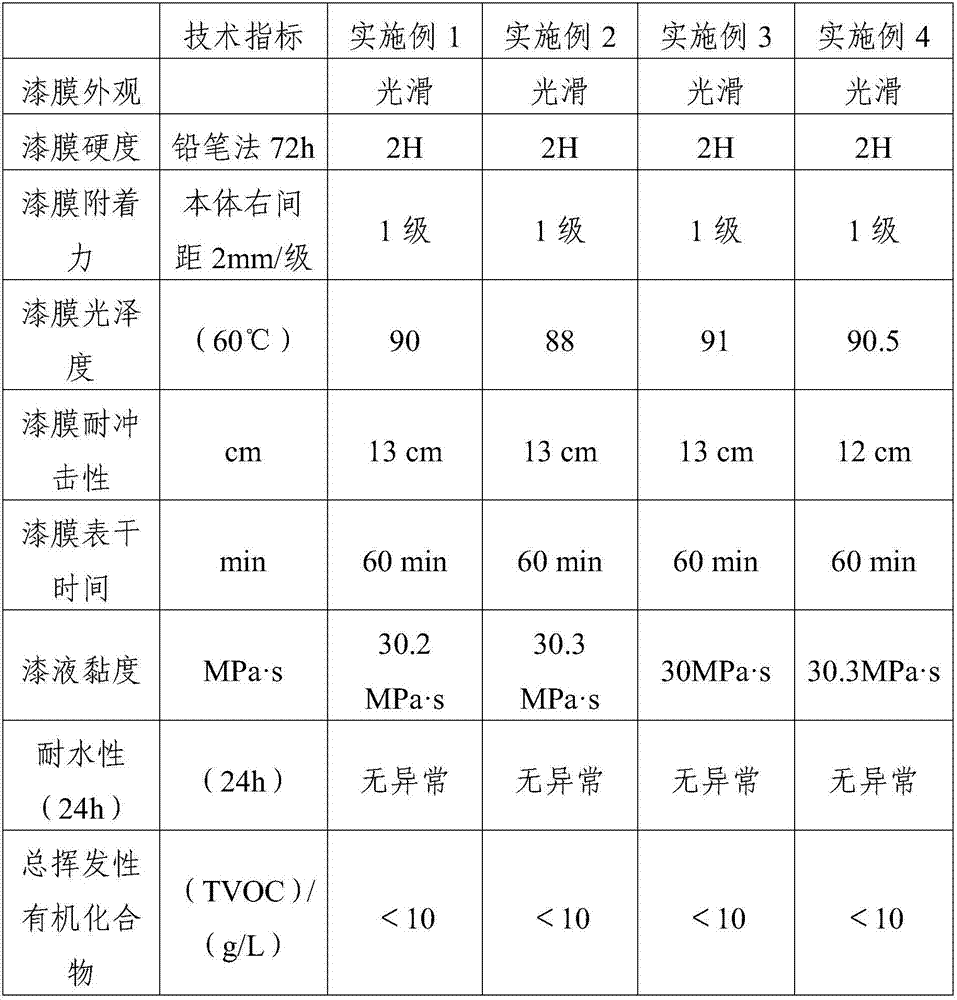

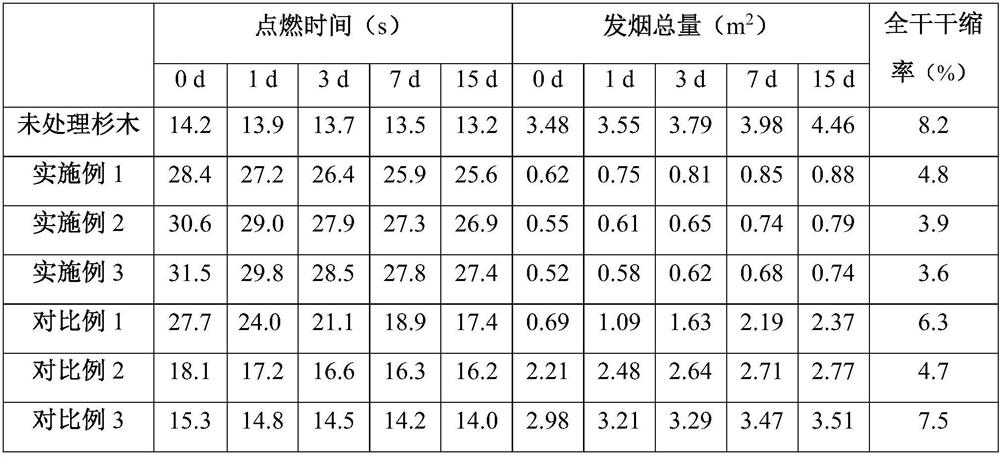

Cunninghamia lanceolata flame-retardant modification treatment method

ActiveCN110733093AGood dispersionImprove stabilityImpregnation spraying apparatusWood treatment detailsOrganic chemistryEcology

The invention discloses a cunninghamia lanceolata flame-retardant modification treatment method, and belongs to the technical field of wood flame-retardant treatment. The flame-retardant modificationtreatment method comprises the following steps: carrying out primary spray modification treatment on cunninghamia lanceolata by using a 4, 4 '-diphenylmethane diisocyanate solution, carrying out secondary spray modification treatment on the cunninghamia lanceolata by using a 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide solution, and finally carrying out tertiary spray modification treatmenton the cunninghamia lanceolata by using a phenolic resin solution. The flame-retardant modification treatment method provided by the invention not only can significantly improve the flame retardancy,flame-retardant stability and dimensional stability of fir, but also is simple and easy to operate, and is convenient for realizing industrial mass production.

Owner:福建省顺昌县升升木业有限公司

Novel high performance acrylic modified polyurethane water-borne wood paint

InactiveCN107418424AMeet performance needsImprove water resistanceAntifouling/underwater paintsPaints with biocidesSolventDimethyl siloxane

The invention relates to the field of wood paint and in particular relates to novel high performance acrylic modified polyurethane water-borne wood paint. The wood paint is prepared from the following raw materials in parts by weight: 60-80 parts of Novel high performance acrylic modified polyurethane water-borne wood paint polyether waterborne polyurethane, 10-20 parts of a hexamethylene diisocyanate tripolymer, 10-30 parts of trihydroxyl methyl propane, 1-10 parts of n-butyltin dilaurate, 0.5-2.0 parts of sodium dodecyl sulfate, 1-5 parts of propylene glycol phenylate, 0.1-1.5 parts of polydimethylsiloxane, 0.3-1.6 parts of fluoro modified acrylate, 0.1-0.6 part of sodium hexametaphosphate, 0.1-0.3 part of a preservative, 0.2-0.8 part of an anti-ageing agent, 20-30 parts of water and a proper amount of a PH regulator. Besides excellent environmental protection and safety properties, the water-borne wood paint prepared by the method provided by the invention also has the advantages of moderate price, high adhesive force, relatively high coating hardness, corrosion resistance, solvent resistance, water resistance, capability of being quickly dried and good glossiness, and meets the market demand.

Owner:肇庆高新区恒泰信息服务有限公司

A kind of flame retardant modification treatment method of Chinese fir

ActiveCN110733093BGood dispersionImprove stabilityImpregnation spraying apparatusWood treatment detailsOrganic chemistryMaterials science

The invention discloses a cunninghamia lanceolata flame-retardant modification treatment method, and belongs to the technical field of wood flame-retardant treatment. The flame-retardant modificationtreatment method comprises the following steps: carrying out primary spray modification treatment on cunninghamia lanceolata by using a 4, 4 '-diphenylmethane diisocyanate solution, carrying out secondary spray modification treatment on the cunninghamia lanceolata by using a 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide solution, and finally carrying out tertiary spray modification treatmenton the cunninghamia lanceolata by using a phenolic resin solution. The flame-retardant modification treatment method provided by the invention not only can significantly improve the flame retardancy,flame-retardant stability and dimensional stability of fir, but also is simple and easy to operate, and is convenient for realizing industrial mass production.

Owner:福建省顺昌县升升木业有限公司

a furniture coating

InactiveCN104263096BStrong coating adhesionFull paint filmAnti-corrosive paintsPyrophylliteDiethyl ether

The invention discloses a furniture coating, which is prepared from the following raw materials in proportion by weight: high-density polyethylene, pentachlorophenol, acetyl tributyl citrate, dimethyl sulfoxide, ammonium dihydrogen phosphate, and EVA resin , ferrous sulfate, cast stone powder, light calcium carbonate, pyrophyllite, chromium carbonate, butylated hydroxyanisole, ammonium octamolybdate, polytetrafluoroethylene, graphite powder, ricinoleic acid, acrylic resin, nano calcium carbonate powder, three Ethanolamine, beryllium oxide, diethylene glycol monoethyl ether, dioctyl maleate, sodium petroleum sulfonate, diethanolamine, tert-butyl cresol, technical lecithin, propylene carbonate, ethyl acetate. Beneficial effects of the present invention: the coating has strong coating adhesion, no yellowing or brittleness, plump paint film, inhibits volatilization of toxic gases, and good heat dissipation effect. Raw materials such as nano-calcium carbonate powder increase the anti-corrosion performance of the product, and the comprehensive performance is superior. .

Owner:SHIFANG MIDEE WOOD IND

Waterborne environment-friendly glass paint

InactiveCN109749542AFull paint filmShorten drying timeWax coatingsPolyurea/polyurethane coatingsRecoatingHardness

The invention relates to the technical field of coatings, in particular to waterborne environment-friendly glass paint which has the advantages of plump paint film, rapidness in drying, short recoating time, excellent chemical resistance, blocking resistance, scratch resistance and adhesive force, high hardness and water resistance, non-flammable and non-explosive properties, no toxicity and foreign taste and the like. The glass paint has good functions of preserving and insulating heat and saving energy. When the glass paint is applied to building curtain walls, glass and the like, heat insulation and heat preservation capability of a building can be effectively improved, and energy consumption is reduced. The preparation method of the waterborne environment-friendly glass paint is simplein process, water can be added into the glass paint to dilute the glass paint in the using process, construction is convenient and rapid, and construction efficiency can be effectively improved.

Owner:吴春燕

A kind of water-based environmental protection crack paint and preparation method thereof

ActiveCN104530846BStrong adhesionExcellent artistic aestheticsAnti-corrosive paintsWater basedWeather resistance

The invention relates to the technical field of paint, and particularly relates to a water-borne environment-friendly crack lacquer and a preparation method thereof. The water-borne environment-friendly crack lacquer has the advantages of excellent adhesion, clear and ultra-strong texture artistic aesthetic feeling, full paint film, high drying speed, excellent chemical resistance, weather resistance and scratch resistance, ultra-strong hardness and the like; and the preparation method of the water-borne environment-friendly crack lacquer is simple in process, water can be directly added for diluting in the using process, the construction is convenient and quick, and the construction efficiency can be effectively improved.

Owner:中山市诚美涂料有限公司

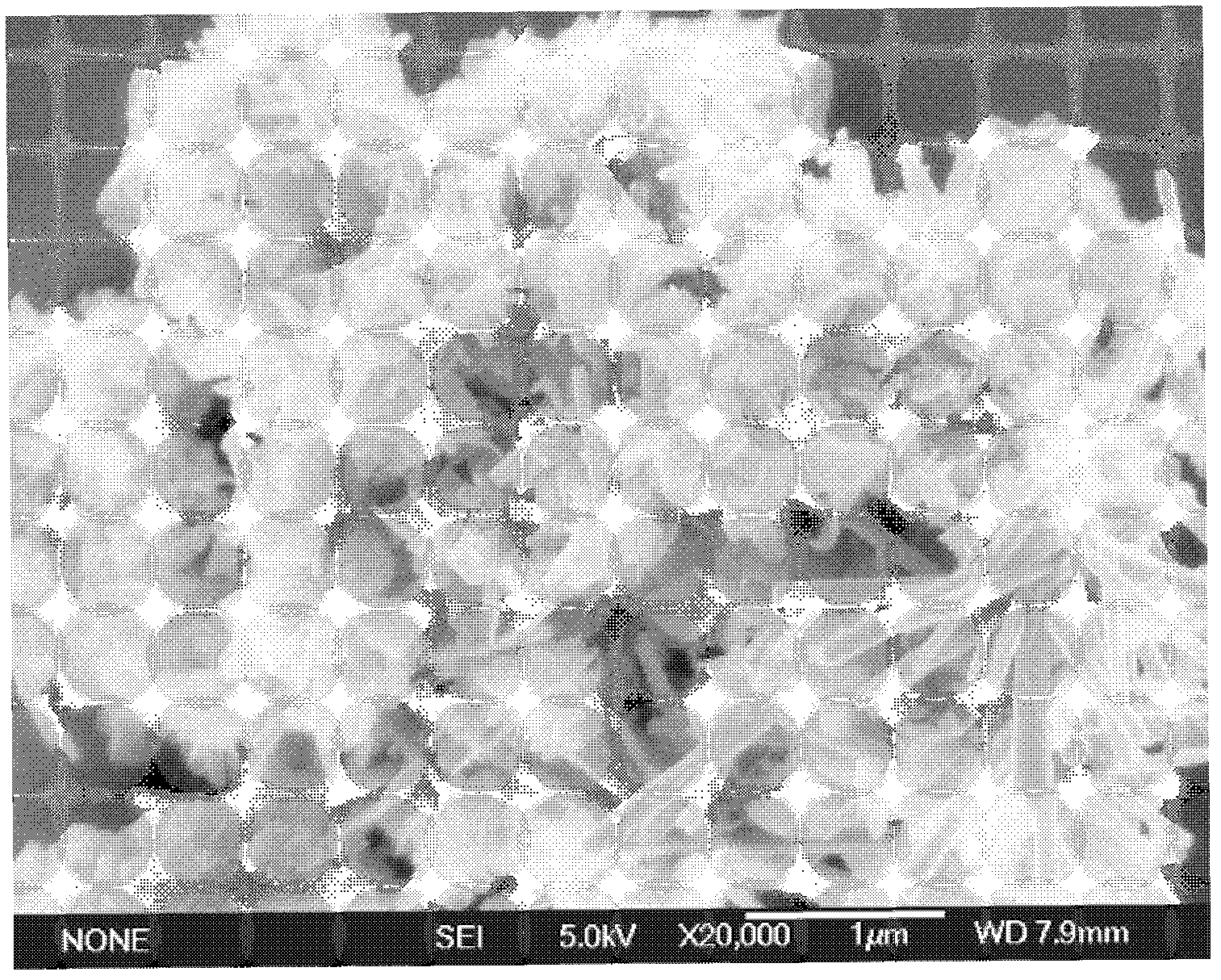

Preparation method and application of ZnO/TiO2 composite powder

ActiveCN102618109BEasy to operateLower temperature conditionsAntifouling/underwater paintsPaints with biocidesAdhesion forceLacquer

The invention discloses a preparation method and application of ZnO / TiO2 composite powder. The preparation method comprises the following steps: dissolving soluble a zinc salt, a surfactant and butyl titanate in alcohol, and mixing to obtain a raw material liquid; adding a strong base aqueous solution to the raw material liquid under the stirring condition to obtain a mixed liquid; and reacting the mixed liquid at 120-180 DEG C for 8-16h, washing and drying to obtain the ZnO / TiO2 composite powder. The preparation method is relatively low in temperature conditions, good in controllability, simple in preparation and strong in operability, is favorable to industrialized popularization and production, and has wide application prospects. The obtained ZnO / TiO2 composite powder is complete in crystallization, small in original granularity, uniform in distribution and low in agglomeration, and is particularly suitable to be used as an additive for an automobile paint to be applied to the automobile paint, so that the automobile finish coat has the advantages of being plump in lacquer film, level and bright, strong in adhesion force, high in hardness, good in light retention rate, excellent in natural solarization performance and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Environment friendly antibacterial waterborne paint and preparation thereof

InactiveCN101486861BImprove adhesionFull paint filmAntifouling/underwater paintsPaints with biocidesEmulsionHardness

The invention provides an environment-friendly antibacterial water paint and a preparation method thereof. The components include deionized water, germicide, assistant for film forming, defoaming agent, wetting agent, dispersant, nanometer TiO2, emulsion or water dispersoid resin, filler, anti-settling agent, flatting agent, thickener, pH regulator, scratch resistance agent or slipping agent, pigment or coloring agent, additive with special function and the like. The preparation method includes the steps of: A. preparing the water dispersoid; B. adding the water dispersoid obtained in the step A into the stirred emulsion, then adding the assistant for film forming, the flatting agent, the thickener, the anti-settling agent, and the pH regulator and uniformly stirring and dispersing the components; C. adding the pigment or the coloring agent; and D. charging water and adjusting the Stormer viscosity at the temperature of 25 DEG C to be 65-90KU, thus obtaining the water paint. The waterpaint provided in the invention has good adhesion to wood materials, full paint films with certain hardness, low VOC, no heavy metal, and the antibacterial and mildewproof functions, and belongs to the environment-friendly and safe children woodwork water paint.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Preparation method of plant modified water-based crackle lacquer

The invention discloses a preparation method of plant modified water-based crackle lacquer and belongs to the technical field of coating preparation. Lotus root and soybeans are fermented, a fermented supernatant fluid is obtained and then mixed with garcinia cambogia juice to obtain a mixture; then the mixture and natural resin of peach gum are mixed for modification to obtain a product, and epoxy resin is modified under the action of a microorganism through the product to obtain modified epoxy resin; and finally, the modified epoxy resin, water-based color paste and other raw materials are blended to obtain base coat, finishing coat is prepared through fluorocarbon resin, and the crackle lacquer can be obtained through combination of the base coat and the finishing coat. The epoxy resin is modified through amino acid in the fermented fluid of the lotus root and soybeans and hydroxycitric acid in garcinia cambogia under the action of the microorganism, various active groups in the epoxy resin are added, the base coat is prepared through the modified epoxy resin so that the chemical bonding force between the crackle lacquer and a base body can be increased, accordingly the attachment force of the crackle lacquer is increased, after curing of the base coat, excellent alkali resistance and attachment force are achieved, extremely low VOC and good flexibility are also achieved, the phenomenon that a lacquer face falls off after cracking of the crackles is avoided, and the application prospects are wide.

Owner:周荣

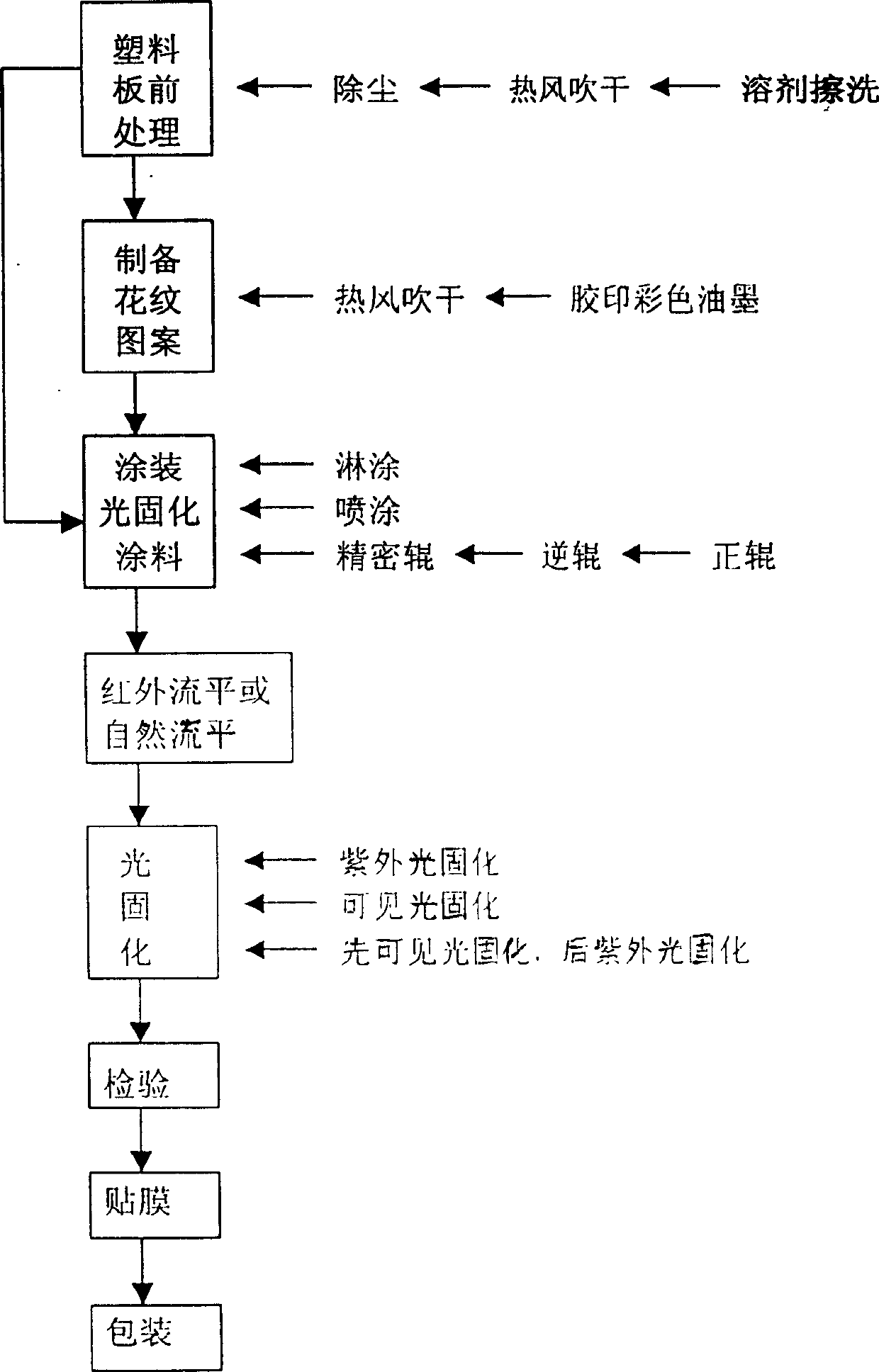

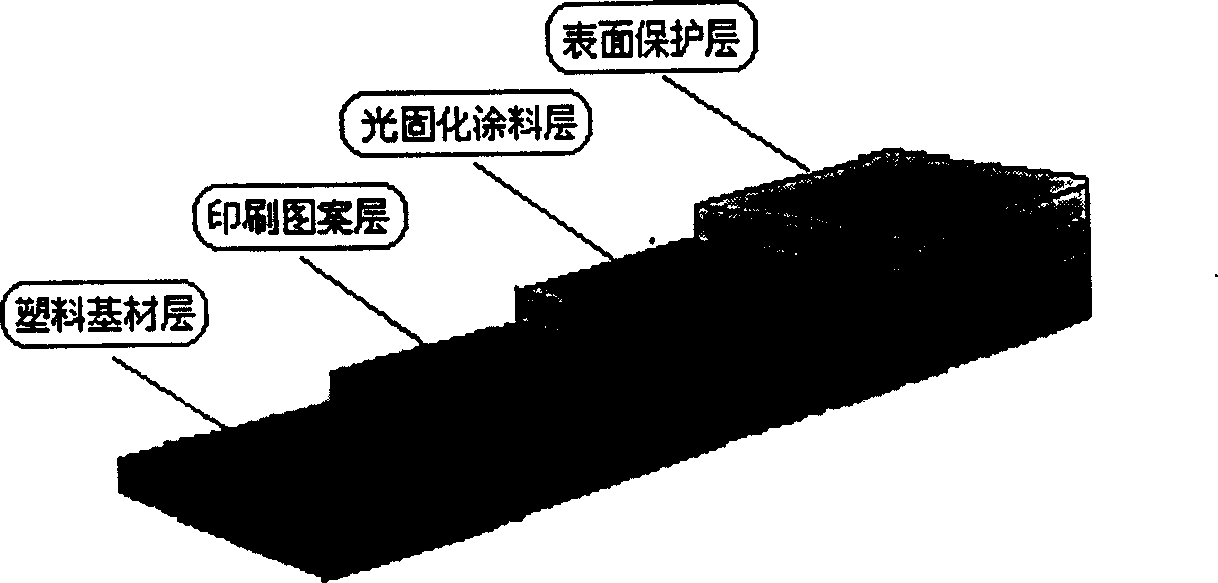

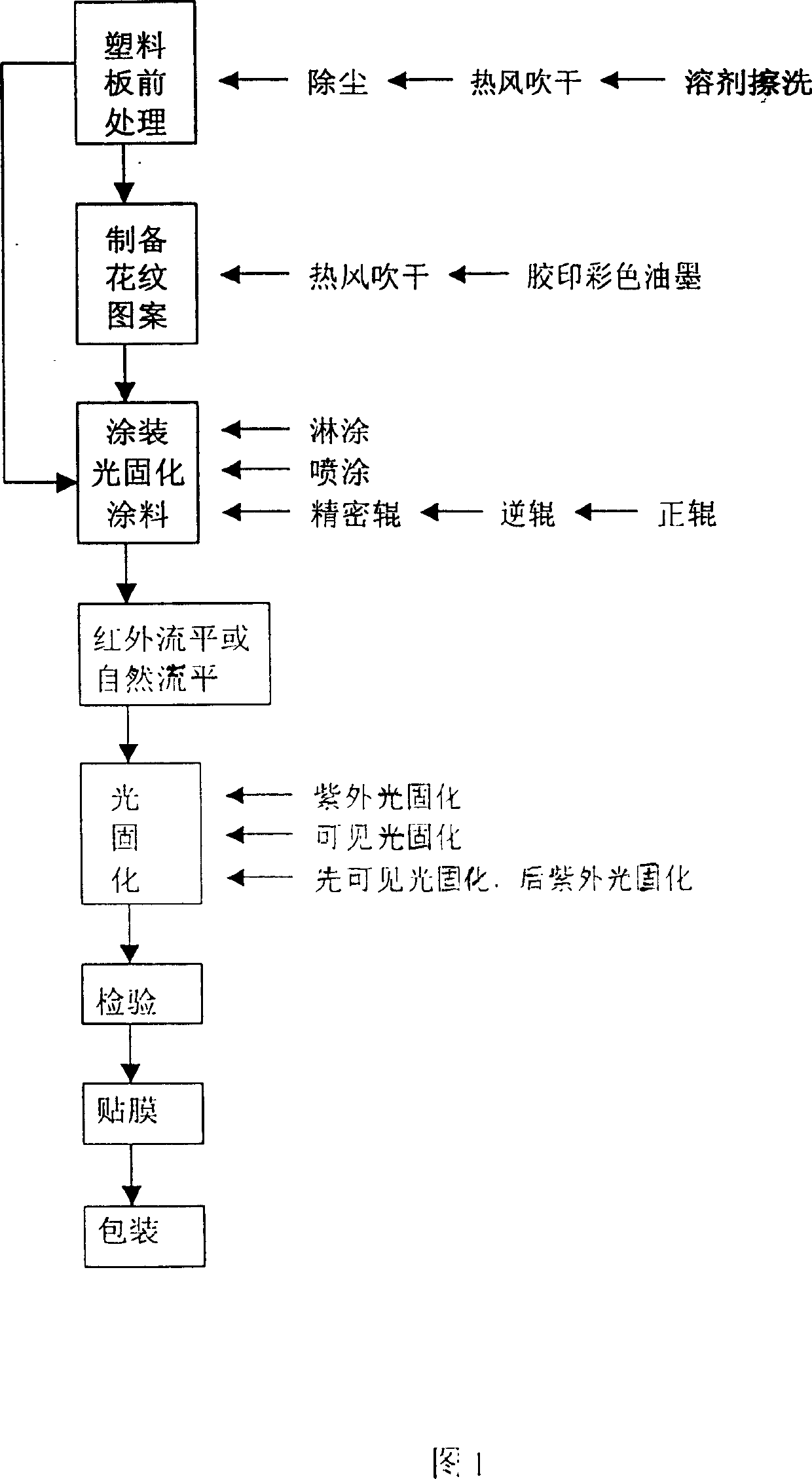

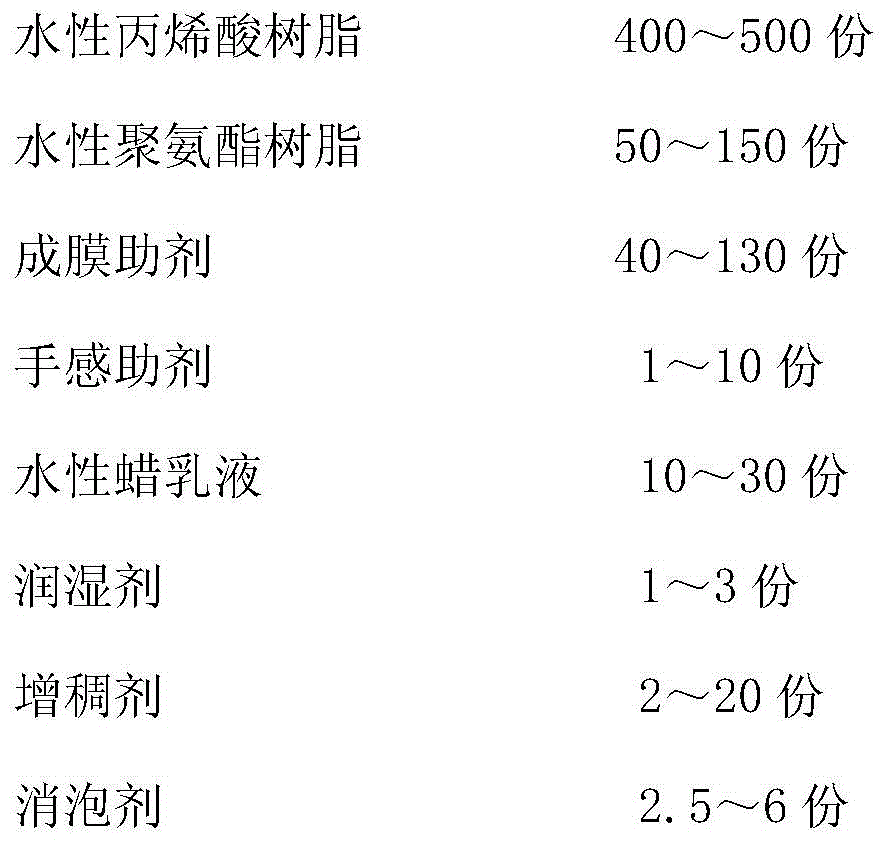

Method for preparing plastic decorative plates

InactiveCN1274741CImprove appearance performanceFull paint filmConstruction materialCoatingsEngineeringMirror effect

Owner:ZHUHAI DONGCHENG UV MATERIALS

A kind of water-based environment-friendly glass paint and preparation method thereof

ActiveCN104530868BFull paint filmShorten drying timeWax coatingsPolyurea/polyurethane coatingsWater basedHardness

The invention belongs to the technical field of paints and particularly relates to an environment-friendly water-based glass paint and a preparation method thereof. The environment-friendly water-based glass paint has the advantages of full paint film, short drying time, short re-applying time, excellent chemical resistance, adhesion resistance and scratch resistance, superhigh hardness, no extraneous odor, excellent adhesion and superstrong water resistance and is nonflammable, nonexplosive and nontoxic. In addition, the environment-friendly water-based glass paint has good heat preserving and insulating and energy saving functions, can be applied to curtain walls and glass of buildings to effectively improve the heat preserving and insulating capacity of buildings and reduce the consumption of energy. The preparation process of the environment-friendly water-based glass paint is simple, and the environment-friendly water-based glass paint can be directly diluted with water in the course of use, can be used in construction conveniently and rapidly and can be improved in construction efficiency.

Owner:广州市诚美涂饰工程有限公司

Anti-theft door metal panel coating

ActiveCN103421413BStrong adhesionNot easy to peel offEpoxy resin coatingsPolyester coatingsPolymer scienceCellulose acetate

An anti-theft door metal panel coating, the composition of which is expressed in parts by mass: 60-70 parts of epoxy resin E-12; 40-45 parts of polyester resin; 20-25 parts of cellulose acetate; PU curing 50-55 parts of agent; 20-30 parts of trioctyl trimellitate; 10-15 parts of titanium dioxide; 25-30 parts of hexamethoxymethylmelamine; 0.05-1 30-40 parts; 30-40 parts of n-butanol p-toluenesulfonate; 5-10 parts of ultraviolet absorber UV-329; the appearance of the product is smooth, and the paint surface is smooth; the coating has strong adhesion and is not easy to peel off; it is wear-resistant and resistant Acid and alkali corrosion, wear 10,000 times, loss 0.01g, long service life; the product has a full paint film, has excellent weather resistance and is not harmful to the user's personal health. It can be widely produced and continuously replace existing materials.

Owner:江苏悠谷未来科技有限公司

Baking automobile finish with high solid content and preparation method thereof

Baking automobile finish with a high solid content and a preparation method thereof relate to an automobile coating composite which comprises the following components by weight: 65% of film-forming resin, 2% of additives, 18% of solvents, and 15% of pigments, wherein the film-forming resin comprises 20%-32% of acrylic resin, 15%-25% of polyester resin, and 15%-25% of amino resin; the solid content of the coating prepared by the invention is about 80%; the coating has less organic solvent; and environmental pollution is reduced. The preparation method can improve construction conditions and improve production efficiency, and the baking automobile finish can increase surface performance and chemical resistance of the automobile body.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Water-borne environment-friendly crack lacquer and preparation method thereof

ActiveCN104530846AStrong adhesionExcellent artistic aestheticsAnti-corrosive paintsWeather resistanceLacquer

The invention relates to the technical field of paint, and particularly relates to a water-borne environment-friendly crack lacquer and a preparation method thereof. The water-borne environment-friendly crack lacquer has the advantages of excellent adhesion, clear and ultra-strong texture artistic aesthetic feeling, full paint film, high drying speed, excellent chemical resistance, weather resistance and scratch resistance, ultra-strong hardness and the like; and the preparation method of the water-borne environment-friendly crack lacquer is simple in process, water can be directly added for diluting in the using process, the construction is convenient and quick, and the construction efficiency can be effectively improved.

Owner:中山市诚美涂料有限公司

Environment-friendly nano inner wall coating

InactiveCN101633811AImprove physical and chemical comprehensive performanceFull paint filmCoatingsNano sio2Isopropylene glycol

The invention relates to environment-friendly nano inner wall coating, which is suitable for the decoration of inner walls of hotels, buildings, schools, hospitals, villas and private residences. The nano inner wall coating is prepared from acrylic resin, propylene glycol, nano SiO2, an assist filming agent and titanium pigment in the weight ratio of 80-160 to 30-70 to 20-50 to 30-65 to 7-18. The environment-friendly nano inner wall coating uses the unusual property of nano materials, and improves the physicochemical comprehensive properties of products significantly. The water-based coating has the advantages of plump and delicate paint films, beautiful colors, good levelling property, strong adhesive force, innocuity, no taste, long-lasting antibiosis, no environmental pollution, and is environment-friendly coating with excellent decoration and construction.

Owner:聂雨淼

Coating for wood furniture

The invention discloses coating for wood furniture. The coating for wood furniture is prepared from the following raw materials according to weight proportion: methyl methacrylate, vinyl chloride-vinyl acetate resin, phenethyl acetate, ethanol, a levelling agent, a defoaming agent, sodium bicarbonate, sodium persulphate and a solvent. The coating for wood furniture has the advantages that the coating can not be yellowed or brittle, a film is full, and volatilization of toxic gas can be inhibited.

Owner:SHIFANG MIDEE WOOD IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com