Formaldehyde-resistance odor-removing total-effect environmental-friendly water-borne wood white paint and preparation technology thereof

A formaldehyde-resistant and deodorizing technology, applied in coatings, polyether coatings, polyurea/polyurethane coatings, etc., can solve the health hazards of wooden furniture manufacturers and users, and the wooden furniture cannot use solvent-based coatings, etc., to achieve Excellent scratch resistance and yellowing resistance, long-lasting fresh living environment, and the effect of reducing the amount of irritating volatiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

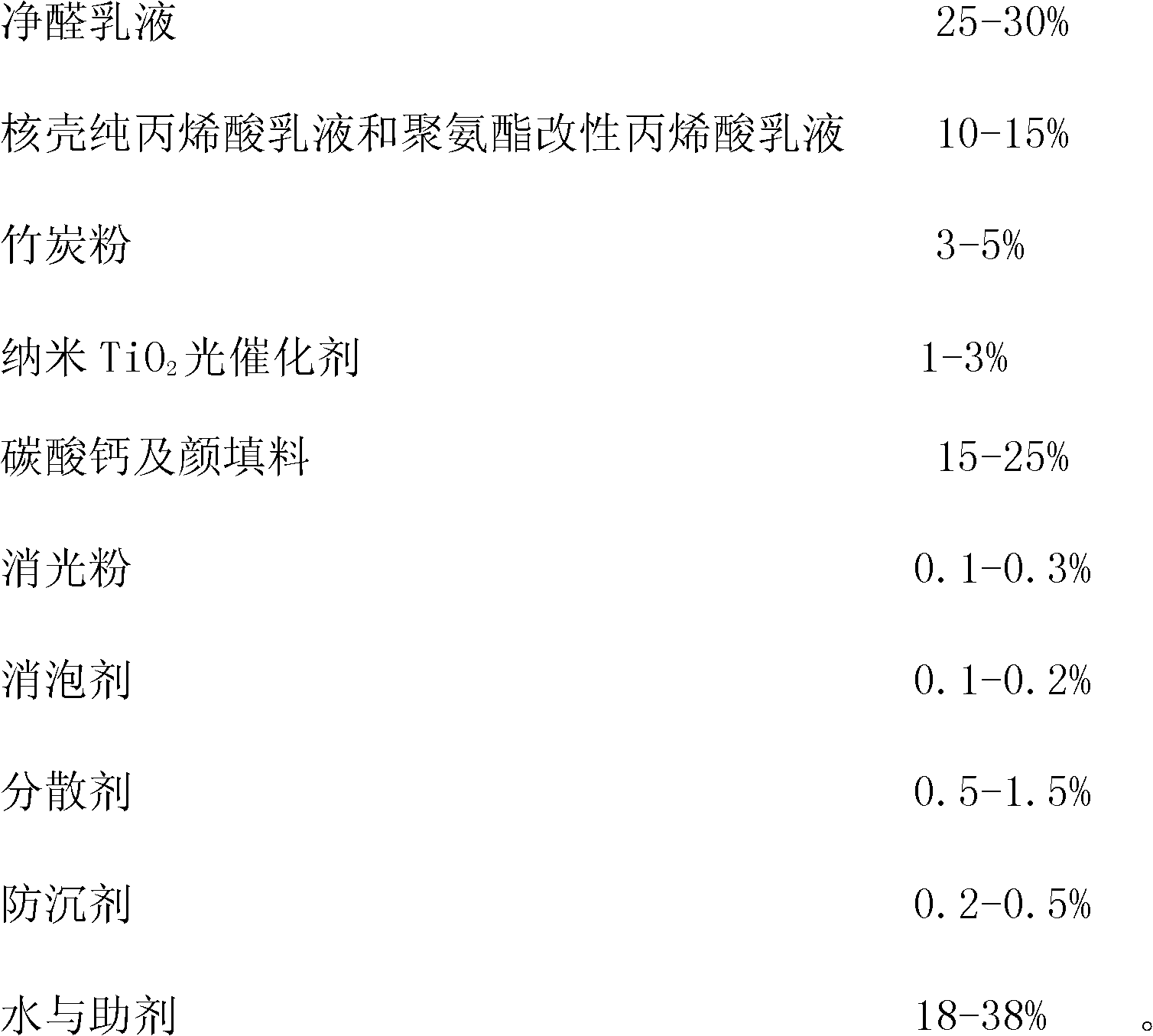

[0044] Prepare 100kg of the present invention's anti-formaldehyde net odor full-effect environmental protection water-based wood white paint, consisting of the following components:

[0045]

[0046]

[0047] First, add core-shell pure acrylic emulsion and polyurethane modified acrylic emulsion into the dispersion tank and carry out medium-speed dispersion, wherein the speed of medium-speed decomposition is 600-800r / min, and then evenly mix micron-sized activated bamboo charcoal powder, high-speed Disperse for 15-30 minutes, wherein the high-speed dispersion speed is 1000-1500r / min, add net aldehyde emulsion and anti-scratch wax additives, water, dispersant, matting agent, defoamer, anti-settling agent and others Components, after dispersing at a medium speed for 40 minutes, take a sample to test the fineness and viscosity of the finished product. If the fineness of the finished product reaches 35-50μm, the viscosity is 30-60mm 2 / s is a qualified product, and then filte...

Embodiment 2

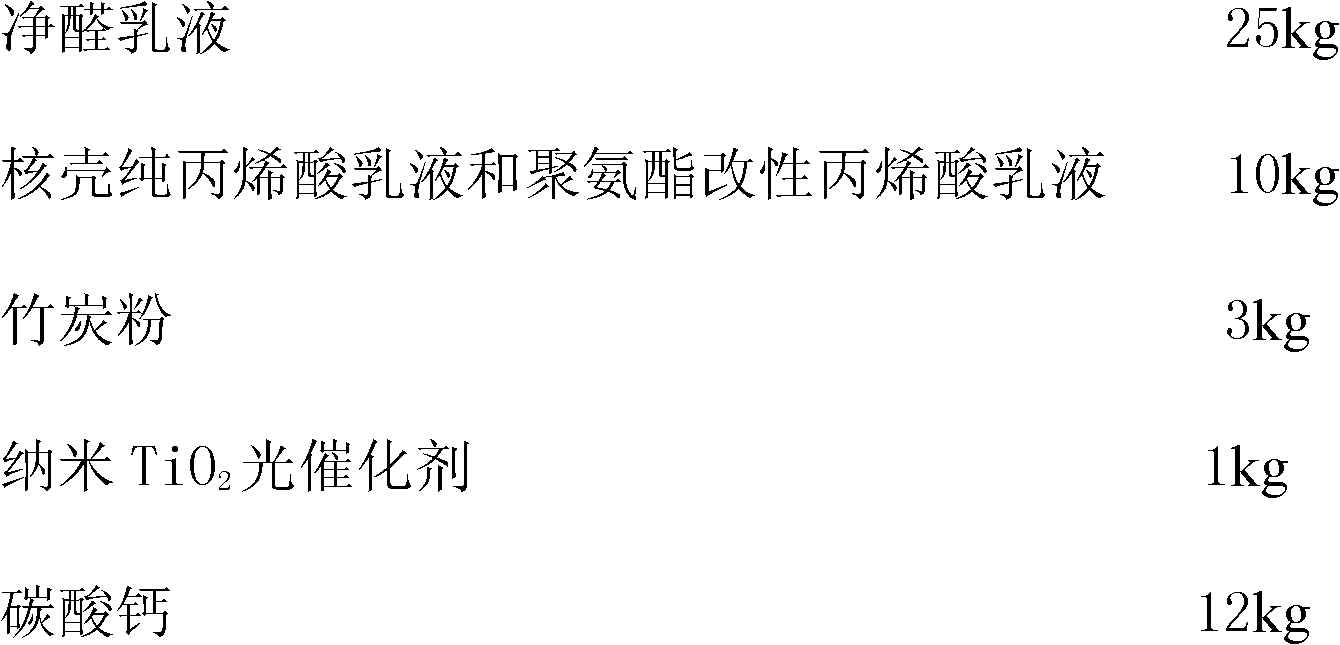

[0049] Prepare 100kg of the present invention's anti-formaldehyde net odor full-effect environmental protection water-based wood white paint, consisting of the following components:

[0050]

[0051] First, add core-shell pure acrylic emulsion and polyurethane modified acrylic emulsion into the dispersion tank and carry out medium-speed dispersion, wherein the speed of medium-speed decomposition is 600-800r / min, and then evenly mix micron-sized activated bamboo charcoal powder, high-speed Disperse for 15-30 minutes, wherein the high-speed dispersion speed is 1000-1500r / min, add net aldehyde emulsion and anti-scratch wax additives, water, dispersant, matting agent, defoamer, anti-settling agent and others Components, after dispersing at a medium speed for 40 minutes, take a sample to test the fineness and viscosity of the finished product. If the fineness of the finished product reaches 35-50μm, the viscosity is 30-60mm 2 / s is a qualified product, and then filtered, canned,...

Embodiment 3

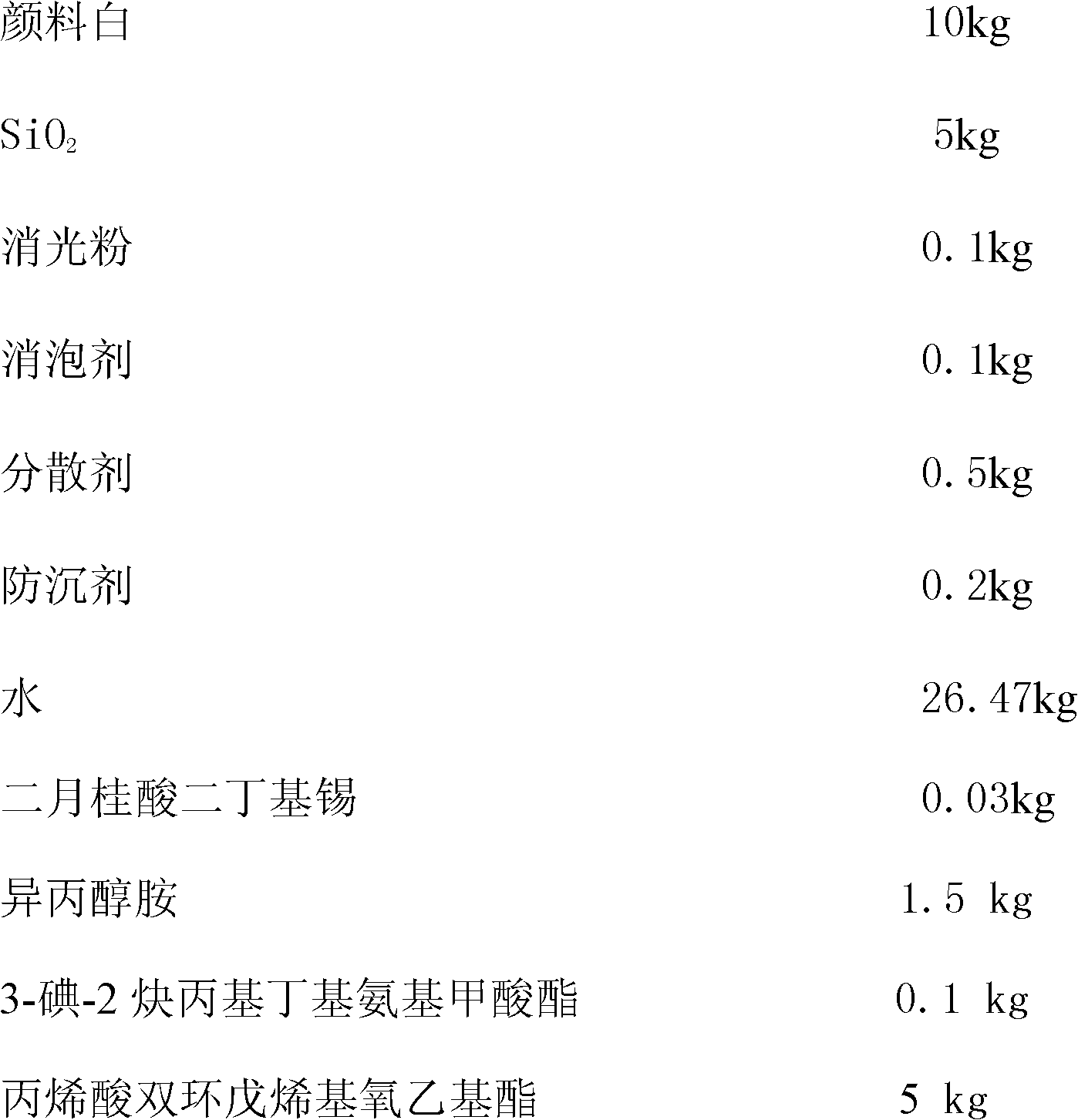

[0053] Prepare 100kg of the present invention's anti-formaldehyde net odor full-effect environmental protection water-based wood white paint, consisting of the following components:

[0054]

[0055]

[0056] First, add core-shell pure acrylic emulsion and polyurethane modified acrylic emulsion into the dispersion tank and carry out medium-speed dispersion, wherein the speed of medium-speed decomposition is 600-800r / min, and then evenly mix micron-sized activated bamboo charcoal powder, high-speed Disperse for 15-30 minutes, wherein the high-speed dispersion speed is 1000-1500r / min, add net aldehyde emulsion and anti-scratch wax additives, water, dispersant, matting agent, defoamer, anti-settling agent and others Components, after dispersing at a medium speed for 40 minutes, take a sample to test the fineness and viscosity of the finished product. If the fineness of the finished product reaches 35-50μm, the viscosity is 30-60mm 2 / s is a qualified product, and then filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com