Tooth whitening gel and preparation method and application thereof

A tooth whitening and gel technology, which is applied in the field of tooth whitening gel and its preparation, can solve the problems of only focusing on the whitening effect, difficulty in whitening gel, and long-term storage, and achieve good tooth whitening effect. The preparation method is stable and reliable. Mature and controllable effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

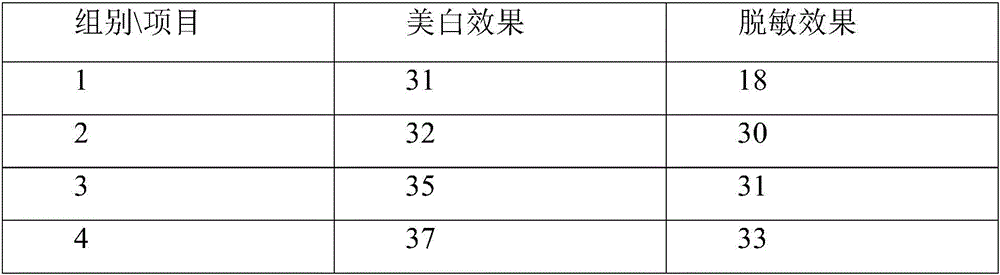

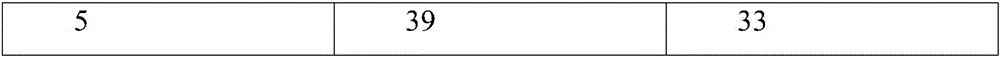

Examples

Embodiment 1

[0033] Follow the steps below to prepare teeth whitening gel

[0034] Prepare the following raw materials in parts by weight: 8 parts of hydrogen peroxide, 5.5 parts of carbomer 940, 40 parts of deionized water, 55 parts of glycerin, 0.5 parts of menthol, 5 parts of xylitol, and 4 parts of triethanolamine.

[0035] The assembly line perfusion production process is adopted, and the room temperature of the production workshop is kept at 18-28°C. The assembly line is set according to the addition of raw materials and time, and one ultraviolet sterilization and disinfection work point, seven perfusion work points, and one sealing treatment work point are set.

[0036] Production workers put batches of plastic transparent containers into the assembly line. With the operation of the assembly line, the plastic containers arrive at the first ultraviolet disinfection point, and all plastic transparent containers undergo 30-minute ultraviolet sterilization.

[0037] After disinfection t...

Embodiment 2

[0040] Follow the steps below to prepare teeth whitening gel

[0041] Prepare the following raw materials in parts by weight: carbamide peroxide, 1.5 parts of carbomer 941, 30 parts of deionized water, 45 parts of glycerin, 0.01 part of menthol, 1 part of xylitol, and 0.5 part of triethanolamine, tooth desensitization Composition 0.1 part.

[0042] Wherein, the tooth desensitizing composition is sodium fluoride, paraformaldehyde, hydroxyethyl cellulose, and deionized water, and the weight ratio between the components is 1:5:10:100.

[0043] The assembly line perfusion production process is adopted, and the room temperature of the production workshop is kept at 18-28°C. The assembly line is set according to the addition of raw materials and time, and one ultraviolet sterilization and disinfection work point, seven perfusion work points, and one sealing treatment work point are set.

[0044] Production workers put batches of plastic transparent containers into the assembly line...

Embodiment 3

[0048] Follow the steps below to prepare teeth whitening gel

[0049] Prepare the following raw materials by weight: 5 parts of sodium percarbonate, 2 parts of carbomer 940, 32 parts of deionized water, 48 parts of glycerin, 0.1 part of menthol, 2 parts of xylitol, and 1 part of triethanolamine, tooth 0.5 part of desensitization composition.

[0050] Wherein, the tooth desensitizing composition is sodium fluoride, paraformaldehyde, hydroxyethyl cellulose, and deionized water, and the weight ratio between the components is 3:8:20:100.

[0051] The assembly line perfusion production process is adopted, and the room temperature of the production workshop is kept at 18-28°C. The assembly line is set according to the addition of raw materials and time, and one ultraviolet sterilization and disinfection work point, seven perfusion work points, and one sealing treatment work point are set.

[0052] Production workers put batches of plastic transparent containers into the assembly li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com