A kind of flame retardant modification treatment method of Chinese fir

A processing method and technology for fir, which can be applied in wood treatment, wood treatment details, wood impregnation, etc., can solve problems such as poor resistance to flame retardant loss, achieve good flatness, small texture differences, and facilitate mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

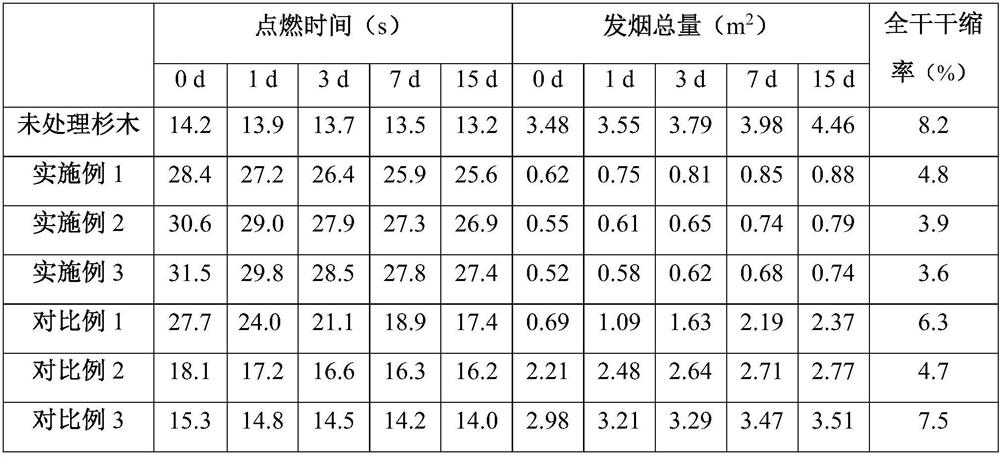

Examples

Embodiment 1

[0017](1) Under the protection of nitrogen, spray the cedar sample uniformly with 5% by weight N,N-dimethylformamide solution of 4,4'-diphenylmethane diisocyanate, and the spray pressure is 0.3MPa , The spraying time is 6s; the sprayed cedar sample is placed in a nitrogen atmosphere for 4h at room temperature, and then vacuum dried at 60℃ for 24h to obtain a modified cedar sample;

[0018](2) Under the protection of nitrogen, use 10% by weight of the dioxane solution of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to evenly spray a modification treatment For the Chinese fir sample, the spray pressure is 0.3MPa, and the spray time is 8s; the sprayed Chinese fir sample is allowed to stand for 6h at room temperature, and then vacuum dried at 60℃ for 24h to obtain the secondary modified Chinese fir sample ;

[0019](3) Use 10% by weight water-soluble phenolic resin aqueous solution to uniformly spray the second modified cedar sample, the spray pressure is 0.4MPa, and the spray time is 4...

Embodiment 2

[0021](1) Under the protection of nitrogen, spray the cedar sample uniformly with 8% by weight N,N-dimethylformamide solution of 4,4'-diphenylmethane diisocyanate, the spray pressure is 0.4MPa , The spraying time is 5s; the sprayed cedar sample is placed in a nitrogen atmosphere for 6h at room temperature, and then vacuum dried at 60℃ for 24h to obtain a modified cedar sample;

[0022](2) Under the protection of nitrogen, use 13% by weight of the dioxane solution of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to evenly spray a modification treatment For the Chinese fir sample, the spray pressure is 0.4MPa, and the spray time is 6s; the sprayed Chinese fir sample is allowed to stand for 9h at room temperature, and then vacuum-dried at 60℃ for 24h to obtain the secondary modified Chinese fir sample ;

[0023](3) Use 15% by weight water-soluble phenolic resin aqueous solution to evenly spray the secondary modified cedar sample, the spray pressure is 0.5MPa, and the spray time is 3s; a...

Embodiment 3

[0025](1) Under the protection of nitrogen, spray the cedar sample uniformly with 10% by weight N,N-dimethylformamide solution of 4,4'-diphenylmethane diisocyanate, the spray pressure is 0.5MPa , The spraying time is 3s; the sprayed cedar sample is placed in a nitrogen atmosphere for 8h at room temperature, and then vacuum dried at 60℃ for 24h to obtain a modified cedar sample;

[0026](2) Under the protection of nitrogen, use 15% by weight of the dioxane solution of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to evenly spray a modification treatment For the Chinese fir sample, the spray pressure is 0.5MPa, and the spray time is 4s; the sprayed Chinese fir sample is allowed to stand for 12h at room temperature, and then vacuum dried at 60℃ for 24h to obtain the secondary modified Chinese fir sample ;

[0027](3) Spray the second modified cedar sample uniformly with 20% by weight water-soluble phenolic resin aqueous solution, the spray pressure is 0.6MPa, and the spray time is 2s; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com